Global Abrasive Waterjet Cutting Machine Market

Market Size in USD Billion

CAGR :

%

USD

1.26 Billion

USD

2.04 Billion

2024

2032

USD

1.26 Billion

USD

2.04 Billion

2024

2032

| 2025 –2032 | |

| USD 1.26 Billion | |

| USD 2.04 Billion | |

|

|

|

|

Abrasive Waterjet Cutting Machine Market Size

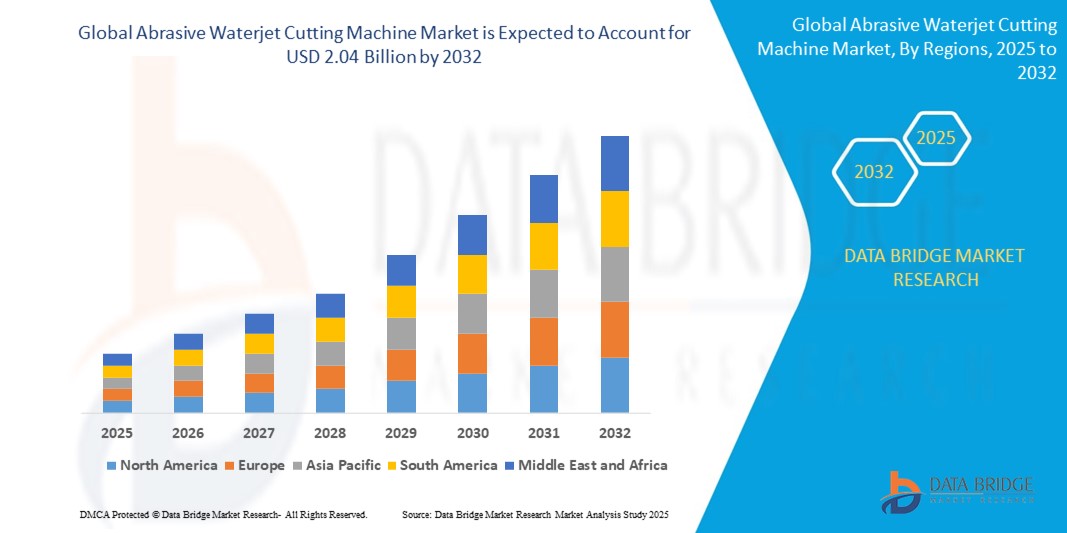

- The global abrasive waterjet cutting machine market size was valued at USD 1.26 billion in 2024 and is expected to reach USD 2.04 billion by 2032, at a CAGR of 6.2% during the forecast period

- The market growth is largely fueled by the increasing adoption of precision cutting technologies across industries such as aerospace, automotive, metal fabrication, and electronics, where demand for high-accuracy, cold-cutting processes is critical to avoid thermal distortion and material degradation

- Furthermore, rising emphasis on clean manufacturing practices, automation, and minimal material waste is positioning abrasive waterjet cutting machines as a preferred solution over traditional thermal cutting methods. These factors are accelerating the deployment of waterjet systems across global manufacturing operations, significantly boosting market expansion

Abrasive Waterjet Cutting Machine Market Analysis

- Abrasive waterjet cutting machines use high-pressure water mixed with abrasive particles to cut hard materials such as metal, glass, stone, and composites with precision and without generating heat. Their cold-cutting nature preserves the material’s integrity, making them ideal for industries where clean, burr-free edges and tight tolerances are required

- The growing demand for flexible, energy-efficient, and environmentally friendly cutting solutions is driving the adoption of abrasive waterjet systems. Industries are increasingly shifting toward these machines for their ability to handle complex geometries, support automation, and reduce secondary processing needs

- Asia-Pacific dominated the abrasive waterjet cutting machine market with a share of 36.15% in 2024, due to expanding industrialization, significant investment in manufacturing infrastructure, and the growing adoption of precision machining across key sectors

- Europe is expected to be the fastest growing region in the abrasive waterjet cutting machine market during the forecast period due to increasing regulatory pressure for cleaner industrial processes and the demand for precision in advanced manufacturing sectors

- 3D waterjet cutting machines segment dominated the market with a market share of 53.02% in 2024, due to its versatile cutting capabilities across complex three-dimensional geometries. These machines are widely used in industries requiring intricate profiles on thick or multi-angled materials such as aerospace and automotive components. The high precision, ability to maintain structural integrity without heat distortion, and suitability for a broad range of materials contribute to their dominant position

Report Scope and Abrasive Waterjet Cutting Machine Market Segmentation

|

Attributes |

Abrasive Waterjet Cutting Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Abrasive Waterjet Cutting Machine Market Trends

“Increasing Automation and CNC Integration”

- The abrasive waterjet cutting machine market is evolving rapidly as automation and CNC (Computer Numerical Control) technologies are more broadly integrated, allowing manufacturers to achieve greater accuracy, flexibility, and operational efficiency in cutting operations across diverse industries

- For instance, OMAX Corporation deploys advanced CNC waterjet systems that seamlessly interface with CAD/CAM software, enabling automated and highly precise cutting of intricate shapes in metals, ceramics, glass, and composites—reducing manual intervention and production errors

- Industry demand for advanced robotic and multi-axis waterjet solutions is rising, facilitating complex, curved, and three-dimensional part production needed in aerospace, automotive, and custom manufacturing sectors

- Integration of real-time monitoring sensors, IoT devices, and adaptive control algorithms helps operators enhance maintenance planning, predict wear on parts, and optimize cutting performance, making these machines more attractive for high-mix, low-volume applications

- The trend toward environmentally friendly production is driving adoption due to waterjet technology’s minimal heat generation, reduced material waste, and safer workplace conditions compared to traditional thermal or mechanical cutting processes

- Manufacturers are investing in the development of user-friendly control interfaces and maintenance aids, making abrasive waterjet cutting systems more accessible to both skilled technicians and new entrants in fabrication and job shops

Abrasive Waterjet Cutting Machine Market Dynamics

Driver

“Increasing Infrastructure Projects”

- Growth in global infrastructure investments, including transportation, energy, and utilities, is significantly boosting demand for abrasive waterjet cutting machines that can precisely cut a broad range of construction materials

- For instance, Flow International Corporation supplies high-capacity waterjet systems for infrastructure projects that require customized cutting of steel, stone, and composite materials, accommodating tight project timelines and diverse design needs

- The ability of abrasive waterjet cutters to deliver precise, heat-free cuts is critical for manufacturing components used in bridge-building, pipelines, and renewable energy systems, aligning with modern engineering standards

- Government and private sector funding in emerging markets, coupled with projects to renovate and upgrade aging infrastructure in developed regions, are keeping demand robust for flexible, high-throughput cutting solutions

- Versatility and compatibility with various materials—metals, concrete, glass, and advanced composites—enable contractors and fabricators to streamline operations with a single, high-performance cutting platform

Restraint/Challenge

“Maintenance and Operational Costs”

- High initial investment, coupled with ongoing operating and maintenance expenses, is a primary challenge for organizations looking to adopt or scale up abrasive waterjet cutting technologies

- For instance, Hypertherm, Inc. and WARDJet Corporation highlight that frequent replacement of high-pressure components, nozzles, and abrasive materials, along with skilled operator requirements, are key contributors to ongoing operational costs in customer case studies

- Routine maintenance—including pump servicing, component checks, and abrasive feed system cleaning—is vital for reliability but can result in downtime and increased labor and spare parts costs

- Energy consumption is notable for high-pressure operations, and water and abrasive media sourcing and disposal also represent recurring expenses that must be optimized

- Businesses operating on thin margins or with limited capital may be deterred by these cumulative costs, especially when paired with training needs for advanced CNC and automation features, impacting adoption among smaller job shops and in developing markets

Abrasive Waterjet Cutting Machine Market Scope

The market is segmented on the basis of type, application, and industry.

- By Type

On the basis of type, the abrasive waterjet cutting machine market is segmented into 3D waterjet cutting machines, micro waterjet cutting machines, and robotic waterjet cutting machines. The 3D waterjet cutting machines segment dominated the largest market revenue share of 53.02% in 2024, primarily due to its versatile cutting capabilities across complex three-dimensional geometries. These machines are widely used in industries requiring intricate profiles on thick or multi-angled materials such as aerospace and automotive components. The high precision, ability to maintain structural integrity without heat distortion, and suitability for a broad range of materials contribute to their dominant position.

The robotic waterjet cutting machines segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by increasing automation in manufacturing and the growing need for flexible, programmable cutting systems. Robotic systems enable high-speed, repeatable, and multi-axis cutting, particularly benefiting high-throughput environments. Their adaptability to different tasks and enhanced safety features are leading to increased adoption across automotive and heavy engineering sectors.

- By Application

On the basis of application, the market is segmented into exotic metal and non-traditional material cutting, glass or metal art, ceramic or stone cutting, gasket cutting, fiberglass cutting, and foam product cutting. The exotic metal and non-traditional material cutting segment held the largest market share in 2024, owing to the rising demand from sectors such as aerospace, defense, and advanced manufacturing, where materials such as titanium, Inconel, and carbon composites are commonly used. Abrasive waterjet technology is favored here for its cold-cutting nature, eliminating heat-affected zones and preserving material properties.

The glass or metal art segment is expected to witness the fastest CAGR from 2025 to 2032, driven by growing usage in decorative architecture and customized design solutions. Artists and fabricators increasingly prefer waterjet cutting for its precision in handling delicate materials such as glass and thin metals without cracking or distortion. The trend of personalization in interior design and signage is further accelerating demand.

- By Industry

On the basis of industry, the market is segmented into metal fabrication, automotive, aerospace, food processing, textile, machine manufacturing, and medical device. The metal fabrication segment led the market revenue in 2024, attributed to the widespread use of waterjet cutting for high-quality edge finishing and the ability to process diverse metal types. Fabricators value waterjet machines for reducing secondary finishing steps and maintaining tight tolerances in both heavy and light gauge metals.

The medical device industry is projected to experience the fastest growth rate from 2025 to 2032, propelled by increasing demand for micro-precision components used in surgical instruments and implants. Micro waterjet cutting enables burr-free, contamination-free cutting of sensitive materials such as stainless steel and titanium, which are critical in healthcare applications. The need for minimally invasive tools and rapid prototyping is also supporting segment expansion.

Abrasive Waterjet Cutting Machine Market Regional Analysis

- Asia-Pacific dominated the abrasive waterjet cutting machine market with the largest revenue share of 36.15% in 2024, driven by expanding industrialization, significant investment in manufacturing infrastructure, and the growing adoption of precision machining across key sectors

- Countries such as China, Japan, and India are leading contributors, leveraging waterjet technology for complex component fabrication in automotive, aerospace, electronics, and heavy engineering

- The region benefits from a robust supply chain, cost-effective manufacturing capabilities, and increasing demand for high-performance cutting tools, solidifying Asia-Pacific’s position as a global leader in abrasive waterjet cutting technology

China Abrasive Waterjet Cutting Machine Market Insight

China accounted for the largest market revenue share in the Asia-Pacific region in 2024, underpinned by its large-scale industrialization, strong domestic production capabilities, and rapidly growing automotive and construction industries. With a rising emphasis on clean and precise cutting technologies, Chinese manufacturers are increasingly adopting abrasive waterjet machines to enhance fabrication quality while maintaining efficiency. The government's push for smart manufacturing and the presence of local equipment providers offering competitive pricing are key factors driving market expansion.

Japan Abrasive Waterjet Cutting Machine Market Insight

The Japan abrasive waterjet cutting machine market is growing steadily, supported by the country’s reputation for precision engineering and its demand for highly accurate, non-thermal cutting methods. Waterjet systems are being widely implemented in sectors such as electronics, automotive, and aerospace, where exacting specifications are required. Japan's focus on sustainable production, minimal material waste, and integration of smart technologies in manufacturing aligns well with the core benefits of abrasive waterjet cutting machines.

North America Abrasive Waterjet Cutting Machine Market Insight

North America holds a significant share in the abrasive waterjet cutting machine market, supported by a mature industrial base and high demand across aerospace, defense, automotive, and precision engineering sectors. The region benefits from early technology adoption, strong R&D investment, and a shift toward lean, automated manufacturing practices. Abrasive waterjet machines are valued for their accuracy, ability to process exotic and composite materials, and their non-thermal nature, which reduces the risk of material distortion. These machines are increasingly being used in high-spec environments where clean cuts and tight tolerances are essential.

U.S. Abrasive Waterjet Cutting Machine Market Insight

The U.S. dominates the North American market, driven by strong adoption of advanced manufacturing technologies across defense, aerospace, and medical sectors. The demand for precise, contamination-free cutting tools is rising, especially for prototyping and high-precision component fabrication. With a focus on productivity, safety, and energy efficiency, U.S. manufacturers are embracing abrasive waterjet systems as a key enabler of innovation. The market is further supported by a well-developed ecosystem of equipment suppliers, system integrators, and research institutions pushing technological improvements in waterjet cutting.

Europe Abrasive Waterjet Cutting Machine Market Insight

Europe is projected to witness the fastest growth in the abrasive waterjet cutting machine market from 2025 to 2032, primarily fueled by increasing regulatory pressure for cleaner industrial processes and the demand for precision in advanced manufacturing sectors. The region’s strong presence in automotive, aerospace, and medical device manufacturing is fostering the shift toward cold-cutting technologies that preserve material integrity. European manufacturers are adopting waterjet systems to meet strict environmental standards, reduce operational waste, and ensure workplace safety. The region is also seeing increased integration of automation and digital controls, making abrasive waterjet systems a strategic fit for modern production lines.

Germany Abrasive Waterjet Cutting Machine Market Insight

The Germany market is expanding rapidly, supported by its leadership in high-tech industrial machinery and automation. The country’s advanced automotive, aerospace, and engineering sectors are key users of waterjet cutting systems, which offer precise, burr-free cuts without thermal deformation. German manufacturers are investing in high-performance machines that align with their commitment to quality, sustainability, and operational efficiency. These trends, combined with a culture of innovation, are accelerating the deployment of abrasive waterjet systems across various applications.

U.K. Abrasive Waterjet Cutting Machine Market Insight

The U.K. abrasive waterjet cutting machine market is experiencing healthy growth, driven by increasing demand for custom metalwork, architectural components, and medical device fabrication. Manufacturers in the U.K. are adopting abrasive waterjet systems for their versatility in handling a range of materials and their ability to produce complex geometries without heat damage. The growing push for digitized manufacturing and the adoption of Industry 4.0 practices are also enhancing the appeal of smart, computer-controlled waterjet technologies.

Abrasive Waterjet Cutting Machine Market Share

The abrasive waterjet cutting machine industry is primarily led by well-established companies, including:

- Colfax Corporation (U.S.)

- DARDI International Corporation (China)

- Omax Corporation (U.S.)

- Flow International Corporation (U.S.)

- Koike Aronson, Inc. (U.S.)

- Hornet Cutting Systems (U.S.)

- WARDJet, LLC (U.S.)

- Waterjet Corporation s.r.l. (Italy)

- Hughes Pumps Ltd (U.K.)

- Semyx Cutting Solutions (U.S.)

- TECHNI Waterjet (Australia)

- Waterjet Systems International (U.S.)

- Resato International (Netherlands)

- Uhde High Pressure Technologies GmbH (Germany)

- MAXIMATOR JET WATERJET CUTTING SYSTEMS (Germany)

Latest Developments in Global Abrasive Waterjet Cutting Machine Market

- In August 2024, an IIT Madras-backed startup unveiled India’s first indigenous abrasive waterjet machine, designed to cut combustible materials without generating heat. With a price point nearly one-third of existing systems, this development is expected to disrupt the Indian market by making advanced cutting technology more accessible, especially for the semiconductor, aviation, defense, and diamond industries, and positioning India as a potential manufacturing hub for cost-effective waterjet solutions

- In March 2024, Boeing, the American aerospace giant, has reversed its previous decision to reduce production of F/A-18 Super Hornet fighter jets by next year after securing a contract to deliver 17 jets by 2027. Valued at USD 1.14 billion, the deal is expected to be completed by April 2027, with initial deliveries beginning in the winter of 2026. As part of the agreement, Boeing will also provide a comprehensive technical data package that includes maintenance, operation, installation, and training information to support F/A-18 and EA-18G sustainment for the U.S. Navy

- In August 2023, Elliott Matsuura Canada has announced new distribution agreements with three organizations to expand its product offerings in Canada. Among the collaborations, the distributor has partnered with Mandelli, a company founded in 1932 with extensive experience in producing 5-axis machines and flexible manufacturing systems. Mandelli’s machining centers will now be available in Canada, targeting industries such as energy, aerospace, and precision machinery

- In September 2022, KMT Waterjet Systems Inc. launched the KMT PRO 50 pump as part of its New Generation waterjet technology, significantly advancing the performance of abrasive waterjet systems. By delivering a 40% increase in cutting speed and reducing garnet usage and utility consumption by up to 50%, the innovation enhances operational efficiency and cost savings, thereby strengthening KMT’s global competitiveness and setting new standards for high-pressure pump systems in the market

- In July 2022, OMAX Corporation introduced the OptiMAX Precision Jet Machining Center, marking its most sophisticated and accurate abrasive waterjet machine to date. With enhanced automation, high processing speed, and exceptional reliability, the OptiMAX series is poised to raise industry benchmarks, reinforcing OMAX’s position in the U.S. and global markets while addressing the growing demand for precision and productivity in manufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Abrasive Waterjet Cutting Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Abrasive Waterjet Cutting Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Abrasive Waterjet Cutting Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.