Global 3d Printing Filament Market

Market Size in USD Billion

CAGR :

%

USD

3.17 Billion

USD

23.00 Billion

2025

2033

USD

3.17 Billion

USD

23.00 Billion

2025

2033

| 2026 –2033 | |

| USD 3.17 Billion | |

| USD 23.00 Billion | |

|

|

|

|

3D Printing Filament Market Size

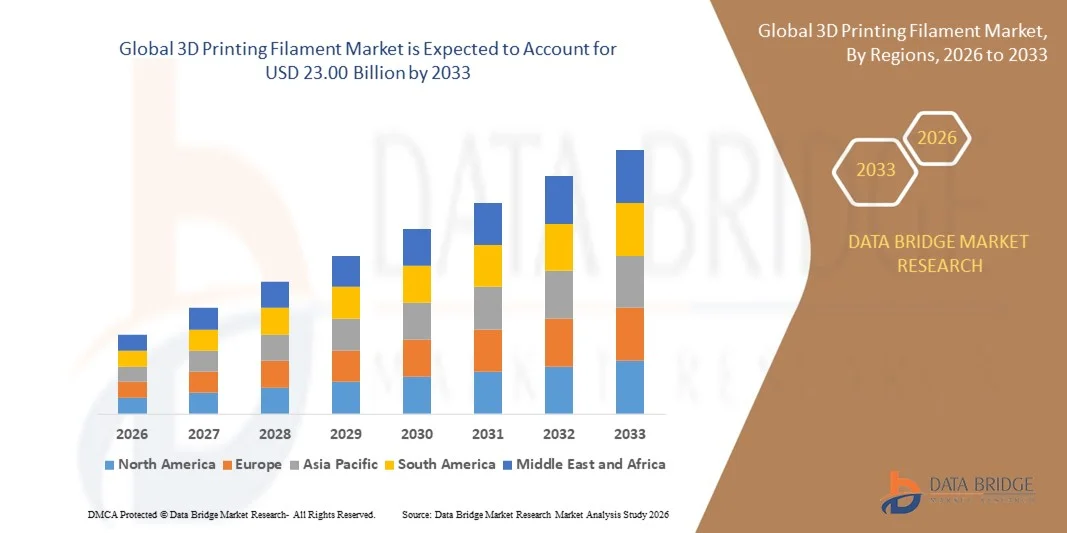

- The global 3D printing filament market size was valued at USD 3.17 billion in 2025 and is expected to reach USD 23.00 billion by 2033, at a CAGR of 28.10% during the forecast period

- The market growth is largely fuelled by the increasing adoption of additive manufacturing across industries, rising demand for customized products, and the expansion of industrial and commercial 3D printing applications

- Growing innovations in filament materials, such as biodegradable, composite, and high-performance polymers, are enhancing product capabilities and broadening end-use applications

3D Printing Filament Market Analysis

- The market is witnessing rapid technological advancements in filament formulations and 3D printing processes, which are enhancing precision, strength, and functionality of printed products

- Rising demand from sectors such as automotive, aerospace, healthcare, and consumer goods is contributing to market expansion, supported by increased awareness of cost-efficiency and production speed benefits

- North America dominated the 3D printing filament market with the largest revenue share of 35.50% in 2025, driven by the increasing adoption of additive manufacturing technologies across industrial, aerospace, and healthcare sectors.

- Asia-Pacific region is expected to witness the highest growth rate in the global 3D printing filament market, driven by expanding manufacturing capabilities, rising demand from automotive and aerospace industries, and increased adoption of 3D printing in education and research institutions

- The plastics segment held the largest market revenue share in 2025, driven by the widespread availability of PLA, ABS, PETG, and other thermoplastic filaments that offer ease of printing, affordability, and compatibility with a wide range of 3D printers. Plastic filaments are extensively used for prototyping, functional parts, and consumer products, making them the most preferred choice across industries

Report Scope and 3D Printing Filament Market Segmentation

|

Attributes |

3D Printing Filament Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• 3D Systems, Inc. (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

3D Printing Filament Market Trends

Rise of Advanced Materials and Customizable Filaments

- The growing adoption of advanced 3D printing filaments is transforming the additive manufacturing landscape by enabling high-precision, durable, and functional parts. Materials such as PLA, ABS, PETG, and specialty composites allow manufacturers to produce components with tailored mechanical, thermal, and aesthetic properties, driving innovation across industries. Increasing integration of multi-material printing and hybrid solutions is expanding application potential across prototyping, tooling, and end-use production. The trend is further supported by collaborations between filament suppliers and printer manufacturers to enhance material compatibility and performance

- Increasing demand for customizable products in healthcare, aerospace, automotive, and consumer goods is accelerating the adoption of specialty filaments. These filaments allow designers and engineers to create lightweight, complex, and application-specific parts that meet evolving technical and regulatory requirements. In addition, the rise of on-demand manufacturing and personalized production is boosting the need for high-performance filaments that can deliver precision and repeatability across diverse applications. Manufacturers are also exploring bio-based and sustainable filament options to meet eco-conscious consumer preferences

- The ease of integrating diverse filaments into desktop, industrial, and professional 3D printers is making them attractive for both large-scale manufacturers and small enterprises. This versatility supports rapid prototyping, on-demand production, and mass customization while reducing lead times and costs. Improved software and slicing tools, along with better print profiles, are simplifying multi-material and complex part production, further increasing adoption. Partnerships between filament developers and hardware companies are creating optimized end-to-end solutions for industrial and commercial users

- For instance, in 2023, several North American and European manufacturing companies reported faster product development cycles and reduced material wastage after incorporating high-performance composite filaments in prototyping and end-use parts. Companies observed better part strength, dimensional accuracy, and surface finish, which reduced post-processing requirements. These success stories are encouraging more industries to adopt filaments for functional, durable, and complex components in sectors such as automotive, healthcare devices, and consumer electronics

- While 3D printing filaments are enabling innovation, their market impact depends on consistent material quality, printer compatibility, and post-processing capabilities. Manufacturers must focus on R&D, sustainable sourcing, and education to fully leverage growing demand. In addition, increasing standardization, certification for industrial use, and training for end-users are becoming essential to maintain reliability, minimize defects, and expand adoption in regulated sectors. Continuous innovation in filament formulations and composites is also critical to meet evolving industry requirements and environmental considerations

3D Printing Filament Market Dynamics

Driver

Rising Demand For Industrial Applications And Functional Prototyping

- The surge in additive manufacturing adoption across automotive, aerospace, and healthcare sectors is driving the need for high-quality 3D printing filaments. These filaments facilitate rapid prototyping, functional testing, and production of end-use components, enhancing operational efficiency. Advancements in high-temperature and chemically resistant filaments are expanding applications to more demanding industrial processes, increasing market opportunities. Collaboration between filament manufacturers and industrial clients ensures customized solutions for specialized requirements

- Consumers and businesses increasingly demand lightweight, durable, and customized products, prompting filament manufacturers to offer materials with enhanced mechanical and thermal properties. This trend supports product differentiation and innovation across multiple industries. The growing trend of functional prototypes and small-batch production drives the need for filaments with superior performance, printability, and post-processing capabilities. Manufacturers are also exploring environmentally friendly and recyclable filaments to meet sustainability goals

- Expansion of desktop and industrial 3D printers in research, education, and small-scale manufacturing is fueling filament consumption. Filaments compatible with varied printers and multi-material setups are particularly preferred for complex designs and applications. In addition, rising adoption in maker spaces, STEM education, and DIY communities is broadening the user base and creating demand for specialty filaments tailored to diverse projects. Training and support for new users are enhancing material utilization efficiency and adoption rates

- For instance, in 2022, several European and North American prototyping companies adopted carbon-fiber reinforced filaments and flexible TPU materials, accelerating product validation and shortening time-to-market. Improved part performance and reduced production errors enabled quicker iterations, enabling faster customer feedback and design optimization. These successful implementations encourage further adoption of advanced filaments across multiple industrial verticals

- While industrial adoption is a key growth driver, challenges such as material cost, compatibility issues, and awareness of advanced filament capabilities must be addressed for sustained market expansion. Companies are increasingly investing in material testing, printer optimization, and user education to overcome these barriers and maximize the benefits of high-performance filaments. Strategic partnerships between filament developers and hardware manufacturers are also critical to ensure reliability and quality

Restraint/Challenge

High Cost Of Specialty Filaments And Limited Material Standardization

- Specialty 3D printing filaments, including carbon-fiber composites, metal-infused, and biodegradable materials, are often expensive, limiting adoption among startups and cost-sensitive users. High prices remain a barrier for widespread implementation in small-scale operations. Additional costs related to storage, material handling, and specialized equipment further add to the financial burden on users

- Variations in filament quality, mechanical properties, and printer compatibility create challenges in maintaining consistent output, especially for critical industrial and medical applications. Inconsistent performance can affect part reliability and customer trust. Lack of uniform standards across suppliers also complicates material selection, calibration, and production repeatability, particularly for multi-material and complex prints

- Limited availability of certain high-performance filaments and supply chain constraints can delay production and product launches. Seasonal demand fluctuations, import restrictions, and raw material scarcity further restrict material accessibility. Dependence on specialized raw materials sourced from specific regions exposes manufacturers to geopolitical and logistic risks that may disrupt supply continuity

- For instance, in 2023, several Asian and North American additive manufacturing firms faced delays in production due to shortages of high-strength nylon and carbon-fiber filaments, impacting project timelines. These supply bottlenecks caused ripple effects on prototyping, on-demand production, and commercial product launches, highlighting the need for robust procurement strategies and inventory management

- While ongoing research and technological advancements improve filament properties and availability, manufacturers must focus on cost optimization, quality standardization, and scalable supply chains to capitalize on the growing 3D printing filament market globally. Adoption of automated material testing, regional manufacturing hubs, and collaborative R&D initiatives will be critical to sustaining market growth and meeting industrial demands efficiently

3D Printing Filament Market Scope

The 3D printing filament market is segmented on the basis of material and application.

- By Material

On the basis of material, the 3D printing filament market is segmented into plastics, metals, ceramics, and others. The plastics segment held the largest market revenue share in 2025, driven by the widespread availability of PLA, ABS, PETG, and other thermoplastic filaments that offer ease of printing, affordability, and compatibility with a wide range of 3D printers. Plastic filaments are extensively used for prototyping, functional parts, and consumer products, making them the most preferred choice across industries.

The metals segment is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing adoption in industrial, aerospace, and healthcare applications that demand high-strength, precision-engineered components. Metal filaments enable the production of durable, load-bearing, and heat-resistant parts with properties similar to traditional metal manufacturing, supporting advanced manufacturing and rapid prototyping. Advancements in metal filament technology and improved printer compatibility are further accelerating market adoption.

- By Application

On the basis of application, the 3D printing filament market is segmented into industrial, aerospace and defense, automotive, healthcare, and others. The industrial segment held the largest market revenue share in 2025, driven by rising demand for rapid prototyping, tooling, and functional components across multiple sectors. Industrial applications benefit from the versatility, durability, and customizability offered by modern filaments, enhancing production efficiency and reducing time-to-market.

The aerospace and defense segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by the need for lightweight, high-strength, and precision parts. 3D printing filaments allow aerospace and defense manufacturers to produce complex geometries, reduce material waste, and accelerate prototyping of critical components. Increasing investment in additive manufacturing for aircraft, spacecraft, and defense equipment is further driving segment growth.

3D Printing Filament Market Regional Analysis

- North America dominated the 3D printing filament market with the largest revenue share of 35.50% in 2025, driven by the increasing adoption of additive manufacturing technologies across industrial, aerospace, and healthcare sectors.

- Consumers and manufacturers in the region highly value the versatility, precision, and high-quality performance offered by advanced filaments such as PLA, ABS, PETG, and carbon-fiber composites for prototyping and end-use parts.

- This widespread adoption is further supported by strong industrial infrastructure, high technological awareness, and government initiatives promoting innovation, establishing 3D printing filaments as a key enabler of rapid manufacturing and customization

U.S. 3D Printing Filament Market Insight

The U.S. 3D printing filament market captured the largest revenue share in 2025 within North America, fueled by the growing utilization of additive manufacturing in aerospace, automotive, and healthcare industries. Manufacturers are increasingly prioritizing lightweight, durable, and application-specific filaments for prototyping, functional testing, and small-batch production. Moreover, the rising integration of industrial 3D printers in research, education, and small enterprises, alongside increasing investments in high-performance filaments, is significantly contributing to the market's expansion.

Europe 3D Printing Filament Market Insight

The Europe 3D printing filament market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by the rising adoption of additive manufacturing technologies and supportive regulatory frameworks across industrial and aerospace sectors. The expansion of green manufacturing initiatives and the increasing demand for lightweight, customizable parts are fostering filament consumption. European manufacturers are also adopting high-strength composite and specialty filaments to meet stringent quality standards and functional requirements.

U.K. 3D Printing Filament Market Insight

The U.K. 3D printing filament market is expected to witness strong growth from 2026 to 2033, driven by increasing investment in additive manufacturing and demand for rapid prototyping solutions across automotive and healthcare industries. In addition, the focus on innovation, product customization, and lightweight components is encouraging businesses to adopt a wide range of filaments. The U.K.’s advanced industrial ecosystem and growing support for R&D in high-performance materials are expected to further stimulate market growth.

Germany 3D Printing Filament Market Insight

The Germany 3D printing filament market is expected to witness substantial growth from 2026 to 2033, fueled by rising adoption of industrial 3D printing in automotive, aerospace, and mechanical engineering sectors. Germany’s emphasis on precision manufacturing and high-quality standards promotes the use of specialty filaments such as carbon-fiber reinforced, metal-infused, and biodegradable materials. Integration of 3D printing technologies in research institutions and industrial enterprises is also expanding, enabling innovative applications and faster production cycles.

Asia-Pacific 3D Printing Filament Market Insight

The Asia-Pacific 3D printing filament market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid industrialization, technological advancements, and increasing investment in additive manufacturing across countries such as China, Japan, and India. The region’s growing manufacturing base, coupled with government initiatives supporting Industry 4.0 and smart factories, is driving filament demand. Moreover, as APAC emerges as a hub for filament production and innovation, the affordability and accessibility of high-performance materials are expanding to a wider consumer and industrial base.

Japan 3D Printing Filament Market Insight

The Japan 3D printing filament market is expected to witness strong growth from 2026 to 2033, fueled by high-tech industrial culture, rapid urbanization, and demand for precision manufacturing solutions. The market is supported by increasing adoption of advanced filaments for healthcare devices, automotive parts, and electronic components. Integration with IoT-enabled printers and industrial automation solutions is further boosting demand, while Japan’s focus on R&D in materials science continues to drive filament innovation.

China 3D Printing Filament Market Insight

The China 3D printing filament market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to the country’s rapidly expanding industrial sector, high rates of technological adoption, and growing interest in additive manufacturing. China is one of the largest markets for both industrial and desktop 3D printing, with filaments being widely used across automotive, aerospace, consumer electronics, and healthcare sectors. The push toward smart factories, coupled with the presence of domestic filament manufacturers and cost-effective solutions, is propelling the market growth in China.

3D Printing Filament Market Share

The 3D Printing Filament industry is primarily led by well-established companies, including:

• 3D Systems, Inc. (U.S.)

• Stratasys Ltd. (U.S.)

• Arkema (France)

• DSM (Netherlands)

• Materialise (Belgium)

• Evonik Industries (Germany)

• SABIC (Saudi Arabia)

• HP Development Company, L.P. (U.S.)

• DuPont (U.S.)

• EOS (Germany)

• BASF SE (Germany)

• Shenzhen Esun Industrial Co., Ltd. (China)

• ENVISIONTEC, INC. (U.S.)

• CRP TECHNOLOGY S.r.l. (Italy)

• Oxford Performance Materials (U.S.)

• WIPRO ENTERPRISES PVT. LTD. (India)

• Markforged (U.S.)

• MCPP (U.S.)

• AIRWOLF 3D PRINTERS (U.S.)

• Forefront Filament (U.S.)

• Keene Village Plastics (U.S.)

Latest Developments in Global 3D Printing Filament Market

- In February 2021, Walkinshaw Andretti United (WAU) partnered with Stratasys Ltd. to leverage Stratasys FDM printers for producing prototypes of customized Supercar parts, as well as tooling and fixtures. This collaboration enables faster development cycles, enhances precision in production, and strengthens WAU’s competitive edge in motorsports, impacting the automotive 3D printing market by demonstrating high-performance applications in vehicle engineering

- In January 2021, Stratasys Ltd. acquired UK-based RP Support Ltd. (RPS) to expand its industrial stereolithography 3D printing solutions. By integrating RPS’ Neo® systems into its global portfolio, Stratasys broadened its polymer solution offerings across the product lifecycle, from concept modeling to manufacturing, improving market reach and diversifying applications in additive manufacturing

- In January 2021, 3D Systems advanced into bioprinting with a focus on human lung regeneration in collaboration with United Therapeutics Corporation and Lung Biotechnology PBC. This initiative aims to develop 3D-printed solid-organ scaffolds, enhancing regenerative medicine capabilities and positioning the company as a key player in biofabrication solutions, with long-term implications for healthcare and medical 3D printing markets

- In February 2021, 3D Systems collaborated with the US Army, Raytheon Technologies, Penn State Applied Science Center, Johns Hopkins University, and Identify3D on a virtual design and qualification project for additively produced multi-laser components. The initiative focuses on improving component performance, cooling efficiency, and system reliability, showcasing 3D printing’s potential in defense applications and accelerating adoption of additive manufacturing in high-precision military technologies

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global 3d Printing Filament Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Printing Filament Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Printing Filament Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.