North America Metal Injection Molding Mim Market

Tamanho do mercado em biliões de dólares

CAGR :

%

USD

893,494.89 Thousand

USD

2,165,296.92 Thousand

2022

2030

USD

893,494.89 Thousand

USD

2,165,296.92 Thousand

2022

2030

| 2023 –2030 | |

| USD 893,494.89 Thousand | |

| USD 2,165,296.92 Thousand | |

|

|

|

North America Metal Injection Molding (MIM) Market, By Type (Carbonyl Method, High-Pressure Gas Atomization, Ultra-High Pressure Water Atomization), Material (Stainless Steel, Low Alloy Steel, Carbon Steel, Magnetic Alloys, Soft Magnetic Alloy, Cobalt Alloy, Zirconia, Alumina, Tool Steel, Tungsten Steel, Titanium, Controlled Expansion Alloys, Hard Metals, High-Temperature Alloys, Iron, Nickle, Chromium, Molybdenum, Carbonyl Iron Powder and Others), Industry (Automotive, Aerospace, Defense and Firearms, Electrical and Electronics, Power Tools, Industrial, Sporting Goods, Medical and Dental, Oil Exploration, IT, Industrial, Consumer Goods and Others) - Industry Trends and Forecast to 2023 to 2030.

North America Metal Injection Molding (MIM) Market Analysis and Size

The essential factors contributing to the growth of the metal injection molding (MIM) market in the forecast period of 2023 to 2030 include rising demand across numerous industries, widely in automotive, electrical, and electronics. The mounting demand in the healthcare industry, growing technological advancements, and increasing demand for lightweight & smaller automotive parts are contributing to the market’s growth. Along with this, the capability to produce great volumes of precision components by the use of MIM is driving the market’s growth.

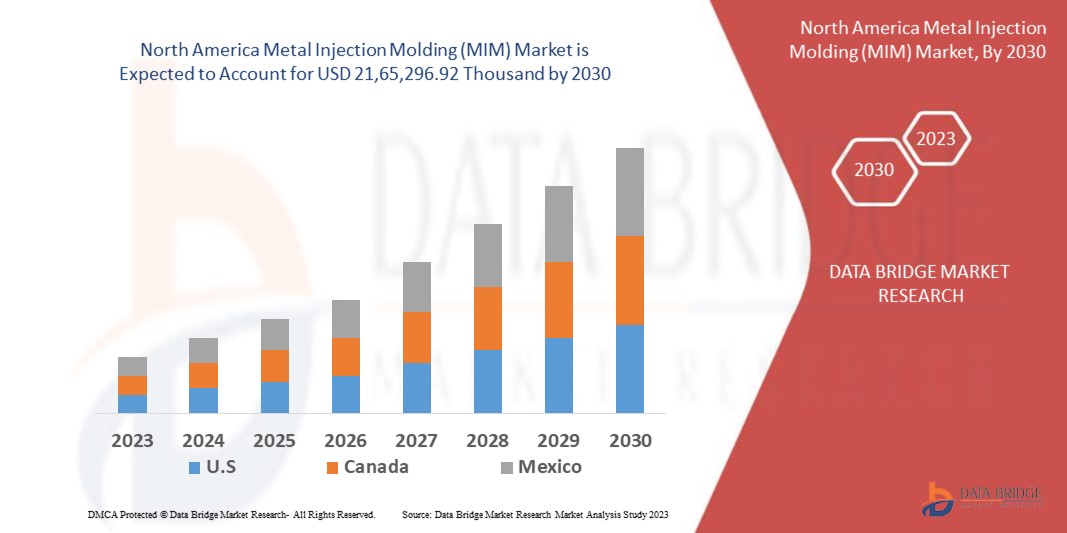

Data Bridge Market Research analyses that the metal injection molding (MIM) market which was USD 8,93,494.89 thousand in 2022, is expected to reach USD 21,65,296.92 thousand by 2030, growing at a CAGR of 11.7% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. 799905.9

North America Metal Injection Molding (MIM) Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015-2020) |

|

Quantitative Units |

Revenue in USD Thousand, Volumes in Units, Pricing in USD |

|

Segments Covered |

Type (Carbonyl Method, High-Pressure Gas Atomization, Ultra-High Pressure Water Atomization), Material (Stainless Steel, Low Alloy Steel, Carbon Steel, Magnetic Alloys, Soft Magnetic Alloy, Cobalt Alloy, Zirconia, Alumina, Tool Steel, Tungsten Steel, Titanium, Controlled Expansion Alloys, Hard Metals, High-Temperature Alloys, Iron, Nickle, Chromium, Molybdenum, Carbonyl Iron Powder and Others), Industry (Automotive, Aerospace, Defense and Firearms, Electrical and Electronics, Power Tools, Industrial, Sporting Goods, Medical and Dental, Oil Exploration, IT, Industrial, Consumer Goods and Others) |

|

Countries Covered |

U.S., Canada and Mexico in North America |

|

Market Players Covered |

ASH Industries (U.S.), Rockleigh Industries. (U.S.), Molex (U.S.), Schunk Group (Germany), Sandvik AB (Sweden), TEKNA. (Canada), PSM Industries (U.S.), GKN Powder Metallurgy (U.S.), Advanced Powder Products, Inc. (U.S.), Alpha Precision Group (U.S.), CMG Technologies (U.K.), Epson Atmix Corporation (Japan), Hitachi, Ltd. (Japan), Smith Metal Products. (U.S.), Parmaco Metal Injection Molding AG (Switzerland), INDO-MIM (India), Optimim. (U.S.), ARC Group Worldwide (U.S.), Dou Yee Technologies. (Singapore), Husky Technologies. (Canada) |

|

Market Opportunities |

|

Market Definition

Metal injection molding (MIM) refers to the process in which metal products are produced with metal injection molding technology. In the method of metal injection molding (MIM) the injection molding’s design is combined with the strength and integrity of wrought metals for providing cost-effective resolutions for extremely complex geometries of parts. The process of metal injection molding involves various steps such as preparing the feedstock, injection molding, binder removal, and others.

North America Metal Injection Molding (MIM) Market Dynamics

Drivers

- Technical advancements and enhanced designs

The metal injection molding procedure allows for attaining the highest precision in the finished product irrespective of the complexity of its design owing to various technological advancements and enhanced designs. It also allows the production of components with accurate tolerances. In comparison to traditional metalworking technologies, metal molding injection design is flexible due to which number of consumers are opting for it which drives the market’s growth.

- Consumes less time and is cost efficient

Metal injection molding (MIM) technique consumes very less time and is a cost-efficient metalworking procedure in comparison to traditional manufacturing methods. Metal injection molding reduces the product development cycle and further, there is no requirement for expensive multistage machining operations, due to which most of the consumers are preferring it. Therefore, less time taken for functioning and cost efficiency are driving the market’s growth.

Opportunities

- High demand from the automotive industry

There is a huge demand for metal injection molding in the automotive manufacturing industry. The mounting demand for electric vehicles (EVs) is further leading to the increased demand for automotive components. There is a requirement for high-quality components in the automotive industry with high precision levels to maintain and meet regulatory and safety standards, therefore, metal injection molding is widely used. Metal injection molding is used in engines, gearboxes, turbochargers, and others which boosts the market’s growth.

- Growing use of firearms

Metal injection molding (MIM) is widely used in the firearms sector. Metal injection molding is used for developing advanced defense equipment which is complex-shaped and heavyweight. Along with this metal injection molding is extensively accepted in the firearms industry for the manufacturing of diverse firearms which are required in the defense industry. It is further used for blocking the trigger from firing and shields the hammer from impacting which boots the market’s growth.

Restraints/Challenges

- Expensive for small production units

The cost of metal injection molding is not reasonable for small-scale projects as the prices are unaffordable. The feedstock such as metal powders and thermoplastic binders are more expensive than feedstock needed for other metallurgical processes such as conventional powder metallurgy. Along with this metal injection molding comprises comparatively high tooling cost that makes this technology not suitable for small production unit which is a major challenge hindering the market’s growth.

- Fluctuations in raw materials

The fluctuation in the price of raw materials used for metal injection molding is a major concern. The materials used in metal injection molding are stainless steel, low alloy steel, carbon steel, magnetic alloys, soft magnetic alloy, cobalt alloy, zirconia, and alumina. The prices of all these materials changes according to the extraction, availability, and demand which can most of the time lead to high prices. This further leads to the high price of metal injection molding. Therefore fluctuations in raw materials are a major challenge hindering the market’s growth.

This metal injection molding (MIM) market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the metal injection molding (MIM) market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Recent Developments

- In 2021, Metal Powder Products, LLC announced that it had completed acquisition of Proform Powdered Metals, Inc., headquartered in the U.S. It is among one of major manufacturers of high-quality sintered bronze bearings, bushings, and spacers.

- In 2021, Argon Medical Devices, Inc. announced acquisition of Matrex Mold and Tool Inc., which is a manufacturer of high-quality precision injection molded products, headquartered in the U.S.

North America Metal Injection Molding (MIM) Market Scope

The metal injection molding (MIM) market is segmented on the basis of type, material and industry. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Carbonyl Method

- High-Pressure Gas Atomization

- Ultra-High Pressure Water Atomization

Material

- Stainless Steel

- Low Alloy Steel

- Carbon Steel

- Magnetic Alloys

- Soft Magnetic Alloy

- Cobalt Alloy

- Zirconia

- Alumina

- Controlled Expansion Alloys

- Hard Metals

- High-Temperature Alloys

- Iron

- Nickle

- Chromium

- Molybdenum

- Carbonyl Iron Powder

- Others

- Tool Steel

- Titanium

- Tungsten

Industry

- Automotive

- Electrical Systems

- Fuel System

- Interiors

- Powertrain

- Safety System

- Others

- Aerospace

- Fasteners

- Screws

- Seatbelt Components

- Bushings

- Rotors

- Others

- Defense and Firearms

- Fire Suppression

- Cam Block

- Sensor Housings

- Others

- Electrical and Electronics

- Fiber Optic Connectors

- Filter Components

- Heat Sinks

- Micro-Switches

- Connectors

- Others

- Power Tools

- Industrial

- Sporting Goods

- Medical and Dental

- Surgical Instruments

- Orthopaedic

- Implants

- Others

- Oil Exploration

- IT

- Consumer Goods

- Others

North America Metal Injection Molding (MIM) Market Regional Analysis/Insights

The metal injection molding (MIM) market is analysed and market size insights and trends are provided by type, material and industry as referenced above.

The countries covered in the metal injection molding (MIM) market report are U.S., Canada and Mexico in North America.

U.S. dominates the metal injection molding market in North America metal injection molding (MIM) market due to more demand for metal products, surging demand for firearms, and the increasing demand in the automotive sector are contributing to the market’s growth in the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and North America Metal Injection Molding (MIM) Market Share Analysis

The metal injection molding (MIM) market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to metal injection molding (MIM) market.

Some of the major players operating in the metal injection molding (MIM) market are:

- ASH Industries (U.S.)

- Rockleigh Industries. (U.S.)

- Molex (U.S.)

- Schunk Group (Germany)

- Sandvik AB (Sweden)

- TEKNA. (Canada)

- PSM Industries (U.S.)

- GKN Powder Metallurgy (U.S.)

- Advanced Powder Products, Inc. (U.S.)

- Alpha Precision Group (U.S.)

- CMG Technologies (U.K.)

- Epson Atmix Corporation (Japan)

- Hitachi, Ltd. (Japan)

- Smith Metal Products. (U.S.)

- Parmaco Metal Injection Molding AG (Switzerland)

- INDO-MIM (India)

- Optimim. (U.S.)

- ARC Group Worldwide (U.S.)

- Dou Yee Technologies. (Singapore)

- Husky Technologies. (Canada)

SKU-

Obtenha acesso online ao relatório sobre a primeira nuvem de inteligência de mercado do mundo

- Painel interativo de análise de dados

- Painel de análise da empresa para oportunidades de elevado potencial de crescimento

- Acesso de analista de pesquisa para personalização e customização. consultas

- Análise da concorrência com painel interativo

- Últimas notícias, atualizações e atualizações Análise de tendências

- Aproveite o poder da análise de benchmark para um rastreio abrangente da concorrência

Metodologia de Investigação

A recolha de dados e a análise do ano base são feitas através de módulos de recolha de dados com amostras grandes. A etapa inclui a obtenção de informações de mercado ou dados relacionados através de diversas fontes e estratégias. Inclui examinar e planear antecipadamente todos os dados adquiridos no passado. Da mesma forma, envolve o exame de inconsistências de informação observadas em diferentes fontes de informação. Os dados de mercado são analisados e estimados utilizando modelos estatísticos e coerentes de mercado. Além disso, a análise da quota de mercado e a análise das principais tendências são os principais fatores de sucesso no relatório de mercado. Para saber mais, solicite uma chamada de analista ou abra a sua consulta.

A principal metodologia de investigação utilizada pela equipa de investigação do DBMR é a triangulação de dados que envolve a mineração de dados, a análise do impacto das variáveis de dados no mercado e a validação primária (especialista do setor). Os modelos de dados incluem grelha de posicionamento de fornecedores, análise da linha de tempo do mercado, visão geral e guia de mercado, grelha de posicionamento da empresa, análise de patentes, análise de preços, análise da quota de mercado da empresa, normas de medição, análise global versus regional e de participação dos fornecedores. Para saber mais sobre a metodologia de investigação, faça uma consulta para falar com os nossos especialistas do setor.

Personalização disponível

A Data Bridge Market Research é líder em investigação formativa avançada. Orgulhamo-nos de servir os nossos clientes novos e existentes com dados e análises que correspondem e atendem aos seus objetivos. O relatório pode ser personalizado para incluir análise de tendências de preços de marcas-alvo, compreensão do mercado para países adicionais (solicite a lista de países), dados de resultados de ensaios clínicos, revisão de literatura, mercado remodelado e análise de base de produtos . A análise de mercado dos concorrentes-alvo pode ser analisada desde análises baseadas em tecnologia até estratégias de carteira de mercado. Podemos adicionar quantos concorrentes necessitar de dados no formato e estilo de dados que procura. A nossa equipa de analistas também pode fornecer dados em tabelas dinâmicas de ficheiros Excel em bruto (livro de factos) ou pode ajudá-lo a criar apresentações a partir dos conjuntos de dados disponíveis no relatório.