Global Microfibrillated Cellulose Market

Market Size in USD Billion

CAGR :

%

USD

13.92 Billion

USD

59.89 Billion

2025

2033

USD

13.92 Billion

USD

59.89 Billion

2025

2033

| 2026 –2033 | |

| USD 13.92 Billion | |

| USD 59.89 Billion | |

|

|

|

|

Microfibrillated Cellulose Market Size

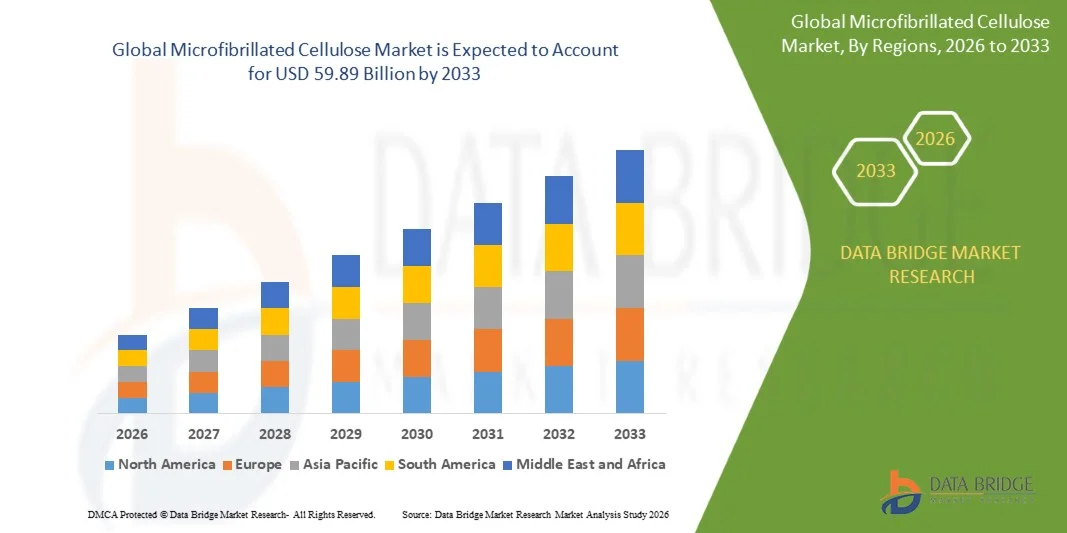

- The global microfibrillated cellulose market size was valued at USD 13.92 billion in 2025 and is expected to reach USD 59.89 billion by 2033, at a CAGR of 20.00% during the forecast period

- The market growth is largely fuelled by the rising demand for sustainable and biodegradable materials across packaging, paper, and personal care industries

- Increasing adoption of microfibrillated cellulose in lightweight composites, coatings, and barrier applications is further accelerating market expansion

Microfibrillated Cellulose Market Analysis

- The market is witnessing significant growth due to growing environmental concerns, stringent regulations promoting bio-based materials, and advancements in nanocellulose production technologies

- Expanding applications in sectors such as automotive, construction, pharmaceuticals, and food & beverages are strengthening the commercial viability and large-scale adoption of microfibrillated cellulose

- North America dominated the microfibrillated cellulose market with the largest revenue share in 2025, driven by strong demand for sustainable materials across packaging, pulp and paper, and specialty applications, along with supportive environmental regulations promoting bio-based alternatives

- Asia-Pacific region is expected to witness the highest growth rate in the global microfibrillated cellulose market, driven by rapid industrialization, rising demand for biodegradable packaging, expanding pulp and paper production capacity, and supportive government initiatives promoting green materials

- The Mechanical Method segment held the largest market revenue share in 2025 driven by its widespread industrial adoption, scalability, and ability to produce high-strength fibrils suitable for reinforcement applications. Mechanical processing is widely utilized in pulp and paper and packaging industries due to its compatibility with existing infrastructure and consistent output quality

Report Scope and Microfibrillated Cellulose Market Segmentation

|

Attributes |

Microfibrillated Cellulose Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Microfibrillated Cellulose Market Trends

“Growing Demand for Sustainable and High-Performance Bio-Based Materials”

• The increasing emphasis on sustainability and circular economy principles is significantly shaping the microfibrillated cellulose market, as industries seek renewable and biodegradable alternatives to conventional synthetic materials. Microfibrillated cellulose is gaining prominence due to its exceptional strength, lightweight nature, and barrier properties, making it suitable for applications across packaging, paper, coatings, and composites. This trend is encouraging manufacturers to integrate bio-based reinforcement materials into product development strategies

• Rising environmental regulations and corporate sustainability commitments are accelerating the adoption of microfibrillated cellulose in packaging and industrial applications. Companies are focusing on reducing plastic usage and carbon footprints, which has led to greater incorporation of cellulose-based materials in films, molded products, and specialty papers. The material’s compatibility with existing manufacturing processes further supports its commercial scalability

• Advancements in nanocellulose production technologies and processing efficiency are improving product performance and cost competitiveness. Enhanced fibrillation techniques and surface modification processes are enabling broader usage in sectors such as automotive, construction, personal care, and pharmaceuticals. These technological improvements are strengthening the material’s functional versatility and expanding its industrial relevance

• For instance, in 2024, Stora Enso in Finland and Sappi in South Africa expanded their bio-based material portfolios by increasing production capacity for microfibrillated cellulose used in sustainable packaging and lightweight composites. These developments were aligned with global sustainability targets and growing demand from consumer goods manufacturers seeking eco-friendly material solution

• While demand for microfibrillated cellulose is expanding, sustained market growth depends on continued technological innovation, cost optimization, and scaling up commercial production. Manufacturers are prioritizing supply chain stability, performance consistency, and collaborative research initiatives to ensure long-term competitiveness against conventional materials

Microfibrillated Cellulose Market Dynamics

Driver

“Rising Adoption of Sustainable and Lightweight Reinforcement Materials”

• Growing global focus on reducing environmental impact is a major driver for the microfibrillated cellulose market. Industries are increasingly adopting bio-based and recyclable materials to comply with regulatory frameworks and corporate sustainability goals. Microfibrillated cellulose offers high strength-to-weight ratio and biodegradability, supporting its integration into packaging, automotive components, and construction materials

• Expanding applications in paper enhancement, barrier coatings, personal care formulations, and advanced composites are contributing to market growth. The material improves mechanical properties, viscosity control, and product durability without compromising environmental standards. This versatility enables manufacturers to meet evolving consumer and industrial requirements

• Companies are investing in research partnerships and pilot-scale production facilities to enhance performance characteristics and broaden application scope. Collaboration between pulp producers, chemical companies, and end-use industries is facilitating faster commercialization and innovation in cellulose-based technologies

• For instance, in 2023, UPM in Finland and Borregaard in Norway reported increased investments in nanocellulose development for packaging and specialty applications. These initiatives were aimed at supporting sustainable product innovation and meeting rising demand for renewable material solutions in European and North American markets

• Although sustainability trends strongly support adoption, large-scale penetration depends on reducing production costs, improving process efficiency, and ensuring consistent quality standards. Strategic investments in advanced processing technologies and integrated supply chains will be essential for maintaining growth momentum

Restraint/Challenge

“High Production Costs and Limited Commercial Scalability”

• The relatively high cost of producing microfibrillated cellulose compared to conventional synthetic materials remains a significant challenge. Energy-intensive fibrillation processes and specialized equipment requirements contribute to elevated manufacturing expenses. These factors can limit adoption among cost-sensitive industries

• Limited awareness and technical understanding in certain developing regions restrict broader market penetration. Some manufacturers remain hesitant due to concerns about compatibility with existing production systems and uncertainty regarding long-term performance outcomes. This slows adoption across emerging markets

• Supply chain constraints and raw material sourcing challenges can also impact scalability. Although cellulose is widely available, maintaining consistent quality and processing efficiency requires advanced infrastructure and skilled technical expertise. Logistical and operational complexities may increase overall production costs

• For instance, in 2024, specialty material distributors in Southeast Asia reported slower commercialization of microfibrillated cellulose-based packaging solutions due to higher upfront investment costs and limited technical knowledge among small and medium-sized manufacturers. Infrastructure gaps and limited pilot-scale facilities were cited as additional barriers

• Addressing these challenges will require process optimization, investment in energy-efficient technologies, and expanded industry education initiatives. Strengthening global production capacity, enhancing technical collaboration, and developing cost-effective formulations will be crucial for unlocking the full potential of the global microfibrillated cellulose market

Microfibrillated Cellulose Market Scope

The market is segmented on the basis of product type, application, and end user.

• By Product Type

On the basis of product type, the microfibrillated cellulose market is segmented into Mechanical Method, Chemical Method, and Biological Method. The Mechanical Method segment held the largest market revenue share in 2025 driven by its widespread industrial adoption, scalability, and ability to produce high-strength fibrils suitable for reinforcement applications. Mechanical processing is widely utilized in pulp and paper and packaging industries due to its compatibility with existing infrastructure and consistent output quality.

The Chemical Method segment is expected to witness the fastest growth rate from 2026 to 2033, driven by its ability to enhance fibrillation efficiency, reduce energy consumption, and improve functional properties such as dispersion and surface modification. Chemical pre-treatment processes enable the production of customized microfibrillated cellulose grades tailored for high-performance applications such as barrier coatings and advanced composites.

• By Application

On the basis of application, the microfibrillated cellulose market is segmented into Performance Enhancer and Barrier Films. The Performance Enhancer segment held the largest market revenue share in 2025 driven by its extensive use in improving mechanical strength, viscosity control, and durability across paper, paints and coatings, and personal care formulations. Its reinforcing capability and lightweight characteristics support broad industrial integration.

The Barrier Films segment is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing demand for sustainable packaging solutions and improved oxygen and grease barrier properties. Microfibrillated cellulose-based films are gaining traction as eco-friendly alternatives to conventional plastic-based materials, particularly in food and consumer goods packaging.

• By End User

On the basis of end user, the microfibrillated cellulose market is segmented into Pulp and Paper, Packaging, Food, Paints and Coatings, Personal Care, and Others. The Pulp and Paper segment held the largest market revenue share in 2025 driven by the material’s ability to enhance paper strength, reduce raw material consumption, and improve printability and surface properties. Its integration into paper manufacturing processes supports cost efficiency and product performance.

The Packaging segment is expected to witness the fastest growth rate from 2026 to 2033, driven by rising regulatory pressure to reduce plastic usage and increasing consumer preference for biodegradable and recyclable materials. Growing demand for sustainable and high-performance packaging solutions is accelerating the adoption of microfibrillated cellulose across global markets.

Microfibrillated Cellulose Market Regional Analysis

• North America dominated the microfibrillated cellulose market with the largest revenue share in 2025, driven by strong demand for sustainable materials across packaging, pulp and paper, and specialty applications, along with supportive environmental regulations promoting bio-based alternatives

• Industries in the region highly value the material’s lightweight strength, biodegradability, and compatibility with existing manufacturing processes, making it an attractive solution for replacing conventional synthetic additives and reinforcements

• This widespread adoption is further supported by advanced research infrastructure, significant investments in nanocellulose production, and increasing corporate commitments toward carbon reduction, establishing microfibrillated cellulose as a preferred material in industrial and consumer applications

U.S. Microfibrillated Cellulose Market Insight

The U.S. microfibrillated cellulose market captured the largest revenue share in 2025 within North America, fueled by strong innovation in sustainable packaging and advanced material development. Manufacturers are increasingly integrating cellulose-based reinforcements into paper, coatings, and composite products to enhance performance and sustainability. The presence of leading pulp producers, research institutions, and government-backed sustainability initiatives further accelerates commercialization. Moreover, rising investments in circular economy practices and renewable material technologies significantly contribute to market expansion.

Europe Microfibrillated Cellulose Market Insight

The Europe microfibrillated cellulose market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by stringent environmental regulations and ambitious carbon neutrality targets. The region’s strong focus on reducing plastic waste and promoting biodegradable materials is fostering widespread adoption across packaging and industrial applications. European manufacturers are actively investing in bio-refinery infrastructure and advanced processing technologies, supporting sustainable material innovation across multiple sectors.

U.K. Microfibrillated Cellulose Market Insight

The U.K. microfibrillated cellulose market is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing demand for sustainable packaging and eco-friendly construction materials. Growing environmental awareness among consumers and businesses is encouraging the transition toward renewable raw materials. The country’s expanding research ecosystem and supportive policy framework for green technologies are further stimulating market development.

Germany Microfibrillated Cellulose Market Insight

The Germany microfibrillated cellulose market is expected to witness the fastest growth rate from 2026 to 2033, fueled by strong industrial capabilities and emphasis on sustainable engineering solutions. Germany’s advanced manufacturing sector is integrating cellulose-based materials into automotive components, coatings, and specialty papers. The country’s commitment to innovation, efficiency, and environmental responsibility supports the adoption of high-performance bio-based materials in both industrial and commercial applications.

Asia-Pacific Microfibrillated Cellulose Market Insight

The Asia-Pacific microfibrillated cellulose market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid industrialization, expanding packaging demand, and increasing investments in sustainable materials across countries such as China, Japan, and India. Government initiatives promoting green manufacturing and reduced plastic consumption are accelerating regional adoption. In addition, the region’s strong pulp and paper production base supports scalable manufacturing of cellulose-based materials.

Japan Microfibrillated Cellulose Market Insight

The Japan microfibrillated cellulose market is expected to witness the fastest growth rate from 2026 to 2033 due to the country’s technological expertise and focus on advanced material innovation. Japanese companies are actively developing high-performance nanocellulose solutions for electronics, automotive, and specialty packaging applications. Integration of microfibrillated cellulose into lightweight composites and functional coatings is gaining traction, supported by strong research collaboration and sustainability initiatives.

China Microfibrillated Cellulose Market Insight

The China microfibrillated cellulose market accounted for the largest market revenue share in Asia Pacific in 2025, attributed to the country’s expanding packaging industry, strong manufacturing base, and increasing emphasis on biodegradable materials. China is investing heavily in sustainable production technologies and bio-based material development to address environmental concerns and reduce plastic dependency. The availability of abundant raw materials and large-scale industrial capacity further strengthens the country’s position in the regional market.

Microfibrillated Cellulose Market Share

The Microfibrillated Cellulose industry is primarily led by well-established companies, including:

- Borregaard AS (Norway)

- Daicel Corporation (Japan)

- Stora Enso (Finland)

- Sappi (South Africa)

- Norske Skog ASA (Norway)

- FiberLean (U.K.)

- CelluComp (U.K.)

- Weidmann Fiber Technology (Switzerland)

- NIPPON PAPER INDUSTRIES CO., LTD. (Japan)

- J. RETTENMAIER & SÖHNE GmbH + Co KG (Germany)

- LENZING AG (Austria)

- Aditya Birla Management Corporation Pvt. Ltd. (India)

- Valmet (Finland)

- ShengXing (China)

- MINGTAI CHEMICAL CO., LTD. (China)

Latest Developments in Microfibrillated Cellulose Market

- In September 2024, Stora Enso Oyj (Finland) established a new production facility dedicated to microfibrillated cellulose to increase manufacturing capacity and meet rising global demand. The facility incorporates advanced, energy-efficient technologies to reduce environmental impact and improve operational efficiency. This expansion reinforces the company’s commitment to sustainability and strengthens its supply capabilities in the growing nanocellulose market

- In August 2024, CelluComp Ltd. (U.K.) entered into a strategic partnership with a leading packaging manufacturer to integrate microfibrillated cellulose into sustainable packaging solutions. This collaboration aims to expand the company’s market presence while enhancing the environmental performance of packaging products. The initiative supports growing global demand for eco-friendly materials and strengthens CelluComp’s competitive positioning in the bio-based materials market

- In July 2024, Nippon Paper Industries Co., Ltd. (Japan) launched a new range of biodegradable microfibrillated cellulose products designed for food packaging applications. The development enhances the company’s product portfolio and supports the shift toward sustainable and compostable packaging materials. This launch positions the company as a key innovator in environmentally responsible packaging solutions and contributes to broader market adoption of bio-based alternatives

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Microfibrillated Cellulose Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Microfibrillated Cellulose Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Microfibrillated Cellulose Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.