Global Digital Twin Market

Market Size in USD Billion

CAGR :

%

USD

26.73 Billion

USD

453.20 Billion

2024

2032

USD

26.73 Billion

USD

453.20 Billion

2024

2032

| 2025 –2032 | |

| USD 26.73 Billion | |

| USD 453.20 Billion | |

|

|

|

|

Digital Twin Market Size

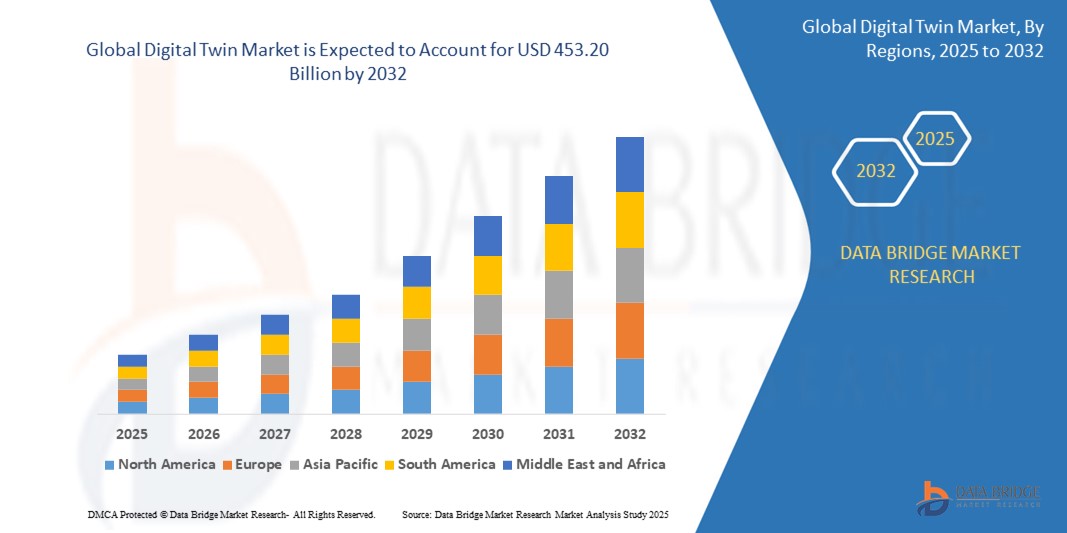

- The global digital twin market size was valued at USD 26.73 billion in 2024 and is expected to reach USD 453.20 billion by 2032, at a CAGR of 42.45% during the forecast period

- The market growth is largely fueled by the increasing adoption of Industry 4.0 practices and the integration of IoT, AI, and cloud technologies, enabling real-time data analysis, predictive maintenance, and operational efficiency across industries

- Furthermore, rising demand for cost-effective, simulation-based planning and the need to minimize downtime in complex systems are positioning digital twins as essential tools for optimizing product lifecycle management, thereby significantly boosting the industry's growth

Digital Twin Market Analysis

- Digital twins, offering real-time virtual representations of physical assets, systems, or processes, are increasingly vital tools in modern industrial operations, product development, and infrastructure management due to their ability to enhance performance monitoring, predictive maintenance, and simulation-driven decision-making

- The escalating demand for digital twin solutions is primarily fueled by the rapid adoption of IoT, AI, and cloud technologies, growing focus on operational efficiency, and the rising need for data-driven insights across sectors such as manufacturing, healthcare, energy, and transportation

- North America dominated the digital twin market with a share of 32.5% in 2024, due to early adoption of advanced technologies, strong presence of key industry players, and increasing demand for predictive maintenance and real-time simulation across sectors

- Asia-Pacific is expected to be the fastest growing region in the digital twin market during the forecast period due to rapid industrialization, smart manufacturing initiatives, and increasing adoption of IoT and AI technologies

- Product digital twin segment dominated the market with a market share of 41.7% in 2024, due to its early adoption across product engineering and manufacturing domains. Companies leverage product twins to model the physical attributes and behaviors of products under various conditions, enabling design validation and customization at scale. The technology helps in ensuring product reliability, compliance, and efficiency before mass production

Report Scope and Digital Twin Market Segmentation

|

Attributes |

Digital Twin Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Digital Twin Market Trends

“Rising Adoption of AI-Driven Predictive Insights”

- A key and expanding trend in the global digital twin market is the integration of artificial intelligence (AI) and machine learning into digital twin platforms to enable advanced predictive analytics and real-time operational insights. This fusion is reshaping asset management by enhancing forecasting accuracy and enabling autonomous system adjustments

- For instance, Siemens leverages AI-powered digital twins in manufacturing to predict equipment failures and optimize production schedules, significantly reducing downtime and operational costs

- AI integration allows digital twins to continuously learn from sensor data and usage patterns, improving decision-making, automating maintenance recommendations, and refining system efficiency over time. These evolving capabilities are accelerating adoption across industries aiming for higher asset reliability and process optimization

- This trend is setting new benchmarks in operational intelligence, prompting vendors to develop more sophisticated, AI-augmented digital twin solutions to meet rising industry expectations for performance and automation

- The demand for AI-enhanced digital twins is rapidly growing in sectors such as energy, transportation, and industrial manufacturing, where system complexity and performance demands are especially high

Digital Twin Market Dynamics

Driver

“Rising Industry 4.0 Initiatives”

- The rapid advancement of Industry 4.0 is a major driver fueling the adoption of digital twin technologies across manufacturing, automotive, energy, and other industrial sectors

- For instance, companies implementing smart factories are leveraging digital twins to simulate production lines, optimize resource utilization, and enable predictive maintenance, significantly improving operational efficiency

- Digital twins align with Industry 4.0 goals by providing real-time synchronization between physical assets and their digital counterparts, allowing for enhanced monitoring, diagnostics, and process automation

- This driver is particularly strong in regions investing heavily in digital transformation, where enterprises seek to increase agility, reduce downtime, and accelerate innovation

- As Industry 4.0 initiatives continue to evolve, digital twins are becoming indispensable tools for achieving interconnected, intelligent, and data-driven industrial environments

Restraint/Challenge

“Integration Complexity with Legacy Infrastructure and Data Silos”

- One significant challenge hindering the wider deployment of digital twins is the complexity of integrating them with legacy IT systems and fragmented data environments

- For instance, older manufacturing facilities often operate on outdated software and siloed data that are incompatible with modern digital twin platforms, leading to costly and time-consuming implementation processes

- Organizations struggle with synchronizing real-time data from multiple sources, ensuring interoperability, and maintaining system accuracy without disrupting existing operations

- These integration issues demand substantial investment in infrastructure upgrades and specialized expertise, which can delay ROI and deter adoption, especially among small and medium enterprises

- Addressing this challenge requires scalable solutions with flexible architectures that can adapt to existing environments and support seamless data flow across platforms

Digital Twin Market Scope

The market is segmented on the basis of technology, application, type, and industry.

• By Technology

On the basis of technology, the digital twin market is segmented into IoT and IIoT, Blockchain, Artificial Intelligence and Machine Learning, Augmented Reality, Virtual Reality and Mixed Reality, Big Data Analytics, and 5G. The IoT and IIoT segment holds the largest market revenue share in 2024, driven by the foundational role of connected devices in enabling real-time data collection and remote monitoring. The proliferation of sensors across industrial and commercial infrastructures supports the deployment of IoT-driven digital twins, facilitating accurate simulations, predictive maintenance, and performance optimization in critical systems. These capabilities are especially important for sectors such as manufacturing and energy, where asset uptime and cost-efficiency are paramount.

The Artificial Intelligence and Machine Learning segment is expected to witness the fastest growth from 2025 to 2032 due to its ability to enhance digital twin intelligence and decision-making capabilities. AI/ML algorithms allow digital twins to self-learn from real-world data, predict failures before they occur, and continuously adapt to dynamic environments. These features are increasingly sought after in advanced industrial automation, smart cities, and healthcare diagnostics, where high precision and autonomous operation are essential.

• By Application

On the basis of application, the market is segmented into product design and development, machine and equipment health monitoring, and process support and service. The product design and development segment dominated the market share in 2024, as digital twins enable rapid prototyping, virtual testing, and iterative design improvements without physical production costs. This leads to reduced time-to-market and enhanced innovation, especially in high-tech industries such as aerospace and automotive. The growing emphasis on sustainable and efficient product lifecycle management further boosts adoption in this segment.

Machine and equipment health monitoring is projected to be the fastest-growing segment through 2032, driven by the increasing demand for predictive maintenance and operational efficiency in manufacturing plants and heavy industries. By continuously mirroring real-time performance data, digital twins help identify anomalies, optimize repair schedules, and extend asset life. This proactive approach is crucial in minimizing downtime and maintaining productivity in mission-critical environments.

• By Type

Based on type, the digital twin market is segmented into product digital twin, process digital twin, and system digital twin. The product digital twin segment held the largest market share of 41.7% in 2024, largely due to its early adoption across product engineering and manufacturing domains. Companies leverage product twins to model the physical attributes and behaviors of products under various conditions, enabling design validation and customization at scale. The technology helps in ensuring product reliability, compliance, and efficiency before mass production.

The system digital twin segment is expected to grow at the highest rate from 2025 to 2032, as complex, interconnected systems such as energy grids, smart factories, and transportation networks increasingly require holistic simulation and monitoring. System twins offer comprehensive insights by integrating data across multiple components and processes, enhancing situational awareness and decision-making in real time.

• By Industry

On the basis of industry, the digital twin market is categorized into aerospace and defense, automotive and transportation, home and commercial, healthcare, energy and utilities, oil and gas, and others. The aerospace and defense segment accounted for the largest revenue share in 2024, supported by the sector’s strong demand for performance optimization, predictive maintenance, and simulation of mission-critical systems. Digital twins in this industry are instrumental in improving aircraft safety, reducing maintenance costs, and simulating flight conditions for enhanced training and design.

The healthcare segment is anticipated to grow at the fastest CAGR from 2025 to 2032, driven by increasing adoption of patient-specific digital twins and digital representations of hospital infrastructure. These innovations support personalized treatment planning, real-time diagnostics, and virtual surgeries. The growing focus on improving patient outcomes, reducing healthcare costs, and enabling telemedicine capabilities continues to push the boundaries of digital twin applications in the medical field.

Digital Twin Market Regional Analysis

- North America dominated the digital twin market with the largest revenue share of 32.5% in 2024, driven by early adoption of advanced technologies, strong presence of key industry players, and increasing demand for predictive maintenance and real-time simulation across sectors

- The region benefits from high investment in R&D, robust IT infrastructure, and rapid digitization of manufacturing and healthcare sectors, which accelerates the deployment of digital twin solutions

- Growth is further supported by the rising integration of digital twins with AI, IoT, and cloud platforms, enabling industries to optimize performance, reduce costs, and enhance operational efficiency

U.S. Digital Twin Market Insight

The U.S. digital twin market captured the largest revenue share in 2024 within North America, fueled by the widespread adoption of IoT-enabled technologies and increasing emphasis on industrial automation. Key industries such as aerospace, automotive, and healthcare are leveraging digital twins to enhance asset performance, simulate real-time conditions, and improve predictive analytics. Strong government support for smart manufacturing and the rapid proliferation of smart infrastructure are further boosting market growth.

Europe Digital Twin Market Insight

The Europe digital twin market is projected to register a strong CAGR during the forecast period, driven by growing demand for sustainable manufacturing, efficient energy management, and predictive maintenance. With stringent regulations promoting energy efficiency and green innovation, industries across Germany, France, and the Nordics are increasingly implementing digital twin technologies. Europe’s emphasis on Industry 4.0 initiatives and smart infrastructure deployment across urban centers is also contributing significantly to market expansion.

U.K. Digital Twin Market Insight

The U.K. digital twin market is expected to grow at a robust CAGR, supported by advancements in smart city initiatives, healthcare digitization, and infrastructure modernization. The government’s investment in digital transformation across public services, coupled with the country's strong academic and tech research ecosystem, is driving innovation in the digital twin space. Applications in urban planning, transport, and utility management are key growth areas.

Germany Digital Twin Market Insight

The Germany digital twin market is anticipated to expand steadily, backed by its leadership in manufacturing automation and engineering excellence. Digital twins are increasingly adopted in the automotive, energy, and industrial machinery sectors to reduce downtime and boost production efficiency. Germany’s focus on sustainable production and innovation under Industry 4.0 initiatives makes it a leading adopter of digital twin technologies in Europe.

Asia-Pacific Digital Twin Market Insight

The Asia-Pacific digital twin market is poised to grow at the fastest CAGR from 2025 to 2032, driven by rapid industrialization, smart manufacturing initiatives, and increasing adoption of IoT and AI technologies in countries such as China, Japan, and South Korea. The region’s emphasis on infrastructure development and smart city projects, coupled with favorable government policies supporting digital transformation, is fostering digital twin integration across multiple industries.

Japan Digital Twin Market Insight

The Japan digital twin market is growing due to strong demand from advanced manufacturing, automotive, and electronics industries. The country’s reputation for precision engineering and early adoption of robotics and automation supports digital twin use for design optimization, maintenance, and performance simulation. Integration of digital twins into healthcare and urban planning is also emerging as a key trend, aligned with Japan’s commitment to innovation and efficiency.

China Digital Twin Market Insight

The China digital twin market accounted for the largest market revenue share in Asia-Pacific in 2024, driven by government-backed initiatives such as "Made in China 2025" and aggressive investment in smart infrastructure. Digital twins are being adopted across smart manufacturing, energy, transportation, and healthcare, with strong support from local tech giants and startups. The country’s vast industrial base and push towards digitalization are key enablers of market growth.

Digital Twin Market Share

The digital twin industry is primarily led by well-established companies, including:

- General Electric (U.S.)

- PTC (U.S.)

- Siemens (Germany)

- SAP SE (Germany)

- Dell Technologies (U.S.)

- Cisco Systems (U.S.)

- Robert Bosch GmbH (Germany)

- Microsoft Corporation (U.S.)

- IBM Corporation (U.S.)

- Ansys (U.S.)

- Swim Inc. (U.S.)

- Oracle Corporation (U.S.)

- NetNumber Inc. (U.S.)

- Telensa (U.K.)

- Actility S.A. (France)

- LINK LABS (U.S.)

- Telia Company (Sweden)

- Accent Advanced Systems, SLU (Spain)

- MediaTek Inc. (Taiwan)

- Halberd Bastion Pty Ltd (Australia)

- Qualcomm Technologies, Inc. (U.S.)

- u-blox (Switzerland)

Latest Developments in Global Digital Twin Market

- In February 2024, Capgemini expanded its strategic alliance with Unity, a leader in real-time 3D content creation. As part of this collaboration, Capgemini acquired Unity’s digital twin professional services unit. This integration allows Unity’s digital twin experts to embed within Capgemini, enhancing the implementation of real-time 3D visualization software specifically for industrial applications of digital twins, thereby accelerating innovation and efficiency in various sectors

- In January 2024, Valeo, a prominent provider of automotive technology, teamed up with Applied Intuition, a software supplier for vehicles, to develop a robust digital twin platform. This platform focuses on advanced driver-assistance systems (ADAS) sensor simulation, enabling original equipment manufacturers (OEMs) to launch reliable and safe ADAS features more quickly. The collaboration represents a significant advancement in automotive safety and technology integration

- In March 2023, WSP formed a collaboration with Amazon Web Services, Inc. to create digital twins for complex infrastructure projects. This partnership leverages AWS's cloud data processing and analytics capabilities to foster innovation and provide sustainable solutions across multiple industries. The collaboration aims to enhance WSP's offerings in infrastructure planning, environmental sustainability, and data-driven decision-making, ultimately driving advancements in infrastructure management and resilience

- In March 2022, Siemens partnered with Protium to leverage twin technology in developing hydrogen refueling infrastructure for aircraft. This collaboration aligns with the U.K. government's goal of achieving net-zero carbon emissions by 2030. By utilizing advanced digital twin technology, the partnership aims to create efficient and sustainable solutions for the aviation industry, promoting greener alternatives and supporting broader initiatives for environmental sustainability

- In February 2022, ANSYS, Inc. entered a strategic partnership with Amazon Web Services, Inc. (AWS) to enhance simulation processes. By deploying ANSYS products on AWS, the collaboration aims to make simulation software more accessible and user-friendly. Users can access powerful simulation tools from any location using a web browser, thereby democratizing advanced engineering simulations and enabling more efficient design and testing processes across various industries

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.