Global Vibration Sensor Market

Market Size in USD Billion

CAGR :

%

USD

4.09 Billion

USD

7.11 Billion

2025

2033

USD

4.09 Billion

USD

7.11 Billion

2025

2033

| 2026 –2033 | |

| USD 4.09 Billion | |

| USD 7.11 Billion | |

|

|

|

|

Vibration Sensor Market Size

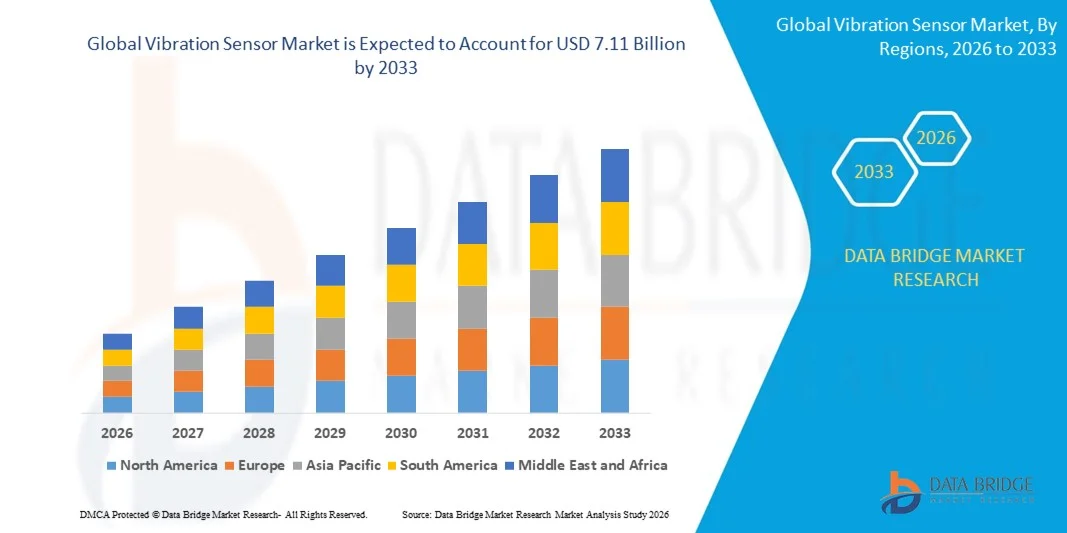

- The global vibration sensor market size was valued at USD 4.09 billion in 2025 and is expected to reach USD 7.11 billion by 2033, at a CAGR of 7.16% during the forecast period

- The market growth is largely fueled by the increasing adoption of predictive maintenance and condition monitoring across industries such as energy, aerospace, manufacturing, and automotive, driving demand for real-time vibration data and operational reliability

- Furthermore, rising industrial focus on minimizing downtime, enhancing equipment lifespan, and improving operational efficiency is establishing vibration sensors as essential tools for machinery monitoring and fault detection. These converging factors are accelerating the uptake of vibration sensor solutions, thereby significantly boosting the industry's growth

Vibration Sensor Market Analysis

- Vibration sensors, offering precise measurement of mechanical oscillations, are increasingly critical components of industrial monitoring and predictive maintenance systems due to their ability to detect faults, misalignments, and abnormal operating conditions in machinery

- The escalating demand for vibration sensors is primarily fueled by the growing emphasis on automation, Industry 4.0 initiatives, and the need for accurate, real-time monitoring solutions that reduce operational costs and prevent unplanned downtime

- North America dominated the vibration sensor market with a share of 37.8% in 2025, due to high adoption of predictive maintenance, industrial automation, and advanced manufacturing practices

- Asia-Pacific is expected to be the fastest growing region in the vibration sensor market during the forecast period due to rapid industrialization, increasing urbanization, and rising adoption of automation technologies in countries such as China, Japan, and India

- Accelerometers segment dominated the market with a market share of 54.35% in 2025, due to their high sensitivity, wide frequency range, and compatibility with diverse machinery monitoring applications. Industries such as energy, manufacturing, and automotive rely heavily on accelerometers for real-time fault detection and predictive maintenance. The ease of integration with condition monitoring systems and their ability to provide accurate vibration data under varying operational conditions further strengthens their demand

Report Scope and Vibration Sensor Market Segmentation

|

Attributes |

Vibration Sensor Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Vibration Sensor Market Trends

Growing Adoption of Predictive Maintenance in Industrial Operations

- A significant trend in the vibration sensor market is the increasing adoption of predictive maintenance strategies across key industrial sectors, driven by the rising need to prevent unexpected equipment failures and optimize operational efficiency. Predictive maintenance relies on real-time vibration monitoring to detect anomalies and forecast maintenance schedules, reducing downtime and extending asset life

- For instance, SKF provides advanced vibration sensors and condition monitoring solutions widely used in manufacturing plants and wind turbines, enabling accurate detection of mechanical faults before they escalate into critical failures. Such implementations enhance reliability, reduce maintenance costs, and improve overall plant productivity

- The integration of vibration sensors in Industrial Internet of Things (IIoT) platforms is accelerating, allowing continuous data acquisition and advanced analytics for machinery health assessment. These sensors are becoming essential for smart factories and connected industrial environments that prioritize automated monitoring and proactive maintenance

- Heavy industries such as automotive, aerospace, and power generation are increasingly deploying vibration sensors to monitor rotating machinery, compressors, and turbines. These applications demand high-sensitivity sensors capable of withstanding harsh operational conditions while delivering precise measurements

- Industries are leveraging wireless and compact vibration sensor technologies to enable flexible installation and remote monitoring across geographically dispersed assets. This trend supports efficient maintenance management and improves decision-making processes through centralized data analysis

- The market is witnessing growing interest in predictive maintenance software and analytics that work in tandem with vibration sensors to offer actionable insights, optimize scheduling, and reduce unplanned outages. This integration is reinforcing the strategic value of vibration sensors as critical enablers of operational efficiency and equipment longevity

Vibration Sensor Market Dynamics

Driver

Rising Demand for Real-Time Equipment Monitoring and Operational Efficiency

- The rising need for real-time equipment monitoring across industrial operations is driving demand for vibration sensors that enable early detection of mechanical issues and improve maintenance efficiency. These sensors provide actionable insights that help optimize production processes, reduce downtime, and extend machinery life

- For instance, Emerson offers vibration monitoring solutions integrated with cloud-based analytics platforms to deliver real-time alerts for pumps, motors, and turbines in manufacturing plants. These solutions allow operators to take preventive action, ensuring operational continuity and minimizing costly repairs

- The trend toward digitalization and smart manufacturing is increasing reliance on vibration sensors for predictive maintenance, process optimization, and asset management. Sensors embedded in IIoT networks allow seamless data collection, facilitating predictive diagnostics and performance tracking

- Regulatory standards and safety compliance requirements are encouraging the deployment of vibration sensors in critical infrastructure to monitor equipment integrity. Real-time monitoring ensures adherence to safety protocols and reduces the risk of operational failures that could compromise personnel or equipment

- Increasing awareness of the cost-saving potential and performance benefits of vibration sensors is reinforcing their adoption across diverse industrial verticals. Companies are integrating these sensors into comprehensive maintenance strategies, positioning them as essential tools for modern operational excellence

Restraint/Challenge

High Costs and Complexity of Sensor Integration

- The vibration sensor market faces challenges due to the high costs associated with deploying advanced sensors and integrating them into existing industrial systems. Complex installation processes, calibration requirements, and system compatibility issues increase overall investment and operational complexity

- For instance, Brüel & Kjær provides precision vibration sensors that require specialized installation and configuration for industrial applications, which can elevate upfront costs and demand skilled personnel. Such integration challenges may slow adoption in smaller facilities with limited technical resources

- Ensuring accurate data collection and analysis requires integration with condition monitoring software, cloud platforms, or SCADA systems, which adds technical complexity. Compatibility issues between legacy machinery and modern sensor systems can further complicate implementation

- High-quality vibration sensors rely on advanced materials, precision electronics, and robust design to operate under extreme temperatures, high vibration, or hazardous conditions, contributing to elevated manufacturing and procurement costs

- The market continues to encounter difficulties in balancing performance requirements with cost-effectiveness and ease of deployment. These challenges necessitate careful planning, skilled workforce, and investment in compatible infrastructure to fully leverage vibration sensor benefits

Vibration Sensor Market Scope

The market is segmented on the basis of type, monitoring process, equipment, and industry vertical.

- By Type

On the basis of type, the vibration sensor market is segmented into accelerometers, proximity probes, displacement sensors, and velocity sensors. The accelerometers segment dominated the market with the largest revenue share of 54.35% in 2025, driven by their high sensitivity, wide frequency range, and compatibility with diverse machinery monitoring applications. Industries such as energy, manufacturing, and automotive rely heavily on accelerometers for real-time fault detection and predictive maintenance. The ease of integration with condition monitoring systems and their ability to provide accurate vibration data under varying operational conditions further strengthens their demand.

The proximity probes segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by increasing adoption in rotating equipment monitoring and critical asset protection applications. For instance, major companies in the oil and gas sector implement proximity probes to monitor turbine shafts and high-speed compressors, enabling early detection of misalignment or imbalance. Their capability to operate under extreme temperature and pressure conditions makes them particularly attractive in industrial environments.

- By Monitoring Process

On the basis of monitoring process, the vibration sensor market is segmented into online vibration monitoring and portable vibration monitoring. Online vibration monitoring dominated the market in 2025 due to its ability to provide continuous, real-time data for critical assets and reduce unplanned downtime. Industries such as power generation and manufacturing prefer online systems for their predictive maintenance capabilities, which enhance operational efficiency and safety. The integration of online monitoring with IoT platforms and cloud analytics further drives its adoption.

Portable vibration monitoring is expected to witness the fastest growth from 2026 to 2033, driven by its flexibility and cost-effectiveness for periodic inspections and maintenance. For instance, companies in the metals and mining sector employ portable vibration devices for spot-checks on rotating machinery, allowing rapid diagnostics without halting production. Their ease of use and ability to capture accurate readings across multiple locations contribute to rising demand.

- By Equipment

On the basis of equipment, the vibration sensor market is segmented into embedded systems, vibration analysers, and vibration meters. Embedded systems dominated the market in 2025, owing to their seamless integration with machinery, automated monitoring, and real-time data analytics capabilities. They allow industries to implement predictive maintenance strategies efficiently and reduce operational disruptions. High adoption is seen across energy and power, automotive, and aerospace sectors due to their reliability and ability to provide continuous asset health insights.

Vibration analysers are projected to register the fastest growth from 2026 to 2033, fueled by advanced diagnostics and detailed analysis capabilities. For instance, major players in the chemical industry utilize vibration analysers to assess complex process equipment, identify faults, and plan maintenance schedules accurately. The growing emphasis on predictive maintenance and reduced downtime drives demand for sophisticated analysers.

- By Industry Vertical

On the basis of industry vertical, the vibration sensor market is segmented into oil and gas, energy and power, metals and mining, chemicals, automotive, aerospace and defense, food and beverages, semiconductors and electronics, pharmaceuticals, healthcare, and others. The energy and power segment dominated the market in 2025, due to the critical need for monitoring turbines, generators, and other high-value rotating assets to ensure uninterrupted power supply. Integration with predictive maintenance systems and regulatory compliance requirements further bolster adoption.

The aerospace and defense segment is expected to witness the fastest growth from 2026 to 2033, driven by rising investments in advanced aircraft, UAVs, and defense equipment that require precise vibration monitoring. For instance, aerospace manufacturers use vibration sensors to monitor engine performance and structural health in real-time, enhancing safety and reliability. The increasing focus on aircraft operational efficiency and the adoption of digital twin technologies support rapid growth in this segment.

Vibration Sensor Market Regional Analysis

- North America dominated the vibration sensor market with the largest revenue share of 37.8% in 2025, driven by high adoption of predictive maintenance, industrial automation, and advanced manufacturing practices

- Industries in the region prioritize real-time condition monitoring, equipment health assessment, and early fault detection using vibration sensors across energy, aerospace, and manufacturing sectors

- This widespread adoption is further supported by strong R&D investments, a technologically advanced industrial base, and increasing regulatory standards for equipment reliability and safety, establishing vibration sensors as a critical tool for operational efficiency

U.S. Vibration Sensor Market Insight

The U.S. vibration sensor market captured the largest revenue share in 2025 within North America, fueled by extensive implementation in aerospace, power generation, and manufacturing industries. Companies are increasingly leveraging vibration sensors for predictive maintenance to minimize downtime and extend asset life. The rising integration of IoT-enabled sensors, cloud analytics, and AI-driven diagnostics further enhances market growth. Moreover, the demand for portable and embedded vibration monitoring solutions in critical equipment supports the expansion of the U.S. market.

Europe Vibration Sensor Market Insight

The Europe vibration sensor market is projected to grow at a significant CAGR during the forecast period, driven by the emphasis on industrial automation, predictive maintenance, and stringent safety regulations. Adoption is rising across energy, metals, and automotive sectors, where continuous monitoring of machinery is essential for operational reliability. European industries are also investing in advanced sensor technologies that improve equipment performance and reduce maintenance costs. Smart factories and Industry 4.0 initiatives are contributing to widespread deployment of vibration sensors across the region.

U.K. Vibration Sensor Market Insight

The U.K. vibration sensor market is expected to expand at a noteworthy CAGR, driven by the growing need for condition-based monitoring and maintenance in manufacturing, energy, and aerospace industries. Businesses are adopting vibration sensors to enhance operational efficiency, minimize downtime, and comply with safety standards. The U.K.’s focus on digital industrial transformation and the adoption of advanced analytics platforms further accelerates market growth. Increasing investments in infrastructure modernization also boost demand for accurate vibration monitoring solutions.

Germany Vibration Sensor Market Insight

The Germany vibration sensor market is anticipated to grow considerably during the forecast period, driven by advanced industrial automation, robust manufacturing infrastructure, and a focus on predictive maintenance. Industries such as automotive, energy, and chemicals increasingly rely on vibration sensors to monitor critical machinery and ensure operational reliability. Integration with IoT systems and data analytics platforms is enhancing equipment performance insights. Germany’s emphasis on sustainability and energy efficiency also promotes the use of precise, real-time vibration monitoring solutions.

Asia-Pacific Vibration Sensor Market Insight

The Asia-Pacific vibration sensor market is poised to register the fastest CAGR from 2026 to 2033, driven by rapid industrialization, increasing urbanization, and rising adoption of automation technologies in countries such as China, Japan, and India. The region’s focus on smart manufacturing, energy efficiency, and predictive maintenance is fueling demand for vibration sensors. Growing manufacturing hubs, coupled with government initiatives supporting Industry 4.0, are enhancing sensor accessibility and affordability.

Japan Vibration Sensor Market Insight

The Japan vibration sensor market is expanding due to the country’s high-tech industrial base, automation-driven manufacturing sector, and focus on equipment reliability. Industries are increasingly deploying vibration sensors for monitoring critical assets in energy, aerospace, and automotive sectors. Integration with IoT and AI-enabled predictive maintenance platforms is driving growth. The aging industrial workforce also encourages adoption of user-friendly, automated monitoring solutions.

China Vibration Sensor Market Insight

The China vibration sensor market accounted for the largest revenue share in Asia-Pacific in 2025, fueled by rapid industrial growth, urbanization, and high manufacturing output. China’s adoption of smart factories and predictive maintenance technologies increases demand for advanced vibration sensors across energy, metals, and automotive sectors. Local manufacturing capabilities, competitive pricing, and government initiatives supporting industrial digitization are key drivers of market expansion.

Vibration Sensor Market Share

The vibration sensor industry is primarily led by well-established companies, including:

- SKF (Sweden)

- Bosch Sensortec GmbH (Germany)

- Honeywell International Inc. (U.S.)

- Emerson Electric Co. (U.S.)

- Texas Instruments Incorporated (U.S.)

- National Instruments Corp. (U.S.)

- Baker Hughes Company (U.S.)

- TE Connectivity (Switzerland)

- NXP Semiconductors (Netherlands)

- OMRON Corporation (Japan)

- Rockwell Automation, Inc. (U.S.)

- DYTRAN INSTRUMENTS INCORPORATED (U.S.)

- KEYENCE CORPORATION (Japan)

- Fluke Corporation (U.S.)

- Amphenol (Maryland), Inc. (U.S.)

- PCB Piezotronics, Inc. (U.S.)

- SPM Instrument AB (Sweden)

- ASC GmbH (Germany)

- Analog Devices, Inc. (U.S.)

- Hansford Sensors (U.K.)

Latest Developments in Global Vibration Sensor Market

- In May 2025, Vestas secured a 495 MW offshore wind order featuring 33 V236-15 MW turbines in Taiwan. This milestone underscores the growing importance of advanced vibration monitoring in large-class wind turbines, as continuous monitoring is critical for predictive maintenance and minimizing downtime. The deployment of these turbines is expected to drive demand for high-precision vibration sensors and monitoring systems, reinforcing their strategic role in the renewable energy sector and supporting reliability in offshore wind operations

- In March 2023, DYTRAN INSTRUMENTS INCORPORATED and ENMO Sound & Vibration Technology entered a partnership covering Belgium, the Netherlands, and Luxembourg. This collaboration strategically strengthens both companies’ positions in the testing and measurement market by combining their technical expertise. The partnership is likely to accelerate innovation in vibration and sound sensing technologies, expand market reach in the Benelux region, and enhance adoption of high-performance sensors across industrial and research applications

- In February 2023, IMI Sensors, a division of PCB Piezotronics Inc., launched the Model 655A91, a budget-friendly 4-20 mA velocity transmitter. Equipped with a 4-pin M12 connector, the device simplifies integration into existing industrial monitoring systems. Its built-in piezoelectric component provides enhanced measurement precision and a broad frequency response from 3.5 Hz to 2 kHz. This launch strengthens the industrial vibration sensor market by offering cost-effective solutions for predictive maintenance, expanding accessibility to small and medium enterprises seeking reliable vibration monitoring

- In January 2023, NSXe Co. Ltd., a Japanese firm specializing in mechanical equipment installation and maintenance solutions, introduced the "conanair" Wi-Fi vibration sensor to the U.S. market. The sensor delivers an affordable solution for detecting bearing damage, targeting cost-sensitive industrial operations. Its introduction is expected to increase adoption of wireless vibration monitoring solutions in the U.S., particularly for industries looking to implement predictive maintenance with lower upfront costs while maintaining measurement accuracy and operational reliability

- In January 2023, HARMAN International, a SAMSUNG subsidiary focusing on automotive technology, unveiled its Sound and Vibration Sensor and External Microphone products. These innovations enhance auditory experiences inside and outside vehicles, enabling applications such as detecting emergency vehicle sirens, capturing driver commands, and identifying collisions or glass breakage. This development strengthens the automotive sensor market by integrating advanced vibration and acoustic sensing into vehicle safety and user-interaction systems, contributing to smarter, more responsive automotive technologies

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Vibration Sensor Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Vibration Sensor Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Vibration Sensor Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.