Global 3d Printing Robot Market

Market Size in USD Billion

CAGR :

%

USD

1.87 Billion

USD

5.11 Billion

2024

2032

USD

1.87 Billion

USD

5.11 Billion

2024

2032

| 2025 –2032 | |

| USD 1.87 Billion | |

| USD 5.11 Billion | |

|

|

|

|

3D Printing Robot Market Size

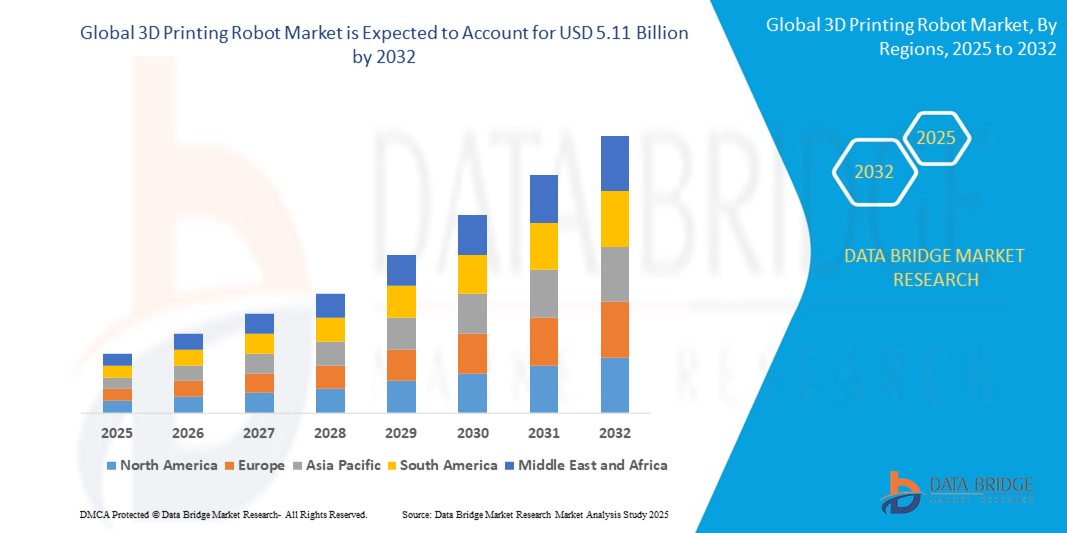

- The global 3D printing robot market size was valued at USD 1.87 billion in 2024 and is expected to reach USD 5.11 billion by 2032, at a CAGR of 13.40% during the forecast period

- The market growth is largely fuelled by the rising demand for large-scale and complex structure manufacturing in industries such as construction, automotive, and aerospace, where robotic additive manufacturing offers improved flexibility, material efficiency, and reduced production time

- In addition, the increasing shift toward automation in manufacturing, coupled with the need for rapid prototyping and reduced operational costs, is accelerating the adoption of 3D printing robots across various industrial sectors

3D Printing Robot Market Analysis

- The integration of robotics with additive manufacturing is enabling automated, precise, and scalable 3D printing processes, which are particularly useful in producing customized parts and structures on-demand

- Advancements in materials science and robotic arm technologies are supporting the development of multifunctional 3D printing systems capable of working with metal, concrete, and polymer-based materials

- North America dominated the 3D printing robot market with the largest revenue share of 39.8% in 2024, driven by strong investments in advanced manufacturing technologies and widespread adoption across aerospace, automotive, and healthcare industries

- Asia-Pacific region is expected to witness the highest growth rate in the global 3D printing robot market, driven by expanding manufacturing capabilities, favorable policies, and increasing demand for cost-effective and scalable production technologies in countries such as China, Japan, and South Korea.

- The robot arm segment dominated the market with the largest market revenue share in 2024, driven by its critical role in enabling precise movement, multi-axis control, and material deposition across varied applications. Industries such as aerospace and construction rely heavily on robotic arms for their ability to handle large structures and complex geometries with consistent accuracy. The increasing demand for automation and efficiency in industrial-scale additive manufacturing has further elevated the importance of advanced robotic arm systems

Report Scope and 3D Printing Robot Market Segmentation

|

Attributes |

3D Printing Robot Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

• Rising Adoption in Construction and Infrastructure Projects • Integration with Artificial Intelligence and Machine Learning |

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

3D Printing Robot Market Trends

“Expansion of Large-Scale 3D Printing Applications”

• Robotic 3D printers are increasingly being integrated with artificial intelligence and machine learning algorithms to enable adaptive decision-making and process optimization during printing which enhances print quality and reduces human supervision requirements across industries

• These smart systems allow real-time monitoring and adjustment of parameters such as temperature, extrusion rate, and path correction which ensures precision and reduces defects even in complex or large-scale components

• The trend is enabling predictive maintenance capabilities in robotic printers by analyzing usage patterns and potential breakdowns thus reducing downtime and increasing production efficiency in high-throughput environments

• For instance companies such as MX3D and Siemens have deployed AI-integrated 3D printing robots for industrial projects where advanced sensing and real-time control are essential for reliable output

• This trend reflects the broader shift toward autonomous manufacturing environments where AI-driven robotics play a central role in streamlining operations and achieving scalable customization

3D Printing Robot Market Dynamics

Driver

“Rising Demand for Customization and Complex Geometries”

• The ability of 3D printing robots to produce customized components and prototypes on-demand without the need for costly tooling is driving adoption across industries such as automotive, healthcare, and consumer electronics, as companies seek to reduce production costs while enhancing product differentiation, thereby enabling quicker responses to customer-specific demands through flexible design adjustments

• Manufacturers are leveraging robotic additive manufacturing to address small-batch orders and rapidly changing design requirements, especially in product development cycles where flexibility and speed are critical, helping them stay competitive in dynamic markets while also minimizing excess inventory and supporting iterative prototyping

• This driver also supports decentralized production models where parts can be printed closer to the point of use, reducing logistics costs and enabling faster turnaround for urgent needs, thereby improving supply chain resilience and reducing dependency on global shipping networks that are prone to disruption

• For instance, the automotive industry is using robotic 3D printers to create vehicle parts with unique specifications, reducing time-to-market and offering design agility for limited edition models, allowing automakers to efficiently deliver personalized features and aesthetics that meet niche consumer preferences without retooling entire production lines

• This demand for rapid, flexible, and cost-effective production continues to propel investment in robotic 3D printing systems, making them essential tools in modern smart factories that prioritize automation, operational efficiency, and the ability to adapt quickly to evolving market trends and customer expectations

Restraint/Challenge

“High Initial Investment and Technical Complexity”

• One of the major barriers to the adoption of 3D printing robots is the high upfront cost associated with acquiring robotic systems, software, and compatible materials which poses a challenge for small and medium-sized enterprises as they often operate with constrained budgets and find it difficult to invest in advanced technologies that require significant capital expenditure and longer return-on-investment cycles

• The integration of robotic 3D printers into existing workflows requires technical expertise and may involve significant changes in infrastructure and employee training which adds to operational complexity and can slow down the adoption process especially in organizations lacking dedicated automation or engineering teams to manage the transition smoothly

• Compatibility issues between software platforms, hardware interfaces, and material properties can further complicate implementation leading to delays or reduced efficiency in manufacturing processes and making it difficult to ensure seamless interoperability among different 3D printing components used across supply chains

• For instance, small-scale manufacturing firms in developing regions often struggle to justify the capital investment required for robotic 3D printing despite its long-term benefits and face additional hurdles such as limited access to financing, inadequate technical support, and uncertain regulatory frameworks that further dampen adoption

• This restraint highlights the need for cost-effective solutions, modular designs, and support services to make robotic additive manufacturing more accessible and scalable across diverse industries by reducing entry barriers, improving ease of integration, and enabling broader participation in the digital manufacturing revolution

3D Printing Robot Market Scope

The market is segmented on the basis of component and service, robot type, and application.

- By Component & Service

On the basis of component and service, the 3D printing robot market is segmented into robot arm, 3D printing head, software, and service. The robot arm segment dominated the market with the largest market revenue share in 2024, driven by its critical role in enabling precise movement, multi-axis control, and material deposition across varied applications. Industries such as aerospace and construction rely heavily on robotic arms for their ability to handle large structures and complex geometries with consistent accuracy. The increasing demand for automation and efficiency in industrial-scale additive manufacturing has further elevated the importance of advanced robotic arm systems.

The software segment is expected to witness the fastest growth rate from 2025 to 2032, driven by advancements in simulation, path planning, and real-time monitoring technologies. Intelligent software solutions are essential in optimizing print quality, minimizing errors, and improving integration with design platforms. The growing focus on smart manufacturing and the need for flexible, user-friendly interfaces are accelerating the demand for robust 3D printing software systems.

- By Robot Type

On the basis of robot type, the market is segmented into articulated, cartesian, SCARA, polar, and delta robots. The articulated robot segment accounted for the largest market share in 2024 owing to its versatility, wide range of motion, and ability to handle intricate 3D printing tasks. These robots are increasingly used in automotive and industrial design for producing parts that require high degrees of precision and flexibility. Their adaptability to different printing heads and materials further strengthens their dominance in the market.

The cartesian robot segment is expected to witness the fastest growth rate from 2025 to 2032, due to their structural simplicity, cost-effectiveness, and suitability for large-format printing. These robots are commonly used in construction and architecture where stability and scalability are critical. The ability to produce large components with consistent layer accuracy positions cartesian robots as a preferred option for industrial-scale additive projects.

- By Application

On the basis of application, the 3D printing robot market is segmented into prototyping, tooling, and functional part manufacturing. The prototyping segment dominated the market with the highest revenue share in 2024, driven by its widespread use in accelerating product development, reducing time-to-market, and enabling design iteration. Industries such as healthcare, automotive, and consumer electronics are utilizing robotic 3D printing for creating detailed prototypes with superior speed and precision. The ability to evaluate and refine designs quickly before mass production enhances the appeal of robotic prototyping solutions.

The functional part manufacturing segment is expected to witness the fastest growth rate from 2025 to 2032, as industries move beyond prototyping towards end-use parts. Robotic 3D printers are now being employed to produce durable, performance-grade components across sectors including aerospace, defense, and industrial machinery. The push for localized production, reduced supply chain dependency, and the ability to manufacture complex parts on demand is propelling the growth of functional part manufacturing using 3D printing robots.

3D Printing Robot Market Regional Analysis

• North America dominated the 3D printing robot market with the largest revenue share of 39.8% in 2024, driven by strong investments in advanced manufacturing technologies and widespread adoption across aerospace, automotive, and healthcare industries

• The region benefits from robust infrastructure, high research and development expenditure, and favorable government initiatives promoting industrial automation and additive manufacturing

• The presence of leading robotics and 3D printing companies, coupled with early technology adoption and demand for high-precision parts, continues to support market expansion across both large enterprises and startups

U.S. 3D Printing Robot Market Insight

The U.S. 3D printing robot market captured the highest revenue share in 2024 within North America, bolstered by increased integration of automation and digital fabrication in industrial sectors. Rising demand for lightweight, complex parts and cost-effective manufacturing solutions has accelerated the adoption of robotic 3D printing in aerospace and defense. In addition, strong collaborations between tech startups, universities, and established manufacturers are fostering innovation and driving commercialization of robotic additive manufacturing solutions

Europe 3D Printing Robot Market Insight

The Europe 3D printing robot market is expected to witness the fastest growth rate from 2025 to 2032, supported by growing emphasis on sustainable production and advanced design capabilities. The adoption of robotic additive manufacturing is particularly strong in automotive, construction, and energy sectors, where precision and efficiency are paramount. Regulatory support for Industry 4.0 practices and focus on circular economy strategies are also enhancing the uptake of 3D printing robots across the region

Germany 3D Printing Robot Market Insight

The Germany 3D printing robot market is expected to witness the fastest growth rate from 2025 to 2032, driven by the country’s strong manufacturing base and emphasis on automation. As a leader in engineering and industrial innovation, Germany is rapidly deploying robotic 3D printers for prototyping, custom tooling, and on-demand parts production. Public-private initiatives and strategic investments in digital manufacturing technologies are further encouraging small and medium-sized enterprises to adopt robotic additive solutions

U.K. 3D Printing Robot Market Insight

The U.K. 3D printing robot market is expected to witness the fastest growth rate from 2025 to 2032, driven by the country's expanding advanced manufacturing sector and commitment to Industry 4.0 adoption. The increasing use of robotic additive manufacturing in sectors such as aerospace, automotive, and construction is supporting market growth. In addition, strong academic research, government-backed innovation programs, and the rising demand for sustainable, on-demand production methods are fostering the adoption of 3D printing robots across both startups and established enterprises in the U.K.

Asia-Pacific 3D Printing Robot Market Insight

The Asia-Pacific 3D printing robot market is expected to witness the fastest growth rate from 2025 to 2032, fueled by rapid industrialization, rising automation, and supportive government policies in countries such as China, Japan, and South Korea. The expansion of electronics, automotive, and consumer goods manufacturing across the region is accelerating demand for flexible and scalable production technologies. Moreover, increased investment in smart factories and 3D printing startups is boosting regional adoption

China 3D Printing Robot Market Insight

The China 3D printing robot market accounted for the largest revenue share in Asia-Pacific in 2024, supported by the nation’s leadership in industrial automation and its rapidly evolving manufacturing landscape. The government’s push toward smart manufacturing and Made in China 2025 initiatives have incentivized adoption across aerospace, construction, and heavy machinery sectors. Affordable labor and strong domestic production capabilities are also driving local innovation and export potential in robotic additive systems

Japan 3D Printing Robot Market Insight

The Japan 3D printing robot market is expected to witness the fastest growth rate from 2025 to 2032, owing to high demand for compact, precision manufacturing solutions and a well-established robotics sector. Japan’s focus on innovation, quality, and miniaturization makes it a key adopter of robotic 3D printers in healthcare, electronics, and automotive applications. With increasing interest in digital twins and IoT-connected systems, Japanese companies are integrating robotic 3D printers into automated production lines to enhance productivity and flexibility

3D Printing Robot Market Share

The 3D Printing Robot industry is primarily led by well-established companies, including:

- KUKA AG (Germany)

- Massive Dimension (US)

- Comau (Italy)

- ABB (Switzerland)

- CEAD B.V. (Netherlands)

- Baubot (Austria)

- Yaskawa Electric Corporation (Japan)

- Caracol (Italy)

- MX3D (US)

- FANUC Corporation (Japan)

- WEBER Maschinenfabrik (Germany)

- Twente Additive Manufacturing (TAM)

- Universal Robots A/S (Denmark)

- Meltio3D (Spain)

- (Netherlands)

- Dobot (China)

Latest Developments in Global 3D Printing Robot Market

- In February 2025, Caracol launched the xHF (Extra Flow) Extruder at JEC World 2025, a high-throughput system compatible with its Heron AM platform. With an extrusion rate of up to 75 kg/h and dual-material processing capability, the extruder enables efficient production of large-scale composite parts. Its advanced torque distribution and thermal control benefit sectors such as aerospace, marine, and construction, strengthening Caracol's position in the industrial additive manufacturing market

- In February 2025, Caracol collaborated with Airtech Advanced Materials Group to integrate Dahltram resins into its Heron AM platforms. This strategic partnership ensures enhanced material compatibility and reliability, supporting the development of high-performance parts for large-scale industrial use and expanding Caracol’s material ecosystem

- In November 2024, Hans Weber Maschinenfabrik partnered with Forward AM to showcase eco-friendly large-format 3D printing using recycled Ultrafuse rPETG pellets. The collaboration resulted in translucent wall panels for architectural applications, highlighting the growing role of sustainable materials in additive manufacturing and promoting environmental responsibility in the sector

- In November 2024, CEAD introduced the Flexcube, a compact Cartesian-style industrial 3D printer featuring a 3+1 axis system for 45-degree printing and integrated CNC milling. Its modular, space-efficient design offers advanced geometric capabilities and is ideal for architecture, tooling, and design industries, boosting versatility and accessibility in large-format 3D printing

- In 2024, Meltio launched its Engine Software Partners ecosystem, teaming up with 12 leading software providers to support hybrid and robotic additive manufacturing. The initiative offers certified tools for non-planar slicing and advanced toolpathing, simplifying integration for users and accelerating the adoption of Meltio’s robotic and CNC-based solutions globally

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global 3d Printing Robot Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Printing Robot Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Printing Robot Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.