Global Metal Moulds Market

Market Size in USD Billion

CAGR :

%

USD

5.37 Billion

USD

6.91 Billion

2025

2033

USD

5.37 Billion

USD

6.91 Billion

2025

2033

| 2026 –2033 | |

| USD 5.37 Billion | |

| USD 6.91 Billion | |

|

|

|

|

What is the Global Metal Moulds Market for Plastic Injection Moulding Size and Growth Rate?

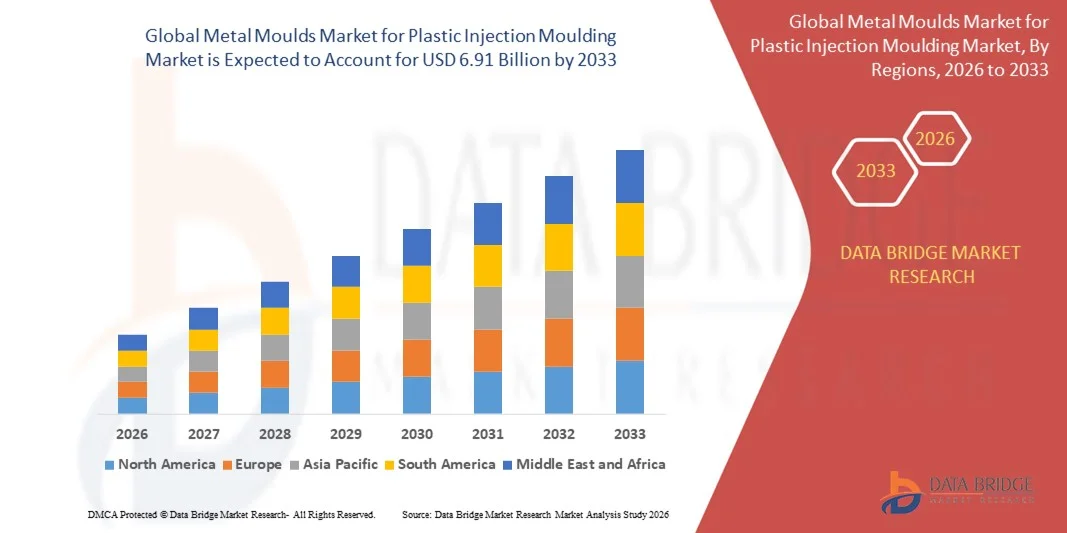

- The global metal moulds market for plastic injection moulding size was valued at USD 5.37 billion in 2025 and is expected to reach USD 6.91 billion by 2033, at a CAGR of 3.20% during the forecast period

- Major factors that are expected to boost the growth of the metal moulds market for plastic injection Moulding in the forecast period are the several benefits related to the injection Moulding precisely for automotive applications involve repeatability, scale and cost and fast prototype with rapid tooling

What are the Major Takeaways of Metal Moulds Market for Plastic Injection Moulding?

- The rise in the need for small packaging is further anticipated to propel the growth of the metal moulds market for plastic injection Moulding. Moreover, the increase in the need for aseptic packaging in the food industry is further estimated to cushion the growth of the metal moulds market for plastic injection Moulding

- Instable raw material expenses is further projected to impede the growth of the metal moulds market for plastic injection Moulding in the timeline period

- In addition, the substantial development of the dairy industry will further provide potential opportunities for the growth of the metal moulds market for plastic injection Moulding in the coming years

- Asia-Pacific dominated the Metal Moulds Market for Plastic Injection Moulding with a 43.8% revenue share in 2025, driven by rapid industrialization, high-volume electronics and automotive manufacturing, and strong investments in R&D activities across China, Japan, India, South Korea, and Southeast Asia

- North America is projected to register the fastest CAGR of 7.9% from 2026 to 2033, supported by rising adoption of automated manufacturing, advanced tooling solutions, and digital process monitoring across the U.S. and Canada

- The Steel segment dominated the market with a 44.3% share in 2025, owing to its superior durability, heat resistance, and ability to maintain dimensional stability during high-volume production

Report Scope and Metal Moulds Market for Plastic Injection Moulding Segmentation

|

Attributes |

Portable Logic Analyzer Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Metal Moulds Market for Plastic Injection Moulding?

Rising Adoption of High-Precision, Multi-Cavity, and Automated Metal Moulds

- The metal moulds market for plastic injection moulding is witnessing strong adoption of high-precision, multi-cavity, and automated moulds designed to support complex part geometries, high-volume production, and advanced polymer materials

- Manufacturers are introducing CNC-machined, modular, and temperature-controlled moulds with enhanced durability, rapid changeover features, and compatibility with Industry 4.0-enabled injection systems

- Growing demand for cost-efficient, high-speed, and energy-saving moulds is driving usage across automotive, electronics, consumer goods, and medical device manufacturing facilities

- For instance, companies such as ENGEL, Husky Injection Molding Systems, Arburg, and Milacron have upgraded their mould solutions with multi-cavity layouts, precision cooling channels, and automated ejection mechanisms, boosting throughput and product quality

- Increasing need for rapid prototyping, lightweight component production, and flexible manufacturing is accelerating adoption of automated and PC-integrated moulding systems

- As plastics and polymer parts become more complex and high-performance, metal moulds remain vital for high-volume production, repeatability, and precision in injection molding

What are the Key Drivers of Metal Moulds Market for Plastic Injection Moulding?

- Rising demand for high-quality, durable, and multi-cavity metal moulds to support automotive, electronics, medical, and consumer product manufacturing

- For instance, in 2025, leading companies such as Husky, Arburg, and Milacron enhanced their mould portfolios with modular designs, rapid cooling channels, and automated ejection systems for faster production cycles

- Growing adoption of electric and hybrid vehicles, advanced consumer electronics, and medical devices is boosting demand for precision injection moulds across North America, Europe, and Asia-Pacific

- Advancements in CNC machining, additive tooling, and temperature-control systems have strengthened accuracy, efficiency, and energy performance of moulds

- Increasing use of high-performance polymers, multi-material parts, and lightweight composites is creating demand for customized and multi-cavity mould solutions

- Supported by steady investments in plastics manufacturing, automotive production, and medical device innovation, the Metal Moulds Market for Plastic Injection Moulding is expected to witness strong long-term growth

Which Factor is Challenging the Growth of the Metal Moulds Market for Plastic Injection Moulding?

- High costs associated with precision, multi-cavity, and automated moulds restrict adoption among small manufacturers and startups

- For instance, during 2024–2025, fluctuations in steel and alloy prices, CNC tooling costs, and long lead times increased manufacturing expenses for global vendors

- Complexity in designing high-precision moulds, cooling systems, and automated ejection mechanisms increases the need for skilled engineers and training

- Limited awareness in emerging markets regarding advanced moulding technologies, multi-cavity benefits, and automation integration slows adoption

- Competition from low-cost mould alternatives, 3D-printed tooling, and hybrid polymer solutions creates pricing pressure and reduces product differentiation

- To address these issues, companies are focusing on cost-optimized designs, rapid tooling, modular systems, and Industry 4.0 integration to increase global adoption of high-precision metal moulds

How is the Metal Moulds Market for Plastic Injection Moulding Segmented?

The market is segmented on the basis of material, manufacturing process, and application.

- By Material

On the basis of material, the metal moulds market for plastic injection moulding is segmented into Steel, Aluminum, and Others. The Steel segment dominated the market with a 44.3% share in 2025, owing to its superior durability, heat resistance, and ability to maintain dimensional stability during high-volume production. Steel moulds are widely preferred for automotive components, electronics housings, and consumer goods that require precise tolerances and long service life. Their robustness allows for repeated cycles without deformation, making them ideal for industrial and high-performance applications.

The Aluminum segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by increasing demand for lightweight moulds in prototyping, short-run production, and rapid tooling applications. Aluminum’s excellent thermal conductivity and machinability support faster cycle times, making it essential for R&D labs, small-scale manufacturers, and sectors focusing on product innovation and cost efficiency.

- By Manufacturing Process

On the basis of manufacturing process, the market is segmented into Standard or CNC Machining and Electric Discharge Machining (EDM). The Standard/CNC Machining segment dominated the market with a 51.2% share in 2025, supported by widespread use across automotive, consumer goods, and electronics sectors. CNC machining enables high-precision shaping, complex geometries, and repeatable accuracy, which is critical for injection moulding of plastic parts requiring tight tolerances. EDM, while slower and costlier, allows intricate cavities, micro-features, and hard metal shaping, making it crucial for specialized components.

The EDM segment is projected to grow at the fastest CAGR from 2026 to 2033, fueled by rising adoption in aerospace, medical devices, and high-precision industrial tooling. Increasing demand for complex, multi-cavity, and micro-structured moulds drives the need for EDM-based solutions in high-performance, technologically advanced applications.

- By Application

On the basis of application, the market is segmented into Packaging, Automotive, Medical, Electronics, Construction, and Others. The Automotive segment dominated the market with a 38.6% share in 2025, driven by adoption of EV electronics, battery housings, ADAS components, and interior/exterior plastic parts requiring high-volume, precise injection moulding. Increasing use of multi-material components and stringent safety regulations also amplify the demand for durable, high-precision metal moulds in automotive production.

The Medical segment is expected to grow at the fastest CAGR from 2026 to 2033, supported by rising demand for disposable medical devices, surgical components, and diagnostic equipment. High-quality metal moulds with tight tolerances and sterilization-resistant materials are crucial for producing safe, reliable, and FDA-compliant medical plastic parts. Innovation in healthcare and personalized medical solutions further fuels adoption in this segment globally.

Which Region Holds the Largest Share of the Metal Moulds Market for Plastic Injection Moulding?

- Asia-Pacific dominated the Metal Moulds Market for Plastic Injection Moulding with a 43.8% revenue share in 2025, driven by rapid industrialization, high-volume electronics and automotive manufacturing, and strong investments in R&D activities across China, Japan, India, South Korea, and Southeast Asia. Widespread adoption of advanced production technologies, embedded systems, and precision manufacturing continues to fuel demand for high-quality metal moulds in automotive, electronics, packaging, and medical sectors

- Leading companies in Asia-Pacific are focusing on advanced CNC machining, EDM, and lightweight alloy moulds to improve efficiency, reduce production cycles, and enhance precision. Government-backed manufacturing incentives, innovation hubs, and industrial modernization programs strengthen the region’s long-term market leadership

- Skilled workforce availability, cost-effective production, and strong local supply chains further reinforce Asia-Pacific’s dominance

China Metal Moulds Market for Plastic Injection Moulding Insight

China is the largest contributor to the region, supported by world-leading automotive and electronics manufacturing capacities, massive industrial investments, and strong government policies promoting smart factories and precision tooling. Rising adoption of EV components, electronic housings, and packaging moulds drives demand for steel and aluminum moulds with high durability and thermal efficiency. Competitive local manufacturing capabilities and export-focused production further strengthen domestic and international market adoption.

Japan Metal Moulds Market for Plastic Injection Moulding Insight

Japan shows steady growth, driven by advanced industrial automation, precision engineering, and modernization of automotive, electronics, and medical device manufacturing. High focus on quality, tight tolerances, and long-life moulds supports adoption of premium steel and CNC-machined moulds. Increasing need for low-defect, high-volume production in automotive and medical applications reinforces market expansion.

India Metal Moulds Market for Plastic Injection Moulding Insight

India is emerging as a major growth hub due to expanding automotive, electronics, and packaging manufacturing, rising startup activity, and government-backed Make-in-India initiatives. Increasing adoption of CNC and EDM technologies for rapid prototyping and small-to-medium batch production is accelerating demand for durable and cost-efficient metal moulds across automotive, electronics, and medical sectors.

South Korea Metal Moulds Market for Plastic Injection Moulding Insight

South Korea contributes significantly with high demand for automotive electronics, consumer electronics, and industrial components. Rapid industrial automation, technological innovation, and growing export-oriented manufacturing drive adoption of high-precision CNC and EDM moulds. Increasing investments in EV components and smart devices further support market expansion.

North America Metal Moulds Market for Plastic Injection Moulding Insight

North America is projected to register the fastest CAGR of 7.9% from 2026 to 2033, supported by rising adoption of automated manufacturing, advanced tooling solutions, and digital process monitoring across the U.S. and Canada. Increasing demand for lightweight, high-performance moulds in automotive, medical, and electronics sectors, coupled with growing R&D investments and smart manufacturing initiatives, drives rapid market growth in the region.

U.S. Metal Moulds Market for Plastic Injection Moulding Insight

The U.S. is the largest contributor in North America, driven by strong automotive, electronics, and medical device production. Advanced CNC machining, rapid prototyping, and high-precision tooling adoption intensify demand for steel and aluminum moulds. Presence of major tooling companies, high-end automotive OEMs, and industrial innovation hubs further strengthens market growth.

Canada Metal Moulds Market for Plastic Injection Moulding Insight

Canada contributes to regional growth due to increasing production in automotive parts, packaging, and industrial machinery. Government initiatives supporting advanced manufacturing, skilled workforce availability, and rising use of CNC and EDM moulding techniques enhance adoption across small and medium-scale enterprises.

Which are the Top Companies in Metal Moulds Market for Plastic Injection Moulding?

The metal moulds market for plastic injection moulding is primarily led by well-established companies, including:

- ENGEL AUSTRIA GmbH (Austria)

- BERICAP (Germany)

- Jade Moulds (Jade Group International) (U.S.)

- MSI Mold Builders (U.S.)

- Enko AS (Norway)

- ERMO – Zone artisanale Marcillé La Ville (France)

- Bunty LLC (U.S.)

- The Rodon Group (U.S.)

- Colonial Machine Co. (U.S.)

- JBJ Technologies Limited (India)

- Michiana Global Mold (U.S.)

- Wayken and WEIKE (China)

- CS Tool Engineering (U.S.)

- GENSINI SRL (Italy)

- Tromosa (Spain)

- Forum Plastics LLC (U.S.)

- Accede Mold & Tool Co., Inc. (U.S.)

- Intertech, Inc. (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Metal Moulds Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Metal Moulds Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Metal Moulds Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.