Global High Speed Steels Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

4.57 Billion

USD

7.20 Billion

2024

2032

USD

4.57 Billion

USD

7.20 Billion

2024

2032

| 2025 –2032 | |

| USD 4.57 Billion | |

| USD 7.20 Billion | |

|

|

|

|

Global High Speed Steels Market Segmentation, By Type (Tungsten High Speed Steel, Molybdenum High Speed Steel, Cobalt High Speed Steel, Others), Product Type (Metal Cutting Tools, Cold Working Tools, Others), Production Method (Conventional HSS, Powder Metallurgy (PM) HSS, Spray Forming (SF) HSS), Grade (M Grade, T Grade, Advance Grade), End User (Automotive Industry, Plastic Industry, Aerospace Industry, Energy Sector, Manufacturing, Mechanical Engineering, Construction, Others) - Industry Trends and Forecast to 2032

High Speed Steels Market Size

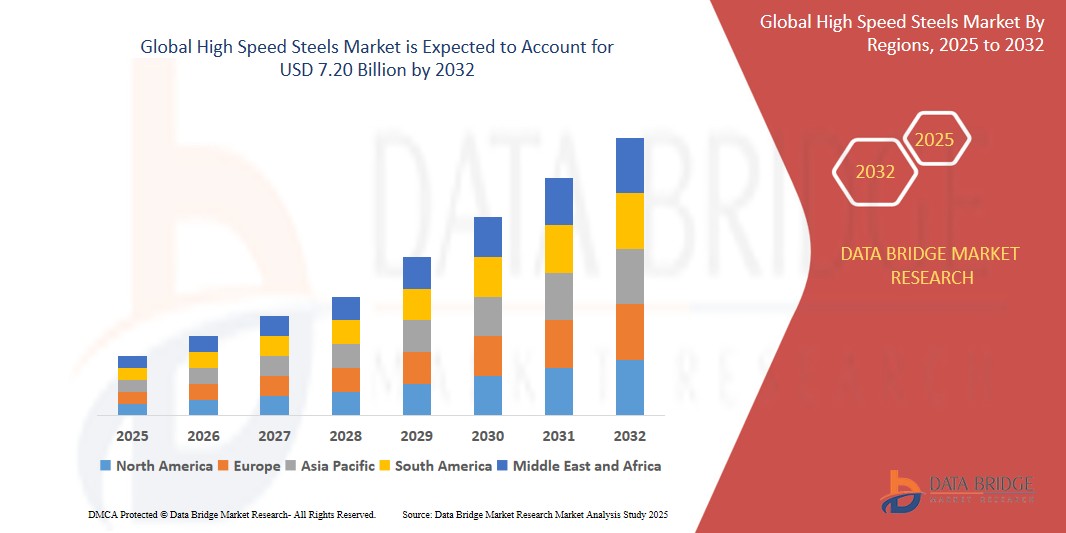

- The global High Speed Steels market was valued atUSD 4.57 billion in 2024 and is expected to reachUSD 7.20 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at aCAGR of 5.85%, primarily driven by the broadly used for metal cutting

- This growth is driven by factors such as These steels have broad application portfolio and witness high demand in various end-use industries.

High Speed Steels Market Analysis

- High-speed steels (HSS) are essential materials used in the production of tools that operate at high cutting speeds and temperatures. These steels are critical in manufacturing processes such as drilling, cutting, and machining, with key applications in industries like automotive, aerospace, and industrial machinery.

- The demand for high-speed steels is largely driven by the increasing need for precision tools in industries requiring high-performance machining. The growth of industries such as automotive, aerospace, and manufacturing is a major factor propelling the market, particularly in regions with a strong industrial base.

- The Asia-Pacific region is the largest market for high-speed steels, with China, India, and Japan being significant contributors. The region's growing industrialization and manufacturing capabilities continue to support the demand for high-speed steels, especially in automotive and machinery sectors.

- For instance, China's automotive industry alone contributes substantially to the demand for high-speed steels, as the country is a major producer of automotive parts and components that require precision cutting tools.

- Globally, high-speed steels are considered one of the most critical materials for cutting tools in industrial manufacturing, following carbide-based tools in terms of importance. Their superior wear resistance and ability to maintain hardness at high temperatures make them indispensable for efficient and high-precision operations.

Report Scope and High Speed Steels Market Segmentation

|

Attributes |

High Speed Steels Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

High Speed Steels Market Trends

“Increased Demand for High-Performance Cutting Tools”

- One prominent trend in the global High-Speed Steels market is the increasing demand for high-performance cutting tools across various industries.

- High-speed steels are increasingly used in advanced machining processes due to their superior wear resistance, high hardness, and ability to maintain performance at elevated temperatures, making them ideal for precision cutting in automotive, aerospace, and industrial manufacturing.

- For instance, in the automotive industry, high-speed steels are being used to manufacture more complex and precise components, which are crucial for improving fuel efficiency and reducing emissions.

- Additionally, the rise in the production of high-precision tools and equipment, driven by technological advancements, is fueling the demand for high-speed steels with specialized properties, such as improved cutting performance and longer tool life.

- This trend is reshaping the global manufacturing landscape, leading to increased demand for advanced cutting tools and strengthening the position of high-speed steels in the market.

High Speed Steels Market Dynamics

Driver

“Rising Demand for High-Performance Cutting Tools in Industrial Applications”

- The increasing need for precision and high-efficiency tools in industries such as automotive, aerospace, and manufacturing is significantly driving the demand for high-speed steels.

- As manufacturing processes become more advanced, industries are looking for cutting tools that can withstand high temperatures, provide extended tool life, and deliver superior performance. High-speed steels meet these needs due to their ability to maintain hardness even at elevated temperatures.

- Automotive and aerospace industries, in particular, require high-speed steels to manufacture intricate components with tight tolerances, driving the demand for durable, high-performance materials.

- The ongoing technological advancements and the shift toward high-efficiency manufacturing practices are expected to further fuel the demand for high-speed steels, which are essential for ensuring the precision and durability of cutting tools.

For instance,

- In July 2023, according to a report by Market Research Future, the aerospace sector’s demand for high-performance materials, including high-speed steels, is expected to grow due to the increasing production of complex parts required in jet engines and aircraft manufacturing.

Opportunity

“Rising Adoption of Additive Manufacturing for Tool Production”

- The growing use of additive manufacturing (3D printing) presents an exciting opportunity for high-speed steels. This technology allows for the production of tools with complex geometries that were previously not possible with traditional methods, enhancing the performance of cutting tools.

- Additive manufacturing enables precise control over the material's structure and composition, potentially improving the properties of high-speed steels and extending their lifespan.

- The use of high-speed steels in additive manufacturing can result in customized cutting tools that meet the specific needs of various industries, driving new applications and increasing demand.

For instance,

- In December 2023, a report from Metal Additive Manufacturing Magazine highlighted the growing adoption of 3D printing in aerospace and automotive industries, with additive manufacturing of cutting tools using high-speed steels providing improved cutting efficiency and reduced material waste.

- The integration of AI in ophthalmic microscopes can also lead to improved patient outcomes, reduced recovery times, and enhanced quality of life. By leveraging AI-powered image analysis, surgeons can identify patients at risk for complications and take proactive measures to prevent them.

Restraint/Challenge

“High Production Costs and Price Volatility”

- The high cost of producing high-speed steels remains a significant challenge for the market. These steels require specialized manufacturing processes, including advanced heat treatments and alloying, which contribute to their high price.

- The price volatility of raw materials, such as tungsten and molybdenum, which are essential components of high-speed steels, further complicates production costs and affects market prices.

- Smaller manufacturers and emerging economies may face challenges in affording these high-cost materials, potentially hindering the adoption of high-speed steels in certain industries.

For instance,

- In November 2023, according to a report from the World Steel Association, fluctuations in the prices of raw materials such as tungsten and cobalt have created price volatility in high-speed steels, making it difficult for companies to maintain cost-effective production. This has led to concerns about the affordability and sustainability of using high-speed steels in low-margin industries.

High Speed Steels Market Scope

The market is segmented on the basis Type, product type, Production Method, Grade, end user, and distribution channel.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Product Type |

|

|

By End User |

|

|

By Grade

|

|

|

By Production Method |

|

|

By Distribution Channel

|

|

High Speed Steels Market Regional Analysis

“North America is the Dominant Region in the High Speed Steels Market”

- North America dominates the High-Speed Steels market, driven by a well-established industrial base, advanced manufacturing technologies, and the presence of major automotive, aerospace, and machinery industries.

- The U.S. holds a significant market share due to high demand for high-precision cutting tools in automotive, aerospace, and industrial applications, where high-speed steels are crucial for efficient and high-performance operations.

- The region’s advanced manufacturing capabilities, coupled with robust R&D investments from leading industrial players, further strengthen the market.

- Additionally, the rapid adoption of automation and smart manufacturing systems in North American industries has increased the need for advanced tools made from high-speed steels, thereby contributing to the region’s dominance in the global market.

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific region is expected to witness the highest growth rate in the High Speed Steels market, driven by rapid industrialization, expansion in manufacturing sectors, and increasing demand for advanced cutting tools.

- Countries such as China, India, and Japan are emerging as key markets due to their growing manufacturing industries and demand for precision tools in automotive, aerospace, and heavy machinery.

- Japan, with its advanced manufacturing techniques and emphasis on high-quality industrial production, remains a significant market for high-speed steels, particularly in the automotive and aerospace sectors.

- China and India, with their large industrial bases and growing demand for high-precision tools, are seeing increased investments in modern manufacturing facilities and cutting-edge technologies. The rising production of automotive parts, machinery, and electronics is boosting the demand for high-speed steels, driving substantial market growth in these countries.

High Speed Steels Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, Type dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

• NACHI-FUJIKOSHI CORP. (Japan)

• Daido Steel (Japan)

• voestalpine High Performance Metals GmbH (Austria)

• Sandvik AB (Sweden)

• Kennametal Inc. (United States)

• Hudson Tool Steel Corporation (United States)

• ERASTEEL (Sweden)

• Friedr. Lohmann GmbH (Germany)

• ArcelorMittal (Luxembourg)

• thyssenkrupp Materials France (France)

• Guhring, Inc. (Germany)

• Heye Special Steel Co., Ltd. (China)

• NIPPON KOSHUHA STEEL CO., LTD. (Japan)

• OSG Corporation (Japan)

• Graphite India Limited (India)

• Crucible Industries LLC (United States)

• DNEPROSPETSSTAL (Ukraine)

• West Yorkshire Steel Ltd. (United Kingdom)

• BIG KAISER Precision Tooling Inc. (Switzerland)

• TIVOLY (France)

Latest Developments in Global High Speed Steels Market

- In January 2025, NACHI-FUJIKOSHI CORP. announced the development of a new line of high-speed steels specifically designed for cutting-edge automotive applications. The new steels are engineered for high wear resistance and enhanced performance in high-temperature conditions, catering to the growing demand for precision components in electric vehicle (EV) production. This development underscores the company’s commitment to supporting the automotive industry's transition to more efficient and sustainable manufacturing processes.

- In December 2024, Daido Steel Co., Ltd. unveiled a new range of high-speed steel products with advanced coatings designed to improve cutting tool longevity and reduce friction. The new coatings aim to enhance tool life in high-precision machining, particularly in the aerospace and automotive industries, where high-performance cutting tools are essential for meeting tight tolerances and demanding production schedules.

- In November 2024, voestalpine High Performance Metals GmbH announced the expansion of its high-speed steel production facility in Austria to meet increasing global demand. The new facility will focus on producing custom high-speed steel grades tailored to specific industrial applications, including aerospace, automotive, and energy sectors, further solidifying the company’s position as a leading supplier in the high-speed steel market.

- In October 2024, Sandvik AB revealed a breakthrough in the development of high-speed steel tools for 3D printing applications. The new range of high-speed steels is designed for use in additive manufacturing, providing exceptional durability and performance for 3D-printed metal parts. This innovation is expected to open new opportunities for industries like aerospace and automotive, where complex, high-performance components can be produced with more precision and efficiency.

- In September 2024, Kennametal Inc. introduced a new line of high-speed steel drills specifically designed for the aerospace industry. The drills feature a unique alloy composition and are coated with a new layer that significantly improves their resistance to wear and heat, extending tool life in high-speed, high-temperature environments typically found in aerospace manufacturing. This innovation is expected to address the growing demand for durable, high-precision tools in the aerospace sector.

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.