Global Chemical Sensor Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

34.58 Billion

USD

57.45 Billion

2025

2033

USD

34.58 Billion

USD

57.45 Billion

2025

2033

| 2026 –2033 | |

| USD 34.58 Billion | |

| USD 57.45 Billion | |

|

|

|

|

Global Chemical Sensor Market Segmentation, By Product Type (Electrochemical, Optical, Pellistor/Catalytic Bead, and Others), Particulate Type (Solid, Liquid, and Gas), Technology (Electromechanical, Biochemical, Electrical, Thermometric, and Others), End User (Industrial, Environmental Monitoring, Medical, Agriculture, Defense and Homeland Security, Oil and Gas, and Others)- Industry Trends and Forecast to 2033

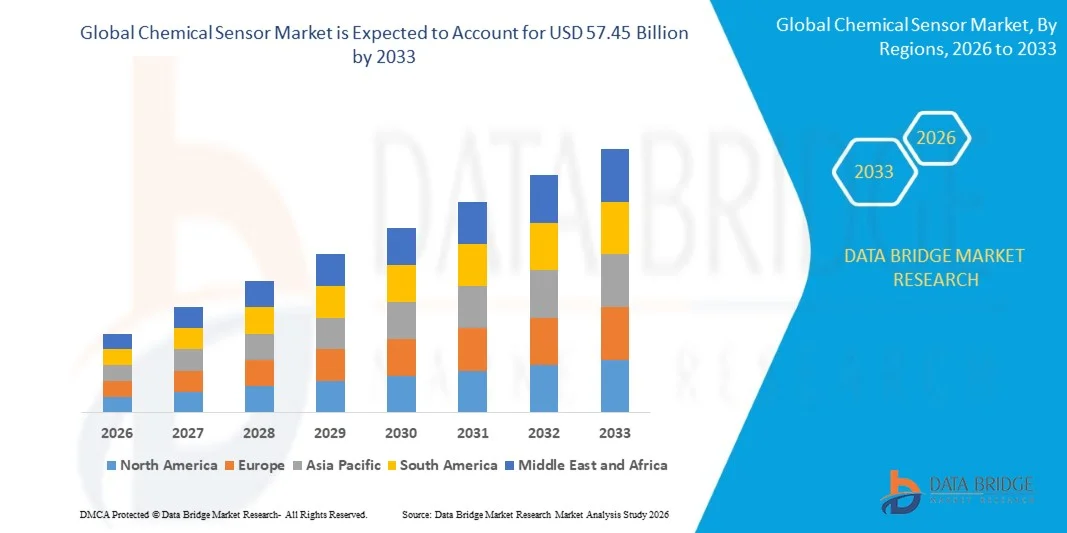

Chemical Sensor Market Size

- The global chemical sensor market size was valued at USD 34.58 billion in 2025 and is expected to reach USD 57.45 billion by 2033, at a CAGR of 6.55% during the forecast period

- The market growth is largely fuelled by the increasing demand for industrial automation, stringent environmental monitoring regulations, and rising adoption of chemical sensors in healthcare, food & beverage, and oil & gas sectors

- Growing technological advancements in sensor materials and miniaturization of devices are further supporting market expansion

Chemical Sensor Market Analysis

- The chemical sensor market is witnessing significant adoption across industrial, healthcare, and environmental monitoring applications

- The increasing need for real-time detection, high sensitivity, and precision in chemical analysis is propelling demand

- North America dominated the chemical sensor market with the largest revenue share of 37.89% in 2025, driven by stringent industrial safety regulations, high adoption of process monitoring systems, and increasing demand for environmental monitoring solutions

- Asia-Pacific region is expected to witness the highest growth rate in the global chemical sensor market, driven by expanding industrial operations, government initiatives for workplace safety and environmental monitoring, and rising demand for cost-effective and technologically advanced sensors

- The Electrochemical segment held the largest market revenue share in 2025, driven by its high sensitivity, reliability, and widespread use in industrial and environmental monitoring applications. Electrochemical sensors are particularly effective for detecting specific gases and chemicals at low concentrations, making them a preferred choice for safety and compliance monitoring

Report Scope and Chemical Sensor Market Segmentation

|

Attributes |

Chemical Sensor Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Chemical Sensor Market Trends

“Rising Demand for Real-Time Monitoring and Industrial Safety”

• The increasing emphasis on workplace safety and environmental monitoring is significantly shaping the chemical sensor market, as industries increasingly require accurate, real-time detection of chemical hazards. Chemical sensors are gaining traction due to their ability to provide precise monitoring, early warning, and compliance with safety regulations across oil & gas, chemical, and manufacturing sectors. This trend encourages adoption in industrial, environmental, and healthcare applications

• Growing awareness around environmental protection, regulatory compliance, and industrial automation has accelerated the demand for chemical sensors in process monitoring, pollution control, and laboratory analysis. Organizations are actively seeking reliable and high-precision sensors, prompting collaborations between sensor manufacturers and end-user industries to enhance detection capabilities and operational safety

• Safety and sustainability trends are influencing purchasing decisions, with companies emphasizing accurate monitoring, regulatory compliance, and eco-friendly practices. These factors help industries minimize risks, optimize processes, and build a safety-oriented operational culture, while also driving certifications and adherence to international standards

• For instance, in 2024, Honeywell in the U.S. and Siemens in Germany expanded their chemical sensor portfolios by introducing advanced gas detection and process monitoring sensors. These launches were in response to rising industrial safety and environmental monitoring requirements, with distribution across industrial, laboratory, and environmental monitoring channels. The products were also promoted as reliable and regulatory-compliant solutions, enhancing operational safety and trust among industrial clients

• While demand for chemical sensors is growing, sustained market expansion depends on continuous R&D, cost-effective production, and maintaining high sensitivity and accuracy. Manufacturers are also focusing on improving scalability, sensor durability, and developing innovative solutions that balance cost, performance, and regulatory compliance for broader adoption

Chemical Sensor Market Dynamics

Driver

“Rising Industrial Safety and Environmental Monitoring Requirements”

• Increasing regulatory standards and safety mandates are a major driver for the chemical sensor market. Industries are adopting advanced sensors to detect hazardous gases, ensure process safety, and comply with environmental regulations, pushing research into novel sensing technologies and materials

• Expanding applications across oil & gas, chemical processing, water treatment, and healthcare are influencing market growth. Chemical sensors enhance monitoring accuracy, process control, and environmental compliance, enabling industries to meet operational and safety standards. The rise of industrial automation and smart factory initiatives further reinforces this trend

• Companies are actively promoting chemical sensor-based solutions through product innovation, marketing campaigns, and adherence to certifications. These efforts are supported by increasing demand for workplace safety, precise detection, and regulatory compliance, encouraging partnerships between sensor manufacturers and end-user industries

• For instance, in 2023, Emerson Electric in the U.S. and ABB in Switzerland reported increased deployment of chemical sensors in process control and environmental monitoring. This expansion followed higher industrial safety and environmental compliance requirements, driving operational efficiency and market adoption. Both companies also highlighted sensor precision, durability, and compliance in marketing campaigns to strengthen trust and customer confidence

• Although rising industrial safety and monitoring trends support growth, wider adoption depends on cost optimization, sensor availability, and scalable production processes. Investment in supply chain efficiency, material sourcing, and advanced sensor technology will be critical for meeting global demand and maintaining competitive advantage

Restraint/Challenge

“High Cost And Technical Complexity Compared To Conventional Sensors”

• The relatively higher cost of advanced chemical sensors compared to conventional detection methods remains a key challenge, limiting adoption among price-sensitive industries. High material and manufacturing costs, along with complex calibration and maintenance requirements, contribute to elevated pricing

• Awareness and understanding of sensor capabilities remain uneven, particularly in developing markets where industrial automation and environmental monitoring are still emerging. Limited knowledge of functional benefits restricts adoption across certain applications, leading to slower market penetration in these regions

• Supply chain and operational challenges also impact market growth, as chemical sensors require precise manufacturing, quality control, and sometimes specialized installation. Logistical complexities and technical training requirements increase operational costs. Companies must invest in proper handling, calibration, and maintenance infrastructure to maintain sensor accuracy

• For instance, in 2024, distributors in India and Brazil supplying sensors for chemical plants and environmental monitoring reported slower uptake due to higher costs and limited technical awareness. Calibration and maintenance requirements were additional barriers, affecting adoption rates among smaller industrial players

• Overcoming these challenges will require cost-efficient manufacturing, expanded technical support networks, and focused educational initiatives for end-users. Collaboration with industrial clients, regulatory bodies, and technology partners can help unlock the long-term growth potential of the global chemical sensor market. Furthermore, developing cost-competitive, user-friendly, and durable sensors will be essential for widespread adoption

Chemical Sensor Market Scope

The market is segmented on the basis of product type, particulate type, technology, and end user.

• By Product Type

On the basis of product type, the chemical sensor market is segmented into Electrochemical, Optical, Pellistor/Catalytic Bead, and Others. The Electrochemical segment held the largest market revenue share in 2025, driven by its high sensitivity, reliability, and widespread use in industrial and environmental monitoring applications. Electrochemical sensors are particularly effective for detecting specific gases and chemicals at low concentrations, making them a preferred choice for safety and compliance monitoring.

The Pellistor/Catalytic Bead segment is expected to witness the fastest growth rate from 2026 to 2033, driven by its durability, accuracy in combustible gas detection, and suitability for harsh industrial environments. These sensors are increasingly adopted in oil & gas, chemical, and mining sectors for their reliable performance and ability to integrate with automated safety systems.

• By Particulate Type

On the basis of particulate type, the chemical sensor market is segmented into Solid, Liquid, and Gas. The Gas segment held the largest revenue share in 2025, fueled by growing industrial and environmental monitoring requirements. Gas sensors are widely used for workplace safety, emissions monitoring, and leak detection, ensuring compliance with safety regulations.

The Liquid segment is expected to witness the fastest growth rate from 2026 to 2033, driven by rising demand in water quality monitoring, chemical processing, and pharmaceutical applications. Liquid chemical sensors are valued for their precision, rapid response, and ability to operate in diverse environmental conditions.

• By Technology

On the basis of technology, the chemical sensor market is segmented into Electromechanical, Biochemical, Electrical, Thermometric, and Others. The Electrical segment held the largest market revenue share in 2025, due to its versatility, high accuracy, and compatibility with industrial automation and IoT-enabled monitoring systems.

The Biochemical segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by increasing applications in medical diagnostics, environmental monitoring, and food safety. Biochemical sensors offer high specificity and sensitivity, making them suitable for detecting low concentrations of biological and chemical analytes.

• By End User

On the basis of end user, the chemical sensor market is segmented into Industrial, Environmental Monitoring, Medical, Agriculture, Defense and Homeland Security, Oil and Gas, and Others. The Industrial segment held the largest revenue share in 2025, driven by the need for workplace safety, process optimization, and regulatory compliance across chemical, oil & gas, and manufacturing facilities.

The Environmental Monitoring segment is expected to witness the fastest growth rate from 2026 to 2033, propelled by increasing awareness of environmental protection, stringent emission norms, and rising adoption of real-time monitoring solutions in air, water, and soil quality assessment.

Chemical Sensor Market Regional Analysis

• North America dominated the chemical sensor market with the largest revenue share of 37.89% in 2025, driven by stringent industrial safety regulations, high adoption of process monitoring systems, and increasing demand for environmental monitoring solutions

• Industries in the region highly value the accuracy, reliability, and real-time monitoring capabilities offered by chemical sensors for workplace safety, emissions control, and process optimization

• This widespread adoption is further supported by well-established industrial infrastructure, high awareness of occupational safety standards, and growing integration of automated and IoT-enabled monitoring systems, establishing chemical sensors as a critical solution for industrial and environmental applications

U.S. Chemical Sensor Market Insight

The U.S. chemical sensor market captured the largest revenue share in 2025 within North America, fueled by extensive deployment across oil & gas, chemical processing, and manufacturing sectors. Industries are increasingly prioritizing workplace safety, process efficiency, and regulatory compliance through high-precision sensors. The growing integration of IoT-enabled monitoring systems and advanced automation technologies further propels market expansion. Moreover, government regulations and safety standards, such as OSHA and EPA mandates, are significantly contributing to adoption across industrial facilities.

Europe Chemical Sensor Market Insight

The Europe chemical sensor market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by stringent environmental regulations, increasing industrial automation, and the growing need for real-time chemical monitoring in manufacturing and environmental applications. Rising urbanization, along with a focus on sustainability and precision monitoring, is fostering adoption across industrial, environmental, and healthcare sectors.

U.K. Chemical Sensor Market Insight

The U.K. chemical sensor market is expected to witness the fastest growth rate from 2026 to 2033, driven by expanding industrial safety initiatives and demand for precise process and environmental monitoring. In addition, regulatory compliance and the adoption of automated monitoring systems are encouraging industries to deploy advanced chemical sensors. The U.K.’s emphasis on innovation and environmental responsibility is expected to continue stimulating market growth.

Germany Chemical Sensor Market Insight

The Germany chemical sensor market is expected to witness the fastest growth rate from 2026 to 2033, fueled by rising awareness of workplace safety, technological innovation, and stringent environmental regulations. Germany’s strong industrial base, emphasis on precision manufacturing, and sustainability initiatives promote the adoption of chemical sensors across industrial, environmental, and laboratory applications. Integration with automated and IoT-enabled systems is increasingly prevalent, aligning with consumer and regulatory expectations.

Asia-Pacific Chemical Sensor Market Insight

The Asia-Pacific chemical sensor market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid industrialization, expanding oil & gas and chemical operations, and growing awareness of environmental monitoring in countries such as China, Japan, and India. The region’s increasing adoption of automated processes, government initiatives promoting industrial safety, and expansion of sensor manufacturing capabilities are fueling market growth. Furthermore, APAC’s cost-effective production and rising local demand are enhancing sensor accessibility.

Japan Chemical Sensor Market Insight

The Japan chemical sensor market is expected to witness the fastest growth rate from 2026 to 2033 due to the country’s technologically advanced industrial landscape, high safety standards, and strong focus on precision monitoring. Adoption is driven by increasing automation, smart factory initiatives, and environmental monitoring requirements. Integration with IoT and industrial control systems, combined with emphasis on sensor reliability and accuracy, is supporting market growth across industrial and environmental sectors.

China Chemical Sensor Market Insight

The China chemical sensor market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to rapid industrial growth, high chemical and manufacturing activity, and strong regulatory enforcement. China is one of the largest markets for chemical sensors, with widespread adoption across industrial, environmental, and laboratory applications. Government initiatives for industrial safety, environmental monitoring, and smart manufacturing, along with strong domestic sensor production, are key factors propelling the market in China.

Chemical Sensor Market Share

The Chemical Sensor industry is primarily led by well-established companies, including:

- ABB (Switzerland)

- BorgWarner Inc. (U.S.)

- Bosch Rexroth AG (Germany)

- Siemens (Germany)

- DENSO CORPORATION (Japan)

- Emerson Electric Co. (U.S.)

- Yokogawa India Ltd. (India)

- Halma plc (U.K.)

- Thermo Fisher Scientific Inc. (U.S.)

- NGK Spark Plugs USA, Inc. (U.S.)

- Alphasense (U.K.)

- AMETEK Inc. (U.S.)

- Alpha MOS (France)

- Honeywell International Inc. (U.S.)

- Figaro Engineering Inc. (Japan)

- NXP Semiconductors (Netherlands)

- Heraeus Holding (Germany)

- General Electric Company (U.S.)

- TE Connectivity (Switzerland)

- Rockwell Automation, Inc. (U.S.)

- STMicroelectronics (Switzerland)

- Infineon Technologies AG (Germany)

- Pepperl+Fuchs (Germany)

Latest Developments in Global Chemical Sensor Market

- In August 2025, Honeywell (U.S.) launched a new line of smart chemical sensors for industrial applications, incorporating advanced AI algorithms to improve detection accuracy and response times. This development strengthens Honeywell’s position in the chemical sensor market by addressing the rising demand for intelligent monitoring solutions and supporting digital transformation initiatives, potentially increasing its market share

- In September 2025, Siemens (Germany) announced a partnership with a leading software company to integrate AI capabilities into its chemical sensor products. The collaboration aims to enhance predictive maintenance features, improving operational efficiency for end-users and enabling Siemens to offer advanced, future-ready solutions, thereby reinforcing its competitive advantage

- In July 2025, Emerson Electric (U.S.) introduced an initiative to develop environmentally friendly chemical sensors that comply with global regulatory standards. This move highlights Emerson’s focus on sustainability, attracting customers prioritizing green technology, and strengthening its position in the market for eco-conscious industrial monitoring solutions

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.