Global Phenol Market

Market Size in USD Billion

CAGR :

%

USD

25.61 Billion

USD

34.25 Billion

2024

2032

USD

25.61 Billion

USD

34.25 Billion

2024

2032

| 2025 –2032 | |

| USD 25.61 Billion | |

| USD 34.25 Billion | |

|

|

|

|

Phenol Market Size

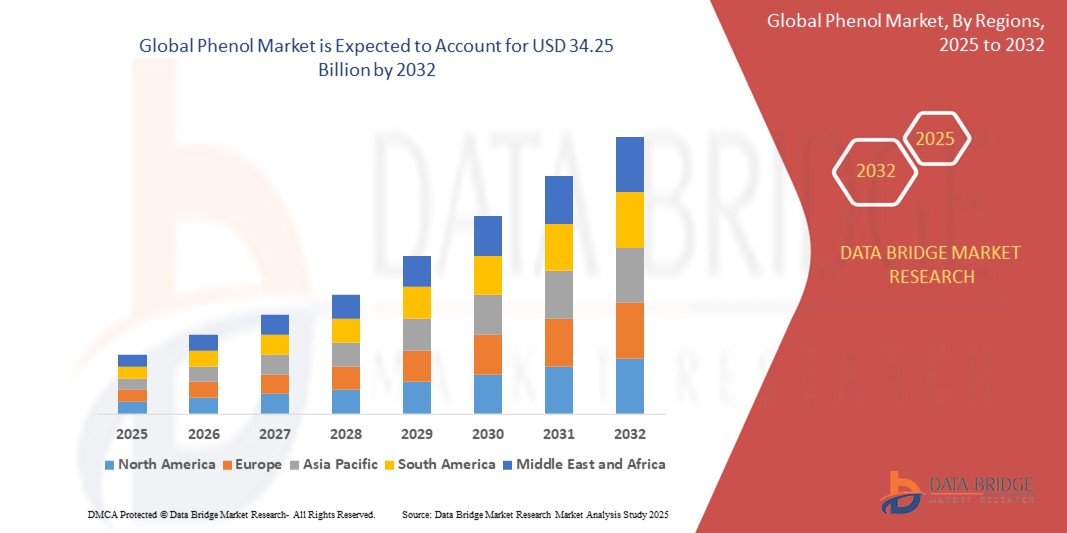

- The global phenol market size was valued at USD 25.61 billion in 2024 and is expected to reach USD 34.25 billion by 2032, at a CAGR of 3.70% during the forecast period

- The market growth is largely fuelled by the increasing demand for bisphenol-A, phenolic resins, and caprolactam across automotive, construction, and electronics sectors, alongside rising applications in pharmaceuticals and cosmetics

- Surging use of phenol-based derivatives in laminates, adhesives, and insulation materials is also contributing to the expanding footprint of phenol in building and construction industries globally

Phenol Market Analysis

- The global phenol market is undergoing a steady transformation, driven by increased consumption in high-growth end-use industries and the shift toward more sustainable manufacturing processes

- Key players are investing in production capacity expansions and technological innovations to meet rising global demand and comply with tightening environmental regulations

- Asia-Pacific dominated the phenol market with the largest revenue share in 2024, primarily driven by high production capacities and strong demand from the construction, automotive, and electronics sectors

- North America region is expected to witness the highest growth rate in the global phenol market, driven by rising demand for polycarbonates and epoxy resins across industries such as automotive, construction, and consumer electronics

- The bisphenol-A segment held the largest market revenue share of 44.6% in 2024, driven by its widespread usage in manufacturing polycarbonates and epoxy resins. The growing demand from sectors such as automotive, construction, and electronics continues to strengthen the need for bisphenol-A, which directly propels phenol consumption. This segment is further supported by the high thermal and chemical stability offered by BPA-derived products, especially in demanding industrial applications

Report Scope and Phenol Market Segmentation

|

Attributes |

Phenol Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

• Expansion of Bio-Based Phenol Production Technologies • Rising Demand from Emerging Economies in Asia-Pacific |

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Phenol Market Trends

“Shift Toward Sustainable and Bio-Based Phenol Alternatives”

- Manufacturers are increasingly investing in the development of bio-phenol from renewable sources such as lignin and corn stover to reduce dependence on petroleum-based inputs

- Rising environmental awareness among consumers and corporations is driving demand for greener alternatives in plastics, coatings, and resins

- Governments and regulatory bodies are introducing incentives and funding for bio-based chemical production to promote circular economy goals

- For instance, the European Union’s Green Deal supports the development of renewable raw materials, encouraging companies to adopt biobased phenol substitutes

- Companies such as Anellotech are pioneering biomass-to-aromatic technologies, signaling a market shift toward low-emission phenol manufacturing

Phenol Market Dynamics

Driver

“Rising Demand for Bisphenol-A (BPA) in Polycarbonate and Epoxy Resin Manufacturing”

- Bisphenol-A (BPA), derived from phenol, is used extensively in producing polycarbonate plastics for electronics, automotive, and consumer goods

- Rapid industrialization in Asia-Pacific is significantly increasing BPA consumption, thereby boosting phenol demand across multiple end-user industries

- Epoxy resins, another BPA application, are in high demand for protective coatings, adhesives, and structural composites in construction and aerospace

- For instance, the expanding electric vehicle (EV) sector is driving demand for lightweight, durable polycarbonates, intensifying phenol usage

- BPA’s versatility and high-performance properties continue to make it indispensable in modern industrial applications, supporting phenol market growth

Restraint/Challenge

“Environmental and Health Concerns Regarding Phenol Handling and Disposal”

- Phenol is classified as toxic and hazardous, with potential health impacts such as respiratory irritation, skin burns, and organ damage if not properly managed

- Environmental contamination due to accidental spills or improper disposal can lead to ecosystem degradation and water source pollution

- Regulatory frameworks such as the U.S. Toxic Substances Control Act (TSCA) require strict phenol monitoring and safety measures, increasing production costs

- For instance, manufacturers in Europe must comply with REACH guidelines that impose heavy restrictions on phenol usage and emissions

- These environmental and safety challenges pose entry barriers for small manufacturers and can hinder growth in highly regulated regions

Phenol Market Scope

The market is segmented on the basis of product type, manufacturing process, classification, application, and end-users.

• By Product Type

On the basis of product type, the phenol market is segmented into phenolic resins, caprolactum, bisphenol-A, and others. The bisphenol-A segment held the largest market revenue share of 44.6% in 2024, driven by its widespread usage in manufacturing polycarbonates and epoxy resins. The growing demand from sectors such as automotive, construction, and electronics continues to strengthen the need for bisphenol-A, which directly propels phenol consumption. This segment is further supported by the high thermal and chemical stability offered by BPA-derived products, especially in demanding industrial applications.

The caprolactum segment is expected to witness the fastest growth rate from 2025 to 2032, owing to its extensive usage in the production of nylon-6 fibers and resins. The rising demand for lightweight, durable materials in textiles and engineering plastics, particularly in emerging markets, is contributing to this robust growth.

• By Manufacturing Process

On the basis of manufacturing process, the phenol market is segmented into the cumene process, Dow process, and Ranching–Hooker process. The cumene process dominated the market in 2024 due to its cost-effectiveness and ability to produce high-purity phenol and acetone simultaneously. This process is preferred by large-scale manufacturers for its operational efficiency and compatibility with modern production plants.

The Dow process is expected to witness the fastest growth rate from 2025 to 2032, as companies explore alternative techniques to improve sustainability and reduce dependence on fossil-based feedstocks.

• By Classification

On the basis of classification, the market is segmented into monohydric, dihydric, and trihydric. The monohydric segment led the market in 2024, accounting for a major share owing to its dominant application in the production of phenol and its derivatives. Its versatility in producing downstream chemicals used in plastics, pharmaceuticals, and flame retardants supports its leadership position.

The trihydric segment is expected to witness the fastest growth rate from 2025 to 2032, due to its application in specialty polymers and chemical formulations, particularly in advanced resin manufacturing.

• By Application

On the basis of application, the phenol market is segmented into epoxy resins, polycarbonates, nylon, bakelite, detergents, phenolic resins, pharmaceutical drugs, and herbicides. The phenolic resins segment emerged as the largest in 2024, attributed to growing use in laminates, insulation, automotive, and construction materials. These resins offer strong thermal resistance and mechanical strength, which are crucial in industrial settings.

The epoxy resins segment is expected to witness the fastest growth rate from 2025 to 2032, supported by rising demand in electronics, coatings, and adhesives, particularly in Asia-Pacific and North America.

• By End-Users

On the basis of end-users, the market is segmented into bisphenol A, phenolic resins, caprolactam, and others. The bisphenol A segment dominated the market in 2024 and is expected to maintain its lead, driven by its role in multiple high-growth industries such as electronics, automotive, and packaging.

The caprolactam segment is expected to witness the fastest growth rate from 2025 to 2032, as the textile and engineering plastic industries increasingly turn to nylon-based materials for performance and sustainability benefits.

Phenol Market Regional Analysis

- Asia-Pacific dominated the phenol market with the largest revenue share in 2024, primarily driven by high production capacities and strong demand from the construction, automotive, and electronics sectors

- The region benefits from low-cost raw materials, favorable government regulations, and a rapidly expanding middle-class population, which fuels demand for polycarbonates and phenolic resins

- In addition, ongoing investments in industrial infrastructure and a robust export network support the region’s market expansion, making it a strategic hub for phenol manufacturing and downstream applications

China Phenol Market Insight

The China phenol market accounted for the largest revenue share in the Asia-Pacific region in 2024, driven by its well-established manufacturing sector and strong domestic demand across automotive, electronics, and construction industries. The availability of low-cost raw materials, favorable trade policies, and government-backed industrialization initiatives support the country’s phenol production and consumption. Furthermore, the growing demand for epoxy resins and polycarbonates in electronic devices and consumer products continues to strengthen market dynamics in China.

Japan Phenol Market Insight

The Japan phenol market is expected to witness the fastest growth rate from 2025 to 2032, supported by its advanced manufacturing capabilities and consistent demand from the electronics and automotive sectors. Japan is a key consumer of high-grade phenol derivatives used in polycarbonates, which are essential in compact electronic components and lightweight vehicle parts. The country’s emphasis on precision engineering, quality materials, and innovation in sustainable polymers drives steady phenol demand. Moreover, local companies continue to invest in eco-friendly resin technologies and bio-based phenol alternatives to align with national carbon neutrality targets.

North America Phenol Market Insight

The North America phenol market is expected to witness the fastest growth rate from 2025 to 2032, fueled by rising demand from the automotive and electronics sectors, particularly for applications such as polycarbonates, bisphenol A, and epoxy resins. The region benefits from well-developed infrastructure, strong R&D investments, and regulatory support for sustainable chemical manufacturing. In addition, the growing adoption of phenol-based composites in electric vehicles and wind energy components contributes to long-term market sustainability.

U.S. Phenol Market Insight

The U.S. phenol market captured the largest share in North America in 2024, supported by a mature manufacturing base and advanced processing technologies. High consumption in end-use industries such as construction, electronics, and pharmaceuticals fuels consistent demand. Moreover, the presence of leading chemical manufacturers and rising investment in bio-based alternatives and high-performance polymers are expected to enhance the market’s competitiveness.

Europe Phenol Market Insight

The Europe phenol market is expected to witness the fastest growth rate from 2025 to 2032, underpinned by environmental regulations, technological innovation, and increasing demand for lightweight materials in automotive and aerospace applications. The region’s focus on green chemistry and recycling initiatives is encouraging the use of sustainable phenol derivatives. Moreover, the growth of the construction and packaging industries across Germany, France, and the U.K. is further supporting phenol consumption in resins and plastics manufacturing.

Germany Phenol Market Insight

The Germany phenol market is expected to witness the fastest growth rate from 2025 to 2032, driven by a robust chemicals industry, innovation in specialty resins, and strong demand from automotive manufacturers. Germany’s emphasis on sustainable production and its leadership in engineering polymers and high-performance materials position it as a key phenol consumer. In addition, partnerships between research institutions and major producers are advancing eco-efficient phenol applications in coatings and electronics.

U.K. Phenol Market Insight

The U.K. phenol market is expected to witness the fastest growth rate from 2025 to 2032, led by increasing demand from the pharmaceutical, construction, and packaging industries. The country imports a significant share of phenol and its derivatives for use in resins, coatings, and drug manufacturing. Growing investments in green building materials and sustainable packaging also support phenol consumption in value-added applications. In addition, the U.K.'s focus on circular economy initiatives and low-carbon innovation is fostering interest in recyclable and bio-based phenolic compounds, enhancing long-term market prospects.

Phenol Market Share

The Phenol industry is primarily led by well-established companies, including:

- KUMHO P&B CHEMICALS., INC (South Korea)

- TPCC (China)

- Shell plc (U.K.)

- Mitsui Chemicals, Inc. (Japan)

- LG Chem (South Korea)

- Honeywell International Inc. (U.S.)

- Solvay (Belgium)

- Aditya Birla Group (India)

- SHENGQUAN GROUP (China)

- PTT Phenol Company Limited. (Thailand)

- Bayer AG (Germany)

- AdvanSix (U.S.)

- Cepsa (Spain)

- INEOS (U.K.)

- Domo Investment Group NV. (Belgium)

- Altivia (U.S.)

- Formosa Plastics Corporation (Taiwan)

- Prasol Chemicals Pvt. Ltd. (India)

- Sasol LTD (South Africa)

- China National Bluestar (Group) Co, Ltd. (China)

- Merck KGaA (Germany)

Latest Developments in Global Phenol Market

- In January 2023, Formosa Chemicals & Fibre Corporation and Mitsubishi Chemical Corporation disclosed a collaboration to advance and market novel composite materials derived from phenol. This partnership aims to create materials that surpass current phenol-based options in terms of strength, weight, and durabililty

- In August 2022, INEOS Phenol revealed the purchase of Mitsui Phenols Singapore Ltd's asset base from Mitsui Chemicals for a total of USD 330 million. This acquisition includes the Jurong phenol and BPA assets, offering integration prospects with existing manufacturing facilities in Germany, Belgium, and the U.S. The acquisition is set to augment the total production capacity by 1 million tonnes

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL PHENOL MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL PHENOL MARKET SIZE

2.3 VENDOR POSITIONING GRID

2.4 MARKETS COVERED

2.5 GEOGRAPHIC SCOPE

2.6 YEARS CONSIDERED FOR THE STUDY

2.7 RESEARCH METHODOLOGY

2.8 TECHNOLOGY LIFE LINE CURVE

2.9 MULTIVARIATE MODELLING

2.1 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.11 DBMR MARKET POSITION GRID

2.12 MARKET APPLICATION COVERAGE GRID

2.13 DBMR MARKET CHALLENGE MATRIX

2.14 IMPORT AND EXPORT DATA

2.15 SECONDARY SOURCES

2.16 GLOBAL PHENOL MARKET : RESEARCH SNAPSHOT

2.17 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 RAW MATERIAL COVERAGE

5.2 PRODUCTION CONSUMPTION ANALYSIS

5.3 IMPORT EXPORT SCENARIO

5.4 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

5.5 PORTER’S FIVE FORCES

5.6 VENDOR SELECTION CRITERIA

5.7 PESTEL ANALYSIS

5.8 REGULATION COVERAGE

5.8.1 PRODUCT CODES

5.8.2 CERTIFIED STANDARDS

5.8.3 SAFETY STANDARDS

5.8.3.1. MATERIAL HANDLING & STORAGE

5.8.3.2. TRANSPORT & PRECAUTIONS

5.8.3.3. HARAD IDENTIFICATION

6 PRICE INDEX

7 PRODUCTION CAPACITY OVERVIEW

8 SUPPLY CHAIN ANALYSIS

8.1 OVERVIEW

8.2 LOGISTIC COST SCENARIO

8.3 IMPORTANCE OF LOGISTICS SERVICE PROVIDERS

9 CLIMATE CHANGE SCENARIO

9.1 ENVIRONMENTAL CONCERNS

9.1.1 ANALYSIS ON HAZARDOUS SUBSTANCES

9.1.2 ANALYSIS ON RECYCLING

9.1.3 ANALYSIS ON ENVIRONMENTAL TECHNOLOGY

9.1.4 ANALYSIS ON ENVIRONMENTAL POLICY

9.2 INDUSTRY RESPONSE

9.3 GOVERNMENT’S ROLE

9.4 ANALYST RECOMMENDATIONS

10 GLOBAL PHENOL MARKET, BY INTERMEDIATE , 2018-2032, (USD MILLION) (KILO TONS)

10.1 OVERVIEW

10.2 PHENOLIC RESINS

10.2.1 BEKLITE

10.2.2 OTHERS

10.3 BISPHENOL A

10.3.1 POLYCARBONATE

10.3.2 EPOXY RESIN

10.4 CYCLOHEXANONE

10.4.1 CAPROLACTAM

10.5 CYCLOHEXANOL

10.5.1 ADIPIC ACID

10.6 ALKYL PHENOL

10.7 ANILINES

10.8 OTHERS

11 GLOBAL PHENOL MARKET, BY CLASSIFICATION, 2018-2032, USD MILLION

11.1 OVERVIEW

11.2 MONOHYDRIC

11.3 DIHYDRIC

11.4 TRIHYDRIC

12 GLOBAL PHENOL MARKET, BY MANUFACTURING PROCESS, 2018-2032, USD MILLION

12.1 OVERVIEW

12.2 CUMENE PROCESS

12.3 DOW PROCESS

12.4 RANCHING–HOOKER PROCESS

12.5 OTHERS

13 GLOBAL PHENOL MARKET, BY APPLICATION, 2018-2032, USD MILLION

13.1 OVERVIEW

13.2 PLASTICS

13.3 ADHESIVES

13.4 LAMINATES

13.5 COATINGS

13.6 CHEMICALS & INTERMEDIATES

13.7 OTHERS

14 GLOBAL PHENOL MARKET, BY END USE, 2018-2032, USD MILLION

14.1 OVERVIEW

14.2 AUTOMOTIVE

14.2.1 AUTOMOTIVE, BY INTERMEDIATE

14.2.1.1. PHENOLIC RESINS

14.2.1.2. BISPHENOL A

14.2.1.3. CYCLOHEXANONE

14.2.1.4. CYCLOHEXANOL

14.2.1.5. ALKYL PHENOL

14.2.1.6. ANILINES

14.2.1.7. OTHERS

14.3 CONSTRUCTION

14.3.1 CONSTRUCTION, BY INTERMEDIATE

14.3.1.1. PHENOLIC RESINS

14.3.1.2. BISPHENOL A

14.3.1.3. CYCLOHEXANONE

14.3.1.4. CYCLOHEXANOL

14.3.1.5. ALKYL PHENOL

14.3.1.6. ANILINES

14.3.1.7. OTHERS

14.4 ELECTRONICS

14.4.1 ELECTRONICS, BY INTERMEDIATE

14.4.1.1. PHENOLIC RESINS

14.4.1.2. BISPHENOL A

14.4.1.3. CYCLOHEXANONE

14.4.1.4. CYCLOHEXANOL

14.4.1.5. ALKYL PHENOL

14.4.1.6. ANILINES

14.4.1.7. OTHERS

14.5 CHEMICALS

14.5.1 CHEMICALS, BY INTERMEDIATE

14.5.1.1. PHENOLIC RESINS

14.5.1.2. BISPHENOL A

14.5.1.3. CYCLOHEXANONE

14.5.1.4. CYCLOHEXANOL

14.5.1.5. ALKYL PHENOL

14.5.1.6. ANILINES

14.5.1.7. OTHERS

14.6 HEALTHCARE

14.6.1 HEALTHCARE, BY INTERMEDIATE

14.6.1.1. PHENOLIC RESINS

14.6.1.2. BISPHENOL A

14.6.1.3. CYCLOHEXANONE

14.6.1.4. CYCLOHEXANOL

14.6.1.5. ALKYL PHENOL

14.6.1.6. ANILINES

14.6.1.7. OTHERS

14.7 OTHERS

14.7.1 OTHERS, BY INTERMEDIATE

14.7.1.1. PHENOLIC RESINS

14.7.1.2. BISPHENOL A

14.7.1.3. CYCLOHEXANONE

14.7.1.4. CYCLOHEXANOL

14.7.1.5. ALKYL PHENOL

14.7.1.6. ANILINES

14.7.1.7. OTHERS

15 GLOBAL PHENOL MARKET , BY GEOGRAPHY, 2018-2032, (USD MILLION) (KILO TONS)

15.1 GLOBAL PHENOL MARKET , (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

15.2 NORTH AMERICA

15.2.1 U.S.

15.2.2 CANADA

15.2.3 MEXICO

15.3 EUROPE

15.3.1 GERMANY

15.3.2 U.K.

15.3.3 ITALY

15.3.4 FRANCE

15.3.5 SPAIN

15.3.6 SWITZERLAND

15.3.7 RUSSIA

15.3.8 TURKEY

15.3.9 BELGIUM

15.3.10 NETHERLANDS

15.3.11 REST OF EUROPE

15.4 ASIA-PACIFIC

15.4.1 JAPAN

15.4.2 CHINA

15.4.3 SOUTH KOREA

15.4.4 INDIA

15.4.5 AUSTRALIA AND NEW ZEALAND

15.4.6 SINGAPORE

15.4.7 THAILAND

15.4.8 INDONESIA

15.4.9 MALAYSIA

15.4.10 PHILIPPINES

15.4.11 REST OF ASIA-PACIFIC

15.5 SOUTH AMERICA

15.5.1 BRAZIL

15.5.2 ARGENTINA

15.5.3 REST OF SOUTH AMERICA

15.6 MIDDLE EAST AND AFRICA

15.6.1 SOUTH AFRICA

15.6.2 EGYPT

15.6.3 SAUDI ARABIA

15.6.4 UNITED ARAB EMIRATES

15.6.5 ISRAEL

15.6.6 REST OF MIDDLE EAST AND AMERICA

16 GLOBAL PHENOL MARKET , COMPANY LANDSCAPE

16.1 COMPANY SHARE ANALYSIS: GLOBAL

16.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

16.3 COMPANY SHARE ANALYSIS: EUROPE

16.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

16.5 MERGERS & ACQUISITIONS

16.6 NEW PRODUCT DEVELOPMENT & APPROVALS

16.7 EXPANSIONS

16.8 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

17 SWOT ANALYSIS AND DATA BRIDGE MARKET RESEARCH ANALYSIS

18 GLOBAL PHENOL MARKET - COMPANY PROFILES

18.1 KUMHO P&B CHEMICALS.,INC,

18.1.1 COMPANY SNAPSHOT

18.1.2 REVENUE ANALYSIS

18.1.3 PRODUCT PORTFOLIO

18.1.4 RECENT DEVELOPMENTS

18.2 ROYAL DUTCH SHELL

18.2.1 COMPANY SNAPSHOT

18.2.2 REVENUE ANALYSIS

18.2.3 PRODUCT PORTFOLIO

18.2.4 RECENT DEVELOPMENTS

18.3 MITSUI CHEMICALS, INC.

18.3.1 COMPANY SNAPSHOT

18.3.2 REVENUE ANALYSIS

18.3.3 PRODUCT PORTFOLIO

18.3.4 RECENT DEVELOPMENTS

18.4 LG CHEM

18.4.1 COMPANY SNAPSHOT

18.4.2 REVENUE ANALYSIS

18.4.3 PRODUCT PORTFOLIO

18.4.4 RECENT DEVELOPMENTS

18.5 HONEYWELL INTERNATIONAL INC

18.5.1 COMPANY SNAPSHOT

18.5.2 REVENUE ANALYSIS

18.5.3 PRODUCT PORTFOLIO

18.5.4 RECENT DEVELOPMENTS

18.6 SOLVAY

18.6.1 COMPANY SNAPSHOT

18.6.2 REVENUE ANALYSIS

18.6.3 PRODUCT PORTFOLIO

18.6.4 RECENT DEVELOPMENTS

18.7 MITSUBISHI CORPORATION

18.7.1 COMPANY SNAPSHOT

18.7.2 REVENUE ANALYSIS

18.7.3 PRODUCT PORTFOLIO

18.7.4 RECENT DEVELOPMENTS

18.8 ADITYA BIRLA CHEMICALS

18.8.1 COMPANY SNAPSHOT

18.8.2 REVENUE ANALYSIS

18.8.3 PRODUCT PORTFOLIO

18.8.4 RECENT DEVELOPMENTS

18.9 SHENGQUAN GROUP

18.9.1 COMPANY SNAPSHOT

18.9.2 REVENUE ANALYSIS

18.9.3 PRODUCT PORTFOLIO

18.9.4 RECENT DEVELOPMENTS

18.1 PTT PHENOL COMPANY LIMITED

18.10.1 COMPANY SNAPSHOT

18.10.2 REVENUE ANALYSIS

18.10.3 PRODUCT PORTFOLIO

18.10.4 RECENT DEVELOPMENTS

18.11 ADVANSIX

18.11.1 COMPANY SNAPSHOT

18.11.2 REVENUE ANALYSIS

18.11.3 PRODUCT PORTFOLIO

18.11.4 RECENT DEVELOPMENTS

18.12 PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

18.12.1 COMPANY SNAPSHOT

18.12.2 REVENUE ANALYSIS

18.12.3 PRODUCT PORTFOLIO

18.12.4 RECENT DEVELOPMENTS

18.13 CEPSA

18.13.1 COMPANY SNAPSHOT

18.13.2 REVENUE ANALYSIS

18.13.3 PRODUCT PORTFOLIO

18.13.4 RECENT DEVELOPMENTS

18.14 INEOS

18.14.1 COMPANY SNAPSHOT

18.14.2 REVENUE ANALYSIS

18.14.3 PRODUCT PORTFOLIO

18.14.4 RECENT DEVELOPMENTS

18.15 DOMO CHEMICALS

18.15.1 COMPANY SNAPSHOT

18.15.2 REVENUE ANALYSIS

18.15.3 PRODUCT PORTFOLIO

18.15.4 RECENT DEVELOPMENTS

18.16 ALTIVIA

18.16.1 COMPANY SNAPSHOT

18.16.2 REVENUE ANALYSIS

18.16.3 PRODUCT PORTFOLIO

18.16.4 RECENT DEVELOPMENTS

18.17 PRASOL CHEMICALS PVT. LTD.

18.17.1 COMPANY SNAPSHOT

18.17.2 REVENUE ANALYSIS

18.17.3 PRODUCT PORTFOLIO

18.17.4 RECENT DEVELOPMENTS

18.18 CHINA NATIONAL BLUESTAR

18.18.1 COMPANY SNAPSHOT

18.18.2 REVENUE ANALYSIS

18.18.3 PRODUCT PORTFOLIO

18.18.4 RECENT DEVELOPMENTS

18.19 MERCK KGAA

18.19.1 COMPANY SNAPSHOT

18.19.2 REVENUE ANALYSIS

18.19.3 PRODUCT PORTFOLIO

18.19.4 RECENT DEVELOPMENTS

18.2 BOREALIS

18.20.1 COMPANY SNAPSHOT

18.20.2 REVENUE ANALYSIS

18.20.3 PRODUCT PORTFOLIO

18.20.4 RECENT DEVELOPMENTS

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

19 QUESTIONNAIRE

20 RELATED REPORTS

21 ABOUT DATA BRIDGE MARKET RESEARCH

Global Phenol Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Phenol Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Phenol Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.