Global Portable Bioprocessing Bioreactors Market

Market Size in USD Billion

CAGR :

%

USD

3.13 Billion

USD

6.38 Billion

2025

2033

USD

3.13 Billion

USD

6.38 Billion

2025

2033

| 2026 –2033 | |

| USD 3.13 Billion | |

| USD 6.38 Billion | |

|

|

|

|

Global Portable Bioprocessing Bioreactors Market Segmentation, By Capacity (1-10L, 10-50L, 50-100L, and 100-500L), Material (Glass, Stainless Steel and Single-Use), Control Type (Automated and Manual), Suppliers (Original Equipment Manufacturers, System Integrators and Engineering Procurement and Construction), End User (Biopharmaceuticals Industry, Academic Institute, and Research Laboratories) - Industry Trends and Forecast to 2033

Portable Bioprocessing Bioreactors Market Size

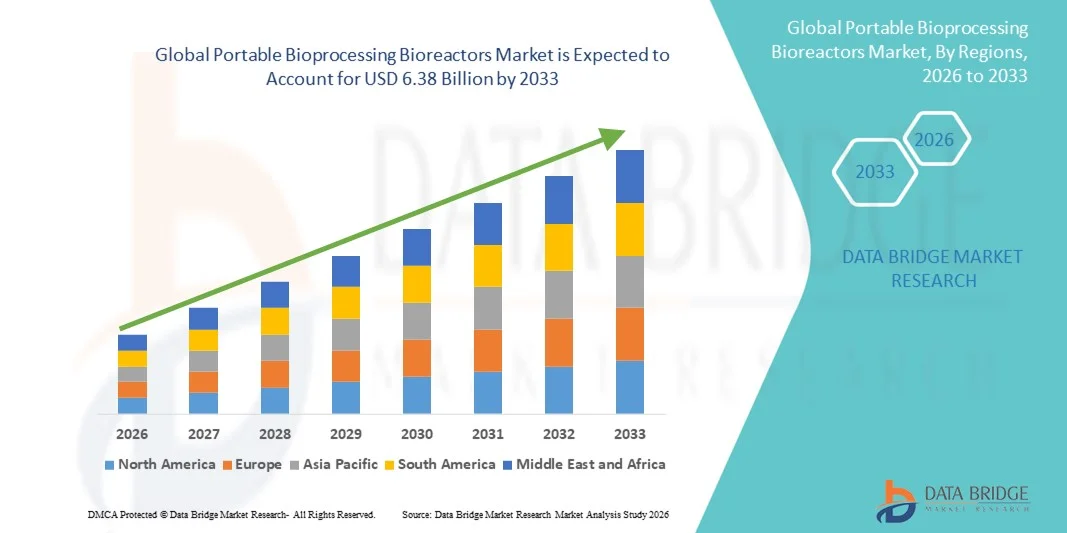

- The global portable bioprocessing bioreactors market size was valued at USD 3.13 billion in 2025 and is expected to reach USD 6.38 billion by 2033, at a CAGR of9.33% during the forecast period

- The market growth is largely fueled by the increasing demand for flexible, scalable, and cost-efficient biomanufacturing solutions, supported by technological advancements in single-use systems, automation, and process monitoring that enable rapid deployment across research and production settings

- Furthermore, rising adoption of portable and modular bioreactors in biopharmaceutical production, cell and gene therapy development, vaccine manufacturing, and academic research, along with the need for faster process optimization and reduced capital expenditure, is accelerating the uptake of Portable Bioprocessing Bioreactors solutions, thereby significantly boosting the overall growth of the Portable Bioprocessing Bioreactors Market

Portable Bioprocessing Bioreactors Market Analysis

- Portable bioprocessing bioreactors, designed to support flexible, scalable, and rapid biomanufacturing, are increasingly important across biopharmaceutical production, cell & gene therapy, and vaccine development due to their mobility, reduced footprint, and compatibility with single-use technologies

- The market growth is primarily driven by rising demand for decentralized and modular biomanufacturing, increasing adoption of single-use bioreactors, and technological advancements in automation, sensors, and real-time process monitoring, enabling faster development cycles and lower capital investment

- North America dominated the portable bioprocessing bioreactors market with an estimated revenue share of around 38.4% in 2025, supported by strong biopharmaceutical R&D activity, high adoption of advanced bioprocessing technologies, and the presence of leading industry players in the U.S.

- Asia-Pacific is expected to be the fastest-growing region during the forecast period, driven by expanding biopharmaceutical manufacturing capacity, increasing government support for biotechnology, rising investments in biosimilars and vaccines, and growing adoption of cost-efficient portable bioreactor systems in countries such as China, India, and South Korea

- The automated segment dominated the market with a revenue share of nearly 57.3% in 2025, driven by the need for precise process control, reproducibility, and reduced human intervention

Report Scope and Portable Bioprocessing Bioreactors Market Segmentation

|

Attributes |

Portable Bioprocessing Bioreactors Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• Sartorius AG (Germany) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework. |

Portable Bioprocessing Bioreactors Market Trends

Increasing Adoption of Modular and Flexible Bioprocessing Solutions

- A significant and accelerating trend in the global portable bioprocessing bioreactors market is the growing adoption of modular, flexible, and mobile bioreactor systems designed to support decentralized manufacturing, rapid deployment, and small-batch biopharmaceutical production

- For instance, in 2024, a global biopharmaceutical manufacturer expanded the use of portable single-use bioreactors at satellite production facilities in North America and Europe to support faster clinical trial material production

- Portable bioprocessing bioreactors enable manufacturers to reduce facility footprints while maintaining high process control and scalability across different production sites

- The increasing focus on personalized medicine, cell and gene therapies, and rapid vaccine development is driving demand for compact and adaptable bioprocessing system

- These bioreactors offer advantages such as reduced setup time, ease of transportation, and compatibility with single-use technologies, supporting agile manufacturing strategies

- As a result, biopharmaceutical companies and contract development and manufacturing organizations (CDMOs) worldwide are increasingly integrating portable bioprocessing bioreactors into their production workflows

Portable Bioprocessing Bioreactors Market Dynamics

Driver

Rising Demand for Biologics and Rapid Biopharmaceutical Production

- The increasing global demand for biologics, vaccines, and advanced therapeutics is a key driver fueling the growth of the Portable Bioprocessing Bioreactors market

- For instance, in March 2025, a leading CDMO in Asia-Pacific adopted portable bioreactor systems to accelerate biologics production timelines for emerging biotech clients

- The need for rapid scale-up and scale-down capabilities in biomanufacturing is encouraging the use of portable and flexible bioprocessing solutions

- Growing investments in biopharmaceutical research and development, particularly in emerging economies, further support the adoption of mobile bioreactor technologies

- Portable bioreactors also enable faster technology transfer between research, pilot, and commercial-scale production, reducing overall development timelines

- Collectively, these factors are significantly driving the global adoption of portable bioprocessing bioreactors across the biopharmaceutical value chain

Restraint/Challenge

High Equipment Costs and Process Standardization Challenges

- The relatively high cost of portable bioprocessing bioreactors and associated consumables remains a key restraint, particularly for small-scale manufacturers and academic research institutions

- For instance, in early 2025, several biotech startups in Latin America delayed investments in portable bioreactor platforms due to budget constraints and limited access to financing

- Ensuring process consistency and reproducibility across different portable systems can be technically challenging, especially in multi-site manufacturing environments

- Regulatory compliance and validation requirements for portable bioprocessing systems may increase implementation complexity and time to market

- Limited availability of skilled personnel trained to operate and optimize portable bioreactor systems can further hinder adoption in certain region

- Addressing these challenges through cost optimization, standardized workflows, and expanded training initiatives will be critical for sustained growth in the Portable Bioprocessing Bioreactors market

Portable Bioprocessing Bioreactors Market Scope

The market is segmented on the basis of capacity, material, control type, suppliers, and end user.

- By Capacity

On the basis of capacity, the Portable Bioprocessing Bioreactors market is segmented into 1–10L, 10–50L, 50–100L, and 100–500L. The 10–50L segment dominated the largest market revenue share of approximately 38.6% in 2025, driven by its widespread adoption in pilot-scale bioprocessing, process optimization, and early-stage clinical manufacturing. These bioreactors offer an optimal balance between scalability and portability, making them highly suitable for biopharmaceutical process development. The segment benefits from strong demand in monoclonal antibody and vaccine production workflows. Compatibility with single-use systems and advanced automation further supports adoption. Academic institutes and CROs increasingly prefer this capacity range due to flexibility and reduced contamination risk. The segment also aligns well with decentralized and modular manufacturing trends. Growing investments in biologics R&D globally reinforce demand.

The 1–10L segment is expected to witness the fastest CAGR of 21.4% from 2026 to 2033, driven by rising use in early-stage research, cell line development, and laboratory-scale bioprocess optimization. These compact systems enable rapid experimentation with minimal resource consumption. Increasing adoption in academic and research laboratories supports growth. Demand is further boosted by startups and biotech firms focusing on personalized medicine and cell & gene therapies. Their portability enables use in non-traditional lab environments. Cost-effectiveness and ease of operation enhance appeal. Continuous innovation in sensor integration accelerates adoption.

- By Material

On the basis of material, the Portable Bioprocessing Bioreactors market is segmented into Glass, Stainless Steel, and Single-Use. The single-use segment accounted for the largest market revenue share of around 46.9% in 2025, driven by its advantages in contamination control, reduced cleaning validation, and faster turnaround times. Single-use bioreactors are widely adopted in biopharmaceutical manufacturing due to regulatory compliance and operational efficiency. The growing emphasis on flexible manufacturing platforms strongly supports this segment. Reduced capital expenditure and lower water and energy consumption further boost demand. Adoption is particularly high in biologics and vaccine manufacturing. The segment benefits from strong uptake in both developed and emerging markets. Increasing outsourcing to CMOs also supports dominance.

The glass bioreactors segment is projected to grow at the fastest CAGR of 20.1% from 2026 to 2033, owing to their extensive use in academic research and small-scale laboratory applications. Glass offers superior visibility and chemical inertness, which is critical for experimental accuracy. Rising academic funding and expansion of life science research facilities fuel growth. Demand is also supported by teaching laboratories and early-stage R&D projects. Improvements in durability and modularity enhance usability. Increased research into cell-based therapies further accelerates adoption.

- By Control Type

On the basis of control type, the Portable Bioprocessing Bioreactors market is segmented into Automated and Manual. The automated segment dominated the market with a revenue share of nearly 57.3% in 2025, driven by the need for precise process control, reproducibility, and reduced human intervention. Automated systems enable real-time monitoring of critical parameters such as pH, temperature, and dissolved oxygen. Their use significantly enhances process efficiency and product consistency. Biopharmaceutical manufacturers increasingly rely on automation to meet regulatory standards. Integration with digital bioprocessing platforms strengthens adoption. Automated systems also support scale-up activities efficiently. High adoption in GMP environments underpins dominance.

The manual control segment is expected to register the fastest CAGR of 19.6% from 2026 to 2033, supported by cost-sensitive research labs and small biotech firms. Manual systems are preferred in early-stage experimentation and educational settings. Simplicity and lower upfront costs drive adoption. Increasing research activity in emerging economies contributes to growth. These systems allow greater flexibility during exploratory studies. Demand is also driven by training and pilot studies. Improvements in user-friendly designs enhance market penetration.

- By Suppliers

On the basis of suppliers, the Portable Bioprocessing Bioreactors market is segmented into Original Equipment Manufacturers (OEMs), System Integrators, and Engineering Procurement and Construction (EPC). The OEM segment held the largest market revenue share of approximately 49.8% in 2025, driven by direct sales of standardized and customized bioreactor systems. OEMs benefit from strong brand recognition and technological expertise. Continuous innovation in portable and single-use bioreactors supports dominance. OEMs also offer integrated software and after-sales support. High trust among pharmaceutical manufacturers boosts preference. Strategic collaborations with biopharma companies further strengthen the segment. Global distribution networks enhance reach.

The system integrators segment is anticipated to grow at the fastest CAGR of 22.2% from 2026 to 2033, driven by demand for customized and turnkey bioprocessing solutions. Integration of bioreactors with upstream and downstream systems accelerates growth. Rising complexity of bioprocess workflows supports demand. Growth is strong in modular and flexible manufacturing setups. Increased outsourcing to CMOs favors system integrators. Their ability to deliver end-to-end solutions enhances adoption. Expansion of biomanufacturing facilities globally fuels growth.

- By End User

On the basis of end user, the Portable Bioprocessing Bioreactors market is segmented into Biopharmaceuticals Industry, Academic Institutes, and Research Laboratories. The biopharmaceuticals industry segment dominated the market with a revenue share of about 52.7% in 2025, driven by rising production of biologics, vaccines, and biosimilars. Portable bioreactors enable flexible manufacturing and rapid scale-up. Strong investment in biologics pipelines supports demand. Adoption is high in both clinical and commercial manufacturing. Regulatory emphasis on process consistency further boosts usage. Increasing cell and gene therapy development reinforces growth. Global expansion of biomanufacturing facilities underpins dominance.

The research laboratories segment is expected to witness the fastest CAGR of 21.9% from 2026 to 2033, supported by increased R&D spending in life sciences. Growth in contract research organizations accelerates adoption. Portable systems enable decentralized and flexible research operations. Rising focus on personalized medicine boosts demand. Expansion of biotech startups further supports growth. Government and private research funding drives uptake. Enhanced accessibility of advanced bioprocessing tools accelerates adoption.

Portable Bioprocessing Bioreactors Market Regional Analysis

- North America dominated the portable bioprocessing bioreactors market with an estimated revenue share of around 38.4% in 2025, supported by strong biopharmaceutical R&D activity, high adoption of advanced bioprocessing technologies, and the presence of leading industry players, particularly in the U.S.

- The region benefits from well-established biomanufacturing infrastructure, early adoption of single-use and modular bioprocessing systems, and increasing demand for flexible production platforms in biologics, vaccines, and cell & gene therapy development

- High healthcare expenditure, robust regulatory frameworks, and significant investments in life sciences innovation continue to position North America as a key hub for portable bioprocessing bioreactor adoption across research and commercial-scale applications

U.S. Portable Bioprocessing Bioreactors Market Insight

The U.S. portable bioprocessing bioreactors market captured the largest revenue share within North America in 2025, driven by intensive biopharmaceutical research, rapid expansion of biologics manufacturing, and strong demand for scalable and mobile bioprocessing solutions. The growing focus on continuous manufacturing, personalized medicine, and decentralized production models is accelerating adoption. Additionally, the presence of major bioprocessing equipment manufacturers and contract development and manufacturing organizations (CDMOs) further strengthens market growth in the country.

Europe Portable Bioprocessing Bioreactors Market Insight

The Europe portable bioprocessing bioreactors market is projected to expand at a steady CAGR during the forecast period, supported by increasing investments in biologics, biosimilars, and advanced therapy medicinal products (ATMPs). Stringent regulatory standards, rising adoption of single-use technologies, and growing emphasis on cost-efficient and flexible biomanufacturing are driving demand across the region. Countries such as Germany, the U.K., and France are witnessing increased uptake in both academic research and commercial bioproduction facilities.

U.K. Portable Bioprocessing Bioreactors Market Insight

The U.K. portable bioprocessing bioreactors market is anticipated to grow at a notable CAGR, driven by strong government support for biotechnology innovation, expanding vaccine and cell therapy research, and increased funding for life sciences startups. The country’s focus on rapid scale-up capabilities and flexible manufacturing platforms is boosting the adoption of portable and modular bioreactor systems.

Germany Portable Bioprocessing Bioreactors Market Insight

The Germany portable bioprocessing bioreactors market is expected to expand at a considerable CAGR during the forecast period, supported by the country’s strong biopharmaceutical manufacturing base and emphasis on engineering excellence. Growing investments in biologics production, biosimilars, and process optimization are encouraging the use of advanced portable bioprocessing systems in both industrial and research settings.

Asia-Pacific Portable Bioprocessing Bioreactors Market Insight

The Asia-Pacific portable bioprocessing bioreactors market is expected to grow at the fastest CAGR during the forecast period, driven by expanding biopharmaceutical manufacturing capacity, increasing government support for biotechnology development, and rising investments in vaccines and biosimilars. The growing adoption of cost-efficient and flexible bioprocessing technologies is accelerating demand across emerging economies in the region.

Japan Portable Bioprocessing Bioreactors Market Insight

The Japan portable bioprocessing bioreactors market is gaining momentum due to the country’s strong focus on regenerative medicine, biologics research, and advanced manufacturing technologies. Increasing adoption of compact and mobile bioprocessing solutions to support small-batch and high-value biologics production is contributing to market growth across research institutes and biopharmaceutical companies.

China Portable Bioprocessing Bioreactors Market Insight

The China portable bioprocessing bioreactors market accounted for a significant share of the Asia-Pacific region in 2025, driven by rapid expansion of domestic biopharmaceutical manufacturing, strong government initiatives supporting biotech innovation, and increasing investments in vaccine and biosimilar production. The growing need for scalable, flexible, and cost-effective bioprocessing solutions is accelerating the adoption of portable bioreactor systems across both public and private sector facilities.

Portable Bioprocessing Bioreactors Market Share

The Portable Bioprocessing Bioreactors industry is primarily led by well-established companies, including:

• Sartorius AG (Germany)

• Eppendorf AG (Germany)

• Thermo Fisher Scientific (U.S.)

• GE Healthcare Life Sciences (U.S.)

• Merck KGaA (Germany)

• PBS Biotech Inc. (U.S.)

• Applikon Biotechnology (Netherlands)

• Pall Corporation (U.S.)

• Bioengineering AG (Switzerland)

• Distek, Inc. (U.S.)

• CellCulture Technologies (U.S.)

• Cytiva (U.S.)

• ABEC Inc. (U.S.)

• Infors HT (Switzerland)

• Xcellerex (U.S.)

• Minucell Biotechnologies GmbH (Germany)

• Repligen Corporation (U.S.)

• Lonza Group AG (Switzerland)

• MilliporeSigma (U.S.)

• ILC Dover (U.S.)

Latest Developments in Global Portable Bioprocessing Bioreactors Market

- In April 2025, Thermo Fisher Scientific launched the 5L DynaDrive Single‑Use Bioreactor, a portable bioprocessing system designed for seamless scaling from 1 to 5,000 L while improving productivity by 27 % compared to traditional glass bioreactors. The system’s compact benchtop design incorporates biobased films and BioTitan retention devices to reduce product loss and enhance sustainability, enabling agile process development and simplified scale‑up for biopharmaceutical firms and CROs

- In April 2025, Culture Biosciences unveiled the Stratyx 250 mobile bioreactor at INTERPHEX 2025, featuring integrated cloud connectivity and remote process control, allowing researchers to adjust parameters in real time via software and optimize bioprocess workflows from a distance — a notable step toward digitalized, flexible biomanufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.