Asia Pacific Extrusion Machinery Market

Market Size in USD Billion

CAGR :

%

USD

4.70 Billion

USD

6.64 Billion

2024

2032

USD

4.70 Billion

USD

6.64 Billion

2024

2032

| 2025 –2032 | |

| USD 4.70 Billion | |

| USD 6.64 Billion | |

|

|

|

|

Asia-Pacific Extrusion Machinery Market Size

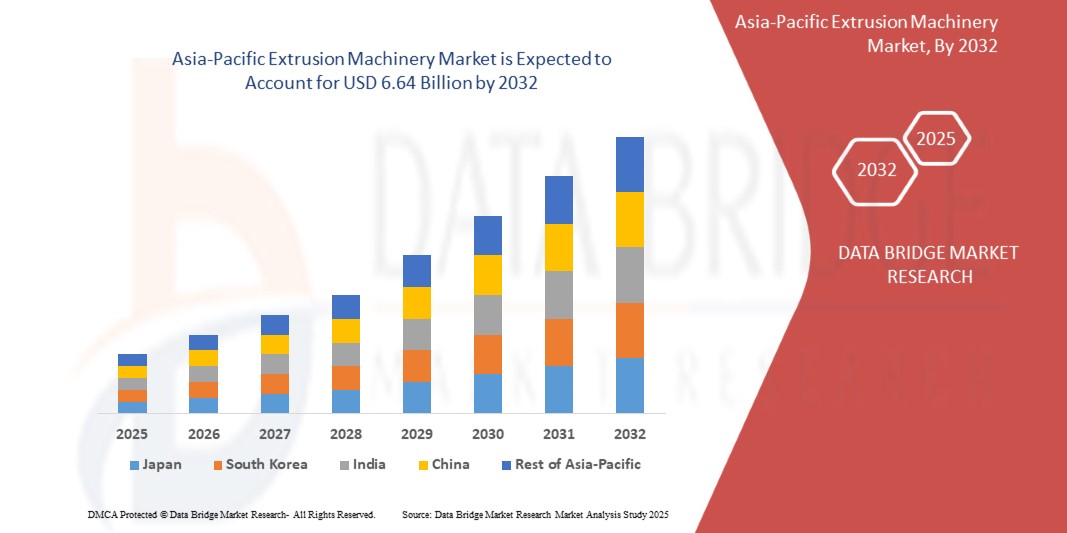

- The Asia-Pacific Extrusion Machinery Market size was valued at USD 4.70 billion in 2024 and is expected to reach USD 6.64 billion by 2032, at a CAGR of 4.4% during the forecast period

- The market growth is largely fueled by the rising demand for lightweight and sustainable materials across industries such as automotive, construction, and packaging, driving widespread adoption of extrusion machinery and advanced production techniques

- Furthermore, increasing technological progress in automation, energy-efficient systems, and precision control is establishing extrusion machinery as a preferred solution for high-volume, cost-effective, and reliable manufacturing. These converging factors are accelerating the uptake of extrusion machinery, thereby significantly boosting the industry’s growth

Asia-Pacific Extrusion Machinery Market Analysis

- Extrusion machinery consists of systems used to shape plastics, metals, and rubber into continuous profiles, components, and products with high consistency and efficiency, serving applications across construction, automotive, packaging, and consumer goods

- The escalating demand for extrusion machinery is primarily fueled by the expansion of infrastructure projects, growing adoption of recyclable and eco-friendly materials, and the rising need for advanced machinery capable of delivering large-scale production with enhanced quality

- China dominated the Asia-Pacific Extrusion Machinery Market in 2024, due to its expansive manufacturing base, large-scale infrastructure projects, and strong automotive and packaging production sectors

- Japan is expected to be the fastest growing country in the Asia-Pacific Extrusion Machinery Market during the forecast period due to its advanced industrial automation sector and rising adoption of precision extrusion technologies

- Single-screw extruders segment dominated the market with a market share of 63.2% in 2024, due to its widespread application in processing plastics, wires, cables, and pipes. Known for their cost-effectiveness, simplicity, and efficiency in handling basic extrusion tasks, single-screw machines remain the most widely preferred. Their ease of maintenance and adaptability to various raw materials also make them highly suitable for small to medium-scale manufacturers. The continuous expansion of the packaging and construction sectors, where single-screw extruders are extensively used, further strengthens their dominance

Report Scope and Asia-Pacific Extrusion Machinery Market Segmentation

|

Attributes |

Asia-Pacific Extrusion Machinery Market Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Asia-Pacific

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Asia-Pacific Extrusion Machinery Market Trends

Increasing Adoption of Energy-Efficient and Automated Extrusion Machinery

- The Asia-Pacific Extrusion Machinery Market is experiencing robust growth due to rising adoption of energy-efficient and automated equipment designed to optimize production while reducing operational costs. Manufacturers are focusing on machinery that maximizes material yield, energy savings, and precision to meet industry demands

- For instance, KraussMaffei Group has launched advanced extrusion systems with automation features that reduce cycle times and energy consumption. These innovations are being adopted by industries seeking higher productivity while maintaining eco-friendly manufacturing practices

- The integration of digital monitoring systems in extrusion equipment is enhancing real-time reporting and predictive maintenance. Smart automation allows operators to detect anomalies early, minimizing downtime and improving consistency in manufacturing outputs

- In addition, the demand for lightweight and specialized extruded products in industries such as packaging, automotive, and construction is driving machinery upgrades. Automated extrusion lines enable customized production with high accuracy, meeting these growing application needs

- Energy efficiency regulations are also encouraging adoption of innovative designs that reduce power usage. Machinery equipped with energy recovery systems and optimized heating solutions is increasingly being adopted to align with sustainability goals and lower production costs

- Altogether, the market is moving toward advanced extrusion technologies combining automation, sustainability, and efficiency. This shift highlights the significant role extrusion machinery plays in sustainable production, shaping the evolution of manufacturing across multiple industries

Asia-Pacific Extrusion Machinery Market Dynamics

Driver

Rapidly Growing Construction and Automotive Industries

- The expansion of construction and automotive industries is a primary driver for extrusion machinery as both sectors depend heavily on extruded components for structural and functional applications. Rising demand for lightweight and durable materials is further strengthening this market

- For instance, extrusion machinery manufacturers such as Milacron Holdings Corp. provide extrusion systems tailored for producing components used in automotive panels, pipes, and construction materials. Their systems are instrumental in raising productivity and enabling cost competitiveness in these industries

- In the construction sector, the rising demand for infrastructure development is increasing the use of extruded components such as pipes, profiles, and panels. Extrusion machinery enables mass production of these materials with enhanced uniformity and precision, ensuring durability in projects

- In addition, the automotive industry’s focus on lightweight solutions to improve fuel efficiency and align with emission targets is boosting demand for extruded parts. Extrusion machinery is critical in producing advanced plastics, composites, and aluminum profiles required in modern vehicles

- This growth trajectory emphasizes extrusion machinery’s indispensable role in major industrial sectors. As construction and automotive industries continue to expand globally, their reliance on extrusion technology will directly reinforce machinery demand and sustain market momentum

Restraint/Challenge

Increasing Regulatory Pressure and Environmental Concerns

- The Asia-Pacific Extrusion Machinery Market faces challenges from growing regulatory pressures and environmental concerns surrounding resource use and energy-intensive processes. Manufacturers are under scrutiny to comply with evolving sustainability and emissions standards, which complicates production strategies

- For instance, extrusion equipment providers such as Coperion encounter increasing requirements to re-engineer machinery designs that align with stricter energy regulations. Compliance with such measures often raises production costs and slows down time-to-market for updated equipment

- The environmental impact of plastics, a major output of extrusion, is creating reputational and operational challenges for the sector. Rising restrictions on single-use plastics and increasing demand for recyclable and biodegradable alternatives add pressure on machinery makers to innovate rapidly

- In addition, regulatory disparities between regions make it difficult for companies to standardize machinery globally. This fragmentation creates delays in adoption and forces manufacturers to invest heavily in design modifications suitable for different compliance environments

- Overcoming these constraints requires significant investment in R&D and sustainable engineering. Developing flexible, energy-efficient, and environmentally adaptive extrusion machinery will be critical in ensuring resilience and continued growth of the Asia-Pacific Extrusion Machinery Market

Asia-Pacific Extrusion Machinery Market Scope

The market is segmented on the basis of type, product type, process output, and end use.

• By Type

On the basis of type, the Asia-Pacific Extrusion Machinery Market is segmented into direct extrusion, indirect extrusion, and hydrostatic extrusion. The direct extrusion segment dominated the largest market revenue share in 2024, owing to its wide application across industries such as construction, automotive, and consumer goods. Direct extrusion is favored for its ability to produce continuous profiles with uniform cross-sections at relatively lower costs compared to other methods. Its simplicity in operation, high material utilization, and suitability for mass production make it the most adopted type. Furthermore, the growing demand for aluminum profiles in infrastructure and transportation significantly reinforces the prominence of direct extrusion machinery.

The indirect extrusion segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by its advantages in producing high-quality products with superior surface finish and reduced frictional losses. This process is increasingly adopted for applications requiring complex and precise geometries, particularly in aerospace and automotive industries. Indirect extrusion’s ability to enhance material properties and extend die life is encouraging industries to shift toward its adoption. Moreover, the rising need for lightweight yet durable components in next-generation mobility solutions further accelerates demand for this type.

• By Product Type

On the basis of product type, the Asia-Pacific Extrusion Machinery Market is segmented into single-screw extruders, twin-screw extruders, and others. The single-screw extruders segment dominated the market with a share of 63.2% in 2024, supported by its widespread application in processing plastics, wires, cables, and pipes. Known for their cost-effectiveness, simplicity, and efficiency in handling basic extrusion tasks, single-screw machines remain the most widely preferred. Their ease of maintenance and adaptability to various raw materials also make them highly suitable for small to medium-scale manufacturers. The continuous expansion of the packaging and construction sectors, where single-screw extruders are extensively used, further strengthens their dominance.

The twin-screw extruders segment is expected to record the fastest growth from 2025 to 2032, owing to their superior mixing capabilities and efficiency in processing complex materials such as composites and reinforced plastics. These machines provide greater flexibility in compounding and blending applications, making them highly attractive for industries such as food processing, pharmaceuticals, and advanced plastics manufacturing. The rising demand for customized formulations and innovative materials is fueling the adoption of twin-screw extruders. Their ability to achieve higher output rates with precise control over product quality positions them as a key growth driver for the market.

• By Process Output

On the basis of process output, the Asia-Pacific Extrusion Machinery Market is segmented into plastic, metal, rubber, and others. The plastic segment dominated the market with the largest revenue share in 2024, primarily due to the massive demand for plastic pipes, films, and sheets across construction, packaging, and consumer goods industries. Plastic extrusion machinery is widely preferred for its versatility, enabling manufacturers to produce products of varying sizes and applications with high precision. The increasing use of plastics in lightweight automotive components and advanced packaging solutions further enhances the adoption of plastic extrusion processes. In addition, the continuous innovation in biodegradable and recyclable plastics provides long-term growth opportunities in this segment.

The metal extrusion segment is projected to witness the fastest growth from 2025 to 2032, driven by the rising demand for lightweight metals such as aluminum and magnesium in automotive, aerospace, and defense applications. Metal extrusion machinery enables the production of high-strength components with excellent dimensional accuracy and durability. With industries shifting towards sustainable mobility and energy-efficient designs, the requirement for extruded metal profiles is rapidly increasing. The growing investments in infrastructure projects and electric vehicles further accelerate the adoption of metal extrusion machinery worldwide.

• By End Use

On the basis of end use, the Asia-Pacific Extrusion Machinery Market is segmented into construction, consumer goods, automotive, food and beverage, healthcare, aerospace & defense, and others. The construction segment dominated the market in 2024, fueled by the high demand for extruded products such as pipes, profiles, and panels in residential and commercial infrastructure projects. Extrusion machinery plays a crucial role in producing building materials with durability and cost efficiency, making it highly relevant for large-scale construction activities. Rapid urbanization, smart city projects, and the emphasis on sustainable building materials further support the dominance of the construction segment.

The automotive segment is anticipated to grow at the fastest CAGR from 2025 to 2032, as the industry increasingly relies on extruded plastics and metals for lightweight and fuel-efficient vehicle components. Extrusion machinery is vital in producing precision parts such as trim profiles, seals, and structural components that meet modern automotive standards. The accelerating shift toward electric vehicles and stringent emission regulations is pushing manufacturers to adopt extrusion-based lightweight materials. Moreover, the rising focus on design flexibility and safety features further boosts demand from the automotive sector.

Asia-Pacific Extrusion Machinery Market Regional Analysis

- China dominated the Asia-Pacific Extrusion Machinery Market with the largest revenue share in 2024, driven by its expansive manufacturing base, large-scale infrastructure projects, and strong automotive and packaging production sectors

- Robust government initiatives promoting industrial modernization, combined with increasing investments in smart factories and automation technologies, reinforce China’s leadership in the regional market

- The integration of energy-efficient extrusion systems, advanced process automation, and digital monitoring solutions enhances production efficiency and sustainability, consolidating its dominant position. The presence of leading domestic machinery manufacturers and collaborations with global players ensure China’s continued dominance during the forecast period

Japan Asia-Pacific Extrusion Machinery Market Insight

Japan is projected to register the fastest CAGR in the Asia Pacific Asia-Pacific Extrusion Machinery Market during 2025–2032, supported by its advanced industrial automation sector and rising adoption of precision extrusion technologies. Japanese industries are increasingly implementing extrusion machinery in automotive, electronics, and high-performance materials to align with Industry 4.0 practices. The country’s strong emphasis on lightweight and recyclable materials, coupled with continuous investments in R&D, is driving innovation in extrusion solutions. Strategic collaborations between Japanese manufacturers and international leaders further reinforce its position as the region’s fastest-growing market.

India Asia-Pacific Extrusion Machinery Market Insight

India is expected to witness steady growth during 2025–2032, fueled by rapid expansion in construction, consumer goods, and automotive sectors. Government initiatives promoting manufacturing under programs such as “Make in India” and rising investments in industrial modernization are accelerating the adoption of extrusion machinery. Increasing demand for cost-effective and scalable solutions among small- and medium-sized enterprises is also supporting growth. Expanding partnerships with global technology providers and the push toward sustainable and energy-efficient production strengthen India’s role as an emerging market in the Asia Pacific region.

Asia-Pacific Extrusion Machinery Market Share

The extrusion machinery industry is primarily led by well-established companies, including:

- Davis Standard (U.S.)

- Coperion GmbH (Germany)

- Milacron, LLC (U.S.)

- Leistritz Extrusionstechnik GmbH (Germany)

- NFM/Welding Engineers, Inc. (U.S.)

- Gneuß Kunststofftechnik GmbH (Germany)

- Reifenhauser (Italy)

- TECNOMATIC SRL (Italy)

- KraussMaffei (Germany)

- Kabra ExtrusionTechnik Ltd. (India)

- Nordson Corporation (U.S.)

Latest Developments in Asia-Pacific Extrusion Machinery Market

- In August 2024, Nordson Corporation completed its acquisition of Atrion Corporation, a recognized leader in medical infusion fluid delivery and cardiovascular solutions. This move significantly expands Nordson’s medical technology portfolio, allowing it to penetrate new therapeutic areas with strong growth potential. The acquisition positions Nordson to capture a larger share of the rapidly growing healthcare and life sciences market, while enhancing its competitiveness through innovation in precision extrusion equipment used for advanced medical applications

- In January 2024, Davis-Standard successfully acquired Extrusion Technology Group (ETG), strengthening its expertise in advanced extrusion systems. This strategic acquisition enhances Davis-Standard’s product offerings and bolsters its market presence in high-demand sectors such as packaging, automotive, and medical. The integration of ETG’s technological know-how is expected to accelerate innovation, improve customer service, and provide more comprehensive extrusion solutions, particularly reinforcing Davis-Standard’s growth and competitiveness in the market

- In November 2023, KraussMaffei relaunched its ZE 28 BluePower laboratory extruder during the Fakuma trade fair, showcasing a more efficient and user-focused design. This product launch enhances KraussMaffei’s extrusion machinery portfolio, providing customers with improved flexibility, operational efficiency, and tailored solutions. The relaunch underscores the company’s commitment to innovation and helps strengthen its positioning in the laboratory and R&D extrusion segment, where precision and adaptability are critical

- In November 2022, AMUT signed a long-term partnership agreement with Spanish company LUISO S.L., marking a strategic expansion in the recycling and cast film Asia-Pacific Extrusion Machinery Markets. The collaboration strengthens AMUT’s service capabilities and boosts its competitiveness in the region by enabling broader customer support and enhanced technology offerings. This partnership aligns with the rising demand for sustainable solutions and positions AMUT as a stronger player in recycling-focused extrusion systems

- In October 2022, ENTEK secured a USD 200 million grant from the U.S. Department of Energy (DOE) to establish a new lithium separator factory in the U.S. This investment scales ENTEK’s production capacity and also supports the electrification of transportation by supplying materials for 1.4 million electric vehicles annually. The development reinforces ENTEK’s role in the battery supply chain and highlights the importance of extrusion technology in advancing clean energy and EV markets

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Asia Pacific Extrusion Machinery Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Asia Pacific Extrusion Machinery Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Asia Pacific Extrusion Machinery Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.