Global Long Steel Market

Market Size in USD Billion

CAGR :

%

USD

675.54 Billion

USD

917.44 Billion

2025

2033

USD

675.54 Billion

USD

917.44 Billion

2025

2033

| 2026 –2033 | |

| USD 675.54 Billion | |

| USD 917.44 Billion | |

|

|

|

|

Long Steel Market Size

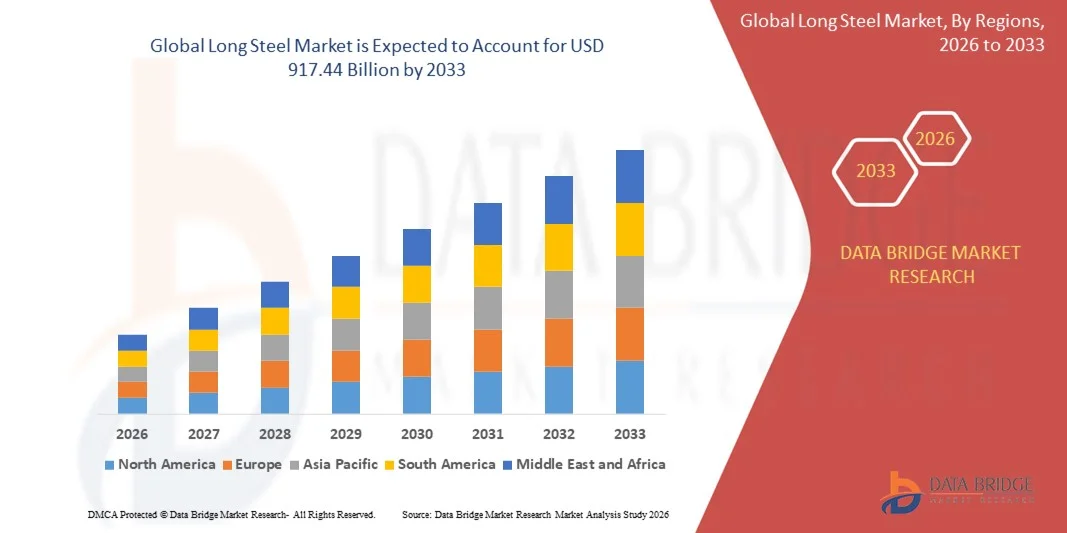

- The global long steel market size was valued at USD 675.54 billion in 2025 and is expected to reach USD 917.44 billion by 2033, at a CAGR of 3.9% during the forecast period

- The market growth is largely fueled by rapid urbanization, expanding infrastructure projects, and rising industrialization across developing and developed regions, leading to increased demand for long steel products in construction, transportation, and industrial applications

- Furthermore, growing government investments in highways, bridges, railways, and commercial buildings, along with private-sector participation in large-scale construction projects, are driving consistent consumption of rebar, structural steel, and wire rods. These converging factors are accelerating the adoption of long steel products, thereby significantly boosting the industry's growth

Long Steel Market Analysis

- Long steel products, including rebar, wire rods, merchant bars, and structural sections, are essential components in construction, industrial manufacturing, and infrastructure projects due to their strength, durability, and versatility in diverse applications

- The escalating demand for long steel is primarily fueled by ongoing urban development, increasing government-funded infrastructure initiatives, and growing industrial activities that require high-quality steel for structural stability and long-term performance

- Asia-Pacific dominated the long steel market with a share of 66.5% in 2025, due to rapid urbanization, expanding infrastructure development, and a strong presence of steel manufacturing hubs

- North America is expected to be the fastest growing region in the long steel market during the forecast period due to large-scale infrastructure projects, modernization of urban facilities, and rising industrial activities

- Basic oxygen furnace segment dominated the market with a market share of 62.5% in 2025, due to its ability to produce high-volume steel efficiently and cost-effectively using iron ore as the primary raw material. The widespread adoption of BOF in large-scale steel plants ensures consistent quality and structural integrity, making it ideal for heavy construction and industrial applications. BOF-produced long steel offers superior mechanical properties and uniformity, which is highly valued in infrastructure and large-scale projects. Its established supply chain and long-standing presence in the steel industry also contribute to strong demand. The segment benefits from integration with advanced metallurgical processes that enhance durability and tensile strength. Government-backed infrastructure projects further reinforce the preference for BOF-produced long steel

Report Scope and Long Steel Market Segmentation

|

Attributes |

Long Steel Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Long Steel Market Trends

High-Strength and Specialty Steel Adoption

- The global long steel market is witnessing a strong trend towards the increased adoption of high-strength and specialty steel grades driven by rapid infrastructure modernization and growing demand for durable construction materials. High-strength long steel products offer superior load-bearing capacity, improved weldability, and reduced material consumption, aligning with both economic and environmental performance objectives in industrial and civil applications

- For instance, ArcelorMittal and Tata Steel have developed advanced microalloyed long steel products optimized for bridges, high-rise buildings, and heavy engineering structures. These innovations meet demanding performance standards while reducing structural weight, thereby contributing to cost efficiency and improved sustainability outcomes in construction projects

- The use of specialty steels such as corrosion-resistant and seismic-grade steel bars is growing in regions prone to harsh environmental conditions and seismic activity. These products enhance structural durability, ensuring long-term stability and reduced maintenance costs for critical infrastructure such as ports, highways, and skyscrapers

- Ongoing innovations in thermomechanical processing and rolling technologies are supporting consistent production of long steel with enhanced mechanical properties. The integration of real-time process monitoring systems enables manufacturers to optimize composition, strength, and flexibility for specific construction and industrial requirements

- In addition, the transition towards green construction practices and the adoption of lower carbon footprint materials are encouraging the development of sustainable long steel grades. Manufacturing companies are focusing on producing steels using electric arc furnaces and scrap recycling to align with global decarbonization targets in the steel industry

- The growing preference for high-strength and specialty long steels highlights an industry transformation towards efficiency, resilience, and sustainability. As governments and private developers increase investment in complex infrastructure projects, the demand for advanced long steel solutions is set to expand steadily across global markets

Long Steel Market Dynamics

Driver

Rising Infrastructure Investments

- The rapid expansion of global infrastructure projects is a key driver fueling demand for long steel products such as bars, wires, and structural sections. Increasing construction of bridges, highways, residential complexes, and industrial buildings is generating strong requirements for reinforcement and structural applications delivered through high-grade long steel products

- For instance, JSW Steel and Nippon Steel Corporation have reportedly increased capacity utilization at their rolling mills to support rising demand from ongoing government infrastructure programs in Asia and the Middle East. Major public and private sector projects focusing on urban redevelopment and energy infrastructure are further strengthening consumption patterns

- The surge in population growth and urbanization has created a persistent need for housing and transportation networks, propelling the usage of long steel in reinforced concrete and pre-stressed structural applications. Long steel products serve as fundamental components ensuring stability, tensile strength, and load distribution across infrastructure types

- In addition, government initiatives emphasizing industrial development corridors, railway expansion, and smart city projects have broadened the scope of investment in mid- to long-term infrastructure projects. These initiatives continue to attract foreign investments and stimulate long steel demand across developing economies

- Sustained infrastructure growth coupled with industrialization trends ensures continuous market expansion for long steel. As countries implement modernization programs to strengthen construction quality and durability standards, the demand for reinforced and specialty-grade long steel will remain a cornerstone for infrastructure advancement and economic development globally

Restraint/Challenge

Raw Material Price Volatility

- Volatility in raw material prices, particularly iron ore, coking coal, and scrap, poses a major challenge for the long steel market. Fluctuating input costs directly influence profit margins and pricing strategies, making financial planning and long-term contracting difficult for producers and end-users

- For instance, data from major steel producers such as Gerdau and Nucor Corporation indicate that frequent price swings in iron ore and energy commodities have affected production economics. Periods of high raw material costs often lead to margin compression and production cuts, impacting supply consistency across global markets

- Global supply chain disruptions, including logistical delays and regional export restrictions, further amplify cost variability in the steel value chain. Dependence on imported raw materials exposes several producers to foreign exchange fluctuations and trade policy uncertainties, complicating cost management and procurement strategies

- In addition, environmental regulations and carbon pricing mechanisms have added operational costs associated with raw material sourcing and processing. These factors collectively contribute to unstable production inputs and hinder predictable market pricing for long steel

- Addressing raw material volatility requires strategic diversification of supply sources, increased scrap recycling, and adoption of energy-efficient manufacturing technologies. Establishing stable procurement frameworks and integrating sustainable resource management practices will be essential to maintain price stability and ensure long-term competitiveness in the global long steel market

Long Steel Market Scope

The market is segmented on the basis of process, product type, type, and end user.

- By Process

On the basis of process, the long steel market is segmented into Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF). The BOF segment dominated the market with the largest revenue share of 62.5% in 2025, driven by its ability to produce high-volume steel efficiently and cost-effectively using iron ore as the primary raw material. The widespread adoption of BOF in large-scale steel plants ensures consistent quality and structural integrity, making it ideal for heavy construction and industrial applications. BOF-produced long steel offers superior mechanical properties and uniformity, which is highly valued in infrastructure and large-scale projects. Its established supply chain and long-standing presence in the steel industry also contribute to strong demand. The segment benefits from integration with advanced metallurgical processes that enhance durability and tensile strength. Government-backed infrastructure projects further reinforce the preference for BOF-produced long steel.

The EAF segment is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing adoption of scrap-based steel production and sustainable practices. EAF offers flexibility in production, lower carbon emissions, and reduced energy consumption compared to BOF, making it attractive for eco-conscious manufacturers. The ability to produce smaller batch sizes efficiently allows rapid response to changing market demands. Rising investments in green steel initiatives and circular economy practices are further accelerating EAF adoption. In addition, advancements in EAF technology have improved energy efficiency and steel quality, boosting its competitiveness. The segment is gaining traction in regions emphasizing environmental regulations and resource optimization.

- By Product Type

On the basis of product type, the long steel market is segmented into Rebar, Wire Rod, Merchant Bar, Rail, and Others. The rebar segment dominated the market with the largest revenue share in 2025, driven by its critical role in reinforcing concrete structures in construction projects. Rebar’s strength, versatility, and cost-effectiveness make it essential for residential, commercial, and infrastructure developments. The growing pace of urbanization and large-scale government-funded infrastructure projects are fueling consistent demand for rebar. Its compatibility with various grades of concrete and ability to withstand seismic and environmental stresses further reinforce its dominance. Leading construction companies prefer rebar for its proven reliability and durability across diverse applications. Technological improvements, such as corrosion-resistant coatings, are enhancing the value proposition of rebar in modern construction.

The wire rod segment is expected to witness the fastest CAGR from 2026 to 2033, driven by its increasing use in manufacturing fasteners, automotive components, and industrial machinery. Wire rods provide uniform diameter, high tensile strength, and flexibility, which are crucial for high-precision industrial applications. For instance, automotive manufacturers such as Tata Steel are adopting wire rods for structural components and reinforcing cables. The segment benefits from rising demand in the automotive and engineering sectors due to rapid industrialization. Wire rods’ adaptability to further processing into springs, wires, and screws enhances their market appeal. Growing export opportunities and evolving industrial applications are boosting wire rod consumption.

- By Type

On the basis of type, the long steel market is segmented into Structural Steel and Prestressing Steel. The structural steel segment dominated the market with the largest revenue share in 2025, driven by its widespread use in building frameworks, bridges, and industrial structures. Structural steel offers high strength-to-weight ratio, durability, and ease of fabrication, making it the preferred choice for large-scale infrastructure projects. Its compatibility with modern construction techniques and ability to meet stringent safety and design codes ensure steady demand. Leading construction firms prioritize structural steel for its reliability and long service life. Technological advancements such as high-strength and corrosion-resistant alloys are enhancing the structural steel portfolio. Government-funded urban development projects further reinforce the segment’s dominance.

The prestressing steel segment is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing adoption in high-rise buildings, bridges, and pre-cast concrete structures. Prestressing steel provides enhanced load-bearing capacity, reduced structural deflection, and improved seismic performance. For instance, Larsen & Toubro has implemented prestressing steel extensively in bridge and metro rail projects to improve durability. Growing infrastructure development in emerging economies is accelerating the use of prestressing steel. In addition, innovations in high-tensile and corrosion-resistant prestressing steel grades are driving adoption. The segment is gaining traction in modern construction practices focused on efficiency and safety.

- By End User

On the basis of end user, the long steel market is segmented into Infrastructure, Railways, Industrial, Construction, and Others. The construction segment dominated the market with the largest revenue share in 2025, driven by rapid urbanization, residential and commercial building projects, and government-funded infrastructure initiatives. Construction activities require consistent, high-quality long steel for structural frameworks, reinforcement, and finishing applications. The segment benefits from continuous technological advancements in steel production, enhancing performance and durability. Leading contractors prefer construction-grade long steel for its compliance with safety standards and engineering specifications. Rising demand for high-rise buildings and smart cities further fuels the market. Steel manufacturers’ focus on customized solutions for construction applications strengthens this segment’s dominance.

The infrastructure segment is expected to witness the fastest CAGR from 2026 to 2033, driven by massive investments in highways, bridges, airports, and metro rail projects. Long steel is essential for load-bearing structures, reinforcing bars, and rail tracks in infrastructure development. For instance, companies such as JSW Steel supply specialized long steel products for national highway and metro projects. Government initiatives to improve connectivity and urban mobility are creating strong growth opportunities. Advanced long steel products, including corrosion-resistant and high-strength varieties, are enhancing infrastructure quality. Rising private-sector participation and public-private partnerships are boosting steel demand in infrastructure projects.

Long Steel Market Regional Analysis

- Asia-Pacific dominated the long steel market with the largest revenue share of 66.5% in 2025, driven by rapid urbanization, expanding infrastructure development, and a strong presence of steel manufacturing hubs

- The region’s cost-effective production landscape, rising investments in industrial and construction projects, and growing exports of long steel products are accelerating market expansion

- Availability of skilled labor, favorable government policies, and rapid industrialization across developing economies are contributing to increased consumption of long steel in both residential and commercial construction sectors

China Long Steel Market Insight

China held the largest share in the Asia-Pacific long steel market in 2025, owing to its position as a global leader in steel production and infrastructure development. The country's robust industrial base, large-scale government-funded projects, and extensive export capabilities for steel products are major growth drivers. Demand is also bolstered by ongoing investments in high-strength and specialty steels for domestic and international markets.

India Long Steel Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by rapid urbanization, government-backed infrastructure projects, and increasing private-sector investments in construction and industrial sectors. Initiatives to modernize transportation, housing, and commercial facilities are strengthening the demand for long steel. In addition, rising exports and adoption of advanced steel grades for industrial and infrastructure applications are contributing to robust market expansion.

Europe Long Steel Market Insight

The Europe long steel market is expanding steadily, supported by strong demand in construction, industrial machinery, and transportation infrastructure. The region places emphasis on high-quality, sustainable, and durable steel products, particularly for building and infrastructure projects. Growing investments in renewable energy, railways, and industrial modernization are further enhancing market growth.

Germany Long Steel Market Insight

Germany’s long steel market is driven by its leadership in automotive, construction, and industrial manufacturing. The country has well-established steel production facilities and R&D networks fostering continuous innovation in steel grades and processing techniques. Demand is particularly strong for structural and prestressing steels used in construction, industrial, and infrastructure applications.

U.K. Long Steel Market Insight

The U.K. market is supported by infrastructure modernization, industrial expansion, and ongoing investment in commercial and residential construction. Emphasis on high-strength and sustainable steel, coupled with strong collaboration between construction firms and steel manufacturers, is sustaining market growth. Adoption of long steel in railways, bridges, and commercial buildings is further contributing to demand.

North America Long Steel Market Insight

North America is projected to grow at the fastest CAGR from 2026 to 2033, driven by large-scale infrastructure projects, modernization of urban facilities, and rising industrial activities. Strong focus on quality, regulatory compliance, and innovation in steel products is boosting demand. In addition, increasing reshoring of steel production and partnerships between industrial and construction companies are supporting market expansion.

U.S. Long Steel Market Insight

The U.S. accounted for the largest share in the North America market in 2025, underpinned by robust infrastructure development, industrial manufacturing, and construction activities. The country’s focus on high-strength, durable, and sustainable steel products is encouraging adoption across commercial, residential, and industrial sectors. Presence of key steel manufacturers and a mature distribution network further solidify the U.S.'s leading position in the region.

Long Steel Market Share

The long steel industry is primarily led by well-established companies, including:

- ArcelorMittal (Luxembourg)

- Gerdau S/A (Brazil)

- Nippon Steel Corporation (Japan)

- POSCO (South Korea)

- Nucor Corporation (U.S.)

- China Baowu Steel Group Corporation Limited (China)

- CMC (Italy)

- PAO Mechel (Russia)

- Steel Dynamics, Inc. (U.S.)

- NLMK (Russia)

- Outokumpu (Finland)

- Acerinox S.A. (Spain)

- Tata Steel Long Products Limited (India)

- Daido Steel Co., Ltd. (Japan)

- Shagang Group Inc. (China)

- Ansteel Group Corporation Limited (China)

- JFE Steel Corporation (Japan)

- EVRAZ plc (U.K.)

- HBIS Group (China)

- Hyundai Steel (South Korea)

Latest Developments in Global Long Steel Market

- In June 2025, Nippon Steel completed the acquisition of U.S. Steel, making it a wholly owned subsidiary. This strategic move significantly enhances Nippon Steel’s long steel production capacity in North America, particularly in structural steel and rail products. The acquisition strengthens the company’s market presence, expands its distribution network, and allows it to serve large-scale infrastructure and industrial projects more efficiently, potentially influencing pricing and supply dynamics in the regional long steel market

- In March 2025, ArcelorMittal Nippon Steel India secured land in Andhra Pradesh to establish a greenfield integrated steel plant with an initial capacity of 7.3 million tonnes per annum. This expansion directly addresses the growing demand for long steel products in India’s infrastructure and construction sectors. The project is expected to boost domestic availability of rebar, structural steel, and wire rods, reduce dependency on imports, and attract further private-sector investments into the steel and construction ecosystem

- In 2025, Steel Authority of India (SAIL) announced a major investment at its Bokaro steel plant to implement thin slab caster technology, with a budget of around ₹15,000 crore. This technological upgrade is set to improve production efficiency, product quality, and yield of long steel products such as rebar and structural sections. The enhanced capabilities position SAIL to better meet the increasing demand from residential, commercial, and industrial construction projects, strengthening its competitive edge in the Indian market

- In 2025, the U.K. government passed the Steel Industry (Special Measures) Act 2025 to protect critical long steel manufacturing capacity. This legislation was enacted to prevent the closure of essential long steel assets, particularly Scunthorpe blast furnaces, which are key for producing rebar and structural steel. By ensuring continuity of domestic production, the government aims to stabilize supply, support construction and infrastructure projects, and maintain competitiveness in the U.K. long steel market

- In 2024, Synergy Capital acquired Saurashtra Fuels’ metallurgical coke plant in Mundra, India, securing an annual supply of 600,000 tonnes of high-quality coking coal. This acquisition strengthens the supply chain for long steel production, ensuring uninterrupted raw material availability for rebar, wire rods, and other structural steel products. It also enables the company to scale production in response to rising domestic and export demand, supporting market expansion in India’s long steel segment

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Long Steel Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Long Steel Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Long Steel Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.