Global Carbon Prepreg Market

Marktgröße in Milliarden USD

CAGR :

%

USD

11.25 Billion

USD

16.75 Billion

2024

2032

USD

11.25 Billion

USD

16.75 Billion

2024

2032

| 2025 –2032 | |

| USD 11.25 Billion | |

| USD 16.75 Billion | |

|

|

|

|

Global Carbon Fiber Prepreg Market Segmentation, By Resin Type (Epoxy, Phenolic, Bismaleimide, Cyanate Ester, Thermoplastic), Manufacturing Process (Hot Melt, Solvent Dip), Application (Aerospace and Defense, Automotive, Sports and Leisure, Wind)- Industry Trends and Forecast to 2032

Carbon Fiber Prepreg Market Size

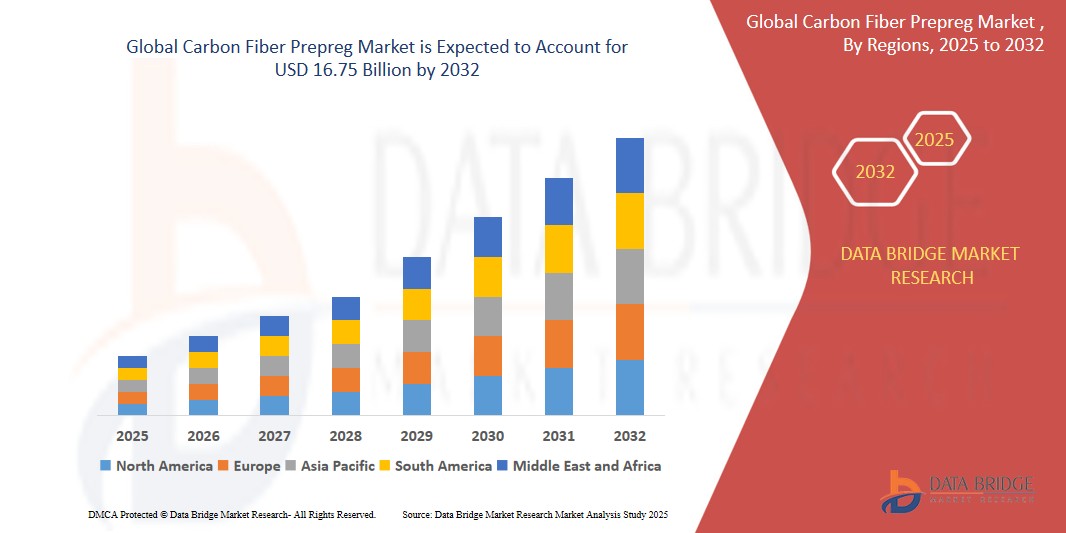

- The global Carbon Fiber Prepreg market size was valued atUSD 11.25 billion in 2024 and is expected to reachUSD 16.75 billion by 2032, at aCAGR of 5.10%during the forecast period

- This growth is driven by factors such as the rising scope of its application in wood-working industry.

Carbon Fiber Prepreg Market Analysis

- Carbon Fiber Prepregs are advanced composite materials used extensively in aerospace, automotive, wind energy, and sports equipment industries due to their high strength-to-weight ratio, rigidity, and corrosion resistance

- The demand for Carbon Fiber Prepregs is significantly driven by the growing need for lightweight and fuel-efficient components, particularly in aerospace and automotive sectors

- North America is expected to dominate the Carbon Fiber Prepregs market due to the presence of key aerospace and defense manufacturers and strong investments in R&D

- Asia-Pacific is expected to be the fastest-growing region in the Carbon Fiber Prepreg market during the forecast period due to expanding industrial base and rising demand in automotive and wind energy applications

- The aerospace and defense segment is expected to dominate the market with a market share of 42.7%, driven by increasing aircraft production and stringent regulatory requirements for lightweight, high-performance materials

Report Scope and Carbon Fiber Prepreg Market Segmentation

|

Attributes |

Carbon Fiber Prepreg Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• SGL Carbon (Germany) • Solvay (Belgium) • Hexcel Corporation (U.S.) • Axiom Materials, Inc. (U.S.) • Koninklijke Ten Cate bv. (Netherlands) • TEIJIN LIMITED. (Japan) • Gurit (Switzerland) • Mitsubishi Chemical Corporation (Japan) • Airtech Advanced Materials Group (U.S.) • TORAY INDUSTRIES, INC. (Japan) • PARK ELECTROCHEMICAL CORP. (U.S.) • TCR Composites (U.S.) • HANKUK CARBON CO.,LTD. (South Korea) • KINECO - KAMAN (India) • Barrday, Inc. (Canada) • TAIWAN FIRST LI-BOND Co., LTD. (Taiwan) • Holding company "Composite" (Russia) • GMS COMPOSITES (Australia) • ABC Composite Materials LLC (U.S.) • North Thin Ply Technology (Switzerland) • Plastic Reinforcement Fabrics Ltd (India) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Carbon Fiber Prepreg Market Trends

““Integration of Automation and AI in Carbon Fiber Prepreg Manufacturing”

- One prominent trend in the carbon fiber prepreg market is the increasing integration of automation and artificial intelligence in manufacturing processes to enhance quality, efficiency, and scalability

- These innovations streamline production by reducing manual errors, optimizing resin impregnation, and ensuring consistent fiber alignment, leading to improved material performance.

- For instance, AI-powered systems are being used to monitor curing cycles and adjust processing parameters in real time, ensuring uniform prepreg quality and reducing waste in aerospace and automotive applications.

- These advancements are transforming the manufacturing landscape, lowering costs, accelerating production timelines, and driving the adoption of carbon fiber prepregs across high-performance industries

Carbon Fiber Prepreg Market Dynamics

Driver

“Surging Demand for Lightweight and High-Performance Materials in Aerospace & Automotive”

- The growing emphasis on fuel efficiency, emission reduction, and performance optimization in aerospace and automotive industries is significantly driving the demand for Carbon Fiber Prepregs

- These industries require materials that offer superior strength-to-weight ratios, stiffness, and thermal resistance—key properties of carbon fiber prepregs

- As governments and regulatory bodies impose stringent emission and safety standards, manufacturers are increasingly adopting advanced composites to meet these requirements without compromising performance

For instance,

- In January 2024, Boeing announced plans to increase the use of carbon fiber prepregs in its next-generation aircraft to achieve up to 20% weight reduction, leading to improved fuel economy and reduced carbon emissions

- As a result, the continuous push for innovation and regulatory compliance in high-performance sectors is accelerating the adoption of carbon fiber prepregs globally

Opportunity

“Expansion in Wind Energy and Electric Vehicle Sectors”

- The global transition toward renewable energy is driving increased investments in wind power, where carbon fiber prepregs are used in long, durable turbine blades

- Simultaneously, the electric vehicle (EV) industry is leveraging these materials to reduce vehicle weight, improve battery efficiency, and enhance overall range

- This dual demand opens up significant growth opportunities for carbon fiber prepreg manufacturers across both clean energy and sustainable mobility markets

For instance,

- In October 2023, Vestas Wind Systems partnered with a composite materials company to develop longer, lightweight blades using high-performance carbon prepregs, aiming to boost turbine efficiency and reduce lifecycle costs

The dual impact of climate goals and technological innovation makes wind energy and EVs a fertile ground for carbon fiber prepreg market expansion.

Restraint/Challenge

“High Cost of Production and Limited Recycling Capabilities”

- The complex manufacturing process and high raw material costs associated with carbon fiber prepregs result in premium pricing, restricting widespread adoption—especially in cost-sensitive industries

- Moreover, challenges in recycling thermoset-based prepregs create environmental concerns and limit sustainability in some applications

- These factors pose barriers to entry for new players and slow down market penetration in emerging economies or lower-margin sectors

For instance,

- In November 2024, according to an article published by the CompositesWorld, the average cost of carbon fiber prepreg materials is 3–5 times higher than traditional alternatives like fiberglass, which constrains their adoption in sectors such as mass-market automotive or consumer goods

- Unless cost-efficient production methods and scalable recycling solutions are developed, these constraints may limit the broader utilization of carbon fiber prepregs in the near term

Carbon Fiber Prepreg Market Scope

The market is segmented on the basis Resin Type, Manufacturing Process, Application,

|

Segmentation |

Sub-Segmentation |

|

By Resin Type |

|

|

By Manufacturing Process |

|

|

By Application |

|

In 2025, the epoxy is projected to dominate the market with the largest share in Resin Type segment

The epoxy segment is expected to dominate the Carbon Fiber Prepreg market with the largest share of 56.22% in 2025 due to its superior mechanical properties, chemical resistance, and strong adhesion capabilities. As a preferred resin in aerospace, automotive, and sporting goods, epoxy-based prepregs provide exceptional strength-to-weight performance. Advancements in composite manufacturing and rising demand for lightweight components further contribute to its market dominance.

The aerospace and defense is expected to account for the largest share during the forecast period in Application market

In 2025, the aerospace and defense segment is expected to dominate the market with the largest market share of 51.31% due to its critical need for lightweight, high-strength materials in aircraft structures and components. Carbon fiber prepregs enhance fuel efficiency, structural performance, and compliance with stringent safety standards. The increasing production of commercial and military aircraft, along with growing defense budgets globally, significantly supports the dominance of this segment..

Carbon Fiber Prepreg Market Regional Analysis

“North America Holds the Largest Share in the Carbon Fiber Prepreg Market”

- North America dominates the Carbon Fiber Prepreg market, driven by the presence of major aerospace, defense, and automotive manufacturers, along with robust R&D investments and advanced composite processing capabilities

- The U.S. holds a significant share due to strong demand from Boeing and other aerospace giants, as well as increasing adoption of lightweight materials in electric vehicles and renewable energy sectors

- The region benefits from a well-established supply chain, skilled workforce, and supportive government initiatives aimed at promoting sustainable and high-performance materials

- In addition, growing military modernization programs and the rising need for energy-efficient mobility solutions are further fueling the demand for carbon fiber prepregs across the region

“Asia-Pacific is Projected to Register the Highest CAGR in the Carbon Fiber Prepreg Market”

- The Asia-Pacific region is expected to witness the highest growth rate in the Carbon Fiber Prepreg market, fueled by booming automotive production, expanding aerospace sectors, and increasing investments in wind energy

- Countries such as China, Japan, South Korea, and India are emerging as high-growth markets due to their growing industrial base and government support for advanced manufacturing

- Japan, a technology leader in carbon composites, continues to drive innovation and adoption in applications ranging from aircraft components to sports equipment

- China and India are witnessing a surge in infrastructure development and clean energy initiatives, with rising demand for lightweight, durable, and high-performance materials—creating ample opportunities for carbon fiber prepreg manufacturers in the region

Carbon Fiber Prepreg Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, Resin Type dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

• SGL Carbon (Germany)

• Solvay (Belgium)

• Hexcel Corporation (U.S.)

• Axiom Materials, Inc. (U.S.)

• Koninklijke Ten Cate bv. (Netherlands)

• TEIJIN LIMITED. (Japan)

• Gurit (Switzerland)

• Mitsubishi Chemical Corporation (Japan)

• Airtech Advanced Materials Group (U.S.)

• TORAY INDUSTRIES, INC. (Japan)

• PARK ELECTROCHEMICAL CORP. (U.S.)

• TCR Composites (U.S.)

• HANKUK CARBON CO.,LTD. (South Korea)

• KINECO - KAMAN (India)

• Barrday, Inc. (Canada)

• TAIWAN FIRST LI-BOND Co., LTD. (Taiwan)

• Holding company "Composite" (Russia)

• GMS COMPOSITES (Australia)

• ABC Composite Materials LLC (U.S.)

• North Thin Ply Technology (Switzerland)

• Plastic Reinforcement Fabrics Ltd (India)

Latest Developments in Global Carbon Fiber Prepreg Market

- In March 2025, Hexcel Corporation announced the opening of a new carbon fiber prepreg manufacturing facility in Casablanca, Morocco, aimed at expanding its global footprint and meeting rising demand from aerospace and defense sectors. The facility is expected to enhance supply chain resilience and support key customers in Europe, the Middle East, and Africa with lightweight, high-performance composite solutions.

- In January 2025, Toray Industries, Inc. unveiled its next-generation high-toughness carbon fiber prepreg system, TORAYCA™ T1100G-12K-190FA, designed specifically for space and military aerospace applications. The product boasts improved impact resistance, thermal stability, and fatigue performance, reinforcing Toray’s position as a leader in advanced composites.

- In November 2024, Gurit announced the development of a bio-based epoxy carbon fiber prepreg, featuring 60% bio-derived content. Targeting the wind energy and marine markets, this innovation aligns with sustainability trends and regulatory pressure to reduce carbon footprints in industrial manufacturing.

- In October 2024, Solvay partnered with Safran to co-develop carbon fiber prepregs for the next generation of aircraft engine nacelles. The initiative focuses on creating materials that can endure high thermal and mechanical loads while reducing weight, aiming to support sustainable aviation targets and increase aircraft fuel efficiency.

- In September 2024, Mitsubishi Chemical Group announced a strategic expansion of its carbon fiber prepreg production capacity in Japan and the U.S., in response to the growing demand from the electric vehicle (EV) and hydrogen energy sectors. The company also introduced advanced automation systems to improve production efficiency and reduce operational costs

SKU-

Erhalten Sie Online-Zugriff auf den Bericht zur weltweit ersten Market Intelligence Cloud

- Interaktives Datenanalyse-Dashboard

- Unternehmensanalyse-Dashboard für Chancen mit hohem Wachstumspotenzial

- Zugriff für Research-Analysten für Anpassungen und Abfragen

- Konkurrenzanalyse mit interaktivem Dashboard

- Aktuelle Nachrichten, Updates und Trendanalyse

- Nutzen Sie die Leistungsfähigkeit der Benchmark-Analyse für eine umfassende Konkurrenzverfolgung

Forschungsmethodik

Die Datenerfassung und Basisjahresanalyse werden mithilfe von Datenerfassungsmodulen mit großen Stichprobengrößen durchgeführt. Die Phase umfasst das Erhalten von Marktinformationen oder verwandten Daten aus verschiedenen Quellen und Strategien. Sie umfasst die Prüfung und Planung aller aus der Vergangenheit im Voraus erfassten Daten. Sie umfasst auch die Prüfung von Informationsinkonsistenzen, die in verschiedenen Informationsquellen auftreten. Die Marktdaten werden mithilfe von marktstatistischen und kohärenten Modellen analysiert und geschätzt. Darüber hinaus sind Marktanteilsanalyse und Schlüsseltrendanalyse die wichtigsten Erfolgsfaktoren im Marktbericht. Um mehr zu erfahren, fordern Sie bitte einen Analystenanruf an oder geben Sie Ihre Anfrage ein.

Die wichtigste Forschungsmethodik, die vom DBMR-Forschungsteam verwendet wird, ist die Datentriangulation, die Data Mining, die Analyse der Auswirkungen von Datenvariablen auf den Markt und die primäre (Branchenexperten-)Validierung umfasst. Zu den Datenmodellen gehören ein Lieferantenpositionierungsraster, eine Marktzeitlinienanalyse, ein Marktüberblick und -leitfaden, ein Firmenpositionierungsraster, eine Patentanalyse, eine Preisanalyse, eine Firmenmarktanteilsanalyse, Messstandards, eine globale versus eine regionale und Lieferantenanteilsanalyse. Um mehr über die Forschungsmethodik zu erfahren, senden Sie eine Anfrage an unsere Branchenexperten.

Anpassung möglich

Data Bridge Market Research ist ein führendes Unternehmen in der fortgeschrittenen formativen Forschung. Wir sind stolz darauf, unseren bestehenden und neuen Kunden Daten und Analysen zu bieten, die zu ihren Zielen passen. Der Bericht kann angepasst werden, um Preistrendanalysen von Zielmarken, Marktverständnis für zusätzliche Länder (fordern Sie die Länderliste an), Daten zu klinischen Studienergebnissen, Literaturübersicht, Analysen des Marktes für aufgearbeitete Produkte und Produktbasis einzuschließen. Marktanalysen von Zielkonkurrenten können von technologiebasierten Analysen bis hin zu Marktportfoliostrategien analysiert werden. Wir können so viele Wettbewerber hinzufügen, wie Sie Daten in dem von Ihnen gewünschten Format und Datenstil benötigen. Unser Analystenteam kann Ihnen auch Daten in groben Excel-Rohdateien und Pivot-Tabellen (Fact Book) bereitstellen oder Sie bei der Erstellung von Präsentationen aus den im Bericht verfügbaren Datensätzen unterstützen.