Europe Oil Refining Catalyst Market

Market Size in USD Million

CAGR :

%

USD

967.60 Million

USD

1,581.04 Million

2025

2033

USD

967.60 Million

USD

1,581.04 Million

2025

2033

| 2026 –2033 | |

| USD 967.60 Million | |

| USD 1,581.04 Million | |

|

|

|

|

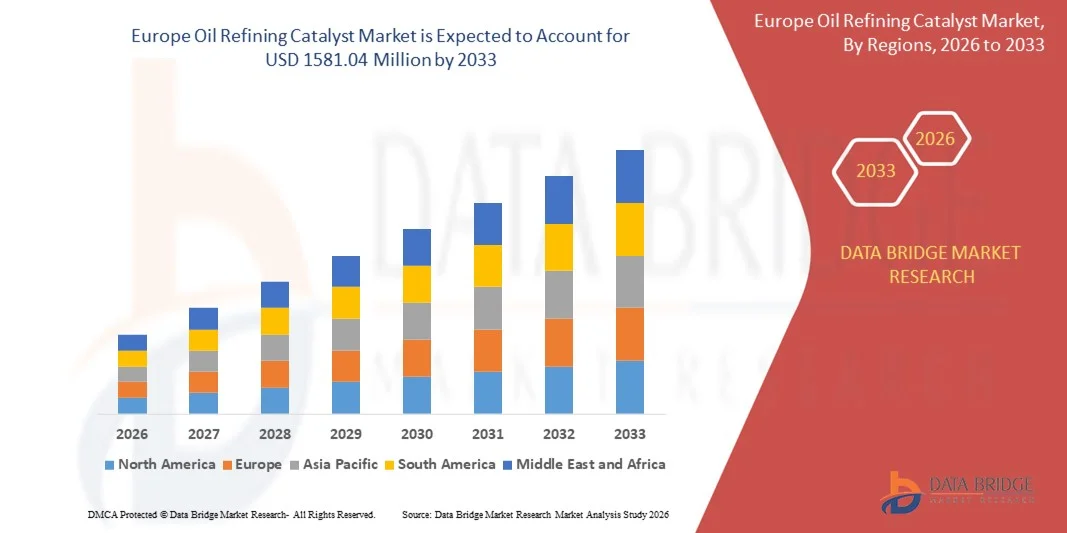

What is the Europe Oil Refining Catalyst Market Size and Growth Rate?

- The Europe oil refining catalyst market size was valued at USD 967.60 million in 2025 and is expected to reach USD 1581.04 million by 2033, at a CAGR of 6.33% during the forecast period

- Market growth is primarily driven by the rising demand for cleaner fuels, stricter environmental regulations, and increased adoption of advanced catalytic processes across petroleum refining operations

- The hydrotreating segment dominated the market in 2024, accounting for over 38% of the total revenue share, driven by stringent sulfur emission regulations and the widespread need for producing ultra-low sulfur diesel and gasoline

What are the Major Takeaways of Oil Refining Catalyst Market?

- Oil refining catalysts are critical materials used to enhance chemical reactions during refining processes, enabling higher conversion efficiency, improved fuel quality, and reduced sulfur and emissions, supporting compliance with environmental standards

- The growing demand for oil refining catalysts is largely driven by the need for high-performance, cost-effective, and environmentally compliant refining solutions, supported by increasing fuel consumption, refinery modernization, and sustained investments in process optimization and catalyst innovation

- Germany dominated the Europe oil refining catalyst market with an estimated 38.60% revenue share in 2025, supported by strong demand from petroleum refining, fuel upgrading, petrochemical production, and residue processing applications

- France is projected to register the fastest CAGR of around 7.5% during the forecast period, driven by increasing adoption of oil refining catalysts in clean fuel production, hydroprocessing units, and refinery modernization projects

- 1000nm-1500nm segment dominated the market with a market share of 45.8% in 2024, due to strong demand in optical communications, LiDAR, and remote sensing. Lasers in this range provide optimal transmission through fiber optic networks, high sensitivity for sensing applications, and reliable performance for industrial processing. Their compatibility with widely used photonic systems and instrumentation enhances their adoption across research, industrial, and telecommunication sectors

Report Scope and Oil Refining Catalyst Market Segmentation

|

Attributes |

Oil Refining Catalyst Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Europe

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Oil Refining Catalyst Market?

Shift Toward Cleaner Fuels and Advanced Refining Processes

- The oil refining catalyst market is witnessing strong momentum due to the growing shift toward cleaner fuel production and advanced refining technologies. Oil refining catalysts play a crucial role in enabling refiners to meet stringent fuel quality standards by improving conversion efficiency and reducing sulfur and emissions

- For instance, BASF SE and Johnson Matthey are continuously enhancing their hydrotreating and hydrocracking catalyst portfolios to support the production of ultra-low sulfur fuels. Similarly, Honeywell UOP offers advanced FCC and hydroprocessing catalysts that help refineries improve yields while complying with environmental regulations

- In fuel processing operations, oil refining catalysts enable refiners to maximize output from heavier crude feeds while maintaining high product quality. Their ability to improve reaction selectivity supports higher yields of gasoline, diesel, and jet fuel, reducing operational waste

- Within upgrading and conversion units, oil refining catalysts enhance processing flexibility by allowing refiners to adapt to varying crude qualities. This capability is increasingly important as refineries shift toward processing heavier and unconventional feedstocks

- Oil refining catalysts also demonstrate growing importance in residue upgrading and biofuel co-processing, supporting refiners’ efforts to align with sustainability goals and energy transition strategies

- Overall, the increasing adoption of oil refining catalysts for cleaner fuel production highlights their essential role in modern refining operations. Their efficiency, adaptability, and regulatory compliance firmly position them as a cornerstone of next-generation refinery technologies

What are the Key Drivers of Oil Refining Catalyst Market?

- The rising need for higher refining efficiency and environmental compliance is a major driver accelerating the oil refining catalyst market. These catalysts enable improved conversion rates, lower emissions, and enhanced fuel quality across refining processes

- For instance, Clariant and Axens provide advanced catalyst solutions that support sulfur removal and octane enhancement while reducing energy consumption. Companies such as Haldor Topsoe are also developing high-performance catalysts designed for long operational lifetimes and improved feedstock flexibility

- The ability of oil refining catalysts to improve yield optimization helps refiners reduce operational costs while maintaining compliance with evolving fuel standards. This balance between performance and efficiency strengthens their long-term economic value

- Growing investments in refinery modernization and capacity expansions further support catalyst demand, particularly in hydroprocessing and FCC units where catalysts are critical to operational performance

- The market’s emphasis on combining productivity, compliance, and cost efficiency reinforces oil refining catalysts as indispensable components of modern petroleum refining, ensuring sustained adoption across global refining infrastructures

Which Factor is Challenging the Growth of the Oil Refining Catalyst Market?

- The high cost of oil refining catalysts presents a key challenge to market growth, as advanced formulations require rare metals, complex chemical compositions, and precision manufacturing techniques, increasing overall expenses

- For instance, premium catalyst solutions offered by companies such as Johnson Matthey and Haldor Topsoe involve higher upfront costs, making them less accessible for smaller or cost-sensitive refineries

- The technical complexity associated with catalyst selection, handling, and regeneration further limits adoption, as refiners require specialized expertise to optimize catalyst performance and lifecycle management

- Catalyst deactivation due to contaminants and harsh operating conditions can also increase replacement frequency, adding to operational costs and impacting refinery profitability

- To address these challenges, manufacturers are focusing on longer catalyst lifespans, regeneration technologies, and cost-optimized formulations, which will be critical in enabling broader adoption of oil refining catalysts across diverse refinery configurations

How is the Oil Refining Catalyst Market Segmented?

The market is segmented on the basis of type, catalyst, distribution channel, and application.

- By Type

On the basis of type, the oil refining catalyst market is segmented into Hydrotreating, Fluidized Catalytic Cracking (FCC), Residue Fluidized Catalytic Cracking (RFCC), Hydrocracking, and Others. The hydrotreating segment dominated the market in 2024, accounting for over 38% of the total revenue share, driven by stringent sulfur emission regulations and the widespread need for producing ultra-low sulfur diesel and gasoline. Hydrotreating catalysts are extensively used to remove sulfur, nitrogen, and other impurities, making them essential across nearly all refinery configurations.

The hydrocracking segment is expected to witness the fastest growth during the forecast period, supported by increasing demand for high-quality middle distillates and the ability to process heavy and unconventional crude oils. Hydrocracking catalysts enable higher conversion efficiency, improved yield flexibility, and superior fuel quality. Growing refinery upgrades and rising consumption of diesel and jet fuel are further accelerating adoption, positioning hydrocracking as a key growth engine in the market.

- By Catalyst

Based on catalyst composition, the market is segmented into Zeolites, Metals, and Chemicals. The zeolites segment dominated the oil refining catalyst market in 2024, capturing approximately 45% of the market share, owing to their superior acidity, thermal stability, and shape-selective properties. Zeolite catalysts are extensively used in FCC and hydrocracking processes to enhance conversion efficiency and maximize gasoline and olefin yields. Their ability to handle heavy feedstocks and improve reaction selectivity makes them a preferred choice among refiners.

The metals segment is projected to grow at the fastest CAGR, driven by increasing demand for hydrotreating and reforming catalysts used in sulfur removal and octane enhancement. Metal-based catalysts, including nickel, molybdenum, platinum, and cobalt, offer high activity and durability under severe operating conditions. Rising environmental regulations and the need for cleaner fuels are further accelerating the adoption of metal-based catalysts across modern refinery operations.

- By Distribution Channel

On the basis of distribution channel, the oil refining catalyst market is segmented into Direct Sales/B2B, Distributors/Third-Party Distributors/Traders, E-Commerce, and Others. The direct sales/B2B segment dominated the market in 2024, accounting for nearly 60% of total revenue, as major refiners prefer direct procurement from catalyst manufacturers to ensure technical support, customized formulations, and long-term supply agreements. Direct sales channels enable close collaboration between catalyst suppliers and refinery operators, optimizing catalyst performance and lifecycle management.

The distributors and third-party distributors segment is expected to grow at the fastest rate, driven by the rising number of small and mid-sized refineries seeking flexible procurement options. These channels offer quicker delivery, localized support, and cost-effective sourcing, particularly in emerging markets. The growing role of traders and regional distributors is enhancing market accessibility and expanding catalyst adoption beyond large-scale refinery networks.

- By Application

By application, the oil refining catalyst market is segmented into Diesel, Kerosene, Distillate Dewax, and Others. The diesel segment dominated the market in 2024, holding over 40% of the total market share, supported by strong global demand for transportation fuels and stringent regulations for low-sulfur diesel. Oil refining catalysts used in diesel production play a critical role in sulfur removal, cetane improvement, and yield optimization, making them indispensable for refinery operations.

The distillate dewax segment is anticipated to witness the fastest growth, driven by increasing demand for high-performance lubricants and low-temperature fuels. Dewaxing catalysts improve cold-flow properties and enhance fuel stability, supporting applications in automotive, industrial, and aviation sectors. Growing emphasis on fuel quality, performance optimization, and specialty petroleum products is accelerating catalyst demand across emerging distillate applications.

Which Region Holds the Largest Share of the Oil Refining Catalyst Market?

- Germany dominated the Europe oil refining catalyst market with an estimated 38.60% revenue share in 2025, supported by strong demand from petroleum refining, fuel upgrading, petrochemical production, and residue processing applications. The country’s advanced refining infrastructure, presence of major integrated oil and chemical companies, and continuous investments in refinery efficiency improvements and catalyst-intensive processes such as hydrotreating, FCC, and hydrocracking continue to drive market leadership

- A strong base of refining and chemical R&D centers, close collaboration between refiners, technology licensors, and catalyst manufacturers, and ongoing advancements in catalyst formulation, regeneration technologies, and feedstock flexibility are further strengthening Germany’s leadership in the Europe oil refining catalyst market

- Growing emphasis on ultra-low sulfur fuel production, processing of heavier crude slates, and strict compliance with European Union environmental regulations is sustaining long-term growth of the oil refining catalyst market across Germany and neighboring European countries

France Oil Refining Catalyst Market Insight

France is projected to register the fastest CAGR of around 7.5% during the forecast period, driven by increasing adoption of oil refining catalysts in clean fuel production, hydroprocessing units, and refinery modernization projects. Rising investments in energy efficiency, emissions reduction, and advanced refining technologies are accelerating market expansion.

Italy Oil Refining Catalyst Market Insight

Italy is witnessing steady growth in the oil refining catalyst market, supported by rising demand from refinery upgrades, residue conversion projects, and capacity optimization initiatives. Increasing focus on improving fuel quality, meeting EU emission standards, and enhancing refinery operational efficiency continues to support consistent market development.

Which are the Top Companies in Oil Refining Catalyst Market?

The oil refining catalyst industry is primarily led by well-established companies, including:

- Royal Dutch Shell plc (Netherlands)

- Exxon Mobil Corporation (U.S.)

- BASF SE (Germany)

- Honeywell International Inc. (UOP LLC) (U.S.)

- Johnson Matthey (U.K.)

- 3M (U.S.)

- Dow (U.S.)

- W. R. Grace & Co.-Conn (U.S.)

- Anten Chemical Co., Ltd (China)

- Clariant (Switzerland)

- China Petrochemical Corporation (Sinopec) (China)

- Albemarle Corporation (U.S.)

- Haldor Topsoe A/S (Denmark)

- Arkema (France)

- Kuwait Catalyst Company (Kuwait)

- JGC C&C (Japan)

- Axens (France)

- Gazpromneft-Catalytic Systems (Russia)

- UNICAT Catalyst Technologies, LLC (U.S.)

- TAIYO KOKO Co., Ltd (Japan)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Europe Oil Refining Catalyst Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Europe Oil Refining Catalyst Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Europe Oil Refining Catalyst Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.