North America Protective Packaging Market

Tamaño del mercado en miles de millones de dólares

Tasa de crecimiento anual compuesta (CAGR) :

%

USD

16.10 Billion

USD

25.50 Billion

2025

2033

USD

16.10 Billion

USD

25.50 Billion

2025

2033

| 2026 –2033 | |

| USD 16.10 Billion | |

| USD 25.50 Billion | |

|

|

|

|

North America Protective Packaging Market Segmentation, By Product type (Flexible, Rigid, Semi-Rigid), material (Plastics, Paper & Paperboard, Foam, Metal, Others), Application (Cushioning, Wrapping, Void Filling, Blocking & Bracing, Insulation, Others), End User (Automotive (2900), Industry, Trade (Retail) (4700), Logistics (4900), Others), Distribution Channel (Direct, Indirect) - Industry Trends and Forecast to 2033

North America Protective Packaging Market Size

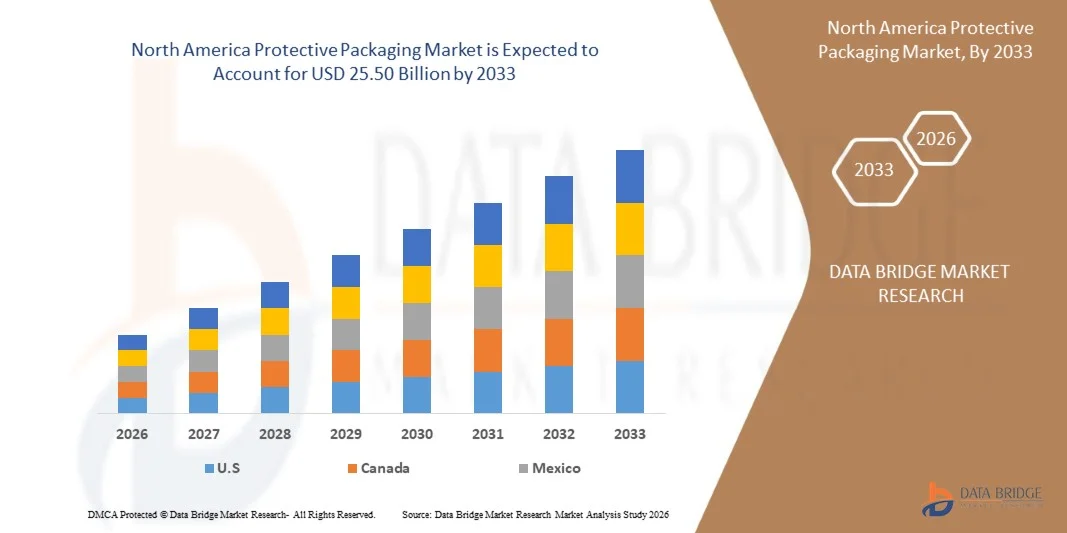

- The North America Protective Packaging Market size was valued at USD 25.50 billion by 2033 from USD 16.10 billion in 2026, growing with a CAGR of 6.0% during the forecast period

- The North America Protective Packaging Market is witnessing steady growth, supported by strong demand from end-use industries such as chemicals, food & beverages, construction materials, and agriculture, driven by increased need for safe handling, storage, and transportation of goods.

- Rising North America trade and export activities, along with growth in bulk transportation and cross-regions logistics, are significantly contributing to the expansion of protective packaging solutions across the region.

- Advancements in warehouse automation, digital inventory systems, and specialized logistics infrastructure including temperature-controlled storage, bonded warehouses, and integrated distribution centers are improving operational efficiency and supporting market scalability.

North America Protective Packaging Market Analysis

- The North America Protective Packaging Market is experiencing steady growth, driven by rising demand from industries such as food & beverages, chemicals, pharmaceuticals, electronics, and industrial goods, where product safety during storage and transportation is critical.

- Increasing adoption of advanced logistics solutions, warehouse automation, and e-commerce distribution networks is accelerating demand for high-performance protective packaging solutions.

- Growing emphasis on sustainability, recyclable materials, and compliance with regulatory standards, along with value-added packaging services, is further strengthening long-term market growth.

- U.S. dominates the market, accounting for 72.46% share, supported by its strong manufacturing base, advanced logistics infrastructure, and high export activity across North America.

- The Flexible protective packaging segment leads the market, holding a 65.79% share, due to its cost-effectiveness, lightweight nature, ease of handling, and suitability for diverse applications.

Report Scope and North America Protective Packaging Market Segmentation

|

Attributes |

North America Protective Packaging Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

North America Protective Packaging Market Trends

“Integration of Smart & Advanced Technologies”

- Smart tracking technologies such as RFID, QR codes, and IoT-enabled sensors are increasingly integrated into protective packaging to enable real-time tracking of shipments, improve inventory visibility, and reduce loss or theft during transit.

- Condition-monitoring solutions embedded in packaging help track temperature, humidity, shock, and vibration, ensuring product integrity—especially for sensitive goods like electronics, pharmaceuticals, and food products.

- Automation and robotics in packaging lines are enhancing efficiency by improving packing speed, consistency, and accuracy, while reducing labor dependency and operational costs.

- Advanced materials and intelligent cushioning systems are being developed to provide enhanced impact resistance, adaptive protection, and optimized material usage, supporting lightweight and sustainable packaging goals.

- Digital integration with logistics and warehouse management systems (WMS) allows data-driven decision-making, predictive maintenance, and seamless coordination across supply chains, improving overall operational performance.

For Instance,

- In April 2025, Sonoco completed the acquisition of TC Transcontinental’s flexible packaging business, enhancing its flexible and automated packaging capabilities a move that expands Sonoco’s tech‑enabled offerings and protective solutions portfolio.

- In March 2024, Sealed Air signed a strategic partnership with DHL Supply Chain to co‑develop more sustainable protective packaging solutions across DHL’s North America logistics network, focusing on efficiency and reduced environmental impact.

- In February 2025, Flexible Packaging Partners completed the acquisition of New Tech Plastics, a blown film manufacturer, allowing the company to scale manufacturing capacity and introduce more advanced, custom protective solutions for industry clients.

- In November 2025, Alexander Watson Associates (AWA) announced the acquisition of the Active & Intelligent Packaging Industry Association (AIPIA) to expand its smart packaging expertise, analytics, and service offerings — strengthening its position in the smart/connected packaging space.

North America Protective Packaging Market Dynamics

Driver

“Growing international trade”

- Growing international trade boosts demand for protective packaging as companies move higher volumes of goods across longer and more complex supply chains. Exporters ship products through multiple handling points such as ports, warehouses, customs facilities, and distribution hubs, which increases the risk of impact, vibration, compression, and environmental exposure.

- protective packaging helps businesses prevent product damage, reduce returns, and maintain quality standards while goods travel by sea, air, rail, and road across borders. Cross-border trade also pushes manufacturers to comply with diverse regulatory, labeling, and safety requirements in different countries.

- protective packaging solutions support these needs by providing tamper resistance, moisture control, thermal insulation, and contamination prevention, especially for pharmaceuticals, electronics, automotive components, and food products.

For Instances

- In October 2024, the World Trade Organization (WTO) revised its forecast for world merchandise trade growth in 2024 to 2.7%, up slightly from the previous estimate of 2.6%, and to 3.0% in 2025.

- In November 2025, according to Press Information Bureau, India’s total exports (Merchandise and Services combined) for November 2025 are estimated at USD 73.99 billion, registering a positive growth of 15.52% vis-à-vis November 2024.

- In November 2025, the National Statistics Office of Vietnam reported that total trade turnover neared USD 840 billion by late November, up 17.2 percent from a year earlier. Exports reached more than USD 430 billion, a 16.1 percent gain that already topped the full-year 2024 figure.

- In November 2025, according to the Office for National Statistics (ONS), the Value of UK total trade in the 12 months to the end of September 2025 reached USD 2,518.47 billion, up 5.1% on the previous 12 months.

Restraint/Challenge

“Volatility in raw material”

- Volatility in raw material prices hampers demand for protective packaging as frequent cost fluctuations disrupt manufacturing budgets and pricing strategies. Sudden increases in pulp, paper, and resin prices raise production costs for protective packaging manufacturers, which forces them to increase product prices for end users.

- Many customers, especially small and medium enterprises, respond by reducing packaging usage, shifting to lower-grade materials, or delaying procurement decisions, which directly suppresses demand. Unstable raw material pricing also creates uncertainty across supply chains and discourages long-term investment in advanced protective packaging solutions. Manufacturers struggle to lock in contracts, maintain profit margins, and plan capacity expansion when input costs change unpredictably.

- As a result, companies prioritize cost control over packaging performance and sustainability upgrades, which slows the adoption of high-value protective packaging products and restrains overall market growth.

For Instances,

- In October 2024, The Times of India reported that kraft paper, a key raw material for corrugated boxes, “skyrocketed by more than 20% in the last three months,” putting severe cost pressure on corrugated-box manufacturers.

- In February 2025, the pulp and paper times newsletter observed that depreciation of the Indian Rupee and rising North America pulp prices (softwood pulp quoted around USD 890/ton) significantly increased the cost of imported raw materials for local paper manufacturers.

- In March 2021, The Economic Times reported that Indian corrugated box manufacturers were facing a raw material crisis as kraft paper prices had risen sharply over the preceding months, driven by increased pulp and paper exports to China, putting severe cost pressure on packaging suppliers.

- In July 2022, Tissue World Magazine reported that in North America, the price of eucalyptus will increase to USD 1,380 per tonne, while in North America, it will increase its prices by USD 40 per tonne, meaning that the cost of one tonne of eucalyptus pulp will now be USD 1,610.

North America Protective Packaging Market Scope

The North America North America Protective Packaging Market is categorized into five notable segments which are based on Product type, Material, Application, End User, Distribution Channel.

By Product Type

On the basis of Product type, North America Protective Packaging Market is segmented into Flexible, Rigid, Semi-Rigid.

The Flexible segment is expected to dominate the market with 65.92% market share and growing with the highest CAGR of 6.2%due to its widespread adoption across e-commerce, logistics, and consumer goods industries, driven by its lightweight nature, cost efficiency, and versatility. Flexible protective packaging solutions such as air pillows, bubble wrap, foam wraps, paper fillers, and cushioning envelopes offer effective shock absorption and void-filling capabilities while reducing overall package weight and transportation costs. The rapid growth of online retail and direct-to-consumer shipping has significantly increased demand for flexible packaging, as these materials are easy to use, scalable, and adaptable to products of varying shapes and size.

By Materials

On the basis Material, the North America Protective Packaging Market is segmented into Plastics, Paper & Paperboard, Foam, Metal, Others.

The Plastics segment is expected to dominate the market with 39.70% market share and CAGR of 6.4% due to its superior durability, versatility, and cost-effectiveness across a wide range of applications. Plastic materials such as polyethylene (PE), polypropylene (PP), polyurethane (PU), and polyvinyl chloride (PVC) offer excellent cushioning, impact resistance, moisture protection, and flexibility, making them highly suitable for safeguarding products during transportation and storage. These materials are widely used in flexible packaging formats such as air pillows, bubble wrap, and protective films, as well as in rigid and semi-rigid solutions, supporting demand across e-commerce, electronics, automotive, pharmaceutical, and industrial sectors. Plastics also enable lightweight packaging, which helps reduce shipping costs and improves logistics efficiency.

By Application

On the basis of Application, the North America Protective Packaging Market is segmented into Cushioning, Wrapping, Void Filling, Blocking & Bracing, Insulation, Others.

The Cushioning segment is expected to dominate the market with 37.33% market share CAGR of 6.6% due to growing need to protect products from shock, vibration, and impact damage throughout increasingly complex supply chains. Cushioning solutions are widely used across industries such as e-commerce, electronics, consumer goods, pharmaceuticals, and automotive, where preventing breakage and product returns is a critical priority. The rapid expansion of online retail and home delivery services has significantly increased demand for effective cushioning materials that can protect items during multiple handling stages and last-mile delivery. Cushioning materials such as bubble wrap, foam inserts, air pillows, and molded pulp provide adaptable protection for products of various shapes, sizes, and weights, making them highly versatile and cost-effective.

By End Use

On the basis of End User, the North America Protective Packaging Market is segmented into Automotive (2900), Industry, Trade (Retail) (4700), Logistics (4900), Others.

The Automotive (2900) segment is expected to dominate the market with 34.24% market share and CAGR of 6.7% due to the high value, complexity, and sensitivity of automotive components and systems that require robust protection during transportation and storage. Automotive manufacturers and suppliers handle a wide range of parts, including engines, transmissions, electronic modules, body panels, and precision components, all of which are vulnerable to shock, vibration, moisture, and corrosion. protective packaging solutions such as molded trays, foam blocks, corrugated boxes, and custom cushioning are essential to prevent damage, ensure component integrity, and maintain just-in-time manufacturing operations. The growth of electric vehicles and advanced automotive electronics has further increased demand for specialized protective packaging with enhanced cushioning and insulation properties.

By Distribution Channel

On the basis of Distribution Channel, the North America Protective Packaging Market is segmented into Direct and Indirect.

The Direct segment is expected to dominate the market with 65.17% market share and CAGR of 5.9% due to the increasing preference of manufacturers and large end users for direct procurement from packaging suppliers. Direct channels enable better customization, consistent quality control, and closer collaboration between packaging manufacturers and end-use industries such as automotive, electronics, pharmaceuticals, and e-commerce. Through direct sales, customers can obtain tailored protective packaging solutions designed to meet specific product dimensions, protection requirements, and sustainability goals, which is particularly important for high-volume and high-value shipments.

North America Protective Packaging Market Regional Analysis

- North America, accounts for 39.84% share in 2025 and projected to reach USD 25.51 billion by 2033. The region’s steady CAGR of 6.0% from 2026–2033 reflects mature but resilient demand, driven by strong e-commerce penetration, advanced logistics infrastructure, and high consumption of electronics, pharmaceuticals, and food products. Sustainability initiatives are shaping product

U.S. North America Protective Packaging Market Insight

U.S. dominates the North American North America Protective Packaging Market, accounting for 72.59% share in 2026 and projected to grow at a CAGR of 6.2% during 2026–2033. Growth is driven by the country’s large-scale e-commerce ecosystem, advanced manufacturing base, and strong demand from food & beverage, electronics, healthcare, and consumer goods industries. High shipment volumes and the need to minimize product damage during transit continue to boost demand for cushioning, void-fill, and protective wraps. Additionally, sustainability trends are influencing product innovation, with increasing adoption of recyclable and biodegradable materials. Ongoing investments in automation, warehousing, and logistics infrastructure further reinforce the U.S. market’s leadership position.

Canada North America Protective Packaging Market Insight

Canada represents a significant share of the North American North America Protective Packaging Market, holding 18.72% in 2026 and expected to grow at a CAGR of 5.7% through 2033. Market growth is supported by expanding e-commerce activity, strong food processing industries, and rising pharmaceutical shipments. Cross-border trade with the United States plays a crucial role, driving demand for reliable protective packaging solutions to ensure product safety during long-distance transportation. Sustainability is a key focus area, with Canadian companies increasingly adopting eco-friendly packaging materials in response to regulatory requirements and consumer preferences. Although smaller than the U.S. market, steady industrial activity and logistics modernization continue to support consistent growth.

North America Protective Packaging Market Share

The Protective Packaging industry is primarily led by well-established companies, including:

- AbrisoJiffy (Netherlands)

- ASH Automated Packaging Systems Inc. (U.S.)

- Atlas Roofing Corporation (U.S.)

- BASF (Germany)

- Blue Box Packaging (U.S.)

- Crown Holdings, Inc. (U.S.)

- Dow Inc. (U.S.)

- FlexiPack (India)

- Huhtamaki (Finland)

- International Paper (U.S.)

- IPG – Intertape Polymer Group (U.S.)

- Mondi Group (U.K.)

- NEFAB Group (Sweden)

- Novolex (U.S.

- Oasis Industries (U.S.)

- Packaging Corporation of America (U.S.)

- Packman Packaging Private Limited (India)

- Packtek (Canada)

- Pregis LLC (U.S.)

- ProAmpac (U.S.)

- Pro-Pac Packaging Limited (Australia)

- Ranpak (U.S.)

- Sealed Air (U.S.)

- Smurfit Westrock (Ireland)

- Sonoco Products Company (U.S.)

- Storopack Hans Reichenecker GmbH (Germany)

- UFP Technologies, Inc. (U.S.)

- Universal Protective Packaging, Inc. (U.S.)

- Veritiv Operating Company (U.S.)

Latest Developments in North America Protective Packaging Market

- In September 2025, Sealed Air Corporation is advancing its strategy as a one-stop shop for fulfillment operations with the launch of the AUTOBAG 850HB Hybrid Bagging Machine, a new automated bagging system engineered to run both poly and paper mailers.

- In November 2025, Smurfit Westrock inaugurated the first-of-its-kind adherence and clinical packaging facility, reinforcing Ireland’s role at the forefront of North America healthcare. Over €40 million was invested in the brand-new site, which will provide packaging solutions for clinical trials and regulated pharma packaging.

- In September 2025, Smurfit Westrock completed its 150th Design2Market project. Design2Market is Smurfit Westrock’s pioneering accelerated development process, dedicated to speeding up the journey from product design to availability in-market.

- In September 2024, Marigold Health Foods has collaborated with Sonoco, a North America leader in sustainable packaging solutions, to introduce a new, fully recyclable packaging solution for a range of plant-based food products, including stock cubes, sauces, and meat and fish alternatives. This innovative packaging marks a significant advancement in sustainable food packaging for consumers and industries alike.

- In October 2024, Sonoco introduces the latest paper packaging innovation with fully recyclable 95% paper-based cans. This more sustainable solution replaces the conventional metal bottom with a fibre-based bottom, making the entire can-body fully recyclable across households in the UK and mainland North America.

SKU-

Obtenga acceso en línea al informe sobre la primera nube de inteligencia de mercado del mundo

- Panel de análisis de datos interactivo

- Panel de análisis de empresas para oportunidades con alto potencial de crecimiento

- Acceso de analista de investigación para personalización y consultas

- Análisis de la competencia con panel interactivo

- Últimas noticias, actualizaciones y análisis de tendencias

- Aproveche el poder del análisis de referencia para un seguimiento integral de la competencia

Metodología de investigación

La recopilación de datos y el análisis del año base se realizan utilizando módulos de recopilación de datos con muestras de gran tamaño. La etapa incluye la obtención de información de mercado o datos relacionados a través de varias fuentes y estrategias. Incluye el examen y la planificación de todos los datos adquiridos del pasado con antelación. Asimismo, abarca el examen de las inconsistencias de información observadas en diferentes fuentes de información. Los datos de mercado se analizan y estiman utilizando modelos estadísticos y coherentes de mercado. Además, el análisis de la participación de mercado y el análisis de tendencias clave son los principales factores de éxito en el informe de mercado. Para obtener más información, solicite una llamada de un analista o envíe su consulta.

La metodología de investigación clave utilizada por el equipo de investigación de DBMR es la triangulación de datos, que implica la extracción de datos, el análisis del impacto de las variables de datos en el mercado y la validación primaria (experto en la industria). Los modelos de datos incluyen cuadrícula de posicionamiento de proveedores, análisis de línea de tiempo de mercado, descripción general y guía del mercado, cuadrícula de posicionamiento de la empresa, análisis de patentes, análisis de precios, análisis de participación de mercado de la empresa, estándares de medición, análisis global versus regional y de participación de proveedores. Para obtener más información sobre la metodología de investigación, envíe una consulta para hablar con nuestros expertos de la industria.

Personalización disponible

Data Bridge Market Research es líder en investigación formativa avanzada. Nos enorgullecemos de brindar servicios a nuestros clientes existentes y nuevos con datos y análisis que coinciden y se adaptan a sus objetivos. El informe se puede personalizar para incluir análisis de tendencias de precios de marcas objetivo, comprensión del mercado de países adicionales (solicite la lista de países), datos de resultados de ensayos clínicos, revisión de literatura, análisis de mercado renovado y base de productos. El análisis de mercado de competidores objetivo se puede analizar desde análisis basados en tecnología hasta estrategias de cartera de mercado. Podemos agregar tantos competidores sobre los que necesite datos en el formato y estilo de datos que esté buscando. Nuestro equipo de analistas también puede proporcionarle datos en archivos de Excel sin procesar, tablas dinámicas (libro de datos) o puede ayudarlo a crear presentaciones a partir de los conjuntos de datos disponibles en el informe.