Global Bioprocessing Downstream Purification Consumables Market

市场规模(十亿美元)

CAGR :

%

USD

9.60 Billion

USD

19.98 Billion

2025

2033

USD

9.60 Billion

USD

19.98 Billion

2025

2033

| 2026 –2033 | |

| USD 9.60 Billion | |

| USD 19.98 Billion | |

|

|

|

|

Global bioprocessing downstream purification consumables market segmentation, By Product Type (Chromatography Resins, Filters, Membranes, Protein A Resins, and Others), End User (Biopharmaceutical Companies, Contract Manufacturing Organizations (CMOs), and Research & Academic Institutes )- Industry Trends and Forecast to 2033

Bioprocessing Downstream Purification Consumables Market Size

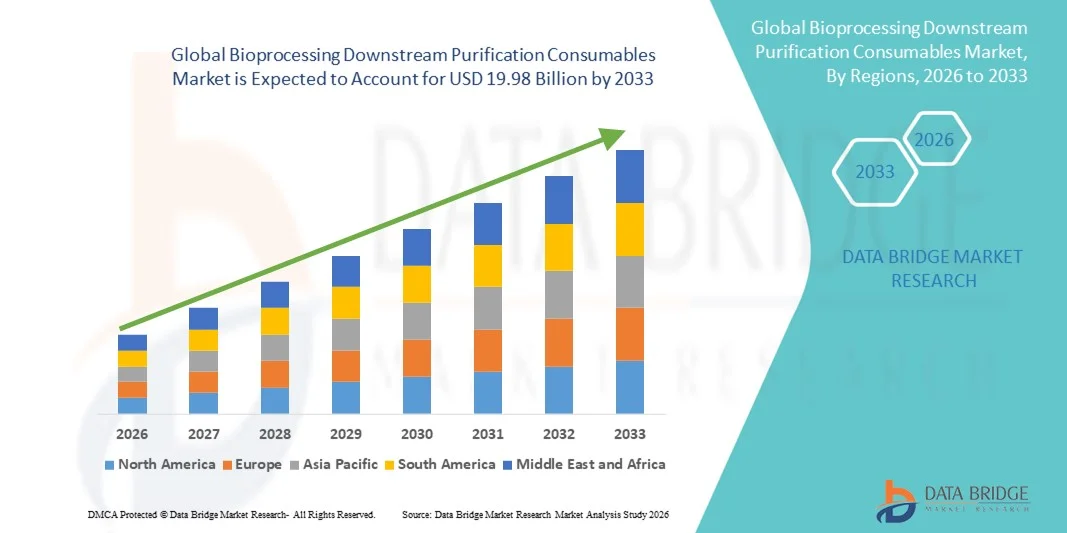

- The global bioprocessing downstream purification consumables market size was valued at USD 9.60 billion in 2025 and is expected to reach USD 19.98 billion by 2033, at a CAGR of 9.60% during the forecast period

- The market growth is largely driven by the rapid expansion of the biopharmaceutical industry and increasing production of biologics, monoclonal antibodies, vaccines, and cell and gene therapies, which require efficient and high-purity downstream purification processes

- Furthermore, rising demand for cost-effective, scalable, and high-performance purification consumables—such as chromatography resins, filters, and membranes—is accelerating adoption across biopharmaceutical manufacturers and contract manufacturing organizations, thereby significantly boosting the growth of the Bioprocessing Downstream Purification Consumables market

Bioprocessing Downstream Purification Consumables Market Analysis

- Bioprocessing downstream purification consumables, including chromatography resins, filters, membranes, and buffers, are critical components in biologics manufacturing, enabling the separation, purification, and polishing of proteins, monoclonal antibodies, vaccines, and advanced cell and gene therapy products across biopharmaceutical production workflows

- The escalating demand for downstream purification consumables is primarily fueled by the rapid growth of biologics and biosimilars, increasing adoption of single-use technologies, rising outsourcing to contract manufacturing organizations (CMOs), and the need for scalable, cost-efficient, and high-yield purification solutions

- North America dominated the bioprocessing downstream purification consumables market with the largest revenue share of 38.6% in 2025, supported by a strong biopharmaceutical manufacturing base, high R&D investments, early adoption of advanced purification technologies, and a robust presence of leading biologics manufacturers and CMOs, particularly in the U.S.

- Asia-Pacific is expected to be the fastest-growing region in the bioprocessing downstream purification consumables market during the forecast period, driven by expanding biopharmaceutical production capacity, increasing investments in biologics manufacturing in China, India, and South Korea, and rising government support for life sciences infrastructure

- The Chromatography Resins segment dominated the largest market revenue share of 42.8% in 2025, driven by its extensive use in high-resolution separation and purification of biologics, monoclonal antibodies, and vaccines

Report Scope and Bioprocessing Downstream Purification Consumables Market Segmentation

|

Attributes |

Bioprocessing Downstream Purification Consumables Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework. |

Bioprocessing Downstream Purification Consumables Market Trends

Rising Adoption of Single-Use and High-Efficiency Purification Technologies

- A major and accelerating trend in the global bioprocessing downstream purification consumables market is the increasing adoption of single-use purification systems and high-efficiency consumables such as chromatography resins, filters, membranes, and disposable tubing assemblies. These solutions are gaining traction due to their ability to reduce contamination risks, minimize cleaning validation requirements, and improve overall operational efficiency in biopharmaceutical manufacturing

- For instance, Cytiva has expanded the adoption of its single-use chromatography columns and filtration consumables across monoclonal antibody and vaccine manufacturing facilities, enabling faster batch turnaround and reduced downtime compared to traditional stainless-steel systems. This shift highlights the growing preference for flexible and contamination-resistant purification consumables in downstream processing

- Advances in purification media, including high-capacity resins and next-generation membrane chromatography consumables, are enabling higher throughput and improved yield while maintaining product purity and regulatory compliance. These innovations are helping manufacturers meet the growing demand for biologics while controlling production costs

- In addition, the growing focus on process intensification and continuous bioprocessing is driving demand for downstream purification consumables that offer scalability, consistency, and compatibility with automated manufacturing platforms. As a result, consumable suppliers are expanding their portfolios to support both batch and continuous purification workflows

Bioprocessing Downstream Purification Consumables Market Dynamics

Driver

Expanding Biopharmaceutical Pipeline and Rising Demand for Biologics

- The rapidly expanding global biopharmaceutical pipeline is a key driver of growth for the Bioprocessing Downstream Purification Consumables market. Increasing approvals and ongoing development of biologics, biosimilars, and advanced therapies are significantly boosting demand for purification consumables used during downstream processing

- For instance, the continued commercial success and scale-up of monoclonal antibody therapies by companies such as Roche and Amgen have driven sustained demand for protein A chromatography resins, depth filters, and virus removal membranes in large-scale biomanufacturing facilities. This trend directly supports the growth of downstream purification consumables

- Rising prevalence of chronic diseases such as cancer, autoimmune disorders, and infectious diseases is accelerating the need for biologic drugs, including monoclonal antibodies and vaccines. This, in turn, is driving consistent demand for chromatography resins, filtration consumables, and buffer preparation products across clinical and commercial manufacturing stages

- Furthermore, the growth of contract development and manufacturing organizations (CDMOs) is contributing to market expansion, as these organizations require reliable, scalable, and regulatory-compliant purification consumables to support multiple clients and diverse product pipelines

Restraint/Challenge

High Costs and Supply Chain Constraints of Specialized Consumables

- One of the primary challenges facing the bioprocessing downstream purification Consumables market is the high cost associated with advanced purification consumables, particularly specialized chromatography resins and membrane systems

- These costs can significantly impact overall manufacturing expenses, especially for small and mid-sized biopharmaceutical companies

- For instance, during periods of heightened biologics production demand, manufacturers have reported extended lead times and higher procurement costs for premium protein A resins supplied by a limited number of global vendors, creating budgetary and scheduling pressures for biomanufacturers. Such constraints highlight the vulnerability of the supply chain for critical purification consumables

- Supply chain constraints and long lead times for critical consumables present additional challenges, particularly during periods of high demand or global disruptions. Dependence on a limited number of qualified suppliers for specialized purification materials can create bottlenecks in production schedules and delay drug development timelines

- Addressing these challenges will require continued innovation in cost-effective purification technologies, diversification of supplier networks, and investments in localized manufacturing and inventory management strategies to ensure long-term market sustainability

Bioprocessing Downstream Purification Consumables Market Scope

The market is segmented on the basis of product type and end user.

- By Product Type

On the basis of product type, the global bioprocessing downstream purification consumables market is segmented into Chromatography Resins, Filters, Membranes, Protein A Resins, and Others. The Chromatography Resins segment dominated the largest market revenue share of 42.8% in 2025, driven by its extensive use in high-resolution separation and purification of biologics, monoclonal antibodies, and vaccines. These resins offer high binding capacity, reproducibility, and scalability, making them essential in commercial biopharmaceutical manufacturing. The growing production of monoclonal antibodies and recombinant proteins further supports segment dominance. Continuous investments in resin innovation and lifecycle optimization enhance process efficiency and yield. Regulatory preference for validated purification technologies also strengthens adoption. Additionally, chromatography resins are compatible with both small-scale research and large-scale commercial production.

The Protein A Resins segment is expected to witness the fastest CAGR of 12.9% from 2026 to 2033, fueled by increasing monoclonal antibody development pipelines and rising demand for high-purity biologics. Protein A resins offer superior selectivity and recovery rates, reducing downstream processing time. Advancements in ligand stability and reusability further improve cost efficiency. Expansion of biosimilar manufacturing and increased outsourcing to CMOs also accelerate segment growth globally.

- By End User

On the basis of end user, the global bioprocessing downstream purification consumables market is segmented into Biopharmaceutical Companies, Contract Manufacturing Organizations (CMOs), and Research & Academic Institutes. The Biopharmaceutical Companies segment accounted for the largest market revenue share of 49.6% in 2025, driven by large-scale biologics production, in-house manufacturing capabilities, and continuous process optimization efforts. These companies require high volumes of purification consumables to support commercial drug production and clinical pipeline expansion. Strong regulatory compliance requirements and the need for consistent batch quality further drive demand. Increased approvals of biologics and vaccines also contribute to segment dominance.

The Contract Manufacturing Organizations (CMOs) segment is projected to register the fastest CAGR of 13.7% from 2026 to 2033, supported by rising outsourcing of downstream processing by small and mid-sized biopharma firms. CMOs benefit from flexible production models, cost efficiency, and specialized purification expertise. Growing biosimilar production, capacity expansions, and long-term manufacturing agreements significantly boost consumable demand. Increased investment in single-use and scalable purification technologies further accelerates segment growth.

Bioprocessing Downstream Purification Consumables Market Regional Analysis

- North America dominated the bioprocessing downstream purification consumables market with the largest revenue share of 38.6% in 2025, supported by a strong biopharmaceutical manufacturing base, high investments in research and development, and early adoption of advanced downstream purification technologies

- The region benefits from the presence of leading biologics manufacturers, contract manufacturing organizations (CMOs), and technology providers that extensively utilize chromatography resins, filtration systems, and other high-performance purification consumables

- In addition, stringent regulatory standards, coupled with a strong focus on product quality, process efficiency, and scalability, continue to drive consistent demand for high-value downstream purification consumables across commercial and clinical manufacturing operations

U.S. Bioprocessing Downstream Purification Consumables Market Insight

The U.S. bioprocessing downstream purification consumables market accounted for the largest revenue share within North America in 2025, driven by its well-established biopharmaceutical ecosystem and continuous expansion of biologics and biosimilars production. The country hosts a high concentration of major pharmaceutical companies, biotechnology firms, and CMOs that rely heavily on advanced purification consumables for monoclonal antibodies, vaccines, and cell- and gene-based therapies. Strong government and private-sector funding for life sciences research, combined with ongoing investments in large-scale manufacturing facilities, continues to propel demand for chromatography resins, depth filters, virus removal filters, and membrane-based purification solutions.

Europe Bioprocessing Downstream Purification Consumables Market Insight

The Europe bioprocessing downstream purification consumables market is projected to grow at a steady CAGR during the forecast period, driven by increasing biologics production, strong regulatory oversight, and rising investments in biomanufacturing infrastructure. Countries across the region are witnessing increased adoption of advanced purification technologies to support the development of biosimilars, vaccines, and novel biologic therapies. The growing presence of CMOs and government-backed initiatives to strengthen pharmaceutical self-sufficiency further support market growth across Western and Northern Europe.

U.K. Bioprocessing Downstream Purification Consumables Market Insight

The U.K. bioprocessing downstream purification consumables market is expected to grow at a notable CAGR, supported by a robust biotechnology sector and strong academic–industry collaboration. The country’s focus on biologics innovation, vaccine development, and translational research is driving demand for high-quality downstream purification consumables. Increasing investments in bioprocessing capacity expansion and the presence of specialized CMOs are further contributing to market growth in the U.K.

Germany Bioprocessing Downstream Purification Consumables Market Insight

Germany bioprocessing downstream purification consumables market represents a key market in Europe, driven by its advanced pharmaceutical manufacturing capabilities and emphasis on high-quality, precision-driven bioprocessing solutions. The country’s strong industrial base, coupled with rising investments in biologics manufacturing and biosimilars production, is fueling demand for chromatography resins, filtration systems, and disposable purification consumables. Germany’s focus on efficiency, sustainability, and regulatory compliance further supports the adoption of innovative downstream purification technologies.

Asia-Pacific Bioprocessing Downstream Purification Consumables Market Insight

The Asia-Pacific bioprocessing downstream purification consumables market region is expected to be the fastest-growing market during the forecast period, driven by expanding biopharmaceutical production capacity and increasing investments in biologics manufacturing across China, India, Japan, and South Korea. Governments across the region are actively supporting life sciences infrastructure development, fostering domestic biologics production, and encouraging technology transfer. The growing number of CMOs and rising adoption of advanced purification consumables to meet global quality standards are significantly accelerating market growth in Asia-Pacific.

Japan Bioprocessing Downstream Purification Consumables Market Insight

Japan’s bioprocessing downstream purification consumables market is experiencing steady growth due to the country’s strong focus on biologics innovation, regenerative medicine, and advanced therapeutic development. The demand for high-purity, reliable purification consumables is increasing as manufacturers invest in next-generation biologics and vaccine production. Japan’s emphasis on quality, automation, and compliance with stringent regulatory frameworks continues to support the adoption of advanced downstream purification solutions.

China Bioprocessing Downstream Purification Consumables Market Insight

China bioprocessing downstream purification consumables market accounted for the largest revenue share in the Asia-Pacific region in 2025, driven by rapid expansion of domestic biopharmaceutical manufacturing, rising healthcare investments, and strong government support for biotechnology development. The country is witnessing significant growth in biologics, biosimilars, and vaccine production, which is fueling demand for chromatography resins, filtration consumables, and disposable purification systems. The presence of a growing number of domestic manufacturers and CMOs, along with increasing exports of biologics, continues to propel the downstream purification consumables market in China.

Bioprocessing Downstream Purification Consumables Market Share

The Bioprocessing Downstream Purification Consumables industry is primarily led by well-established companies, including:

• Cytiva (U.S.)

• Merck KGaA (Germany)

• Thermo Fisher Scientific (U.S.)

• Sartorius AG (Germany)

• Danaher Corporation (U.S.)

• Repligen Corporation (U.S.)

• 3M Company (U.S.)

• Pall Corporation (U.S.)

• GEA Group (Germany)

• Lonza Group (Switzerland)

• Asahi Kasei Corporation (Japan)

• Tosoh Corporation (Japan)

• Purolite (U.K.)

• Bio-Rad Laboratories (U.S.)

• Avantor, Inc. (U.S.)

• Agilent Technologies (U.S.)

• WuXi Biologics (China)

• Eppendorf AG (Germany)

• Separation Scientific (U.S.)

Latest Developments in Global Bioprocessing Downstream Purification Consumables Market

- In June 2024, Ecolab Life Sciences, through its Purolite resin business in partnership with Repligen Corporation, launched DurA Cycle, a new Protein A chromatography resin engineered for large-scale monoclonal antibody purification, offering enhanced efficiency and performance for commercial biologics downstream processing. This development supports higher throughput and reduced processing costs in purification workflows, reflecting the industry’s push toward more robust and scalable purification consumables

- In January 2025, Bio-Rad Laboratories, Inc. launched Nuvia wPrime 2A Media, a weak anion exchange and hydrophobic interaction (AEX-HIC) mixed-mode chromatography resin designed to enable tunable, scalable purification from lab to manufacturing scales. This new resin enhances downstream purification flexibility and reproducibility for a broad range of biomolecules, addressing growing demand in biotherapeutic production

- In July 2025, Purilogics (a Donaldson Life Sciences business) announced the commercial availability of Purexa™ NAEX Prep, its first manufacturing-grade anion-exchange membrane chromatography consumable, featuring high binding capacity and compatibility with standard chromatography systems to accelerate plasmid DNA purification and other downstream processes. This launch highlights increasing adoption of advanced membrane chromatography consumables in GMP-compliant bioprocessing

- In May 2025, Thermo Fisher Scientific introduced Nexus SUC, a major new single-use chromatography platform designed to streamline integration between upstream and downstream purification steps in biopharmaceutical manufacturing, particularly for flexible and modular facility designs. The platform reflects broader trends toward single-use purification consumables that reduce cleaning validation and cross-contamination risks

- In February 2025, Thermo Fisher Scientific announced its planned acquisition of Solventum’s purification and filtration business for approximately USD 4.1 billion, a strategic move to expand its footprint in bioprocessing filtration consumables and enhance its downstream purification portfolio in support of biologics production. The deal is expected to close by the end of 2025 and complements Thermo Fisher’s existing bioprocessing consumables offerings

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。