Asia Pacific Explosion Proof Equipment Market

Market Size in USD Billion

CAGR :

%

USD

1.87 Billion

USD

3.29 Billion

2024

2032

USD

1.87 Billion

USD

3.29 Billion

2024

2032

| 2025 –2032 | |

| USD 1.87 Billion | |

| USD 3.29 Billion | |

|

|

|

|

Asia-Pacific Explosion-Proof Equipment Market Size

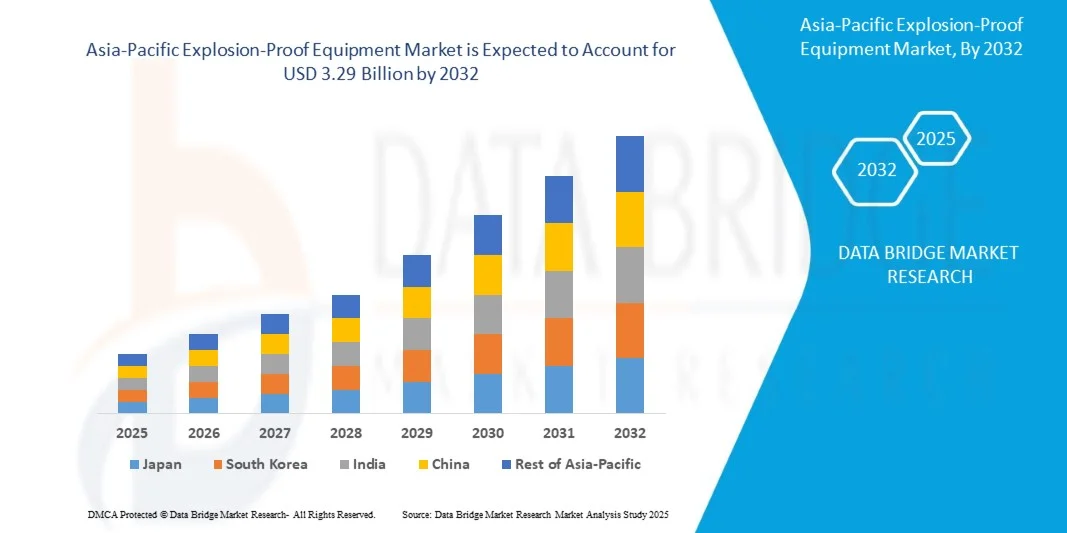

- The Asia-Pacific explosion-proof equipment market was valued at USD 1.87 billion in 2024 and is projected to reach USD 3.29 billion by 2032, growing at a CAGR of 7.30% during the forecast period

- The market expansion is primarily driven by stringent safety regulations, rapid industrialization, and increased investments in oil & gas, mining, and chemical sectors across emerging economies in the region

- Additionally, the demand for reliable and advanced safety solutions in hazardous environments is fueling the adoption of explosion-proof equipment, thereby propelling sustained growth across diverse industrial applications

Asia-Pacific Explosion-Proof Equipment Market Analysis

- Explosion-proof equipment, designed to prevent ignition of surrounding explosive atmospheres, is becoming increasingly critical in ensuring safety and operational continuity across hazardous industrial environments such as oil & gas, mining, and chemical processing sectors in both developed and developing regions of Asia-Pacific

- The rising demand for explosion-proof equipment is primarily driven by stringent regulatory frameworks, increasing industrial safety awareness, and the need to minimize operational risks and downtime in volatile environments

- China dominated the Asia-Pacific Explosion-Proof Equipment Market with the largest revenue share of 38.7% in 2024, fueled by rapid industrial expansion, strong government mandates on workplace safety, and significant investments in energy and manufacturing infrastructure

- India is expected to be the fastest growing country in the Asia-Pacific Explosion-Proof Equipment Market during the forecast period, owing to accelerated urbanization, expanding petrochemical sectors, and increased adoption of automation in industrial operations

- The hardware segment accounted for the largest market revenue share in 2024 due to the extensive deployment of robust physical safety components, including enclosures, sensors, and control systems, in hazardous environments

Report Scope and Asia-Pacific Explosion-Proof Equipment Market Segmentation

|

Attributes |

Explosion-Proof Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Asia-Pacific

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Asia-Pacific Explosion-Proof Equipment Market Trends

“Integration of IoT and Smart Monitoring in Hazardous Environments”

- A key trend reshaping the explosion-proof equipment market is the integration of IoT-based smart monitoring systems, which provide real-time diagnostics, predictive maintenance, and remote accessibility in high-risk environments. These systems enhance operational safety, reduce downtime, and support compliance with global safety standards

- For instance, Pepperl+Fuchs has developed smart sensors and explosion-proof interfaces that enable communication in hazardous zones while offering diagnostics and process data monitoring through industrial Ethernet protocols

- IoT-enabled explosion-proof equipment allows operators to monitor environmental conditions such as gas concentration, temperature, and pressure levels in real-time, ensuring proactive safety responses. This data-driven approach also aids in reducing false alarms and ensuring timely maintenance

- Smart monitoring capabilities are particularly vital in oil & gas, chemical, and mining industries, where the stakes of equipment failure or undetected hazards are extremely high. By combining rugged construction with intelligent functionality, companies can optimize safety and performance simultaneously

- The trend is driving manufacturers such as R. STAHL and BARTEC to innovate digital-ready explosion-proof solutions that integrate easily into broader industrial automation and control systems. These systems support scalable upgrades while meeting zone-specific certification standards

- As industrial operations continue to digitize and demand for safe, efficient solutions in hazardous zones rises, the adoption of intelligent, connected explosion-proof systems is expected to accelerate across both developed and emerging markets

Asia-Pacific Explosion-Proof Equipment Market Dynamics

Driver

“Stringent Safety Regulations and Growing Industrial Hazard Awareness

- Stringent safety standards imposed by regulatory bodies such as ATEX (Europe), IECEx (International), and NEC (U.S.) are a major force driving the demand for explosion-proof equipment across hazardous industrial environments

- For instance, industries in Europe and the Middle East have increasingly adopted certified explosion-proof solutions following regional compliance mandates aimed at minimizing explosion risks and protecting workers

- The rising awareness of industrial hazards, coupled with increasing investments in safety infrastructure, has propelled demand from industries such as oil & gas, petrochemicals, pharmaceuticals, and mining where volatile atmospheres are common

- Explosion-proof devices including enclosures, lighting systems, motors, and cable glands are essential in preventing ignition sources, and their usage is expanding due to greater automation and the deployment of electrical systems in explosive zones

- Major players such as ABB and Eaton are launching certified products that comply with international safety regulations and also offer digital features, enabling safer and smarter operations in demanding environments

Restraint/Challenge

“High Installation Costs and Maintenance Complexity”

- One of the significant challenges facing the explosion-proof equipment market is the high cost of installation and the ongoing complexity of maintenance in compliance with global safety standards

- For instance, installing certified equipment in Zone 0 or Zone 1 environments requires specialized engineering, robust materials, and skilled labor, which adds to the overall project cost and deters small-scale operators

- Maintaining the performance and compliance of such equipment involves routine inspection, calibration, and documentation, which can be resource-intensive. This is particularly challenging in remote or offshore locations where access is limited

- Failure to maintain certified conditions may lead to regulatory non-compliance or equipment malfunction, increasing liability risks. Consequently, companies must invest in both qualified personnel and sophisticated monitoring systems

- To address this issue, manufacturers are working to streamline product design, extend maintenance intervals, and introduce modular solutions that reduce total lifecycle costs without compromising safety or compliance

Asia-Pacific Explosion-Proof Equipment Market Scope

The market is segmented on the basis of offering, temperature class, zone, connectivity service, location, method of protection, equipment, and end user.

- By Offering

On the basis of offering, the explosion-proof equipment market is segmented into hardware, software, and services. The hardware segment dominated the market with a 63.4% revenue share in 2024, attributed to the extensive deployment of rugged physical components such as enclosures, sensors, and control systems vital for preventing ignition in hazardous environments. These hardware elements are foundational in industries like oil & gas and chemical processing where safety and durability are critical.

the services segment is projected to witness the fastest CAGR of 20.8% from 2025 to 2032, fueled by the rising demand for installation, inspection, maintenance, and regulatory compliance services. Growing complexities in safety standards and the necessity of continuous operational safety drive organizations to increasingly outsource these services, ensuring equipment reliability and regulatory adherence.

- By Temperature Class

Based on temperature class, the market is segmented into T1 (>450°C), T2 (>300°C to <450°C), T3 (>200°C to <300°C), T4 (>135°C to <200°C), T5 (>100°C to <135°C), and T6 (>85°C to <100°C). The T4 segment held the largest market share of 36.2% in 2024, favored for its balance between safety and operational efficiency, commonly used in refineries and processing plants handling flammable gases.

The T6 segment is expected to grow at the fastest CAGR of 22.5% from 2025 to 2032, driven by stringent safety requirements in pharmaceutical, food processing, and dust-prone industries where ignition temperatures are lower, necessitating highly sensitive and reliable explosion-proof solutions.

- By Zone

On the basis of zone, the market is segmented into Zone 0, Zone 1, Zone 2, Zone 20, Zone 21, and Zone 22. Zone 1 commanded the largest revenue share of 41.0% in 2024, due to its frequent exposure to explosive atmospheres during normal operations, particularly in upstream oil and gas and chemical plants. Equipment designed for Zone 1 offers robust sealing and durability to prevent ignition.

The Zone 21 segment is anticipated to exhibit the fastest CAGR of 21.3% through 2032, supported by the rising adoption of explosion-proof equipment in industries where explosive dust is intermittently present, such as food milling, pharmaceuticals, and agricultural storage.

- By Connectivity Service

Based on connectivity service, the explosion-proof equipment market is divided into wired and wireless segments. The wired segment dominated with a 68.7% market share in 2024, favored in industrial setups requiring stable, secure communication free from electromagnetic interference risks.

the wireless segment is expected to register the fastest CAGR of 23.9% from 2025 to 2032, driven by the increasing integration of wireless IoT-enabled sensors and monitoring systems that facilitate real-time data access, remote monitoring, and easier installation in challenging environments.

- By Location

On the basis of location, the market is segmented into indoor and outdoor. The outdoor segment held the largest market share of 56.4% in 2024, largely due to its extensive use in rugged environments such as oil rigs, gas pipelines, and mining sites, where weather-resistant and durable equipment is essential to prevent ignition.

The indoor segment is projected to grow at the fastest CAGR of 19.7% from 2025 to 2032, driven by rising safety regulations in enclosed industrial spaces such as laboratories, production lines, and storage facilities, where accumulation of gases or dust creates significant explosion risks.

- By Method of Protection

The market is segmented into explosion proof, explosion prevention, and explosion segregation methods. In 2024, explosion prevention led the market with a 28.1% revenue share, fueled by the demand for intrinsically safe equipment that minimizes ignition risk by controlling energy levels.

The explosion proof segment is forecast to witness the fastest growth rate, with a CAGR of 22.4% from 2025 to 2032, driven by its reliability in containing explosions within enclosures, making it vital for high-risk zones such as oil refineries and gas facilities.

- By Equipment

Based on equipment, the market comprises cable glands and accessories, process instruments, industrial controls, motors, strobe beacons, lightning products, sensors, bells and horns, fire alarms/call points, speakers and tone generators, and visual and audible combination units. The cable glands and accessories segment dominated the market with a 30.8% share in 2024, due to their essential role in maintaining enclosure integrity and preventing flame propagation through cable entries.

The sensors segment is projected to record the fastest CAGR of 24.8% from 2025 to 2032, driven by the increasing need for real-time environmental monitoring and predictive maintenance in volatile industrial environments.

- By End User

On the basis of end user, the market includes oil and gas, chemical and petrochemical, energy and power, mining, pharmaceutical, food processing, marine and ship building, aerospace, military and defense, and others. The oil and gas segment held the largest market share of 35.4% in 2024, reflecting the industry’s extensive use of explosion-proof solutions to mitigate hazards in extraction, refining, and distribution.

The pharmaceutical segment is expected to witness the fastest CAGR of 21.7% between 2025 and 2032, driven by stringent regulations ensuring safe manufacturing environments, particularly when handling volatile solvents and active pharmaceutical ingredients.

Asia-Pacific Explosion-Proof Equipment Market Regional Analysis

- China dominates the explosion-proof equipment market with the largest revenue share of 38.7% in 2024, driven by stringent industrial safety regulations, rising investments in oil & gas infrastructure, and a strong presence of hazardous location-based industries

- The region benefits from advanced technological adoption, consistent regulatory enforcement by bodies such as OSHA and NEC, and a strong demand for explosion-proof solutions across chemical processing and energy sectors

- Growth is further supported by a mature industrial base, rapid integration of industrial IoT solutions in hazardous environments, and increased emphasis on worker safety compliance across both legacy and new industrial facilities

India Explosion-Proof Equipment Market Insight

The India explosion-proof equipment market is expected to witness the fastest growth rate within Asia-Pacific, driven by increasing industrial safety regulations, strong growth in oil refining, and infrastructure projects. With expanding pharmaceutical, fertilizer, and mining industries, India is seeing a surge in demand for reliable explosion-proof technologies. Government initiatives such as “Make in India” and increased FDI in energy and heavy industries are contributing to the adoption of certified safety systems across hazardous environments.

Asia-Pacific Explosion-Proof Equipment Market Share

The Explosion-Proof Equipment industry is primarily led by well-established companies, including:

- R. STAHL AG (Germany)

- Extronics (U.K.)

- Honeywell International Inc (U.S.)

- ABB (Switzerland)

- BARTEC Top Holding GmbH (Germany)

- Eaton (Ireland)

- Pepperl+Fuchs (Germany)

- Bosch Rexroth AG (Germany)

- MarechalElectric (France)

- Pelco (U.S.)

- DEHN SE (Germany)

- Schneider Electric (France)

- nVent (U.K.)

- Axis Communications AB (Sweden)

- ClearView Communications LTD (U.K.)

- Zenitel (Norway)

- MIRETTI (Italy)

- Emerson Electric Co (U.S.)

What are the Recent Developments in Asia-Pacific Explosion-Proof Equipment Market?

- In November 2024, Konecranes expanded its explosion-proof equipment portfolio with the launch of the EX C-series electric chain hoist, engineered for use in Zone 1/2/21 hazardous environments. Introduced across the EMEA and APAC regions, the hoist incorporates advanced safety and efficiency features, making it ideal for operations in explosive atmospheres such as oil refineries, chemical plants, and gas facilities

- In August 2022, ARCHON Industries, Inc. launched the EX20100 explosion-proof light, specifically engineered to provide continuous illumination for various industrial equipment in hazardous and non-hazardous areas. Designed for use in Class I Division I Group C&D and Class I Division II Group C&D locations, the luminaire enhances safety and visibility in challenging environments

- In April 2022, Mitsubishi Heavy Industries, Ltd., in partnership with ENEOS Corporation, introduced the second-generation 'EX ROVR' plant inspection robot with explosion-proof capabilities. Utilizing remote maintenance technology, it enhances worker safety, increases work efficiency, and ensures continuous facility inspections in potentially explosive atmospheres, catering to the demands of the explosion-proof equipment market

- In February 2022, Pyroban reintroduced Ex Solutions Consulting to aid manufacturers in addressing their Ex design and certification needs or skill shortages. This service expedites the delivery of explosion-proof products to market, minimizing Ex certification expenses. It serves as a valuable resource for manufacturers navigating the complexities of the explosion-proof equipment market

- In May 2021, Zenitel and AMAG Technology collaborated to provide a cutting-edge security solution for a development in West Los Angeles. Covering 200,000 square feet across eight floors, the project integrates explosion-proof equipment to ensure safety and security in both the creative office space and on-site apartments

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Asia Pacific Explosion Proof Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Asia Pacific Explosion Proof Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Asia Pacific Explosion Proof Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.