Global Metal Bonding Adhesives Market

Taille du marché en milliards USD

TCAC :

%

USD

4.12 Billion

USD

6.35 Billion

2024

2032

USD

4.12 Billion

USD

6.35 Billion

2024

2032

| 2025 –2032 | |

| USD 4.12 Billion | |

| USD 6.35 Billion | |

|

|

|

|

Global Metal Bonding Adhesives Market, By Resin Type (Epoxy-based Metal Bonding Adhesives, Acrylic-based Metal Bonding Adhesives, Polyurethane-based Metal Bonding Adhesives, Silicone- based Metal Bonding Adhesives, and Others), Application (Automotive, Aerospace and Defense, Electrical and Electronics, Industrial Assembly, Construction and Infrastructure, Marine, Medical, and Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa)- Industry Trends and Forecast to 2032

Metal Bonding Adhesives Market Size

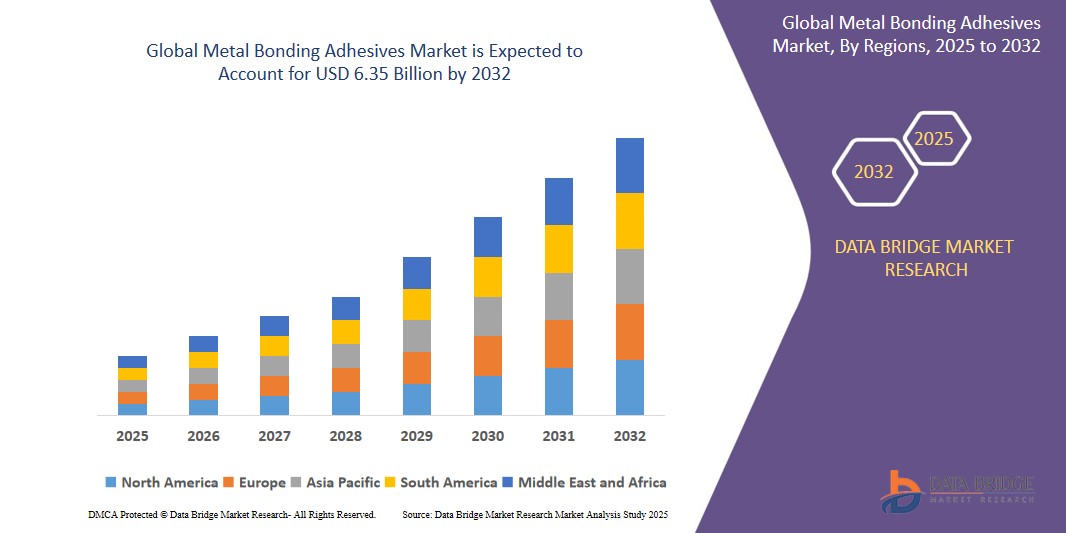

- The Global Metal Bonding Adhesives Market was valued atUSD 4.12 Billion in 2024 and is expected to reachUSD 6.35 Billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at aCAGR of 5.60%, primarily driven by the demand for lightweight, durable, and corrosion-resistant solutions in automotive, aerospace, electronics, and construction industries, ensuring strong, long-lasting bonds between metal surfaces.

- The growth of the global Metal Bonding Adhesives market is driven by demand for strength, durability, corrosion resistance, and lightweight assembly.

Metal Bonding Adhesives Market Analysis

- The market is expanding due to increasing demand for lightweight materials, high-performance bonding solutions in automotive, aerospace, and electronics sectors, and the shift from mechanical fasteners to adhesives.

- Innovations in epoxy, acrylic, and polyurethane adhesives offer enhanced strength, flexibility, and heat resistance, supporting broader applications across extreme environments and enabling the replacement of welding or riveting in metal joining.

- Environmental regulations and the push for sustainable manufacturing are driving the adoption of solvent-free, low-VOC metal bonding adhesives, aligning with green initiatives across automotive, electronics, and construction industries.

Report Scope and Metal Bonding Adhesives Market Segmentation

|

Attributes |

Metal Bonding Adhesives Key Market Insights |

|

Segments Covered |

•By Resin Type:Epoxy-based Metal Bonding Adhesives, Acrylic-based Metal Bonding Adhesives, Polyurethane-based Metal Bonding Adhesives, Silicone- based Metal Bonding Adhesives, and Others •By Application:Automotive, Aerospace and Defense, Electrical and Electronics, Industrial Assembly, Construction and Infrastructure, Marine, Medical, and Others |

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metal Bonding Adhesives Market Trends

“Growing demand for lightweight, durable adhesives in automotive and aerospace industries”

- Automotive manufacturers are increasingly using metal bonding adhesives to reduce vehicle weight, improve fuel efficiency, and enhance crash performance without compromising structural integrity.

- In aerospace, adhesives are replacing traditional fasteners to lower aircraft weight, improve aerodynamics, and ensure high durability under extreme temperature and pressure conditions.

➤ For instance, High-performance aerospace adhesives are vital for modern aircraft, offering benefits like weight reduction, improved aerodynamics, structural integrity, and enhanced durability. They simplify assembly, resist harsh conditions, and ensure long-term reliability across components—from interiors to engines—making them essential for safe, efficient, and innovative aerospace manufacturing and maintenance processes.

- Lightweight, durable adhesives support design flexibility, corrosion resistance, and long-term reliability, making them ideal for next-generation transportation technologies in both commercial and defense sectors.

Metal Bonding Adhesives Market Dynamics

Driver

“Technological advancements in adhesives improve aerospace design flexibility, reduce weight, and enhance durability.”

- Technological advancements in adhesives enable lightweight bonding solutions, reducing the overall weight of aerospace structures and enhancing fuel efficiency without compromising the structural integrity of components.

- New adhesive technologies allow for greater design flexibility, enabling the bonding of dissimilar materials like composites and metals, fostering innovation in aerospace component manufacturing and assembly.

- Improved adhesive formulations offer enhanced durability by resisting extreme environmental factors such as temperature fluctuations, vibrations, and UV radiation, ensuring longer lifespans for aerospace components and structures.

- Advanced aerospace adhesives provide excellent fatigue resistance, improving the overall performance and safety of aircraft by reducing stress concentrations and preventing material failure during high-stress operations.

Opportunity

“Increased demand for lightweight, durable adhesives in aerospace”

- As aerospace manufacturers seek to improve fuel efficiency, the demand for lightweight adhesives grows, offering cost-effective, strong bonding solutions while reducing overall aircraft weight and improving performance.

- Increased focus on sustainability and environmental regulations creates an opportunity for adhesives that reduce the carbon footprint, contributing to more efficient aircraft production with lower environmental impact.

- Technological advancements in adhesives enable faster, more reliable assembly processes, reducing labor costs and production time, which boosts profitability in the aerospace manufacturing and repair industries.

- The demand for high-performance adhesives in critical aerospace applications, such as engine components and composite bonding, presents opportunities for innovation, leading to stronger, longer-lasting materials and components.

Restraint/Challenge

“High cost and regulatory compliance challenges hinder adhesive adoption”

- The high initial cost of advanced aerospace adhesives makes adoption challenging for manufacturers, particularly smaller companies, limiting their access to cutting-edge bonding solutions despite long-term benefits.

- Adherence to stringent regulatory standards, such as aerospace certifications and environmental compliance, increases the complexity and cost of adhesive production, slowing down innovation and industry-wide adoption.

- Limited knowledge and training among industry professionals on new adhesive technologies and proper application techniques pose challenges, potentially leading to inefficiencies and inconsistent performance in aerospace manufacturing.

Metal Bonding Adhesives Market Scope

The market is segmented on the basis of resin type and application.

|

Segmentation |

Sub-Segmentation |

|

By Resin Type |

|

|

By Application |

|

Metal Bonding Adhesives Market Regional Analysis

“The Asia Pacific (APAC) is the Dominant Region in the Metal Bonding Adhesives Market”

- The Asia-Pacific region leads the global metal bonding adhesives market, driven by strong growth in the automotive and aerospace industries, particularly in China, Japan, and India.

- Manufacturing hubs in countries like India, Thailand, and Indonesia offer cost-effective labor and raw materials, boosting the demand for metal bonding adhesives in the region.

- The increasing demand for electric vehicles and the expansion of automotive production in Asia further propel the need for innovative adhesive solutions, reinforcing the region's market dominance.

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific region is expected to experience rapid growth due to increasing industrialization, urbanization, and manufacturing activities, particularly in China and India.

- Expansion of automotive, electronics, and construction sectors in Asia-Pacific countries drives demand for advanced metal bonding adhesives across industries.

- Relocation of manufacturing hubs to cost-effective locations like India and Southeast Asia boosts adhesive market growth through competitive advantages.

Metal Bonding Adhesives Market Share

The competitive landscape of the Metal Bonding Adhesives market offers insights into key players and their market positioning. Key details include company overview, financial performance, revenue generation, market potential, and investment in research and development. Additionally, the analysis covers new market initiatives, global presence, production facilities, manufacturing capacities, and strategic expansions. Companies are evaluated based on their strengths, weaknesses, product innovation, and competitive advantages in nutraceuticals, pharmaceuticals, cosmetics, and functional foods.

The Major Market Leaders Operating in the Market Are:

- Henkel AG & Co. KGaA (Germany)

- 3M Company (U.S.)

- H.B. Fuller Company (U.S.)

- Sika AG (Switzerland)

- Lord Corporation (U.S.)

- ITW Performance Polymers (U.S.)

- Messer Group (Germany)

- Ashland Global Holdings Inc. (U.S.)

- BASF SE (Germany)

- The Dow Chemical Company (U.S.)

- Scotchman Industries (U.S.)

- Wacker Chemie AG (Germany)

- Permabond LLC (U.S.)

- LORD Corporation (U.S.)

- Cytec Industries Inc. (U.S.)

Latest Developments in Global Metal Bonding Adhesives Market

- Henkel showcased its innovative adhesive solutions at Interzum 2024, including the TECHNOMELT PUR 270 series. This polyurethane-based adhesive offers high initial strength, low application weight, and excellent temperature resistance, ideal for edge banding in furniture manufacturing. It enhances production efficiency while ensuring durability and versatility for various substrates.

SKU-

Accédez en ligne au rapport sur le premier cloud mondial de veille économique

- Tableau de bord d'analyse de données interactif

- Tableau de bord d'analyse d'entreprise pour les opportunités à fort potentiel de croissance

- Accès d'analyste de recherche pour la personnalisation et les requêtes

- Analyse de la concurrence avec tableau de bord interactif

- Dernières actualités, mises à jour et analyse des tendances

- Exploitez la puissance de l'analyse comparative pour un suivi complet de la concurrence

Méthodologie de recherche

La collecte de données et l'analyse de l'année de base sont effectuées à l'aide de modules de collecte de données avec des échantillons de grande taille. L'étape consiste à obtenir des informations sur le marché ou des données connexes via diverses sources et stratégies. Elle comprend l'examen et la planification à l'avance de toutes les données acquises dans le passé. Elle englobe également l'examen des incohérences d'informations observées dans différentes sources d'informations. Les données de marché sont analysées et estimées à l'aide de modèles statistiques et cohérents de marché. De plus, l'analyse des parts de marché et l'analyse des tendances clés sont les principaux facteurs de succès du rapport de marché. Pour en savoir plus, veuillez demander un appel d'analyste ou déposer votre demande.

La méthodologie de recherche clé utilisée par l'équipe de recherche DBMR est la triangulation des données qui implique l'exploration de données, l'analyse de l'impact des variables de données sur le marché et la validation primaire (expert du secteur). Les modèles de données incluent la grille de positionnement des fournisseurs, l'analyse de la chronologie du marché, l'aperçu et le guide du marché, la grille de positionnement des entreprises, l'analyse des brevets, l'analyse des prix, l'analyse des parts de marché des entreprises, les normes de mesure, l'analyse globale par rapport à l'analyse régionale et des parts des fournisseurs. Pour en savoir plus sur la méthodologie de recherche, envoyez une demande pour parler à nos experts du secteur.

Personnalisation disponible

Data Bridge Market Research est un leader de la recherche formative avancée. Nous sommes fiers de fournir à nos clients existants et nouveaux des données et des analyses qui correspondent à leurs objectifs. Le rapport peut être personnalisé pour inclure une analyse des tendances des prix des marques cibles, une compréhension du marché pour d'autres pays (demandez la liste des pays), des données sur les résultats des essais cliniques, une revue de la littérature, une analyse du marché des produits remis à neuf et de la base de produits. L'analyse du marché des concurrents cibles peut être analysée à partir d'une analyse basée sur la technologie jusqu'à des stratégies de portefeuille de marché. Nous pouvons ajouter autant de concurrents que vous le souhaitez, dans le format et le style de données que vous recherchez. Notre équipe d'analystes peut également vous fournir des données sous forme de fichiers Excel bruts, de tableaux croisés dynamiques (Fact book) ou peut vous aider à créer des présentations à partir des ensembles de données disponibles dans le rapport.