Global 3d Printing Elastomers Market

Market Size in USD Million

CAGR :

%

USD

281.60 Million

USD

1,678.46 Million

2025

2033

USD

281.60 Million

USD

1,678.46 Million

2025

2033

| 2026 –2033 | |

| USD 281.60 Million | |

| USD 1,678.46 Million | |

|

|

|

|

3D Printing Elastomers Market Size

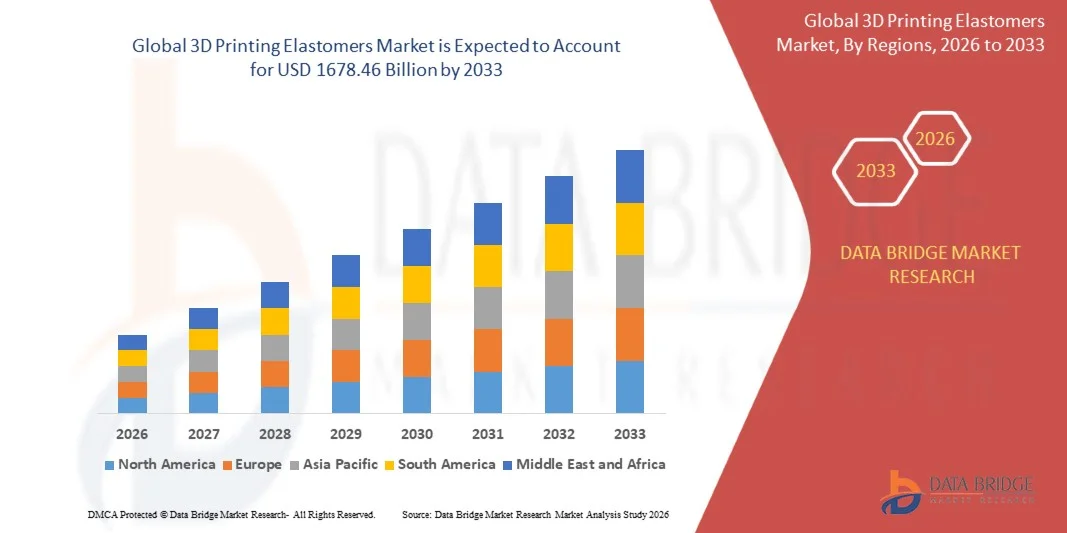

- The global 3D printing elastomers market size was valued at USD 281.6 million in 2025 and is expected to reach USD 1678.46 million by 2033, at a CAGR of 25.00% during the forecast period

- The market growth is largely driven by the expanding adoption of additive manufacturing across automotive, healthcare, aerospace, and consumer goods industries, supported by continuous advancements in elastomer material formulations and printing technologies that enable flexible, lightweight, and durable components

- Furthermore, rising demand for rapid prototyping, customization, and cost-efficient low-volume production is positioning 3D printing elastomers as a preferred material solution, with these combined factors accelerating market adoption and contributing significantly to overall industry growth

3D Printing Elastomers Market Analysis

- 3D printing elastomers, which provide rubber-like flexibility, resilience, and design freedom, are becoming essential materials in modern manufacturing workflows, particularly for functional prototyping, end-use parts, and customized applications across multiple industries

- The increasing demand for 3D printing elastomers is primarily fueled by the shift toward digital manufacturing, growing emphasis on lightweight and ergonomic product designs, and the need for faster product development cycles with enhanced performance characteristics

- North America dominated the 3D printing elastomers market with a share of around 45% in 2025, due to strong adoption of additive manufacturing across automotive, aerospace, and healthcare industries

- Asia-Pacific is expected to be the fastest growing region in the 3D printing elastomers market during the forecast period due to rapid industrialization, expanding manufacturing capacity, and increasing adoption of 3D printing technologies

- Filament segment dominated the market with a market share of 45.5% in 2025, due to its wide compatibility with desktop and industrial FDM/FFF printers and ease of handling during printing. Filament-based elastomers are preferred for rapid prototyping and low-to-medium volume production due to consistent material flow and reduced processing complexity. Manufacturers favor filaments for their availability in multiple hardness grades, supporting diverse functional applications. The strong presence of FDM technology across industrial and consumer segments further reinforces filament demand. Cost efficiency and minimal post-processing requirements also support its dominance

Report Scope and 3D Printing Elastomers Market Segmentation

|

Attributes |

3D Printing Elastomers Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

3D Printing Elastomers Market Trends

“Adoption of High-Performance and Application-Specific Elastomer Materials”

- A prominent trend in the 3D printing elastomers market is the increasing adoption of high-performance and application-specific elastomer materials designed to meet demanding industrial requirements. Manufacturers are focusing on elastomers that offer improved flexibility, durability, and mechanical strength to support functional prototyping and end-use part production across automotive, healthcare, and industrial manufacturing sectors

- For instance, BASF has developed advanced elastomer formulations under its Ultracur3D and Elastollan product lines that are widely used in automotive and industrial 3D printing applications. These materials enable manufacturers to produce flexible components with enhanced wear resistance and long-term performance, supporting broader industrial adoption

- The trend is further reinforced by the growing use of elastomer materials in electric vehicle components where lightweight and vibration-damping properties are essential. Companies are leveraging 3D printed elastomers for seals, gaskets, and interior components that require consistent performance under variable operating conditions

- In the healthcare sector, application-specific elastomers are increasingly used for medical devices, prosthetics, and orthodontic applications where comfort, flexibility, and biocompatibility are critical. Material suppliers and printer manufacturers are collaborating to ensure elastomers meet regulatory and performance requirements

- Industrial users are also adopting specialized elastomers for tooling, jigs, and fixtures to improve operational efficiency and reduce downtime. These materials allow rapid customization and faster replacement compared to conventional manufacturing approaches

- The growing availability of tailored elastomer materials optimized for specific printing technologies is strengthening this trend. This shift toward high-performance and application-driven elastomers is supporting wider acceptance of 3D printing elastomers across diverse end-use industries

3D Printing Elastomers Market Dynamics

Driver

“Rising Demand for Flexible and Customized Components Across Industries”

- The rising demand for flexible and customized components across multiple industries is a key driver supporting the growth of the 3D printing elastomers market. Manufacturers are increasingly seeking materials that allow design freedom, rapid iteration, and customization without compromising functional performance

- For instance, Stratasys supplies TPU-based elastomer materials compatible with its FDM and PolyJet platforms, which are widely used for producing customized automotive and consumer product components. These solutions enable manufacturers to accelerate product development while meeting specific design and performance requirements

- In the medical sector, companies such as 3D Systems provide elastomeric materials used in patient-specific prosthetics and orthotic devices. The ability to tailor products to individual anatomical needs is driving strong demand for elastomer-based additive manufacturing

- The increasing integration of additive manufacturing into production workflows is encouraging industries to replace traditional molding methods with elastomer 3D printing for low-volume and complex parts. This transition is reinforcing the demand for flexible and customizable elastomer materials

- As industries continue to prioritize design flexibility and faster time to market, the reliance on 3D printing elastomers for customized components is expected to remain a strong growth driver for the market

Restraint/Challenge

“High Material Cost and Limited Standardization in Elastomer 3D Printing”

- The 3D printing elastomers market faces challenges related to high material costs and limited standardization across printing technologies and material formulations. Advanced elastomer materials often require complex chemical compositions and stringent quality control, which increases production costs for manufacturers

- For instance, high-performance elastomer resins developed by companies such as Covestro and Arkema are priced significantly higher than conventional plastics due to specialized raw materials and processing requirements. These cost factors can limit adoption among small and medium-sized manufacturers

- The lack of standardized material properties across different 3D printing platforms creates compatibility challenges for end users. Elastomers designed for one printing technology may not perform consistently on another, increasing testing and validation efforts

- In addition, limited industry-wide standards for elastomer performance and durability create uncertainty for end users seeking long-term reliability. This constraint impacts scalability and broader commercialization of elastomer-based 3D printing solutions

- These cost and standardization challenges continue to restrain market growth by increasing barriers to entry and adoption, particularly for organizations with limited capital resources

3D Printing Elastomers Market Scope

The market is segmented on the basis of form, material, technology, and end-use industry.

• By Form

On the basis of form, the 3D Printing Elastomers market is segmented into powder, filament, and liquid. The filament segment dominated the market with the largest revenue share of 45.5% in 2025, driven by its wide compatibility with desktop and industrial FDM/FFF printers and ease of handling during printing. Filament-based elastomers are preferred for rapid prototyping and low-to-medium volume production due to consistent material flow and reduced processing complexity. Manufacturers favor filaments for their availability in multiple hardness grades, supporting diverse functional applications. The strong presence of FDM technology across industrial and consumer segments further reinforces filament demand. Cost efficiency and minimal post-processing requirements also support its dominance.

The liquid segment is anticipated to witness the fastest growth from 2026 to 2033, supported by rising adoption of SLA and DLP technologies. Liquid elastomers enable high-resolution printing and superior surface finish, making them suitable for complex geometries and precision parts. Increasing demand from medical, dental, and electronics applications is accelerating uptake. Advancements in photopolymer formulations are improving mechanical performance and durability. These factors collectively position liquid elastomers as the fastest-growing form segment.

• By Material

On the basis of material, the market is segmented into TPE and SBR & SBS. The TPE segment accounted for the dominant market share in 2025 due to its flexibility, recyclability, and balanced mechanical properties. TPE-based elastomers offer excellent elasticity, abrasion resistance, and processability across multiple 3D printing technologies. Their ability to be reprocessed aligns with sustainability goals, increasing adoption among manufacturers. TPE materials are widely used in automotive interiors, consumer products, and industrial components. Consistent performance and broad application suitability support their leading position.

The SBR & SBS segment is expected to register the fastest growth during the forecast period, driven by increasing use in impact-resistant and cushioning applications. These materials provide enhanced toughness and rubber-like behavior suitable for functional end-use parts. Growing demand for cost-effective elastomers in consumer goods and footwear prototyping supports expansion. Improvements in printability and formulation stability are expanding their application scope. This combination of performance and cost benefits is driving rapid growth.

• By Technology

On the basis of technology, the 3D Printing Elastomers market is segmented into FDM/FFF, SLA, SLS, and DLP. The FDM/FFF segment dominated the market in 2025 due to its widespread adoption, lower equipment cost, and compatibility with elastomeric filaments. This technology supports scalable production and rapid prototyping with minimal setup time. Industries favor FDM/FFF for functional testing and customized parts. The availability of a broad range of elastomer grades strengthens its market presence. Ease of operation and material versatility continue to drive dominance.

The SLA and DLP segments are projected to witness the fastest growth from 2026 to 2033, driven by demand for high-precision elastomer parts. These technologies enable fine feature resolution and smooth surface finishes, critical for medical, dental, and electronics components. Advancements in elastomeric resins are improving strength and flexibility. Increasing adoption of digital manufacturing in healthcare and high-end consumer products supports growth. This trend positions photopolymer-based technologies as key growth drivers.

• By End-Use Industry

On the basis of end-use industry, the market is segmented into automotive, consumer goods, aerospace & defense, and medical & dental. The automotive segment held the largest revenue share in 2025, driven by demand for lightweight, flexible, and durable components. 3D printed elastomers are used in seals, gaskets, interior parts, and prototyping applications. Automotive manufacturers leverage additive manufacturing to reduce lead times and enable design customization. The push toward electric vehicles further supports elastomer demand. Strong integration of 3D printing in automotive R&D sustains dominance.

The medical & dental segment is expected to grow at the fastest rate over the forecast period, supported by increasing use of patient-specific devices. Elastomeric materials are widely applied in orthodontics, prosthetics, surgical guides, and wearable medical components. The ability to produce customized, biocompatible parts enhances adoption. Rising investment in digital healthcare manufacturing accelerates growth. Precision, comfort, and rapid production capabilities position this segment as the fastest growing.

3D Printing Elastomers Market Regional Analysis

- North America dominated the 3D printing elastomers market with the largest revenue share of around 45% in 2025, driven by strong adoption of additive manufacturing across automotive, aerospace, and healthcare industries

- Manufacturers in the region highly value the design flexibility, rapid prototyping capability, and performance advantages offered by elastomer-based 3D printing materials for functional and end-use parts

- This widespread adoption is supported by advanced manufacturing infrastructure, high R&D spending, and early integration of Industry 4.0 practices, positioning 3D printing elastomers as a key material choice for industrial innovation

U.S. 3D Printing Elastomers Market Insight

The U.S. 3D printing elastomers market captured the largest revenue share in 2025 within North America, fueled by strong demand from automotive prototyping, medical devices, and aerospace applications. Companies are increasingly using elastomeric materials to develop lightweight, flexible, and customized components. The presence of major 3D printer manufacturers, material suppliers, and technology developers further strengthens market growth. Rising investments in digital manufacturing and rapid product development continue to accelerate adoption across industrial and healthcare sectors.

Europe 3D Printing Elastomers Market Insight

The Europe 3D printing elastomers market is projected to expand at a steady CAGR during the forecast period, driven by strong focus on advanced manufacturing, sustainability, and precision engineering. Growth is supported by increasing use of additive manufacturing in automotive, aerospace, and consumer goods production. European manufacturers emphasize material efficiency and recyclability, encouraging adoption of elastomer-based solutions. Expansion of industrial 3D printing hubs across the region is further supporting market development.

U.K. 3D Printing Elastomers Market Insight

The U.K. 3D printing elastomers market is anticipated to grow at a notable CAGR, supported by increasing adoption of additive manufacturing in healthcare, aerospace, and research institutions. Demand for customized medical devices and flexible components is strengthening material uptake. The country’s strong academic research base and government-backed innovation programs are contributing to market expansion. Rising use of 3D printing in prototyping and low-volume production continues to support growth.

Germany 3D Printing Elastomers Market Insight

The Germany 3D printing elastomers market is expected to expand at a considerable CAGR, driven by the country’s strong automotive and industrial manufacturing base. German manufacturers are increasingly adopting elastomer materials for functional prototyping and end-use parts requiring durability and flexibility. Emphasis on high-quality engineering, automation, and digital production workflows supports material demand. Integration of additive manufacturing into industrial supply chains is accelerating market growth.

Asia-Pacific 3D Printing Elastomers Market Insight

The Asia-Pacific 3D printing elastomers market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by rapid industrialization, expanding manufacturing capacity, and increasing adoption of 3D printing technologies. Countries such as China, Japan, and India are witnessing rising demand for elastomer materials across automotive, electronics, and healthcare sectors. Government initiatives promoting advanced manufacturing and localized production are further supporting market expansion.

Japan 3D Printing Elastomers Market Insight

The Japan 3D printing elastomers market is gaining momentum due to strong demand for precision manufacturing and advanced material solutions. Japanese industries are increasingly using elastomer-based 3D printing for robotics, electronics, and medical applications. The focus on high-performance, compact, and flexible components is driving adoption. Continuous innovation in material science and additive manufacturing technologies supports sustained growth.

China 3D Printing Elastomers Market Insight

The China 3D printing elastomers market accounted for the largest revenue share in Asia Pacific in 2025, supported by rapid industrial growth, expanding domestic manufacturing, and strong adoption of additive manufacturing technologies. China’s position as a global manufacturing hub is driving large-scale use of elastomer materials for prototyping and production. Availability of cost-effective materials and growing investment in smart manufacturing are key factors propelling market expansion across multiple industries.

3D Printing Elastomers Market Share

The 3D printing elastomers industry is primarily led by well-established companies, including:

- Stratasys Ltd. (U.S.)

- Materialise NV (Belgium)

- EnvisionTEC GmbH (Germany)

- 3D Systems, Inc. (U.S.)

- Autodesk Inc. (U.S.)

- General Electric Company (U.S.)

- Made In Space, Inc. (U.S.)

- Canon Inc. (Japan)

- voxeljet AG (Germany)

- BASF SE (Germany)

- Arkema S.A. (France)

- Evonik Industries AG (Germany)

- Henkel AG & Co. KGaA (Germany)

- Covestro AG (Germany)

- SABIC (Saudi Arabia)

Latest Developments in Global 3D Printing Elastomers Market

- In September 2024, 3D Systems launched a new line of elastomeric materials specifically designed for medical applications, including prosthetics and implants, strengthening its footprint in the healthcare segment. This launch addresses the rising demand for personalized, flexible, and biocompatible materials, enabling advanced patient-specific solutions. By expanding its medical-grade elastomer portfolio, 3D Systems enhances its competitive positioning in a high-growth, high-value end-use market. The development reflects the broader market shift toward customized healthcare manufacturing using additive technologies

- In August 2024, Stratasys announced a strategic partnership with a leading automotive manufacturer to develop customized elastomer components for electric vehicles, reinforcing its position in the automotive sector. This collaboration aligns with increasing demand for lightweight and durable materials critical for EV production. The partnership strengthens Stratasys’s market presence by supporting sustainable manufacturing practices and next-generation vehicle design. It also highlights the growing role of elastomer-based 3D printing in automotive innovation

- In July 2024, BASF unveiled a new elastomer formulation that significantly improves the mechanical properties of 3D printed parts, enhancing its leadership in material innovation. The improved stiffness and flexibility expand the use of elastomers in functional and end-use industrial applications. This development positions BASF as a key influencer in setting performance benchmarks within the 3D printing elastomers market. The innovation is expected to intensify competition and accelerate adoption of high-performance elastomer materials

- In November 2020, BASF SE entered into a partnership with Photocentric Ltd. to launch the Daylight Product Line, Ultracur3D EPD, for 3D printing applications including prototyping, engineering, and serial automotive part production. These resins provide a balance of high stiffness and flexibility, supporting demanding industrial requirements. The collaboration strengthened BASF’s market presence in photopolymer-based elastomers and expanded its reach into automotive manufacturing. This move contributed to the broader adoption of elastomer resins in high-volume production environments

- In January 2020, 3D Systems developed the Figure 4 Jewelry Solution, a technology optimized for the 3D printed jewelry market, reinforcing its Figure 4 platform capabilities. This solution addressed the need for precision, flexibility, and scalability in jewelry manufacturing. The development strengthened 3D Systems’ position in specialized, design-intensive applications of elastomer and resin-based printing. It also supported market expansion by enabling efficient mass customization within the jewelry segment

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global 3d Printing Elastomers Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Printing Elastomers Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Printing Elastomers Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.