Global Drilling Fluid Additives Market

Market Size in USD Billion

CAGR :

%

USD

1.60 Billion

USD

3.24 Billion

2025

2033

USD

1.60 Billion

USD

3.24 Billion

2025

2033

| 2026 –2033 | |

| USD 1.60 Billion | |

| USD 3.24 Billion | |

|

|

|

|

Drilling Fluid Additives Market Size

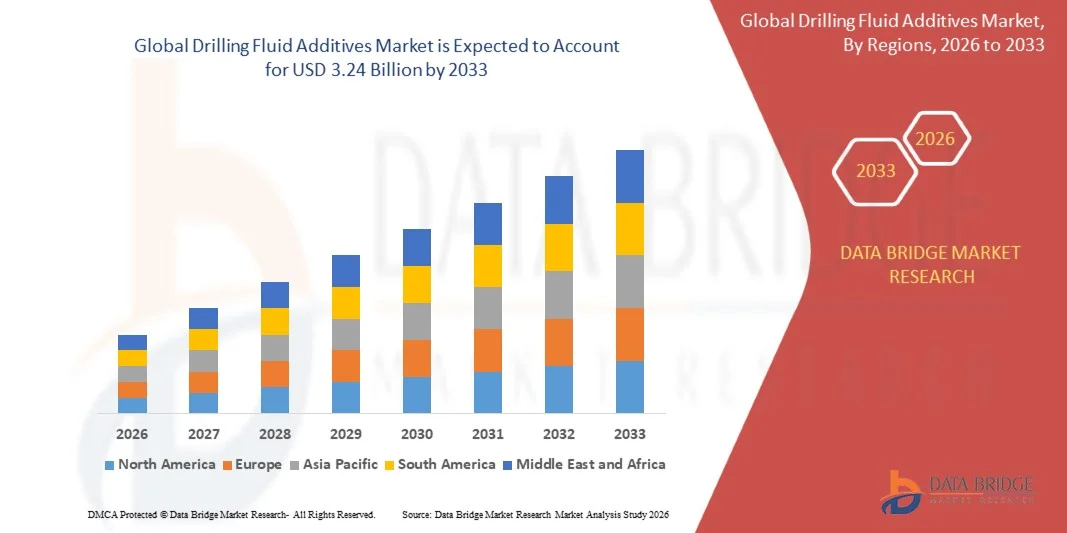

- The global drilling fluid additives market size was valued at USD 1.60 billion in 2025 and is expected to reach USD 3.24 billion by 2033, at a CAGR of 9.20% during the forecast period

- The market growth is largely fueled by increasing exploration and production activities in both onshore and offshore oil and gas operations, driving demand for high-performance drilling fluids and advanced additive solutions

- Furthermore, rising adoption of technologically advanced drilling methods and high-performance fluid formulations, such as corrosion inhibitors, viscosifiers, and fluid loss control additives, is establishing drilling fluid additives as critical components in modern drilling operations. These converging factors are accelerating the uptake of specialized additives, thereby significantly boosting the industry’s growth

Drilling Fluid Additives Market Analysis

- Drilling fluid additives, including surface modifiers, dispersants, corrosion inhibitors, and viscosifiers, are increasingly vital in maintaining wellbore stability, optimizing drilling efficiency, and preventing equipment corrosion under challenging reservoir and environmental conditions

- The escalating demand for drilling fluid additives is primarily fueled by growing exploration in complex and deepwater reservoirs, rising focus on operational efficiency, and increasing regulatory emphasis on environmentally compliant and sustainable fluid solutions

- North America dominated the drilling fluid additives market with a share of around 30% in 2025, due to the growing adoption of advanced drilling technologies and increasing exploration and production activities in the region

- Asia-Pacific is expected to be the fastest growing region in the drilling fluid additives market during the forecast period due to increasing exploration and production activities in countries such as China, India, and Australia

- Water based segment dominated the market with a market share of 41.7% in 2025, due to its cost-effectiveness, environmental compliance, and widespread use across onshore drilling operations. Water-based drilling fluids are preferred for their ease of preparation, availability of raw materials, and compatibility with a broad range of additives, allowing operators to optimize drilling performance efficiently. The segment also sees strong demand due to regulatory support and the growing focus on reducing environmental impact, making water-based fluids a standard choice in conventional drilling activities. Enhanced formulations that improve lubricity, thermal stability, and fluid loss control continue to strengthen the segment’s market position

Report Scope and Drilling Fluid Additives Market Segmentation

|

Attributes |

Drilling Fluid Additives Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Drilling Fluid Additives Market Trends

“Growing Adoption of High-Performance and Environmentally Friendly Additives”

- A significant trend in the drilling fluid additives market is the increasing adoption of high-performance and environmentally friendly additives that improve drilling efficiency, maintain wellbore stability, and reduce environmental impact. Operators are seeking fluid formulations that can withstand extreme temperatures and pressures while minimizing ecological footprint, making advanced additives essential for modern drilling projects

- For instance, Halliburton’s BaraXtreme water-based drilling fluid system incorporates advanced fluid loss control and high-performance additives designed to enhance hydraulic efficiency in challenging sandstone and shale formations. Such solutions are strengthening operational reliability and reducing downtime in complex drilling environments

- The use of biodegradable and low-toxicity additives is growing rapidly as companies strive to comply with stringent environmental regulations in regions such as North America and Europe. This is positioning eco-friendly additives as critical components in deepwater and onshore drilling projects where sustainability requirements are increasingly enforced

- Exploration in unconventional reservoirs, such as shale and tight gas formations, is boosting demand for multi-functional additives that provide improved rheology, cuttings transport, and shale inhibition. The rising integration of advanced chemical formulations into drilling fluids is improving performance under high-pressure, high-temperature conditions and enhancing overall wellbore stability

- Energy companies are increasingly investing in research and development to formulate additives that can reduce operational risks and enhance recovery rates. This trend is accelerating innovation in fluid chemistry, driving a stronger preference for additives capable of optimizing drilling performance while maintaining environmental compliance

- The market is witnessing strong growth in regions such as the U.S., Brazil, and the North Sea where high-performance drilling operations require specialized additives to meet operational and regulatory demands. The incorporation of these advanced additives is reinforcing the transition toward more efficient, sustainable, and safe drilling operations across the globe

Drilling Fluid Additives Market Dynamics

Driver

“Rising Exploration and Production Activities in Onshore and Offshore Oil & Gas”

- The growing demand for drilling fluid additives is primarily driven by the expansion of onshore and offshore oil and gas exploration and production activities. Companies are increasingly relying on additives to maintain wellbore stability, prevent corrosion, and optimize drilling efficiency in complex reservoirs

- For instance, SLB (Schlumberger) has supplied advanced drilling fluid systems and additives for Shell’s offshore deepwater projects, enhancing operational reliability and wellbore safety. Such deployments highlight the critical role of additives in enabling complex drilling operations and improving recovery rates

- The rising focus on deepwater and unconventional drilling operations in regions such as the Gulf of Mexico, Brazil, and West Africa is boosting the adoption of specialized fluid additives. These additives are essential to address the challenges posed by high pressures, extreme temperatures, and chemically reactive formations

- Energy companies are increasingly investing in technologically advanced additives that provide multi-functional benefits, such as improved rheology, fluid loss control, and shale stabilization. This is reinforcing the adoption of high-performance fluid systems capable of reducing operational risks and enhancing efficiency

- The expanding global energy landscape, with new wells being drilled across diverse environments, continues to strengthen this driver. The increasing need for reliable, high-performance, and environmentally compliant additives is propelling adoption across onshore, offshore, and unconventional drilling projects

Restraint/Challenge

“High Cost and Complexity of Advanced Drilling Fluid Formulations”

- The drilling fluid additives market faces challenges due to the high cost and technical complexity involved in developing advanced fluid formulations. Producing multi-functional additives that meet performance requirements under extreme conditions requires significant investment in research, testing, and specialized equipment

- For instance, companies such as Baker Hughes invest in high-precision chemical development and laboratory testing to create biodegradable, high-performance additives. These rigorous processes increase production costs and extend product development timelines, limiting price flexibility in the market

- The complexity of blending additives to provide corrosion inhibition, fluid loss control, and rheological stability in a single formulation adds operational and manufacturing challenges. Maintaining consistent quality across diverse reservoir conditions further complicates production and application processes

- The reliance on specialized raw materials, such as proprietary polymers and surfactants, increases supply-chain vulnerability and can contribute to price volatility. Manufacturers must balance performance, regulatory compliance, and cost efficiency while meeting growing demand

- Scaling up high-performance additive production while maintaining reliability, environmental compliance, and competitive pricing continues to be a key constraint. These challenges collectively place pressure on manufacturers to innovate efficiently and optimize operational and production processes to sustain market growth

Drilling Fluid Additives Market Scope

The market is segmented on the basis of type and fluid formation.

• By Type

On the basis of type, the drilling fluid additives market is segmented into surface modifiers, dispersants, corrosion inhibitors, fluid viscosifiers, biocides, defoamers, and others. The corrosion inhibitors segment dominated the market with the largest revenue share in 2025, driven by their critical role in protecting drilling equipment and pipelines from rust and chemical degradation during drilling operations. Operators increasingly prioritize corrosion inhibitors to ensure operational efficiency, reduce downtime, and extend the life of expensive drilling machinery. The segment also benefits from advancements in environmentally friendly formulations that meet regulatory standards, enhancing their adoption in offshore and onshore drilling projects. Strong compatibility with various drilling fluid systems further contributes to their widespread use, making corrosion inhibitors a staple in modern drilling operations.

The fluid viscosifiers segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by rising demand for stable drilling operations under extreme temperature and pressure conditions. For instance, companies such as M-I SWACO are developing advanced viscosifiers that enhance the rheological properties of drilling fluids, allowing for better cuttings suspension and transport. Increasing offshore exploration and deepwater drilling activities are driving the need for additives that maintain consistent fluid viscosity, ensuring wellbore stability. The ability of modern viscosifiers to reduce fluid loss and improve drilling efficiency further accelerates market growth. In addition, their integration with multi-functional drilling fluids provides operational benefits, making fluid viscosifiers highly sought after in new drilling projects.

• By Fluid Formation

On the basis of fluid formation, the drilling fluid additives market is segmented into synthetic-based, water-based, and oil-based fluids. The water-based segment dominated the market with the largest revenue share of 41.7% in 2025, driven by its cost-effectiveness, environmental compliance, and widespread use across onshore drilling operations. Water-based drilling fluids are preferred for their ease of preparation, availability of raw materials, and compatibility with a broad range of additives, allowing operators to optimize drilling performance efficiently. The segment also sees strong demand due to regulatory support and the growing focus on reducing environmental impact, making water-based fluids a standard choice in conventional drilling activities. Enhanced formulations that improve lubricity, thermal stability, and fluid loss control continue to strengthen the segment’s market position.

The synthetic-based segment is expected to witness the fastest CAGR from 2026 to 2033, fueled by its superior performance in extreme drilling conditions and deepwater operations. For instance, companies such as Halliburton are expanding their synthetic-based additive portfolios to enhance drilling efficiency while minimizing environmental impact. Synthetic fluids provide better thermal stability, reduced toxicity, and improved shale inhibition compared to traditional water-based fluids, driving adoption in complex drilling projects. Rising investments in offshore and unconventional resource exploration increase demand for high-performance drilling fluids. In addition, the growing need for customized fluid solutions tailored to challenging reservoir conditions further accelerates the adoption of synthetic-based formations.

Drilling Fluid Additives Market Regional Analysis

- North America dominated the drilling fluid additives market with the largest revenue share of around 30% in 2025, driven by the growing adoption of advanced drilling technologies and increasing exploration and production activities in the region

- Oil and gas operators in North America prioritize high-performance additives that enhance drilling efficiency, reduce equipment wear, and provide effective corrosion and fluid loss control in both onshore and offshore operations

- This widespread adoption is further supported by well-established oilfield infrastructure, technological expertise, and stringent regulatory standards, establishing drilling fluid additives as a critical component in modern drilling operations

U.S. Drilling Fluid Additives Market Insight

The U.S. drilling fluid additives market captured the largest revenue share in 2025 within North America, fueled by high exploration activity and extensive shale development initiatives. Operators are increasingly focusing on additives that improve wellbore stability, reduce operational downtime, and meet environmental regulations. The adoption of high-performance synthetic and water-based additives, alongside growing investments in unconventional resource extraction, is driving market growth. Moreover, increasing technological integration for real-time monitoring of drilling fluids enhances operational efficiency and promotes the use of advanced additives.

Europe Drilling Fluid Additives Market Insight

The Europe drilling fluid additives market is projected to expand at a substantial CAGR during the forecast period, primarily driven by stringent environmental and operational regulations and the need for high-performance drilling solutions. Countries such as Norway and the Netherlands are witnessing rising offshore exploration, fostering adoption of corrosion inhibitors, viscosifiers, and specialty additives. European operators are also emphasizing eco-friendly formulations and advanced fluid systems to optimize drilling efficiency while reducing environmental impact. The market is further supported by well-developed oil and gas infrastructure and technological expertise in fluid management systems.

U.K. Drilling Fluid Additives Market Insight

The U.K. drilling fluid additives market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by offshore exploration in the North Sea and the adoption of advanced fluid technologies. Operators are increasingly utilizing additives to ensure wellbore stability, prevent corrosion, and improve drilling efficiency in complex environments. The U.K.’s emphasis on regulatory compliance, safety, and sustainable operations is boosting demand for environmentally compliant drilling fluids and additives. Furthermore, the presence of specialized service providers and research initiatives in drilling chemistry is expected to support market expansion.

Germany Drilling Fluid Additives Market Insight

The Germany drilling fluid additives market is expected to expand at a considerable CAGR during the forecast period, fueled by rising onshore and offshore oil and gas exploration and a growing focus on sustainable drilling practices. Germany’s technologically advanced infrastructure and stringent environmental regulations encourage the use of high-performance and eco-friendly additives. Operators are increasingly investing in fluid systems that improve efficiency, reduce operational risks, and minimize environmental impact. In addition, collaboration with service providers and additive manufacturers supports the development and adoption of customized fluid solutions for complex drilling conditions.

Asia-Pacific Drilling Fluid Additives Market Insight

The Asia-Pacific drilling fluid additives market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by increasing exploration and production activities in countries such as China, India, and Australia. Rising urbanization, industrialization, and energy demand are promoting investment in both onshore and offshore drilling projects. The region’s growing adoption of advanced drilling technologies and high-performance additives ensures efficient operations under challenging reservoir conditions. In addition, APAC’s emergence as a manufacturing hub for drilling fluids and additives is improving availability and reducing costs, expanding accessibility for local operators.

Japan Drilling Fluid Additives Market Insight

The Japan drilling fluid additives market is gaining momentum due to advanced offshore exploration activities, technological expertise, and a focus on operational efficiency. Operators are increasingly deploying additives that provide superior thermal stability, corrosion protection, and fluid loss control for deepwater and complex reservoirs. The country’s emphasis on sustainable and eco-friendly operations is encouraging the adoption of synthetic and water-based fluid additives. Moreover, integration of real-time monitoring systems with drilling fluid management is enhancing additive performance and reliability across drilling operations.

China Drilling Fluid Additives Market Insight

The China drilling fluid additives market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to the country’s expanding oil and gas production, rapid industrialization, and technological adoption. High-performance additives are increasingly used to optimize drilling efficiency, prevent corrosion, and maintain wellbore stability in both onshore and offshore projects. Government initiatives supporting energy infrastructure development, along with a robust domestic additive manufacturing base, are key factors propelling market growth. The availability of cost-effective additives and growing exploration in unconventional reserves further strengthens China’s position as a leading market in the region.

Drilling Fluid Additives Market Share

The drilling fluid additives industry is primarily led by well-established companies, including:

- Akzo Nobel N.V. (Netherlands)

- BASF SE (Germany)

- Chevron Phillips Chemical Company LLC (U.S.)

- Dow Inc. (U.S.)

- Innospec Inc. (U.S.)

- Tetra Technologies, Inc. (U.S.)

- Halliburton Company (U.S.)

- Schlumberger Limited (France)

- Baker Hughes Company (U.S.)

- Newpark Resources Inc. (U.S.)

- National Oilwell Varco, Inc. (U.S.)

- Weatherford International plc (Switzerland)

- Clariant AG (Switzerland)

- Croda International Plc (U.K.)

- Lubrizol Corporation (U.S.)

Latest Developments in Global Drilling Fluid Additives Market

- In September 2025, Newpark Fluids Systems entered a strategic collaboration with Intelligent Mud Solutions (IMS) to integrate real-time drilling fluid measurement and analytics into drilling operations. This development enhances operators’ ability to monitor fluid behavior continuously, optimize drilling performance, and minimize non-productive time. The integration of autonomous monitoring technology with advanced fluid additives is expected to drive greater adoption of high-performance fluids in North America and other mature markets, increasing efficiency, reducing operational risks, and reinforcing the importance of data-driven fluid management in complex drilling environments

- In January 2025, Halliburton secured a multi-year contract to supply its advanced drilling fluid systems and fluid loss control additives for deepwater and exploration wells in Brazil. This strengthens Halliburton’s position in offshore markets and underscores the growing demand for high-performance additives capable of maintaining wellbore stability under extreme conditions. The contract highlights the strategic role of additives in reducing drilling complications, optimizing operations, and supporting large-scale offshore exploration, signaling increased market reliance on technologically advanced fluid solutions

- In 2025, Baker Hughes expanded its drilling fluid additives portfolio through the acquisition of a specialty chemicals manufacturer focused on biodegradable fluid additives. This move significantly boosts the company’s capabilities in providing environmentally friendly drilling solutions, catering to operators facing stricter regulatory compliance. The development is likely to accelerate the adoption of sustainable additives across global markets, driving growth in the eco-conscious segment of the drilling fluid additives industry while supporting operational efficiency and environmental safety

- In September 2024, SCF Partners, Inc. completed the acquisition of Newpark Fluids Systems’ fluids segment, enhancing its product and service offerings for drilling and completion fluids. This expansion allows SCF to provide more customized solutions for various reservoir conditions, reinforcing its competitive position in North America. The acquisition is expected to stimulate innovation in additive formulations, improve market coverage, and promote the adoption of high-performance drilling fluids in both onshore and offshore operations

- In August 2024, AES Drilling Fluids acquired HydroLite Operating LLC, broadening its capabilities in fluid systems for well drill-outs and cleanouts. This acquisition strengthens AES’s market presence and enables the company to serve a wider variety of reservoir conditions with specialized additives. The development is poised to increase demand for advanced fluid solutions that enhance wellbore stability, optimize drilling efficiency, and reduce operational downtime, highlighting the critical role of fluid additives in modern drilling projects

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Drilling Fluid Additives Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Drilling Fluid Additives Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Drilling Fluid Additives Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.