Global 3d Laser Scanner Market

Market Size in USD Billion

CAGR :

%

USD

3.30 Billion

USD

6.12 Billion

2024

2032

USD

3.30 Billion

USD

6.12 Billion

2024

2032

| 2025 –2032 | |

| USD 3.30 Billion | |

| USD 6.12 Billion | |

|

|

|

|

3D Laser Scanner Market Size

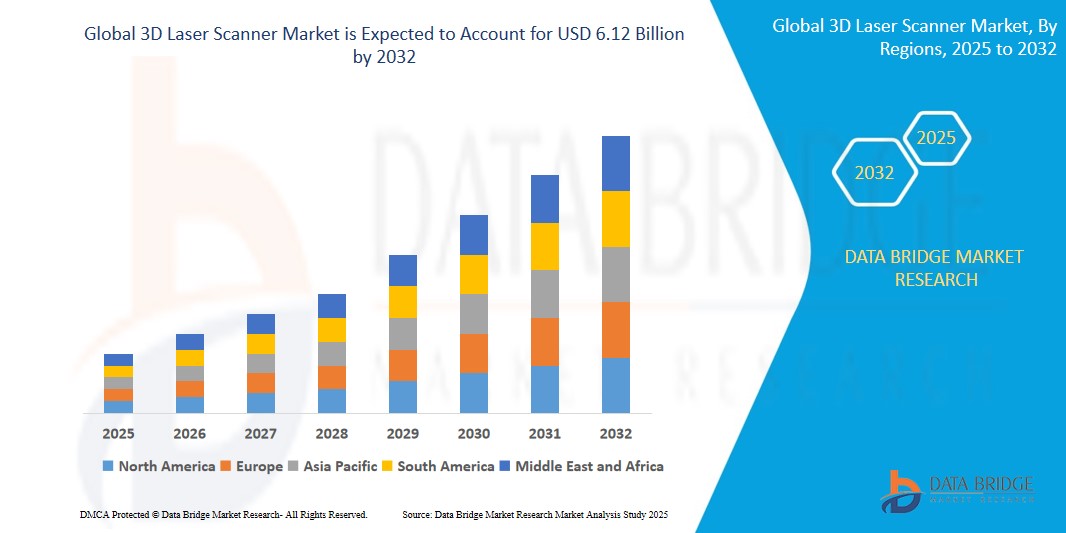

- The Global 3D Laser Scanner Market size was valued at USD 3.30 billion in 2024 and is expected to reach USD 6.12 billion by 2032, at a CAGR of 7.10% during the forecast period

- This market growth is driven by factors such as increasing adoption of 3D scanning in construction and manufacturing, rising demand for high-precision scanning in industrial design, technological advancements, and the integration of 3D laser scanners with AI and robotics.

3D Laser Scanner Market Analysis

- 3D Laser Scanners are indispensable tools across industries such as automotive, aerospace, architecture, and healthcare, providing highly accurate, non-contact 3D surface capture for quality control, reverse engineering, and digital modeling applications. Their precision and efficiency are crucial for achieving tight tolerances and accelerating product development cycles.

- The market demand is significantly fueled by the rising adoption of 3D printing, reverse engineering applications, and stringent quality inspection standards, particularly in high-value sectors like aerospace and defense.

- North America is expected to dominate the Global 3D Laser Scanner Market throughout the forecast period, attributed to the region’s strong industrial base, rapid technological advancements, and growing integration of 3D scanning in manufacturing and healthcare operations.

- Asia-Pacific is projected to be the fastest-growing region in the market due to increased infrastructure development, rising manufacturing activity, and expanding awareness of the benefits of 3D scanning technology across sectors like construction and healthcare.

- The quality control and inspection 3D laser scanner segment is anticipated to lead the market with a substantial share of 56.11%, driven by its versatility in capturing accurate data across mid-sized objects and environments. These scanners strike a balance between portability and scanning distance, making them ideal for industrial applications such as plant inspections, construction site mapping, and automotive component analysis.

Report Scope and 3D Laser Scanner Market Segmentation

|

Attributes |

3D Laser Scanner Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

3D Laser Scanner Market Trends

“Increasing Demand for High-Precision Quality Control in Manufacturing”

- One of the primary factors fueling the growth of the 3D laser scanner market is the rising emphasis on precision and quality assurance across various manufacturing sectors. As industries such as aerospace, automotive, electronics, and energy become more quality-driven, they require advanced metrology tools that can deliver highly accurate dimensional measurements and surface analysis.

- 3D laser scanners offer non-contact, high-speed, and high-resolution inspection capabilities, which makes them ideal for detecting manufacturing defects, dimensional inconsistencies, or surface deviations without halting production.

- These devices are particularly valuable in sectors like aerospace and automotive, where even the slightest error in dimensions can lead to critical performance issues or product recalls.

- For instance: In the aerospace sector, companies like Boeing and Airbus use 3D laser scanning systems during fuselage and wing assembly stages to detect alignment deviations, reducing downtime and ensuring compliance with safety standards.

3D Laser Scanner Market Dynamics

Driver

“Rising Integration of 3D Scanning with Smart Manufacturing and Digital Twins”

- Another strong driver is the increasing integration of 3D laser scanning technologies with digital transformation strategies, particularly under Industry 4.0 frameworks. Modern production systems are moving toward automation, predictive analytics, and digital twin technologies, all of which rely heavily on accurate 3D data.

- 3D laser scanners play a pivotal role in enabling real-time data acquisition, reverse engineering, and digital simulation for predictive maintenance, virtual prototyping, and performance optimization.

- This is especially relevant in construction, energy, and shipbuilding industries where accurate site or component visualization aids project planning and reduces execution risks.

- For instance: Construction companies engaged in large-scale infrastructure projects are using terrestrial 3D laser scanners to capture site conditions and create detailed BIM (Building Information Models), enabling accurate project planning and reducing rework costs.

Opportunity

“Expanding Infrastructure and Industrial Base in Emerging Economies”

- Rapid industrialization and urban expansion in emerging markets, especially in the Asia-Pacific, Middle East, and parts of Africa, present a significant growth opportunity for the 3D laser scanner market. These regions are witnessing increasing investments in smart manufacturing, industrial automation, and public infrastructure.

- Governments in countries like India, China, and Indonesia are launching nationwide programs focused on boosting manufacturing competitiveness and digital capabilities. These efforts are accelerating the adoption of technologies such as 3D scanning in civil engineering, utilities, and transport infrastructure.

- As awareness of the long-term cost savings and operational efficiencies offered by 3D scanning grows, companies in these markets are expected to integrate these systems across various application areas.

- For instance: In India, initiatives like “Smart Cities Mission” and “Make in India” are driving demand for precise measurement tools in urban planning, industrial layout mapping, and infrastructure upgrades, all of which can benefit significantly from 3D laser scanning solutions.

Restraint/Challenge

“High Initial Capital Investment and Maintenance Costs”

- Despite their benefits, the high acquisition and maintenance costs of 3D laser scanning systems remain a major barrier to adoption, particularly for small and medium enterprises (SMEs). These systems often require skilled operators, periodic calibration, and significant IT infrastructure for data processing and storage.

- Moreover, the integration of 3D scanning solutions into existing workflows may require additional training, customization, and investment in compatible software platforms further escalating the total cost of ownership.

- This becomes a deterrent in price-sensitive markets or among businesses operating under tight budget constraints, where conventional measurement tools or lower-cost alternatives are still widely used.

- For instance: Small fabrication units and local manufacturing workshops in developing countries often avoid adopting 3D scanning technologies due to high setup and maintenance costs, choosing instead to rely on manual inspection methods despite their lower accuracy.

3D Laser Scanner Market Scope

The 3D laser scanner market is segmented on the basis of range, product, type, offering, application and end users.

|

Segmentation |

Sub-Segmentation |

|

By Range |

|

|

By Product |

|

|

By Type |

|

|

By Offering

|

|

|

By Application |

|

|

By End Users

|

|

In 2025, the Quality Control and Inspection Segment is Projected to Dominate the Market in the Application Segment

The quality control and inspection segment is expected to lead the 3D laser scanner market with a 56.11% share in 2025. This growth is fueled by rising demand for precision in manufacturing, especially in automotive and aerospace sectors. 3D scanners enable fast, accurate, non-contact measurement, improving product quality and reducing defects. Their role in automating inspection processes and supporting compliance further boosts adoption.

In 2025, the Medium Range Segment is Expected to Account for the Largest Share in the Range Segment

The medium range segment is projected to hold the largest market share of 51.26% in 2025, due to its broad usage in industrial and construction applications. These scanners offer an ideal mix of range, accuracy, and mobility, making them suitable for mid-size parts and environments. Increasing use in plant inspections, structural surveys, and reverse engineering drives segment growth.

3D Laser Scanner Market Regional Analysis

“North America Holds the Largest Share in the 3D Laser Scanner Market”

- North America continues to lead the global 3D laser scanner market, largely due to the widespread adoption of advanced scanning technologies across industries such as automotive, aerospace, construction, and healthcare.

- The United States plays a pivotal role, supported by strong industrial infrastructure, a robust manufacturing base, and early adoption of automation and quality control tools.

- The presence of leading market players, coupled with consistent investment in R&D and innovation in metrology and 3D scanning solutions, has solidified the region’s position.

- Furthermore, favorable regulatory frameworks and increased demand for high-precision, non-contact measurement tools in various sectors have further accelerated the use of 3D laser scanners across the region.

“Asia-Pacific is Projected to Register the Highest CAGR in the 3D Laser Scanner Market”

- The Asia-Pacific region is poised to exhibit the fastest growth during the forecast period, driven by rising industrialization, expanding manufacturing capabilities, and increasing adoption of digital inspection technologies.

- China, India, and Japan are at the forefront of this growth, supported by government-led initiatives to modernize infrastructure and enhance production efficiency across sectors like automotive, electronics, and construction.

- Japan stands out with its mature industrial ecosystem and strong focus on precision engineering, encouraging widespread use of advanced 3D scanning systems for quality assurance and design validation.

- In China and India, the rapid growth of manufacturing hubs, increasing investments in industrial automation, and the entry of global players offering cost-effective scanning technologies are contributing to market expansion.

- Additionally, rising awareness about product quality standards and the need for detailed 3D modeling in sectors like heritage preservation and reverse engineering are further driving adoption across the region.

3D Laser Scanner Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Hexagon AB(Sweden)

- FARO(United States)

- CREAFORM(Canada)

- Perceptron, Inc.(United States)

- Nikon Metrology NV(Belgium)

- Trimble Inc.(United States)

- ZEISS (Germany)

- TOPCON CORPORATION(Japan)

- RIEGL Laser Measurement Systems GmbH(Austria)

- Artec Europe(Luxembourg)

- Surphaser(United States)

- DeWalt Corporation(United States)

- WENZEL Group (Germany)

- NextEngine, Inc.(United States)

- SGM Lightwave, LLC(United States)

- Precise Visual Technologies(United States)

- Technics Group (United States)

- CyberOptics(United States)

- IMAG’ING(France)

- McKim & Creed, Inc.(United States)

Latest Developments in Global 3D Laser Scanner Market

- In February 2025, FARO Technologies unveiled the next-generation FARO Focus Core Laser Scanner, designed for construction, public safety, and manufacturing industries. The upgraded model offers enhanced scanning speed and data accuracy, integrating advanced cloud-based processing to streamline workflows and reduce project turnaround times. This release highlights FARO’s continued investment in delivering efficient, portable, and cost-effective 3D scanning solutions.

- In November 2024, Hexagon AB introduced a major update to its Leica RTC360 3D laser scanner, now equipped with AI-powered edge computing capabilities. This development allows real-time data refinement directly on the device, significantly improving scanning efficiency on complex construction and industrial sites while minimizing post-processing time.

- In October 2024, Trimble Inc. announced a strategic collaboration with NVIDIA to integrate real-time visualization into its X7 3D laser scanning platform. The integration enables high-definition rendering of scan data for construction and civil engineering professionals, enhancing precision and planning capabilities during onsite operations.

- In August 2024, RIEGL Laser Measurement Systems GmbH introduced its new VZ-600i terrestrial laser scanner, engineered for large-scale surveying, geospatial analysis, and industrial mapping. The VZ-600i combines ultra-fast data acquisition with high-point density output, targeting professionals in mining, infrastructure, and environmental monitoring.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global 3d Laser Scanner Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Laser Scanner Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Laser Scanner Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.