Global Polymer Foams Market

Market Size in USD Million

CAGR :

%

USD

511.50 Million

USD

673.56 Million

2025

2033

USD

511.50 Million

USD

673.56 Million

2025

2033

| 2026 –2033 | |

| USD 511.50 Million | |

| USD 673.56 Million | |

|

|

|

|

Polymer Foams Market Size

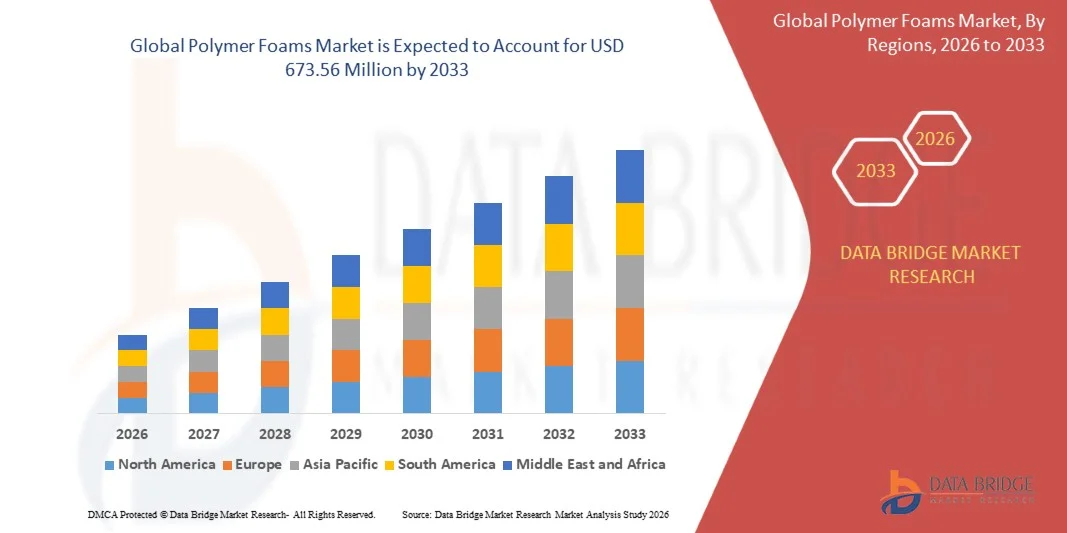

- The global polymer foams market size was valued at USD 511.50 million in 2025 and is expected to reach USD 673.56 million by 2033, at a CAGR of 3.50% during the forecast period

- The market growth is largely fuelled by the increasing demand for lightweight, durable, and energy-efficient materials across automotive, construction, packaging, and electronics industries

- Rising adoption of polymer foams in insulation, cushioning, and protective applications is further driving growth

Polymer Foams Market Analysis

- The market is witnessing significant innovation in bio-based and eco-friendly polymer foams, driven by regulatory pressure and sustainability trends

- Growing applications in automotive lightweighting, thermal insulation, and protective packaging are influencing market demand

- North America dominated the polymer foams market with the largest revenue share in 2025, driven by growing demand for lightweight, durable, and energy-efficient materials across automotive, construction, packaging, and electronics industries

- Asia-Pacific region is expected to witness the highest growth rate in the global polymer foams market, driven by rising industrialization, expanding construction activities, and increasing demand for cost-effective and energy-efficient foam materials

- The Polyurethane (PU) Foam segment held the largest market revenue share in 2025, driven by its widespread use in furniture, automotive, and construction applications due to excellent cushioning, insulation, and durability properties. PU foams are preferred for their versatility, lightweight nature, and ability to provide comfort and structural support across various industries

Report Scope and Polymer Foams Market Segmentation

|

Attributes |

Polymer Foams Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Polymer Foams Market Trends

“Rising Demand for Lightweight and Energy-Efficient Materials”

- The growing focus on lightweight, durable, and energy-efficient materials is significantly shaping the polymer foams market, as industries increasingly prefer materials that reduce weight without compromising structural integrity. Polymer foams are gaining traction due to their ability to provide thermal insulation, cushioning, and impact resistance, strengthening adoption across automotive, construction, packaging, and electronics industries

- Increasing awareness around sustainability and cost-efficiency has accelerated the demand for polymer foams in insulation, packaging, and protective applications. Manufacturers are prioritizing eco-friendly formulations and recyclable materials, prompting innovations in foam design that improve functional performance while reducing environmental impact

- Lightweighting and energy-efficiency trends are influencing purchasing decisions, with companies emphasizing material performance, durability, and compliance with industry standards. These factors help brands differentiate products, build client trust, and drive adoption of high-performance polymer foam solutions

- For instance, in 2024, BASF in Germany and Huntsman Corporation in the U.S. expanded their polymer foam portfolios by introducing high-performance, lightweight, and recyclable foam solutions for automotive and construction applications. These launches were in response to rising demand for sustainable and high-performance materials, with distribution across industrial, commercial, and retail sectors

- While demand for polymer foams is growing, sustained market expansion depends on continuous R&D, cost-effective production, and maintaining performance standards. Manufacturers are also focusing on improving scalability, supply chain reliability, and developing innovative solutions that balance cost, quality, and sustainability for broader adoption

Polymer Foams Market Dynamics

Driver

“Growing Preference for Lightweight and Energy-Efficient Materials”

- Rising adoption of lightweight, high-performance materials is a major driver for the polymer foams market. Industries such as automotive, construction, and electronics are increasingly using foams to reduce weight, improve energy efficiency, and enhance product durability

- Expanding applications in insulation, packaging, cushioning, and protective solutions are influencing market growth. Polymer foams help improve thermal performance, impact resistance, and sound absorption, enabling manufacturers to meet consumer and regulatory requirements

- Manufacturers are actively promoting high-performance and sustainable polymer foam solutions through product innovation, eco-certifications, and marketing initiatives. These efforts are supported by growing demand for energy-efficient and environmentally responsible materials

- For instance, in 2023, Covestro in Germany and Sekisui Chemical in Japan reported increased production of lightweight and recyclable foam products for automotive and construction applications. This expansion followed higher demand for energy-efficient and sustainable solutions, strengthening client relationships and market differentiation

- Although rising lightweighting and sustainability trends support growth, wider adoption depends on cost optimization, raw material availability, and scalable production processes. Investment in process efficiency, eco-friendly materials, and advanced formulation technology will be critical for meeting global demand and maintaining competitive advantage

Restraint/Challenge

“High Production Costs and Raw Material Volatility”

- The relatively higher production costs of advanced polymer foams compared to conventional materials remain a key challenge, limiting adoption among price-sensitive manufacturers. Complex processing methods and fluctuating raw material prices contribute to elevated costs

- Uneven awareness of performance and sustainability benefits in emerging markets further restricts adoption. Limited understanding of foam applications in insulation, packaging, and protective solutions can slow market penetration

- Supply chain and logistics challenges also impact growth, as polymer foams require specialized storage, handling, and transportation to maintain material properties. Variations in raw material quality and availability can disrupt production schedules and increase operational expenses

- For instance, in 2024, distributors in Southeast Asia and Latin America supplying automotive and construction manufacturers reported slower uptake due to higher prices and limited awareness of foam performance advantages. Logistical complexities and quality compliance issues were additional barriers

- Overcoming these challenges will require cost-efficient production, expanded supply networks, and focused educational initiatives for manufacturers and end-users. Collaboration with distributors, industrial clients, and certification bodies can help unlock the long-term growth potential of the global polymer foams market. Developing cost-competitive, high-performance, and eco-friendly formulations will be essential for widespread adoption

Polymer Foams Market Scope

The market is segmented on the basis of type and application

• By Type

On the basis of type, the polymer foams market is segmented into Polyurethane (PU) Foam, Polyethylene (PE) Foam, Polypropylene (PP) Foam, Ethylene-Vinyl Acetate (EVA), and Others. The Polyurethane (PU) Foam segment held the largest market revenue share in 2025, driven by its widespread use in furniture, automotive, and construction applications due to excellent cushioning, insulation, and durability properties. PU foams are preferred for their versatility, lightweight nature, and ability to provide comfort and structural support across various industries.

The Polyethylene (PE) Foam segment is expected to witness the fastest growth rate from 2026 to 2033, driven by its high impact resistance, thermal insulation, and packaging capabilities. PE foams are increasingly adopted in protective packaging, sports equipment, and industrial applications, supporting their rapid market expansion

• By Application

On the basis of application, the market is segmented into Furniture and Bedding, Transportation, Packaging, Construction, and Others. The Furniture and Bedding segment held the largest market share in 2025, fueled by rising demand for comfortable, durable, and lightweight cushioning solutions in residential and commercial settings.

The Packaging segment is expected to witness the fastest growth from 2026 to 2033, driven by the increasing need for protective, lightweight, and shock-absorbing materials across e-commerce, logistics, and industrial sectors

Polymer Foams Market Regional Analysis

- North America dominated the polymer foams market with the largest revenue share in 2025, driven by growing demand for lightweight, durable, and energy-efficient materials across automotive, construction, packaging, and electronics industries

- Consumers and manufacturers in the region highly value foams for their cushioning, insulation, impact resistance, and thermal efficiency, which are essential for high-performance applications

- This widespread adoption is further supported by advanced manufacturing infrastructure, high industrial output, and increasing focus on sustainability, establishing polymer foams as a preferred solution for multiple sectors

U.S. Polymer Foams Market Insight

The U.S. polymer foams market captured the largest revenue share in 2025 within North America, fueled by rising investments in automotive lightweighting, building insulation, and protective packaging solutions. Manufacturers are increasingly adopting high-performance foams that offer thermal insulation, energy efficiency, and durability. The push for sustainable and recyclable foam materials, combined with advanced production technologies, is significantly contributing to market growth.

Europe Polymer Foams Market Insight

The Europe polymer foams market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by stringent environmental regulations and increasing demand for eco-friendly and recyclable materials. Urbanization and growth in automotive, construction, and packaging industries are fostering foam adoption. European manufacturers are also focusing on innovative and lightweight solutions to meet performance and sustainability requirements.

U.K. Polymer Foams Market Insight

The U.K. polymer foams market is expected to witness the fastest growth rate from 2026 to 2033, driven by the adoption of lightweight and energy-efficient materials in construction, transportation, and consumer goods. In addition, government regulations promoting sustainable building materials and the increasing focus on reducing carbon footprints are encouraging the use of advanced polymer foams.

Germany Polymer Foams Market Insight

The Germany polymer foams market is expected to witness the fastest growth rate from 2026 to 2033, fueled by high awareness of sustainable materials and the demand for advanced, eco-conscious solutions. Germany’s emphasis on innovation, lightweighting in automotive, and energy-efficient building materials promotes adoption, with polymer foams increasingly integrated into industrial and commercial applications.

Asia-Pacific Polymer Foams Market Insight

The Asia-Pacific polymer foams market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid urbanization, rising disposable incomes, and industrial expansion in countries such as China, Japan, and India. Increasing infrastructure projects, automotive production, and packaging needs, combined with government initiatives for sustainable materials, are driving foam adoption across the region.

Japan Polymer Foams Market Insight

The Japan polymer foams market is expected to witness the fastest growth rate from 2026 to 2033 due to high technological adoption, urbanization, and demand for energy-efficient, lightweight materials. Polymer foams are increasingly used in automotive, electronics, and construction applications. Japan’s aging population is also likely to spur demand for comfort-focused applications such as furniture, bedding, and healthcare products.

China Polymer Foams Market Insight

The China polymer foams market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to rapid industrialization, urbanization, and growth in automotive, construction, and packaging sectors. China is one of the largest markets for polymer foams, with increasing adoption in residential, commercial, and industrial applications. Government support for lightweighting, energy efficiency, and sustainable materials, alongside competitive domestic manufacturing, is a key factor propelling the market.

Polymer Foams Market Share

The Polymer Foams industry is primarily led by well-established companies, including:

- BASF SE (Germany)

- Dow (U.S.)

- Recticel (Belgium)

- Sealed Air (U.S.)

- HUNTSMAN INTERNATIONAL LLC (U.S.)

- Armacell (Germany)

- JSP Corporation (Japan)

- Covestro AG (Germany)

- Kingspan Group (Ireland)

- Woodbridge Foam Corporation (Canada)

- FoamPartner Group (Switzerland)

- Evonik Industries AG (Germany)

- PolyOne Corporation (U.S.)

- Sekisui Chemical Co., Ltd. (Japan)

- Recticel Insulation (Belgium)

- US Foam Corporation (U.S.)

Latest Developments in Global Polymer Foams Market

- In September 2024, Armacell, capacity expansion, announced an investment to expand ArmaGel XG production at its Pune (India) facility. The new plant will add 1 million square meters per annum, enhancing the company’s aerogel insulation capacity. This expansion addresses rising global demand for energy-efficient insulation and strengthens Armacell’s position as a key supplier in the aerogel market

- In June 2024, Armacell, acquisition, acquired E&M Industries’ engineering business to incorporate insulation jacketing into its portfolio. This acquisition helps transition Armacell from a material supplier to a comprehensive industrial solutions provider and expands its presence in Australia, boosting regional market reach and service capabilities

- In May 2024, Zotefoams, strategic partnership, signed a Global Alliance Agreement with Suzhou Shincell New Materials Co., Ltd. The collaboration enables technology sharing, joint product development, and co-marketing of products. By integrating Shincell’s expertise, Zotefoams can broaden its product portfolio, access new markets, and accelerate innovation in polymer foam solutions

- In February 2024, Saint-Gobain, acquisition, completed the purchase of CSR Limited for USD 2.96 billion. This move strengthens its footprint in the Australian construction market and the broader Asia-Pacific region. CSR’s sustainable building products portfolio allows Saint-Gobain to offer integrated insulation and construction solutions, enhancing its competitive advantage

- In December 2023, BASF, product launch, introduced Irgastab PUR 71, an advanced antioxidant for polyols and polyurethane foams. Free from aromatic amines, it improves regulatory compliance and performance while supporting sustainability goals. This innovation enables foam manufacturers to meet stricter environmental and safety standards and enhances market adoption of eco-friendly solutions

- In September 2023, Covestro, collaboration, partnered with the Selena Group of Poland to develop sustainable polyurethane foams for building insulation. The ISSC Plus-certified material contains plant-based feedstocks, reducing carbon footprint by 60% compared to fossil-derived alternatives. This initiative promotes eco-friendly construction and positions both companies as leaders in sustainable insulation

- In September 2023, Aeroflex USA, product launch, introduced AEROFLEX Breathe-EZ, a fiber-free EPDM closed-cell duct insulation for North America. Designed for energy conservation, condensation control, and acoustic attenuation, it meets International Mechanical Code standards for flame and smoke. The product strengthens Aeroflex’s offerings in sustainable, high-performance building insulation and enhances its market competitiveness

- In July 2022, Armacell, acquisition, acquired AD IZOLIR, a Serbian pre-insulated pipe manufacturer. The deal includes production facilities in Zrenjanin and Alibunar, establishing a business presence in Serbia. This acquisition expands Armacell’s European operations and product offerings in industrial insulation solutions

- In November 2022, Huntsman, product launch, released Acoustiflex VEF BIO, a viscoelastic foam for automotive acoustic applications. Made from up to 20% bio-based content, it reduces the carbon footprint of carpet back-foaming by up to 25%. The innovation supports sustainability in the automotive sector while enhancing performance and market differentiation

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Polymer Foams Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Polymer Foams Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Polymer Foams Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.