Global Welded Spiral Heat Exchangers Market

Market Size in USD Billion

CAGR :

%

USD

1.83 Billion

USD

2.50 Billion

2025

2033

USD

1.83 Billion

USD

2.50 Billion

2025

2033

| 2026 –2033 | |

| USD 1.83 Billion | |

| USD 2.50 Billion | |

|

|

|

|

Global Welded Spiral Heat Exchangers Market Segmentation, By Type (Plate, Tube, and Shell), Application (Petrochemicals, Food & Beverages, Steel Making, Pharmaceutical, Wastewater Treatment, Pulp & Paper, and Others), Flow Type (Counter-Current Flow and Co-Current Flow) - Industry Trends and Forecast to 2033

What is the Global Welded Spiral Heat Exchangers Market Size and Growth Rate?

- The global welded spiral heat exchangers market size was valued at USD 1.83 billion in 2025 and is expected to reach USD 2.50 billion by 2033, at a CAGR of12.30% during the forecast period

- Rise in the stringent environmental regulations acts as a crucial factor accelerating the market growth, also increasing demand for battery thermal management system, rise in the expansion of industrial activities in developing countries, rise in the demand for turbochargers, and rise in the demand of vehicles due to rise in population and increasing disposable income

What are the Major Takeaways of Welded Spiral Heat Exchangers Market?

- Rise in adoption of energy saving equipment due to rise in the cost of energy and rise in demand for automotive components in engineering industrial and commercial applications are the major factors among others boosting the welded spiral heat exchangers market

- Moreover, rise in the battery thermal management system, increasing technological advancements and rising research and development activities will further create new opportunities for welded spiral heat exchangers market

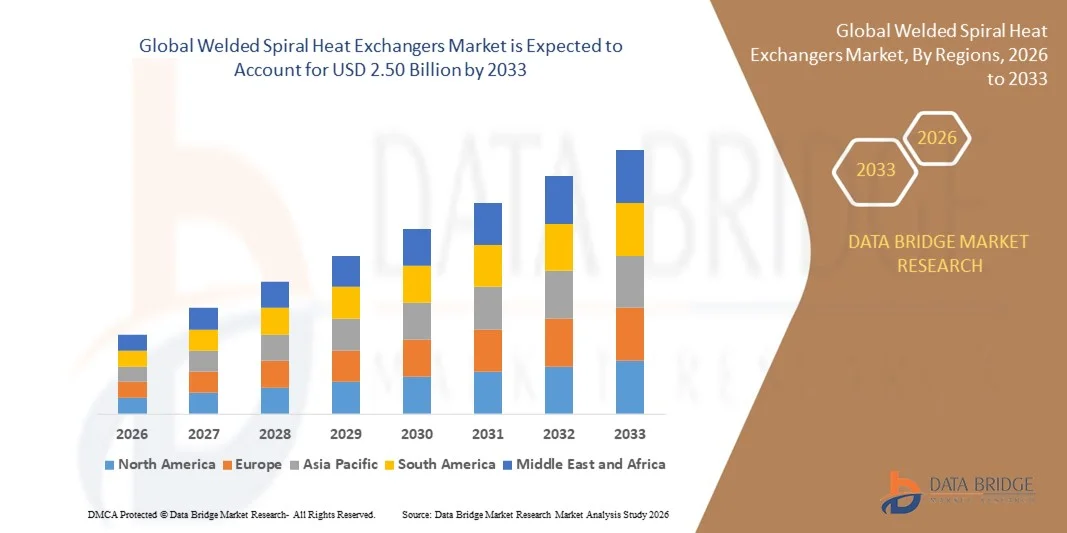

- North America is projected to register the fastest CAGR of 8.25% from 2026 to 2033, driven by modernization of industrial facilities, rising investment in wastewater treatment, shale gas processing, and increasing focus on energy-efficient heat transfer solutions across the U.S. and Canada

- Asia-Pacific dominated the welded spiral heat exchangers market with an estimated 41.36% revenue share in 2025, driven by rapid industrialization, large-scale investments in petrochemicals, steel manufacturing, wastewater treatment, and expanding food & beverage processing industries across China, India, Japan, South Korea, and Southeast Asia

- The Plate-type welded spiral heat exchangers dominated the market with an estimated 44.6% share in 2025, owing to their compact footprint, high heat transfer efficiency, and superior performance in handling viscous, fouling, and particulate-laden fluids

Report Scope and Welded Spiral Heat Exchangers Market Segmentation

|

Attributes |

Welded Spiral Heat Exchangers Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Welded Spiral Heat Exchangers Market?

Increasing Shift Toward Compact, High-Efficiency, and Custom-Engineered Welded Spiral Heat Exchangers

- The welded spiral heat exchangers market is witnessing growing adoption of compact and space-efficient designs that offer high thermal efficiency while handling viscous, fouling, and high-pressure fluids across industrial processes

- Manufacturers are increasingly focusing on fully welded, gasket-free constructions to improve operational safety, reduce leakage risks, and enable use in corrosive and high-temperature environments

- Rising demand for custom-engineered spiral heat exchangers tailored to specific flow rates, pressure conditions, and media characteristics is strengthening adoption across chemicals, petrochemicals, and energy industries

- For instance, leading companies such as HRS Heat Exchangers, Alfa Laval, and Danfoss are enhancing spiral exchanger designs with improved turbulence control, higher heat transfer coefficients, and reduced maintenance requirements

- Increasing emphasis on energy efficiency, compact plant layouts, and process intensification is accelerating deployment of welded spiral heat exchangers in modern industrial facilities

- As industries prioritize reliability, efficiency, and reduced downtime, Welded Spiral Heat Exchangers will remain critical for advanced thermal management solutions

What are the Key Drivers of Welded Spiral Heat Exchangers Market?

- Rising demand for energy-efficient heat transfer solutions in chemical processing, oil & gas, power generation, pulp & paper, and wastewater treatment industries

- For instance, during 2024–2025, several industrial manufacturers expanded investments in process optimization and heat recovery systems, increasing demand for compact welded spiral exchangers

- Growing focus on handling viscous, fouling, and particulate-laden fluids is boosting adoption, as spiral designs offer self-cleaning flow paths and lower fouling rates

- Advancements in welding technologies, material engineering, and corrosion-resistant alloys have enhanced durability and operational lifespan

- Increasing implementation of sustainable manufacturing practices and waste heat recovery systems is creating strong long-term demand

- Supported by industrial expansion, energy efficiency regulations, and infrastructure upgrades, the Welded Spiral Heat Exchangers market is expected to witness steady global growth

Which Factor is Challenging the Growth of the Welded Spiral Heat Exchangers Market?

- High initial capital costs compared to conventional shell-and-tube or plate heat exchangers limit adoption among small and mid-scale industrial operators

- For instance, during 2024–2025, fluctuations in raw material prices, particularly stainless steel and specialty alloys, increased manufacturing costs

- Complex design and customization requirements can lead to longer lead times and higher engineering expenses

- Limited technical awareness in developing regions regarding performance advantages and lifecycle cost benefits slows market penetration

- Competition from alternative heat exchanger technologies offering lower upfront costs creates pricing pressure

- To address these challenges, manufacturers are focusing on cost-optimized designs, modular configurations, and lifecycle value positioning to expand global adoption of Welded Spiral Heat Exchangers

How is the Welded Spiral Heat Exchangers Market Segmented?

The market is segmented on the basis of type, application, and flow type.

- By Type

On the basis of type, the welded spiral heat exchangers market is segmented into Plate, Tube, and Shell. The Plate-type welded spiral heat exchangers dominated the market with an estimated 44.6% share in 2025, owing to their compact footprint, high heat transfer efficiency, and superior performance in handling viscous, fouling, and particulate-laden fluids. These exchangers are widely preferred in chemical processing, wastewater treatment, and pulp & paper industries due to their self-cleaning flow paths, reduced fouling rates, and lower maintenance requirements. Their fully welded, gasket-free design further enhances operational safety and reliability in high-pressure and corrosive environments.

The Shell-type segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by rising demand for robust heat exchangers capable of handling extreme temperatures and pressures in petrochemical, oil & gas, and heavy industrial applications. Increasing investments in large-scale process industries are accelerating adoption of shell-based configurations.

- By Application

On the basis of application, the market is segmented into Petrochemicals, Food & Beverages, Steel Making, Pharmaceutical, Wastewater Treatment, Pulp & Paper, and Others. The Petrochemicals segment dominated the market with a 38.9% share in 2025, supported by extensive use of welded spiral heat exchangers in crude processing, heat recovery, and handling corrosive and high-viscosity fluids. Their ability to operate under high pressure and temperature conditions while minimizing fouling makes them ideal for continuous petrochemical operations.

The Wastewater Treatment segment is projected to register the fastest CAGR from 2026 to 2033, driven by growing global focus on water reuse, industrial effluent treatment, and environmental compliance. Increasing investments in municipal and industrial wastewater infrastructure are significantly boosting demand for efficient and low-maintenance heat transfer solutions.

- By Flow Type

On the basis of flow type, the welded spiral heat exchangers market is segmented into Counter-Current Flow and Co-Current Flow. The Counter-Current Flow segment dominated the market with an estimated 61.3% share in 2025, as it offers higher thermal efficiency, better temperature control, and improved heat recovery compared to co-current designs. This flow configuration is widely adopted in energy-intensive industries seeking maximum heat transfer effectiveness and reduced operational costs.

The Co-Current Flow segment is expected to grow at the fastest CAGR during 2026–2033, driven by increasing use in specialized processes where controlled temperature gradients and gentle heat transfer are critical, particularly in food & beverage and pharmaceutical applications.

Which Region Holds the Largest Share of the Welded Spiral Heat Exchangers Market?

- Asia-Pacific dominated the welded spiral heat exchangers market with an estimated 41.36% revenue share in 2025, driven by rapid industrialization, large-scale investments in petrochemicals, steel manufacturing, wastewater treatment, and expanding food & beverage processing industries across China, India, Japan, South Korea, and Southeast Asia. Strong growth in energy-intensive industries, rising demand for efficient heat recovery systems, and increasing focus on operational efficiency continue to fuel adoption of welded spiral heat exchangers across the region

- Leading manufacturers in Asia-Pacific are expanding production capacity and introducing advanced welded designs to handle high-viscosity, corrosive, and fouling-prone fluids, strengthening regional competitiveness. Continuous infrastructure development and industrial expansion support long-term market dominance

- Availability of cost-effective manufacturing, strong supply chains, and supportive government policies for industrial development further reinforce Asia-Pacific’s leadership

China Welded Spiral Heat Exchangers Market Insight

China represents the largest market in Asia-Pacific, supported by extensive petrochemical capacity, steel manufacturing, pulp & paper production, and large-scale wastewater treatment projects. Rising investments in energy efficiency, heat recovery systems, and industrial process optimization are driving demand for welded spiral heat exchangers. Strong domestic manufacturing capabilities, competitive pricing, and government-led industrial modernization initiatives further support widespread adoption across heavy industries.

India Welded Spiral Heat Exchangers Market Insight

India is emerging as a fast-growing market due to expanding chemical processing, food & beverage manufacturing, pharmaceuticals, and infrastructure-led wastewater treatment projects. Increasing focus on energy-efficient thermal systems, process optimization, and sustainable industrial operations is boosting adoption. Government initiatives supporting industrial growth, coupled with rising investments in refining and specialty chemicals, are strengthening demand for welded spiral heat exchangers across end-use sectors.

Japan Welded Spiral Heat Exchangers Market Insight

Japan shows steady growth driven by advanced manufacturing practices, stringent quality standards, and high demand from pharmaceutical, specialty chemical, and food processing industries. The country’s strong emphasis on reliability, compact equipment design, and energy efficiency supports adoption of high-performance welded spiral heat exchangers. Continuous upgrades in industrial facilities and focus on process precision further reinforce long-term market stability.

North America Welded Spiral Heat Exchangers Market

North America is projected to register the fastest CAGR of 8.25% from 2026 to 2033, driven by modernization of industrial facilities, rising investment in wastewater treatment, shale gas processing, and increasing focus on energy-efficient heat transfer solutions across the U.S. and Canada.

U.S. Welded Spiral Heat Exchangers Market Insight

The U.S. leads growth in North America, driven by strong demand from petrochemicals, pulp & paper, food processing, and industrial heat recovery applications. Rising investments in plant modernization, shale gas processing, and energy-efficient thermal solutions are accelerating adoption. Stringent environmental regulations and sustainability initiatives further increase demand for robust, low-maintenance welded spiral heat exchangers across industrial facilities.

Canada Welded Spiral Heat Exchangers Market Insight

Canada contributes steadily due to growth in chemical processing, mining, oil & gas, and municipal wastewater treatment projects. Increasing focus on energy conservation, environmental compliance, and efficient heat transfer systems supports market expansion. Investments in industrial upgrades and sustainable infrastructure, combined with demand for durable and corrosion-resistant heat exchangers, continue to drive adoption across multiple end-use industries.

Which are the Top Companies in Welded Spiral Heat Exchangers Market?

The welded spiral heat exchangers industry is primarily led by well-established companies, including:

- AKG Thermal Systems, Inc. (U.S.)

- American Industrial Heat Transfer, Inc. (U.S.)

- Banco Products Ltd (India)

- Climetal S.L. – Heat Exchanger (Spain)

- Constellium (France)

- DENSO CORPORATION (Japan)

- G&M Radiator Mfg Ltd (Canada)

- HRS Process Systems Ltd. (India)

- MAHLE GmbH (Germany)

- MODINE MANUFACTURING COMPANY (U.S.)

- Nippon Light Metal Co., Ltd (Japan)

- Precision Micro (U.K.)

- Valeo (France)

- T.RAD Co., Ltd (Japan)

- Calsonic Kansei Corporation (Japan)

- Hanon Systems (South Korea)

- Radiant Heat Exchanger Pvt. Ltd. (India)

- Universal Heat Exchangers Limited (India)

- Dana Limited (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Welded Spiral Heat Exchangers Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Welded Spiral Heat Exchangers Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Welded Spiral Heat Exchangers Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.