Asia Pacific And South East Asia Multisensor Coordinate Measuring Machine Market

Market Size in USD Million

CAGR :

%

USD

310.47 Million

USD

583.22 Million

2024

2032

USD

310.47 Million

USD

583.22 Million

2024

2032

| 2025 –2032 | |

| USD 310.47 Million | |

| USD 583.22 Million | |

|

|

|

|

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Size

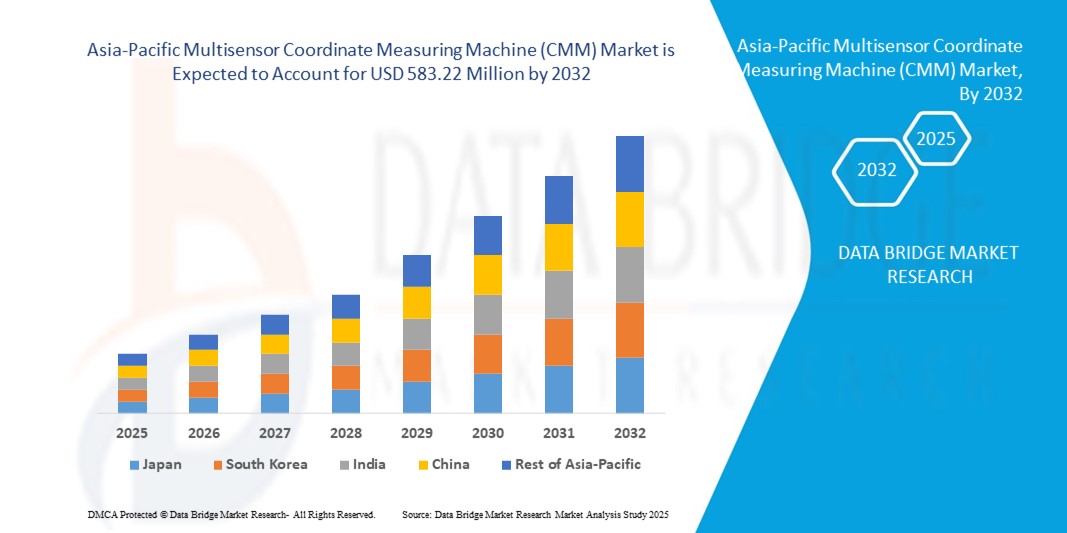

- The Asia-Pacific and South-East Asia multisensor coordinate measuring machine (CMM) market size was valued at USD 310.47 million in 2024 and is expected to reach USD 583.22 million by 2032, at a CAGR of 8.2% during the forecast period

- The market growth is largely fueled by the increasing adoption of advanced manufacturing technologies and the rising need for high-precision measurement solutions across industries such as automotive, aerospace, electronics, and heavy machinery. The integration of multisensor systems, combining contact and non-contact measurement capabilities, is enhancing accuracy, efficiency, and quality control in production processes

- Furthermore, growing emphasis on industrial automation, digitalization, and compliance with stringent quality standards is driving demand for multisensor coordinate measuring machines. These factors are accelerating the adoption of versatile coordinate measuring machine solutions, thereby significantly boosting the overall growth of the market

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Analysis

- Multisensor CMMs are precision measurement systems that combine different types of sensors—such as tactile probes, laser scanners, and optical systems—to perform highly accurate dimensional inspections on components of varying sizes and complexities. These machines are critical in ensuring quality, reducing defects, and supporting advanced manufacturing processes

- The escalating demand for multisensor CMMs is primarily driven by the need for enhanced production accuracy, reduced rework, and faster inspection cycles. In addition, industries are increasingly leveraging CMMs for reverse engineering, virtual simulation, and profiling, reflecting a shift toward precision-driven, automated, and data-integrated manufacturing environments

- China dominated the multisensor coordinate measuring machine (CMM) market in 2024, due to its expansive manufacturing base, rapid industrialization, and increasing adoption of precision engineering solutions across automotive, aerospace, and heavy machinery sectors

- India is expected to be the fastest growing country in the multisensor coordinate measuring machine (CMM) market during the forecast period due to rapid industrial growth, increasing quality compliance requirements, and rising adoption of automated inspection systems in manufacturing

- Hardware segment dominated the market with a market share of 55.5% in 2024, due to the critical role of high-precision mechanical and sensor components in ensuring accurate measurements. Manufacturers and industrial users prioritize hardware reliability and durability, as it directly impacts measurement precision and repeatability across diverse applications. Furthermore, the rising adoption of advanced probing systems and integration of multiple sensors into coordinate measuring machine hardware is boosting demand. Hardware investments are also supported by continuous technological advancements, including high-speed scanning and multi-axis capabilities, making it the cornerstone of the coordinate measuring machine market

Report Scope and Multisensor Coordinate Measuring Machine (CMM) Market Segmentation

|

Attributes |

Multisensor Coordinate Measuring Machine (CMM) Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Asia-Pacific and South-East Asia

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Trends

Growing use of Multisensor CMMs for Automated High-Precision Inspections

- The rising need for automated, high-precision inspection is significantly boosting the adoption of multisensor coordinate measuring machines. Manufacturers across industries such as automotive, aerospace, and electronics are increasingly shifting towards these machines to achieve faster inspection rates, improved accuracy, and reduced dependency on manual measurement systems

- For instance, Hexagon AB has introduced multisensor CMMs that integrate optical, tactile, and laser scanning sensors into one system. This innovation allows manufacturers to conduct high-precision inspections across diverse components, ensuring higher throughput and comprehensive quality analysis for complex geometries

- The versatility of multisensor CMMs allows measurements to be conducted on a single setup without requiring multiple specialized machines. This reduces inspection time and also minimizes errors associated with repositioning, ultimately improving productivity and operational efficiency

- With growing demand in industries such as aerospace and medical devices, where component tolerances are extremely tight, multisensor systems provide a highly reliable solution. The ability to seamlessly switch between sensors enhances capability in handling parts of varying sizes, shapes, and materials with maximum precision

- The integration of multisensor CMMs with automated workflows, robotic loading systems, and data-driven quality management platforms is expanding their role in smart factories. Their contribution to Industry 4.0 initiatives is making them a backbone for fully digitalized manufacturing processes

- In conclusion, the growing adoption of these machines highlights a fundamental shift toward flexible, efficient, and automated inspection systems. As the need for superior precision and productivity grows, multisensor CMMs are becoming indispensable in modern industrial environments

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Dynamics

Driver

Increasing Emphasis on Quality Control

- The rising emphasis on quality control across manufacturing industries is a major driver for the adoption of multisensor CMMs. As manufacturers strive to meet stringent standards and customer expectations, accurate and reliable measurement technologies have become central to achieving competitive advantage

- For instance, Zeiss Group has developed advanced multisensor CMMs tailored for automotive and aerospace applications. Their use in engine component and aircraft part inspection showcases how companies are integrating these machines to strengthen quality assurance practices while streamlining complex inspection needs

- The ability of these machines to provide high measurement accuracy for intricate components makes them critical for industries producing precision parts. Manufacturers are increasingly recognizing that investment in advanced measuring systems can prevent costly recalls, reduce rework, and enhance customer trust

- Global supply chains are demanding stricter quality adherence as part of compliance with international standards such as ISO and AS9100. This has amplified industry-wide reliance on multisensor CMMs as they help provide traceable, accurate reports and minimize disputes over product conformity

- Taken together, the importance of quality control in modern manufacturing underlines the necessity of multisensor CMMs. Their superior ability to maintain consistency, enhance process control, and improve customer satisfaction ensures steady market growth and adoption

Restraint/Challenge

High Cost of Advanced CMM Systems

- The high initial cost of acquiring advanced multisensor coordinate measuring machine systems is a significant challenge for widespread adoption. The combination of precision sensors, automation modules, and software integration makes these machines far more expensive than conventional measurement solutions

- For instance, Mitutoyo has highlighted the substantial upfront investment required for multisensor coordinate measuring machine deployment. Small and mid-sized manufacturers often find such costs prohibitive, limiting access to advanced measurement capabilities despite the clear benefits of these systems

- Frequent calibration, software updates, and maintenance further add to the cost burden, making ownership more expensive over time. This becomes a hurdle for smaller enterprises that may not have sufficient resources for continual upkeep of high-tech systems

- In addition, the need for highly skilled labor to operate multisensor CMMs contributes to rising overall ownership costs. Training requirements and specialized expertise increase the financial commitment, creating an additional barrier to adoption in developing manufacturing environments

- Ultimately, the high cost of multisensor coordinate measuring machine systems restricts adoption to larger organizations with strong financial capabilities. Overcoming this restraint will require industry innovation in cost optimization, scalable solutions, and possibly leasing or service-based models to broaden market accessibility

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Scope

The market is segmented on the basis of component, type, load capacity, application, end-user, and distribution channel.

- By Component

On the basis of component, the multisensor coordinate measuring machine market is segmented into hardware, software, and services. The hardware segment dominated the largest market revenue share of 55.5% in 2024, driven by the critical role of high-precision mechanical and sensor components in ensuring accurate measurements. Manufacturers and industrial users prioritize hardware reliability and durability, as it directly impacts measurement precision and repeatability across diverse applications. Furthermore, the rising adoption of advanced probing systems and integration of multiple sensors into coordinate measuring machine hardware is boosting demand. Hardware investments are also supported by continuous technological advancements, including high-speed scanning and multi-axis capabilities, making it the cornerstone of the coordinate measuring machine market.

The software segment is anticipated to witness the fastest growth rate from 2025 to 2032, fueled by increasing reliance on advanced analytics, automated inspection routines, and integration with CAD/CAM systems. Modern coordinate measuring machine software enables real-time data analysis, complex geometric measurements, and seamless visualization, allowing manufacturers to optimize production processes. Software upgrades and cloud-based solutions are driving faster adoption among end users seeking enhanced efficiency, precision, and traceability in measurement and quality control operations.

- By Type

On the basis of type, the market is segmented into fixed and portable CMMs. The fixed coordinate measuring machine segment held the largest market revenue share in 2024 due to its robustness, high accuracy, and suitability for high-volume industrial environments. Fixed systems are preferred in industries such as automotive and aerospace, where precision and repeatability are critical for quality assurance. Their ability to accommodate larger workpieces and integrate with automated production lines makes them a long-term investment for manufacturers seeking consistency and reliability.

The portable coordinate measuring machine segment is expected to witness the fastest CAGR from 2025 to 2032, driven by growing demand for on-site inspection and flexibility in measuring large or immovable components. Portable systems allow quality engineers to perform precise measurements directly on the shop floor, reducing downtime and enhancing operational efficiency. Advancements in lightweight materials, wireless communication, and multisensor integration are further boosting the adoption of portable CMMs across diverse industries.

- By Load Capacity

On the basis of load capacity, the market is segmented into more than 20 kg and less than 20 kg. The more than 20 kg segment dominated the largest market revenue share in 2024, driven by its capability to handle large, heavy workpieces typically found in automotive, aerospace, and heavy machinery sectors. These CMMs ensure high precision even for bulky components, meeting the stringent quality standards required in critical applications. High load capacity systems also support multiple sensor configurations and advanced probing mechanisms, enhancing versatility and efficiency in complex measurement tasks.

The less than 20 kg segment is projected to witness the fastest growth rate from 2025 to 2032 due to the rising demand for lightweight, compact coordinate measuring machine solutions suitable for small-scale manufacturing and specialized components. Their ease of deployment, cost-effectiveness, and ability to integrate with automated production setups make them attractive for precision-driven applications in electronics, medical devices, and energy sectors.

- By Application

On the basis of application, the market is segmented into quality control and inspection, profiling and assessment, virtual simulation, and reverse engineering. The quality control and inspection segment dominated the largest market revenue share in 2024, driven by the universal need for precise verification of component dimensions and tolerances. Industries rely on CMMs to maintain high product standards, reduce defects, and comply with regulatory and safety requirements. Integration with automated inspection systems further enhances efficiency, making quality control a primary driver for coordinate measuring machine adoption.

The reverse engineering segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by growing use in prototyping, redesign, and legacy part reproduction. CMMs enable accurate digitization of physical objects, supporting innovation and iterative product development. Rising adoption in aerospace, automotive, and medical industries for reverse engineering purposes is boosting the demand for advanced multisensor systems capable of high-precision surface scanning and 3D modeling.

- By End User

On the basis of end user, the market is segmented into aerospace and defense, automotive, medical, heavy machinery, electronics, energy and power, and others. The automotive segment dominated the largest market revenue share in 2024, driven by stringent quality standards, complex component geometries, and high-volume production requirements. Multisensor CMMs are critical in ensuring dimensional accuracy, reducing rework, and maintaining operational efficiency in assembly lines. Continuous innovation in automotive manufacturing, including electric vehicle components, further supports high adoption of CMMs.

The medical segment is anticipated to witness the fastest growth rate from 2025 to 2032 due to rising demand for precision-engineered medical devices, implants, and surgical instruments. The critical nature of these components, combined with stringent regulatory compliance requirements, is driving the adoption of advanced CMMs. Portable and multisensor systems are increasingly preferred for their ability to measure intricate and small-scale medical components accurately.

- By Distribution Channel

On the basis of distribution channel, the market is segmented into direct and indirect channels. The direct channel dominated the largest market revenue share in 2024, driven by manufacturers’ preference for direct engagement with end users to offer customized solutions, technical support, and after-sales services. Direct sales enable better understanding of client requirements, configuration of multisensor setups, and maintenance agreements, which are critical for high-value investments such as CMMs.

The indirect channel is expected to witness the fastest CAGR from 2025 to 2032, fueled by growing partnerships with distributors, resellers, and system integrators. This approach allows manufacturers to expand market reach, especially in regions where direct presence is limited, and provides end users with easier access to coordinate measuring machine solutions, installation services, and training. Increasing adoption in SMEs and emerging markets is supporting growth through indirect channels.

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Regional Analysis

- China dominated the multisensor coordinate measuring machine (CMM) market with the largest revenue share in 2024, driven by its expansive manufacturing base, rapid industrialization, and increasing adoption of precision engineering solutions across automotive, aerospace, and heavy machinery sectors

- Robust government initiatives promoting advanced manufacturing technologies, along with the rising emphasis on quality control and industrial automation, reinforce China’s leadership in the regional market

- The presence of leading domestic coordinate measuring machine manufacturers, collaborations with global technology providers, and the introduction of advanced yet cost-effective multisensor systems continue to consolidate China’s dominant position during the forecast period. Increasing investment in smart factories and industrial IoT adoption further strengthen market penetration across diverse industrial hubs

Japan Multisensor Coordinate Measuring Machine Market Insight

The Japan market is anticipated to grow steadily from 2025 to 2032, supported by its highly developed manufacturing sector and strong focus on precision, quality, and innovation. Japanese industries are increasingly adopting advanced multisensor coordinate measuring machine solutions to ensure high accuracy and compliance with stringent industrial standards. The demand for compact, multifunctional, and high-precision systems is rising due to limited factory floor space and the focus on miniaturized components in electronics and automotive sectors. Continuous R&D investments and collaborations between Japanese coordinate measuring machine manufacturers and global technology players reinforce the market’s steady growth outlook. Japan’s commitment to precision engineering, innovation, and operational efficiency underpins its strong regional positioning.

India Multisensor Coordinate Measuring Machine Market Insight

India is projected to register the fastest CAGR in the Asia-Pacific multisensor coordinate measuring machine market during 2025–2032, fueled by rapid industrial growth, increasing quality compliance requirements, and rising adoption of automated inspection systems in manufacturing. Expansion of industrial infrastructure, government initiatives promoting advanced manufacturing, and growing awareness of precision measurement benefits are accelerating adoption. Demand for affordable, versatile, and easy-to-install coordinate measuring machine solutions is particularly strong among emerging SMEs and automotive suppliers. Expanding distribution channels, partnerships with global coordinate measuring machine providers, and increased focus on digitalization and Industry 4.0 practices ensure India’s emergence as the fastest-growing market in the region.

Southeast Asia Multisensor Coordinate Measuring Machine Market Insight

The Southeast Asia market is expected to grow at a notable pace from 2025 to 2032, driven by expanding automotive, electronics, and aerospace manufacturing hubs in countries such as Thailand, Vietnam, and Indonesia. Increasing industrial automation, rising demand for high-precision components, and government incentives for technology adoption are supporting market growth. Local manufacturers are increasingly collaborating with international coordinate measuring machine solution providers to enhance access to advanced inspection technologies. Rapid urbanization, investment in industrial parks, and growing emphasis on quality standards across manufacturing sectors are strengthening the regional market outlook.

Asia-Pacific Multisensor Coordinate Measuring Machine (CMM) Market Share

The multisensor coordinate measuring machine (CMM) industry is primarily led by well-established companies, including:

- ZEISS Group (Germany)

- Nikon Corporation (Japan)

- Hexagon AB (Sweden)

- Innovalia Metrology (Spain)

- Automated Precision Inc. (API) (U.S.)

- WENZEL Group (Germany)

- Quality Vision International (QVI) (U.S.)

- Sinowon Innovation Metrology Manufacture Limited (China)

- Mitutoyo Corporation (Japan)

- Renishaw plc (U.K.)

- Perceptron, Inc. (U.S.)

- Werth Messtechnik GmbH (Germany)

- LK Metrology (U.K.)

- Baker Gauges India Pvt. Ltd. (India)

- Accurate (India)

- DUKIN CO., LTD. (South Korea)

Latest Developments in Asia-Pacific and South-East Asia Multisensor Coordinate Measuring Machine (CMM) Market

- In November 2024, Zeiss inaugurated its first global capability center in Bengaluru, India, marking a significant expansion in the region. This center focuses on cloud computing, cybersecurity, network operations, and the development of software services for its metrology solutions. The establishment of this facility, along with plans to double its Indian workforce to 5,000 within three years, strengthens Zeiss’s presence in the Asia-Pacific market. The facility is set to become the company’s largest investment outside Germany, highlighting strategic focus on the region’s growing demand for advanced metrology and precision measurement solutions

- In August 2023, Hexagon launched an AI-integrated coordinate measuring machine software that improved real-time inspection accuracy by 38% across automotive and industrial clients. This advancement enhances precision and operational efficiency of multisensor CMMs, particularly for high-precision industries. The integration of artificial intelligence into coordinate measuring machine software represents a major technological development, positioning Hexagon as a leader in providing next-generation metrology solutions in the Asia-Pacific region

- In May 2023, Innovalia Metrology announced the launch of its M3 Hybrid solution, which combines machinery, sensors, and software to optimize the quality control process. The system offers both contact and non-contact measurements, and the seamless integration with M3 software allows precise measurements on parts of any shape and size. This launch has strengthened Innovalia Metrology’s presence and competitive positioning in the Asia-Pacific and Southeast Asia multisensor coordinate measuring machine market

- In March 2023, Nikon Metrology partnered with automation firms to integrate robotic arms with CMMs, improving throughput by 36% in high-mix production environments. The integration of robotics reduces human intervention, enhances productivity, and provides flexible measurement capabilities, benefiting electronics, automotive, and other precision-driven manufacturing industries. This strategic move reinforces Nikon Metrology’s influence in the rapidly evolving regional market

- In September 2020, Baker Gauges India Pvt. Ltd. entered the coordinate measuring machines market through a collaboration with Aberlink Ltd., U.K., for sales of their CMMs in India. This partnership expanded the availability of advanced coordinate measuring machine solutions in the region, supporting industrial quality control and measurement needs, and helping the company establish a foothold in the growing Asia-Pacific and Southeast Asia market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Asia Pacific And South East Asia Multisensor Coordinate Measuring Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Asia Pacific And South East Asia Multisensor Coordinate Measuring Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Asia Pacific And South East Asia Multisensor Coordinate Measuring Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.