Global Fibre Reinforced Plastic Frp Rebar Market

Market Size in USD Million

CAGR :

%

USD

619.40 Million

USD

1,533.62 Million

2025

2033

USD

619.40 Million

USD

1,533.62 Million

2025

2033

| 2026 –2033 | |

| USD 619.40 Million | |

| USD 1,533.62 Million | |

|

|

|

|

Global Fibre Reinforced Plastic (FRP) Rebar Market Segmentation, By Resin Type (Vinyl Ester, Polyester, and Others), Fiber Type (Glass Fiber Reinforced Plastic, Basalt Fiber Reinforced Plastic, and Carbon Fiber Reinforced Plastic), Application (Highways, Bridges, & Buildings, Water Treatment Plants, Marine Structures & Waterfronts, and Others) - Industry Trends and Forecast to 2033

Fibre Reinforced Plastic (FRP) Rebar Market Size

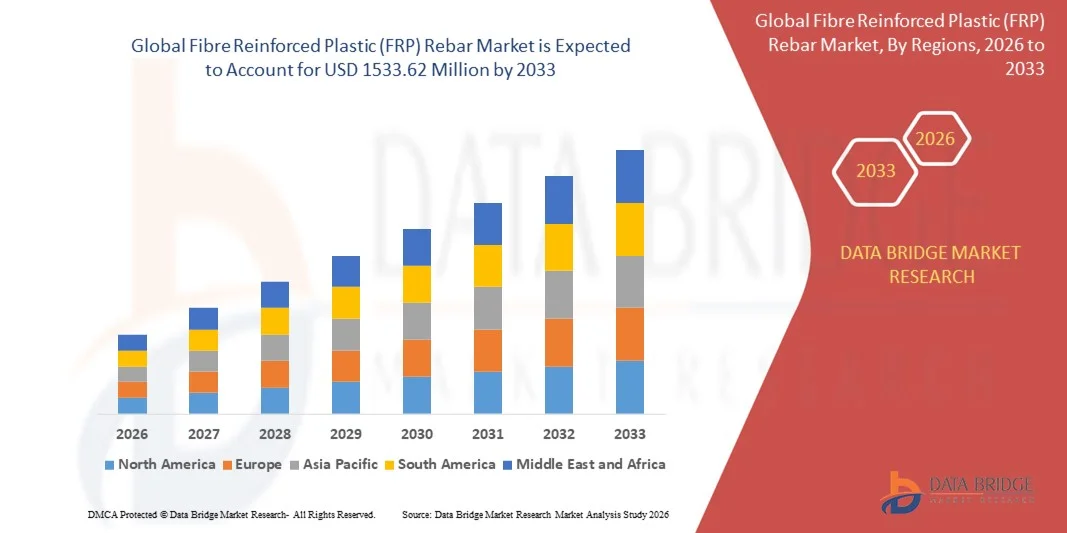

- The global Fibre Reinforced Plastic (FRP) Rebar market size was valued at USD 619.40 million in 2025 and is expected to reach USD 1533.62 million by 2033, at a CAGR of 12.00% during the forecast period

- The market growth is largely fueled by the increasing adoption of corrosion-resistant and lightweight construction materials, which are enhancing the durability and lifespan of concrete structures across residential, commercial, and infrastructure projects

- Furthermore, rising investments in large-scale infrastructure, urbanization, and government initiatives promoting sustainable and low-maintenance construction solutions are driving the demand for FRP rebars, establishing them as a preferred alternative to traditional steel reinforcement. These converging factors are accelerating the adoption of FRP rebars, thereby significantly boosting the industry’s growth

Fibre Reinforced Plastic (FRP) Rebar Market Analysis

- Fibre Reinforced Plastic (FRP) Rebar, offering high-strength, corrosion-resistant, and lightweight reinforcement for concrete structures, are increasingly vital in modern construction, particularly for highways, bridges, marine structures, and water treatment plants, due to their enhanced durability and long-term cost benefits

- The escalating demand for Fibre Reinforced Plastic (FRP) Rebar is primarily fueled by the need for maintenance-free infrastructure, stringent durability standards, and the growing preference for sustainable construction materials that reduce lifecycle costs and improve structural safety

- North America dominated the Fibre Reinforced Plastic (FRP) Rebar market with a share of around 40% in 2025, due to the growing adoption of corrosion-resistant construction materials and increasing investments in infrastructure development

- Asia-Pacific is expected to be the fastest growing region in the Fibre Reinforced Plastic (FRP) Rebar market during the forecast period due to rapid urbanization, increasing infrastructure spending, and rising demand for corrosion-resistant construction materials in countries such as China, India, and Japan

- Glass fiber reinforced plastic segment dominated the market with a market share of 46.8% in 2025, due to its excellent strength-to-weight ratio and ease of fabrication. Glass fiber reinforced plastics are often used in construction due to their robustness and resistance to corrosion. The market also sees strong demand for glass fiber types due to their widespread availability and compatibility with various resin systems

Report Scope and Fibre Reinforced Plastic (FRP) Rebar Market Segmentation

|

Attributes |

Fibre Reinforced Plastic (FRP) Rebar Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Fibre Reinforced Plastic (FRP) Rebar Market Trends

Rising Adoption of Corrosion-Resistant Construction Materials

- A significant trend in the Fibre Reinforced Plastic (FRP) Rebar market is the increasing adoption of corrosion-resistant and lightweight reinforcement materials in construction projects, driven by the growing need for durable, long-lasting infrastructure across highways, bridges, marine structures, and buildings. Fibre Reinforced Plastic (FRP) Rebar are gaining traction due to their ability to withstand harsh environmental conditions, reduce maintenance costs, and extend the service life of concrete structures

- For instance, Strongwell Corporation supplies pultruded Fibre Reinforced Plastic (FRP) Rebar used in coastal bridge projects and industrial constructions, which significantly enhance durability in corrosive environments. Such applications are increasing confidence in FRP solutions and positioning them as viable alternatives to traditional steel reinforcements in challenging conditions

- The use of Fibre Reinforced Plastic (FRP) Rebar is also expanding in water treatment plants and marine infrastructure where exposure to chemicals and saline water accelerates steel corrosion. Companies such as Fiberline Composites A/S are supplying specialized FRP solutions for desalination plants and piers, supporting safer and longer-lasting structural performance

- Rising awareness among governments and construction firms about the long-term cost benefits of Fibre Reinforced Plastic (FRP) Rebar is further strengthening adoption. Public infrastructure projects in the U.S., U.K., and Japan are increasingly specifying FRP reinforcements to comply with corrosion-resistance standards, driving demand in both new constructions and retrofitting projects

- The lightweight nature of Fibre Reinforced Plastic (FRP) Rebar also supports faster construction timelines and reduced labor costs, which is particularly important in large-scale urbanization projects. This is attracting major construction companies such as CTS Bridges Ltd to integrate Fibre Reinforced Plastic (FRP) Rebar into bridge and roadway projects, demonstrating their operational efficiency and structural advantages

- Overall, the market is witnessing a strong shift toward Fibre Reinforced Plastic (FRP) Rebar due to their superior performance, sustainability, and ability to meet increasingly stringent infrastructure durability requirements, thereby reinforcing growth across residential, commercial, and industrial construction segments

Fibre Reinforced Plastic (FRP) Rebar Market Dynamics

Driver

Increasing Infrastructure Development and Urbanization

- The growing investment in large-scale infrastructure projects and rapid urbanization across North America, Europe, and Asia-Pacific is driving the demand for Fibre Reinforced Plastic (FRP) Rebar. These materials are increasingly favored due to their corrosion resistance, lightweight properties, and long-term cost benefits over traditional steel reinforcement

- For instance, Sika AG has expanded its Fibre Reinforced Plastic (FRP) Rebar manufacturing facility in North America to cater to rising demand in highways, bridges, and urban development projects. This expansion enables faster project completion and meets stringent durability requirements, positioning Fibre Reinforced Plastic (FRP) Rebar as essential components in modern construction

- Government-backed initiatives targeting resilient and sustainable infrastructure, such as coastal highway projects in the U.S. and bridge rehabilitation programs in Japan, are accelerating the adoption of FRP reinforcement materials. These developments are promoting Fibre Reinforced Plastic (FRP) Rebar as preferred solutions for long-term infrastructure stability

- The trend toward smart, sustainable cities is also contributing to FRP rebar adoption, as urban planners prioritize materials that reduce maintenance costs and enhance structural longevity. Companies such as FiberCore Europe BV are supplying Fibre Reinforced Plastic (FRP) Rebar for urban transport and high-rise projects, supporting infrastructure that is both durable and cost-efficient

- Furthermore, the construction of industrial plants, water treatment facilities, and marine structures increasingly relies on FRP rebars to withstand chemical exposure and harsh environmental conditions, reinforcing their role in long-lasting, safe, and efficient construction

Restraint/Challenge

High Initial Cost Compared to Traditional Steel Rebars

- The Fibre Reinforced Plastic (FRP) Rebar market faces challenges due to the higher upfront cost of FRP materials compared to conventional steel reinforcement. The advanced manufacturing processes, specialized fibers, and resins required to produce FRP rebars contribute to elevated production costs, which can limit adoption, particularly in price-sensitive regions

- For instance, Bedford Reinforced Plastics and B&B FRP Manufacturing Inc. highlight that while Fibre Reinforced Plastic (FRP) Rebar reduce long-term maintenance expenses, the initial material cost remains significantly higher than traditional steel, affecting small-scale project feasibility

- In addition, the need for specialized installation techniques and training for construction personnel adds to the overall project cost. The reliance on skilled labor to handle FRP reinforcement and ensure proper bonding within concrete structures can delay project timelines and increase expenditure

- The market also faces limitations in regions with lower awareness of long-term benefits and cost savings, where decision-makers continue to favor conventional steel reinforcements for their familiarity and lower immediate investment

- Scaling production while maintaining consistent quality standards and durability is another constraint, as manufacturers must balance performance requirements with economic feasibility to remain competitive in global markets

Fibre Reinforced Plastic (FRP) Rebar Market Scope

The market is segmented on the basis of resin type, fiber type, and application.

- By Resin Type

On the basis of resin type, the market is segmented into vinyl ester, polyester, and others. The vinyl ester segment dominated the market with the largest market revenue share in 2025, driven by its superior chemical resistance and mechanical properties. Vinyl ester resins are often preferred in construction applications for their durability and ability to withstand harsh environmental conditions. The market also sees strong demand for vinyl ester resins due to their compatibility with various fiber reinforcements and the availability of diverse formulations enhancing performance and longevity.

The polyester segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by increasing adoption in infrastructure projects. Polyester resins offer cost-effectiveness and ease of processing, making them suitable for large-scale applications. The versatility and adaptability of polyester resins also contribute to their growing popularity across different construction sectors.

- By Fiber Type

On the basis of fiber type, the market is segmented into glass fiber reinforced plastic, basalt fiber reinforced plastic, and carbon fiber reinforced plastic. The glass fiber reinforced plastic segment held the largest market revenue share of 46.8% in 2025, driven by its excellent strength-to-weight ratio and ease of fabrication. Glass fiber reinforced plastics are often used in construction due to their robustness and resistance to corrosion. The market also sees strong demand for glass fiber types due to their widespread availability and compatibility with various resin systems.

The basalt fiber reinforced plastic segment is expected to witness the fastest CAGR from 2026 to 2033, driven by its superior thermal stability and environmental resistance. Basalt fibers are particularly popular for applications requiring enhanced durability and performance under extreme conditions. Their growing adoption in infrastructure projects further fuels market growth.

- By Application

On the basis of application, the market is segmented into highways, bridges & buildings, water treatment plants, marine structures & waterfronts, and others. The highways, bridges & buildings segment dominated the market with the largest market revenue share in 2025, driven by the high demand for durable and long-lasting construction materials. These applications often require materials with excellent mechanical and chemical resistance, making FRP composites ideal. The market also sees strong demand in this segment due to increasing infrastructure development and government investments.

The water treatment plants segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by rising urbanization and the need for corrosion-resistant materials. FRP composites in water treatment applications offer reliability, low maintenance, and enhanced lifespan. Their growing adoption in industrial and municipal projects further supports market expansion.

Fibre Reinforced Plastic (FRP) Rebar Market Regional Analysis

- North America dominated the Fibre Reinforced Plastic (FRP) Rebar market with the largest revenue share of around 40% in 2025, driven by the growing adoption of corrosion-resistant construction materials and increasing investments in infrastructure development

- Consumers in the region highly value the durability, lightweight properties, and long-term cost savings offered by Fibre Reinforced Plastic (FRP) Rebar compared to traditional steel reinforcement

- This widespread adoption is further supported by strict regulations on concrete structures, rising maintenance costs of steel, and the growing focus on sustainable and resilient construction practices, establishing FRP rebars as a preferred solution for highways, bridges, and buildings

U.S. Fibre Reinforced Plastic (FRP) Rebar Market Insight

The U.S. Fibre Reinforced Plastic (FRP) Rebar market captured the largest revenue share in 2025 within North America, fueled by large-scale infrastructure projects and government initiatives promoting durable and sustainable construction materials. The adoption of FRP rebars is increasingly prioritized in coastal and industrial regions due to their corrosion resistance and longer lifespan. Moreover, the integration of Fibre Reinforced Plastic (FRP) Rebar in bridge rehabilitation and marine construction projects is further accelerating market growth.

Europe Fibre Reinforced Plastic (FRP) Rebar Market Insight

The Europe Fibre Reinforced Plastic (FRP) Rebar market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by stringent building codes and the need for corrosion-resistant materials in infrastructure development. The increase in urbanization, coupled with rising government investments in transportation and public works, is fostering Fibre Reinforced Plastic (FRP) Rebar adoption. European construction companies are also drawn to the lightweight and high-strength properties of FRP rebars, which contribute to faster construction timelines and reduced labor costs.

U.K. Fibre Reinforced Plastic (FRP) Rebar Market Insight

The U.K. Fibre Reinforced Plastic (FRP) Rebar market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by growing awareness of sustainable construction materials and the demand for long-lasting infrastructure. In addition, the need to reduce maintenance costs and extend the lifespan of bridges, roads, and buildings is encouraging widespread FRP rebar usage. The U.K.’s well-developed construction sector, combined with adoption in both new projects and retrofitting applications, is expected to continue fueling market growth.

Germany Fibre Reinforced Plastic (FRP) Rebar Market Insight

The Germany Fibre Reinforced Plastic (FRP) Rebar market is expected to expand at a considerable CAGR during the forecast period, fueled by the country’s focus on advanced infrastructure and innovation in construction technologies. Germany’s stringent durability standards and preference for eco-friendly materials promote the adoption of Fibre Reinforced Plastic (FRP) Rebar, particularly in bridges, marine structures, and industrial projects. The use of FRP rebars for high-performance concrete structures is also gaining traction, aligning with local consumer and regulatory expectations.

Asia-Pacific Fibre Reinforced Plastic (FRP) Rebar Market Insight

The Asia-Pacific Fibre Reinforced Plastic (FRP) Rebar market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by rapid urbanization, increasing infrastructure spending, and rising demand for corrosion-resistant construction materials in countries such as China, India, and Japan. The region's focus on smart and sustainable urban infrastructure is accelerating FRP rebar adoption. Furthermore, APAC’s manufacturing capabilities and cost advantages are making FRP rebars increasingly accessible across residential, commercial, and industrial projects.

Japan Fibre Reinforced Plastic (FRP) Rebar Market Insight

The Japan Fibre Reinforced Plastic (FRP) Rebar market is gaining momentum due to the country’s emphasis on earthquake-resistant and corrosion-resistant infrastructure. The adoption of Fibre Reinforced Plastic (FRP) Rebar is driven by the growing number of high-rise buildings, coastal projects, and aging infrastructure requiring durable reinforcement solutions. The integration of FRP rebars in combination with advanced concrete technologies is fueling market growth.

China Fibre Reinforced Plastic (FRP) Rebar Market Insight

The China Fibre Reinforced Plastic (FRP) Rebar market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to the country’s expanding infrastructure development, rapid urbanization, and high investment in transportation and industrial projects. China stands as one of the largest markets for FRP rebars, with strong domestic manufacturing capabilities ensuring affordability and availability. The push for sustainable and long-lasting construction materials, coupled with government initiatives for coastal and marine infrastructure, is further propelling market growth.

Fibre Reinforced Plastic (FRP) Rebar Market Share

The Fibre Reinforced Plastic (FRP) Rebar industry is primarily led by well-established companies, including:

- AXION Structural Innovations LLC (U.S.)

- B&B FRP Manufacturing Inc. (U.S.)

- Bedford Reinforced Plastics (U.K.)

- Creative Composites Group (U.K.)

- CTS Bridges Ltd (U.K.)

- FiberCore Europe BV (Netherlands)

- Fiberline Composites A/S (Denmark)

- Strongwell Corporation (U.S.)

- Hughes Brothers, Inc. (U.S.)

- Lifespan Structures Ltd (U.K.)

- Vectorply (U.S.)

Latest Developments in Global Fibre Reinforced Plastic (FRP) Rebar Market

- In September 2025, BASF SE launched a new line of eco-friendly FRP rebars utilizing recycled materials. This development strengthens BASF’s position in the sustainable construction segment, attracting environmentally conscious clients and enhancing brand loyalty. The initiative also supports global sustainability trends, potentially driving higher adoption of FRP rebars in green infrastructure projects across Europe and North America

- In August 2025, Sika AG inaugurated a new manufacturing facility in North America to expand production capacity for its innovative FRP rebar solutions. This strategic move is likely to improve supply chain efficiency, reduce lead times, and enable Sika to meet the rising demand in the region, thereby reinforcing its competitive market position and supporting growth in large-scale infrastructure projects

- In July 2025, Hexion Inc. formed a strategic partnership with a leading construction firm to develop customized FRP rebar solutions for major infrastructure projects. This collaboration leverages Hexion’s advanced material science capabilities, enabling innovative applications, accelerating adoption in large-scale projects, and enhancing market penetration in the U.S. construction sector

- In June 2025, Owens Corning expanded its FRP rebar production line to cater to growing demand in marine and coastal infrastructure projects. The expansion is expected to increase regional supply, reduce dependency on imports, and provide tailored solutions for high-corrosion environments, thereby strengthening Owens Corning’s foothold in the North American market

- In May 2025, Jushi Group launched a new high-strength FRP rebar product designed specifically for earthquake-resistant construction. This innovation enhances the structural safety and durability of buildings in seismic zones, driving adoption in high-risk regions and positioning Jushi as a leading supplier of specialized FRP rebars in the Asia-Pacific market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Fibre Reinforced Plastic Frp Rebar Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Fibre Reinforced Plastic Frp Rebar Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Fibre Reinforced Plastic Frp Rebar Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.