Global Fermentation Defoamer Market

Market Size in USD Billion

CAGR :

%

USD

2.51 Billion

USD

3.76 Billion

2025

2033

USD

2.51 Billion

USD

3.76 Billion

2025

2033

| 2026 –2033 | |

| USD 2.51 Billion | |

| USD 3.76 Billion | |

|

|

|

|

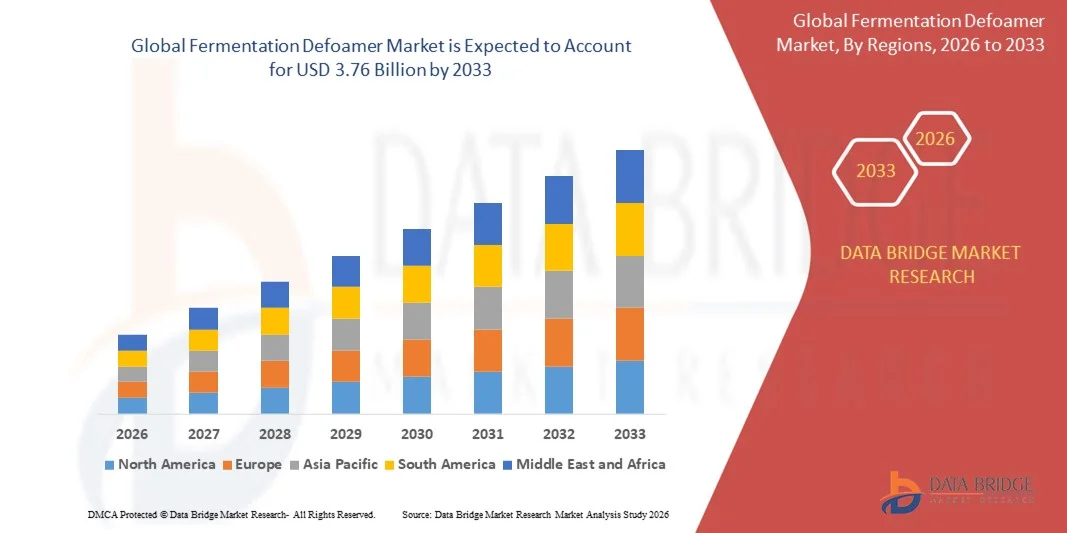

What is the Global Fermentation Defoamer Market Size and Growth Rate?

- The global fermentation defoamer market size was valued at USD 2.51 billion in 2025 and is expected to reach USD 3.76 billion by 2033, at a CAGR of5.20% during the forecast period

- The increase in demand from food and beverages industry is expected to augment market growth.

- The rise in the health care expenditure, increasing demand from pharmaceutical industry for manufacturing antibiotics, steroids, vaccines as well as the high demand for bio-fuels and rise in the demand from chemical industry due to its properties of polymerization, organic acids and amino acids are also expected to be as the major factors leading to the growth of the fermentation defoamer market. The major factor accountable for the growth of the market is the rapid shift towards alternative fuels

What are the Major Takeaways of Fermentation Defoamer Market?

- The rise in investments in R& D activities, rapid of eco-friendly material such as water based and alkyl polyacrylates and the high pharmaceutical industry growth are projected to create lucrative opportunities in the above mentioned forecast period

- However, the rise in the awareness on consumption of alcoholic products which uses fermentation defoamer extensive for its manufacturing and stringent regulations related to product usage are expected to act as major restraining factors towards the growth of the fermentation defoamer market

- North America dominated the fermentation defoamer market with a 41.10% revenue share in 2025, driven by extensive industrial fermentation activities, advanced biopharmaceutical production, dairy processing, and biofuel manufacturing across the U.S. and Canada

- Asia-Pacific is projected to register the fastest CAGR of 8.39% from 2026 to 2033, fueled by rising food and beverage manufacturing, increasing pharmaceutical fermentation, and expanding biofuel production across China, Japan, India, South Korea, and Southeast Asia

- The Silicone Defoamer segment dominated the market with a 42.3% share in 2025, driven by its excellent foam suppression efficiency, chemical stability, and compatibility with various fermentation processes, including yeast, bacterial, and algae-based systems

Report Scope and Fermentation Defoamer Market Segmentation

|

Attributes |

Fermentation Defoamer Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Fermentation Defoamer Market?

Increasing Shift Toward Eco-Friendly, High-Efficiency, and Specialized Fermentation Defoamers

- The fermentation defoamer market is witnessing growing adoption of environmentally friendly, low-toxicity, and high-performance defoamers designed to enhance fermentation efficiency, reduce contamination, and optimize bioprocessing yields

- Manufacturers are introducing tailored defoamer formulations compatible with specific fermentation processes, including bacterial, yeast, and algae-based applications, providing consistent foam control without affecting microbial growth

- Rising demand for cost-effective, easy-to-use, and scalable solutions is driving usage across industrial biotechnology plants, pharmaceutical fermentation units, biofuel production facilities, and academic research labs

- For instance, companies such as Dow, BASF, Evonik, and Wacker have expanded their portfolios with silicone-based, mineral-oil-free, and water-dispersible defoamers for enhanced process performance

- Increasing focus on sustainable production, reduced chemical residues, and regulatory compliance is accelerating adoption of specialty Fermentation Defoamers across global fermentation industries

- As fermentation technologies advance and process complexity increases, fermentation defoamers will remain essential for improving yield, maintaining product quality, and minimizing operational disruptions

What are the Key Drivers of Fermentation Defoamer Market?

- Rising demand for high-performance defoamers that prevent foam-related production losses, maintain sterility, and support large-scale fermentation operations

- For instance, in 2025, leading companies such as Dow, BASF, Evonik, and Wacker introduced next-generation formulations with improved dispersion, bio-compatibility, and process stability, driving industry adoption

- Expansion of pharmaceutical, biotechnology, bioethanol, and specialty chemicals sectors is boosting demand for reliable foam control solutions across U.S., Europe, and Asia-Pacific regions

- Continuous innovation in defoamer chemistry, including silicone-free, emulsifiable, and biodegradable variants, has enhanced process efficiency, safety, and cost-effectiveness

- Increasing implementation of automated and continuous fermentation systems requires advanced defoamers compatible with high-speed mixing, bioreactor sensors, and process analytical technologies

- Supported by growing biopharmaceutical production, industrial fermentation scaling, and bio-based chemical manufacturing, the fermentation defoamer market is projected to witness steady long-term growth

Which Factor is Challenging the Growth of the Fermentation Defoamer Market?

- High costs associated with specialty, eco-friendly, and process-specific defoamers limit adoption among small-scale producers and research facilities

- For instance, during 2024–2025, fluctuations in raw material prices, supply chain disruptions, and stricter regulatory standards increased formulation costs for several global vendors

- Complexity in developing defoamers compatible with sensitive microbial cultures and high-temperature processes requires advanced R&D and process validation

- Limited awareness regarding formulation selection, optimal dosing, and process integration slows adoption in emerging fermentation markets

- Competition from generic defoamers, in-house formulations, and alternative foam control strategies creates pricing pressure and reduces product differentiation

- To address these challenges, companies are focusing on cost-efficient, biodegradable, and multi-application defoamers, technical support, and process integration guidance to boost global adoption of fermentation defoamers

How is the Fermentation Defoamer Market Segmented?

The market is segmented on the basis of type, product, and end user.

- By Type

On the basis of type, the fermentation defoamer market is segmented into Silicone Defoamer, Polyether Defoamer, Polyether Modified Silicon Defoamer, and Others. The Silicone Defoamer segment dominated the market with a 42.3% share in 2025, driven by its excellent foam suppression efficiency, chemical stability, and compatibility with various fermentation processes, including yeast, bacterial, and algae-based systems. Silicone defoamers are widely adopted across industrial fermentation, pharmaceutical bioreactors, and biofuel production due to their effectiveness at low concentrations and minimal interference with microbial growth.

The Polyether Modified Silicon Defoamer segment is expected to grow at the fastest CAGR from 2026 to 2033, fueled by demand for high-performance, biodegradable, and process-specific formulations suitable for sensitive bioprocesses and large-scale continuous fermentation operations.

- By Product

On the basis of product, the market is segmented into Silicone-Based, Oil-Based, and Others. The Silicone-Based segment dominated the market with a 45.7% share in 2025, owing to its high stability, low surface tension, and consistent foam control across diverse fermentation environments.

Oil-Based defoamers are gaining traction as the fastest-growing segment, driven by their cost-effectiveness, adaptability to various pH conditions, and suitability for large-volume industrial bioprocessing. These defoamers are extensively utilized in food, beverage, bioethanol, and pharmaceutical fermentation applications where uniform foam suppression is critical for productivity and quality.

- By End User

On the basis of end user, the market is segmented into Dairy Products, Alcoholic Beverages, Food Products, Pharmaceuticals, Chemicals, and Others. The Dairy Products segment dominated the market with a 38.6% share in 2025, supported by widespread usage in milk processing, cheese production, and yogurt fermentation to prevent foam formation and maintain product quality.

The Pharmaceutical segment is projected to grow at the fastest CAGR from 2026 to 2033, owing to increasing adoption of fermentation-based drug manufacturing, vaccine production, and biopharmaceutical research. Rising demand for high-quality, contaminant-free processes in pharma and biotechnology sectors is driving the deployment of advanced, process-specific defoamers globally.

Which Region Holds the Largest Share of the Fermentation Defoamer Market?

- North America dominated the fermentation defoamer market with a 41.10% revenue share in 2025, driven by extensive industrial fermentation activities, advanced biopharmaceutical production, dairy processing, and biofuel manufacturing across the U.S. and Canada. Strong adoption of advanced bioprocessing technologies, automated fermentation systems, and quality monitoring tools continues to fuel demand for Fermentation Defoamers across food, beverage, chemical, and pharmaceutical sectors

- Leading companies in North America are introducing high-efficiency silicone, polyether, and hybrid defoamer solutions tailored for large-scale fermentation, continuous bioreactors, and sensitive pharmaceutical processes, strengthening the region’s technological advantage. Continuous investment in process optimization, bioengineering, and industrial biotechnology drives long-term market growth

- High concentration of R&D centers, skilled workforce, and established industrial fermentation infrastructure further reinforce regional market leadership

U.S. Fermentation Defoamer Market Insight

The U.S. is the largest contributor in North America, supported by widespread industrial fermentation applications, including dairy, alcoholic beverages, pharmaceuticals, and biofuels. Increasing production of biopharmaceuticals, probiotics, and bioethanol intensifies demand for high-performance defoamers that prevent foam-related process disruptions, ensure product quality, and improve yield. Presence of leading biotech and food processing companies, coupled with robust regulatory standards, further drives market adoption.

Canada Fermentation Defoamer Market Insight

Canada contributes significantly to regional growth, driven by expanding food processing, bioethanol, and pharmaceutical fermentation facilities. Adoption of advanced fermentation monitoring tools and high-quality defoamers in dairy, beverage, and specialty chemical production enhances process efficiency. Government initiatives promoting bio-industrial research and skilled workforce availability support market expansion across the country.

Asia-Pacific Fermentation Defoamer Market

Asia-Pacific is projected to register the fastest CAGR of 8.39% from 2026 to 2033, fueled by rising food and beverage manufacturing, increasing pharmaceutical fermentation, and expanding biofuel production across China, Japan, India, South Korea, and Southeast Asia. High-volume production of dairy, alcoholic beverages, and bio-based chemicals increases demand for effective defoaming solutions. Rapid industrialization, growing startup ecosystems, and government-backed bioprocessing initiatives continue to accelerate market growth.

China Fermentation Defoamer Market Insight

China is the largest contributor to Asia-Pacific due to massive food, beverage, and pharmaceutical manufacturing capacity. Rising industrial fermentation, bioethanol production, and dairy processing drive demand for silicone and polyether-based defoamers. Local production capabilities and cost-effective solutions further expand adoption in domestic and export markets.

Japan Fermentation Defoamer Market Insight

Japan shows steady growth supported by precision fermentation processes in pharmaceuticals, dairy, and specialty chemicals. Focus on high-quality bioprocessing, low-contamination standards, and reliable defoaming solutions drives premium product adoption. Increasing automation and high-value fermentation output reinforce long-term market expansion.

India Fermentation Defoamer Market Insight

India is emerging as a key growth hub, driven by expanding dairy, alcoholic beverage, and pharmaceutical fermentation facilities. Rising adoption of advanced bioreactors, probiotics, and industrial biotechnology solutions fuels defoamer usage in production and R&D environments. Government support for food technology and bio-industrial initiatives further accelerates market penetration.

South Korea Fermentation Defoamer Market Insight

South Korea contributes significantly due to strong demand in dairy, bioethanol, and pharmaceutical fermentation sectors. Rapid expansion of industrial fermentation plants, biotech startups, and functional food production drives the adoption of advanced silicone and polyether defoamers. Technological innovation, high manufacturing standards, and growing R&D ecosystems support sustained market growth.

Which are the Top Companies in Fermentation Defoamer Market?

The fermentation defoamer industry is primarily led by well-established companies, including:

- Wacker Chemie AG (Germany)

- Blackburn Chemicals Ltd. (U.K.)

- Shin-Etsu Chemical Co., Ltd. (Japan)

- Momentive (U.S.)

- SIXIN NORTH AMERICA, INC. (U.S.)

- ADDAPT Chemicals B.V. (Netherlands)

- Accepta (Germany)

- Dow (U.S.)

- Hydrite Chemical (U.S.)

- Thurs Organics Pvt. Ltd. (India)

- Indotech Organiics (India)

- Spak Orgochem (India) Pvt. Ltd. (India)

- SAN NOPCO LIMITED (Japan)

- PENNWHITE (U.K.)

- Schill + Seilacher "Struktol" GmbH (Germany)

- Elkem ASA (Norway)

What are the Recent Developments in Global Fermentation Defoamer Market?

- In May 2024, Momentive Performance Materials group (Momentive), a global provider of high-performance silicones and specialty solutions, was fully acquired by KCC Corporation (KCC), resulting in the exit of minority shareholder SJL Partners, LLC. KCC, which had been the majority shareholder since 2020, had announced the anticipated acquisition in March. This strategic move is expected to strengthen KCC’s portfolio in silicone-based and specialty chemical solutions globally

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Fermentation Defoamer Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Fermentation Defoamer Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Fermentation Defoamer Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.