Global Metal Bonding Adhesives Market

Tamanho do mercado em biliões de dólares

CAGR :

%

USD

4.12 Billion

USD

6.35 Billion

2024

2032

USD

4.12 Billion

USD

6.35 Billion

2024

2032

| 2025 –2032 | |

| USD 4.12 Billion | |

| USD 6.35 Billion | |

|

|

|

|

Global Metal Bonding Adhesives Market, By Resin Type (Epoxy-based Metal Bonding Adhesives, Acrylic-based Metal Bonding Adhesives, Polyurethane-based Metal Bonding Adhesives, Silicone- based Metal Bonding Adhesives, and Others), Application (Automotive, Aerospace and Defense, Electrical and Electronics, Industrial Assembly, Construction and Infrastructure, Marine, Medical, and Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa)- Industry Trends and Forecast to 2032

Metal Bonding Adhesives Market Size

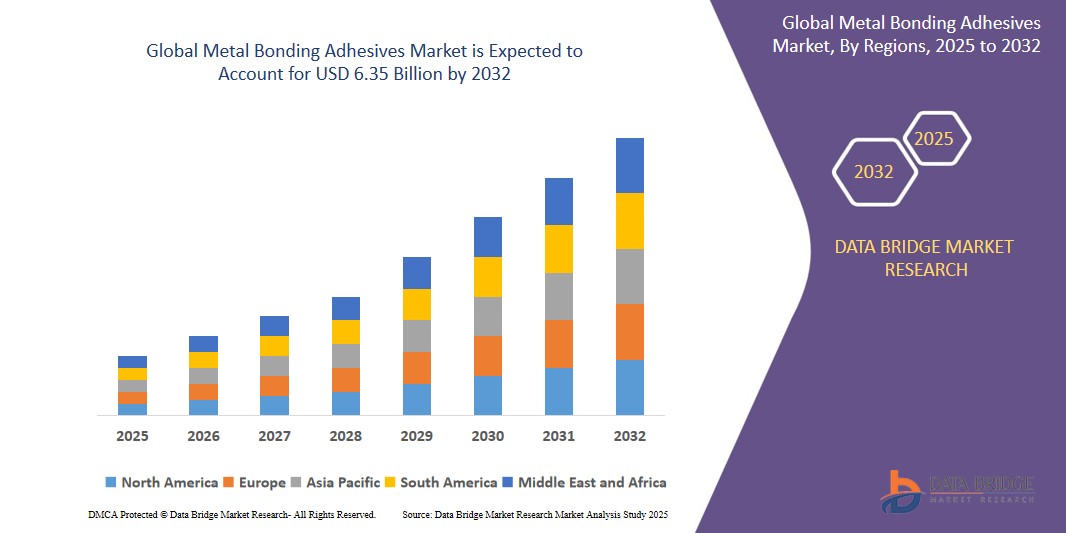

- The Global Metal Bonding Adhesives Market was valued atUSD 4.12 Billion in 2024 and is expected to reachUSD 6.35 Billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at aCAGR of 5.60%, primarily driven by the demand for lightweight, durable, and corrosion-resistant solutions in automotive, aerospace, electronics, and construction industries, ensuring strong, long-lasting bonds between metal surfaces.

- The growth of the global Metal Bonding Adhesives market is driven by demand for strength, durability, corrosion resistance, and lightweight assembly.

Metal Bonding Adhesives Market Analysis

- The market is expanding due to increasing demand for lightweight materials, high-performance bonding solutions in automotive, aerospace, and electronics sectors, and the shift from mechanical fasteners to adhesives.

- Innovations in epoxy, acrylic, and polyurethane adhesives offer enhanced strength, flexibility, and heat resistance, supporting broader applications across extreme environments and enabling the replacement of welding or riveting in metal joining.

- Environmental regulations and the push for sustainable manufacturing are driving the adoption of solvent-free, low-VOC metal bonding adhesives, aligning with green initiatives across automotive, electronics, and construction industries.

Report Scope and Metal Bonding Adhesives Market Segmentation

|

Attributes |

Metal Bonding Adhesives Key Market Insights |

|

Segments Covered |

•By Resin Type:Epoxy-based Metal Bonding Adhesives, Acrylic-based Metal Bonding Adhesives, Polyurethane-based Metal Bonding Adhesives, Silicone- based Metal Bonding Adhesives, and Others •By Application:Automotive, Aerospace and Defense, Electrical and Electronics, Industrial Assembly, Construction and Infrastructure, Marine, Medical, and Others |

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metal Bonding Adhesives Market Trends

“Growing demand for lightweight, durable adhesives in automotive and aerospace industries”

- Automotive manufacturers are increasingly using metal bonding adhesives to reduce vehicle weight, improve fuel efficiency, and enhance crash performance without compromising structural integrity.

- In aerospace, adhesives are replacing traditional fasteners to lower aircraft weight, improve aerodynamics, and ensure high durability under extreme temperature and pressure conditions.

➤ For instance, High-performance aerospace adhesives are vital for modern aircraft, offering benefits like weight reduction, improved aerodynamics, structural integrity, and enhanced durability. They simplify assembly, resist harsh conditions, and ensure long-term reliability across components—from interiors to engines—making them essential for safe, efficient, and innovative aerospace manufacturing and maintenance processes.

- Lightweight, durable adhesives support design flexibility, corrosion resistance, and long-term reliability, making them ideal for next-generation transportation technologies in both commercial and defense sectors.

Metal Bonding Adhesives Market Dynamics

Driver

“Technological advancements in adhesives improve aerospace design flexibility, reduce weight, and enhance durability.”

- Technological advancements in adhesives enable lightweight bonding solutions, reducing the overall weight of aerospace structures and enhancing fuel efficiency without compromising the structural integrity of components.

- New adhesive technologies allow for greater design flexibility, enabling the bonding of dissimilar materials like composites and metals, fostering innovation in aerospace component manufacturing and assembly.

- Improved adhesive formulations offer enhanced durability by resisting extreme environmental factors such as temperature fluctuations, vibrations, and UV radiation, ensuring longer lifespans for aerospace components and structures.

- Advanced aerospace adhesives provide excellent fatigue resistance, improving the overall performance and safety of aircraft by reducing stress concentrations and preventing material failure during high-stress operations.

Opportunity

“Increased demand for lightweight, durable adhesives in aerospace”

- As aerospace manufacturers seek to improve fuel efficiency, the demand for lightweight adhesives grows, offering cost-effective, strong bonding solutions while reducing overall aircraft weight and improving performance.

- Increased focus on sustainability and environmental regulations creates an opportunity for adhesives that reduce the carbon footprint, contributing to more efficient aircraft production with lower environmental impact.

- Technological advancements in adhesives enable faster, more reliable assembly processes, reducing labor costs and production time, which boosts profitability in the aerospace manufacturing and repair industries.

- The demand for high-performance adhesives in critical aerospace applications, such as engine components and composite bonding, presents opportunities for innovation, leading to stronger, longer-lasting materials and components.

Restraint/Challenge

“High cost and regulatory compliance challenges hinder adhesive adoption”

- The high initial cost of advanced aerospace adhesives makes adoption challenging for manufacturers, particularly smaller companies, limiting their access to cutting-edge bonding solutions despite long-term benefits.

- Adherence to stringent regulatory standards, such as aerospace certifications and environmental compliance, increases the complexity and cost of adhesive production, slowing down innovation and industry-wide adoption.

- Limited knowledge and training among industry professionals on new adhesive technologies and proper application techniques pose challenges, potentially leading to inefficiencies and inconsistent performance in aerospace manufacturing.

Metal Bonding Adhesives Market Scope

The market is segmented on the basis of resin type and application.

|

Segmentation |

Sub-Segmentation |

|

By Resin Type |

|

|

By Application |

|

Metal Bonding Adhesives Market Regional Analysis

“The Asia Pacific (APAC) is the Dominant Region in the Metal Bonding Adhesives Market”

- The Asia-Pacific region leads the global metal bonding adhesives market, driven by strong growth in the automotive and aerospace industries, particularly in China, Japan, and India.

- Manufacturing hubs in countries like India, Thailand, and Indonesia offer cost-effective labor and raw materials, boosting the demand for metal bonding adhesives in the region.

- The increasing demand for electric vehicles and the expansion of automotive production in Asia further propel the need for innovative adhesive solutions, reinforcing the region's market dominance.

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific region is expected to experience rapid growth due to increasing industrialization, urbanization, and manufacturing activities, particularly in China and India.

- Expansion of automotive, electronics, and construction sectors in Asia-Pacific countries drives demand for advanced metal bonding adhesives across industries.

- Relocation of manufacturing hubs to cost-effective locations like India and Southeast Asia boosts adhesive market growth through competitive advantages.

Metal Bonding Adhesives Market Share

The competitive landscape of the Metal Bonding Adhesives market offers insights into key players and their market positioning. Key details include company overview, financial performance, revenue generation, market potential, and investment in research and development. Additionally, the analysis covers new market initiatives, global presence, production facilities, manufacturing capacities, and strategic expansions. Companies are evaluated based on their strengths, weaknesses, product innovation, and competitive advantages in nutraceuticals, pharmaceuticals, cosmetics, and functional foods.

The Major Market Leaders Operating in the Market Are:

- Henkel AG & Co. KGaA (Germany)

- 3M Company (U.S.)

- H.B. Fuller Company (U.S.)

- Sika AG (Switzerland)

- Lord Corporation (U.S.)

- ITW Performance Polymers (U.S.)

- Messer Group (Germany)

- Ashland Global Holdings Inc. (U.S.)

- BASF SE (Germany)

- The Dow Chemical Company (U.S.)

- Scotchman Industries (U.S.)

- Wacker Chemie AG (Germany)

- Permabond LLC (U.S.)

- LORD Corporation (U.S.)

- Cytec Industries Inc. (U.S.)

Latest Developments in Global Metal Bonding Adhesives Market

- Henkel showcased its innovative adhesive solutions at Interzum 2024, including the TECHNOMELT PUR 270 series. This polyurethane-based adhesive offers high initial strength, low application weight, and excellent temperature resistance, ideal for edge banding in furniture manufacturing. It enhances production efficiency while ensuring durability and versatility for various substrates.

SKU-

Obtenha acesso online ao relatório sobre a primeira nuvem de inteligência de mercado do mundo

- Painel interativo de análise de dados

- Painel de análise da empresa para oportunidades de elevado potencial de crescimento

- Acesso de analista de pesquisa para personalização e customização. consultas

- Análise da concorrência com painel interativo

- Últimas notícias, atualizações e atualizações Análise de tendências

- Aproveite o poder da análise de benchmark para um rastreio abrangente da concorrência

Metodologia de Investigação

A recolha de dados e a análise do ano base são feitas através de módulos de recolha de dados com amostras grandes. A etapa inclui a obtenção de informações de mercado ou dados relacionados através de diversas fontes e estratégias. Inclui examinar e planear antecipadamente todos os dados adquiridos no passado. Da mesma forma, envolve o exame de inconsistências de informação observadas em diferentes fontes de informação. Os dados de mercado são analisados e estimados utilizando modelos estatísticos e coerentes de mercado. Além disso, a análise da quota de mercado e a análise das principais tendências são os principais fatores de sucesso no relatório de mercado. Para saber mais, solicite uma chamada de analista ou abra a sua consulta.

A principal metodologia de investigação utilizada pela equipa de investigação do DBMR é a triangulação de dados que envolve a mineração de dados, a análise do impacto das variáveis de dados no mercado e a validação primária (especialista do setor). Os modelos de dados incluem grelha de posicionamento de fornecedores, análise da linha de tempo do mercado, visão geral e guia de mercado, grelha de posicionamento da empresa, análise de patentes, análise de preços, análise da quota de mercado da empresa, normas de medição, análise global versus regional e de participação dos fornecedores. Para saber mais sobre a metodologia de investigação, faça uma consulta para falar com os nossos especialistas do setor.

Personalização disponível

A Data Bridge Market Research é líder em investigação formativa avançada. Orgulhamo-nos de servir os nossos clientes novos e existentes com dados e análises que correspondem e atendem aos seus objetivos. O relatório pode ser personalizado para incluir análise de tendências de preços de marcas-alvo, compreensão do mercado para países adicionais (solicite a lista de países), dados de resultados de ensaios clínicos, revisão de literatura, mercado remodelado e análise de base de produtos . A análise de mercado dos concorrentes-alvo pode ser analisada desde análises baseadas em tecnologia até estratégias de carteira de mercado. Podemos adicionar quantos concorrentes necessitar de dados no formato e estilo de dados que procura. A nossa equipa de analistas também pode fornecer dados em tabelas dinâmicas de ficheiros Excel em bruto (livro de factos) ou pode ajudá-lo a criar apresentações a partir dos conjuntos de dados disponíveis no relatório.