Global Aluminum Flat Rolled Products Market

Market Size in USD Billion

CAGR :

%

USD

52.78 Billion

USD

89.33 Billion

2024

2032

USD

52.78 Billion

USD

89.33 Billion

2024

2032

| 2025 –2032 | |

| USD 52.78 Billion | |

| USD 89.33 Billion | |

|

|

|

|

Aluminum Flat-Rolled Products Market Size

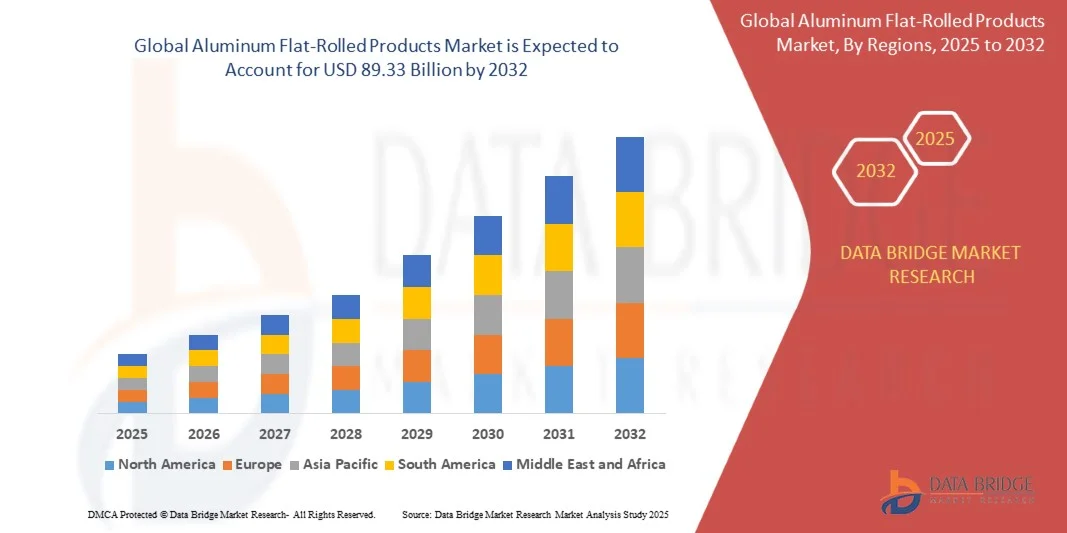

- The global aluminum flat-rolled products market size was valued at USD 52.78 billion in 2024 and is expected to reach USD 89.33 billion by 2032, at a CAGR of 6.8% during the forecast period

- The market growth is largely fueled by increasing industrialization, rapid urbanization, and growing demand for lightweight, durable, and corrosion-resistant materials across construction, automotive, packaging, and consumer goods sectors

- Furthermore, rising focus on sustainability, energy efficiency, and the adoption of recycled and low-carbon aluminum products are driving manufacturers to expand production capacities and invest in advanced rolling and finishing technologies, accelerating market growth

Aluminum Flat-Rolled Products Market Analysis

- Aluminum flat-rolled products include sheets, plates, foil stock, can stock, and fin stock, which are widely used across construction, automotive, aerospace, packaging, and electrical industries due to their lightweight, high strength-to-weight ratio, and corrosion resistance

- The escalating demand is primarily fueled by rapid urban infrastructure development, increasing production of electric and lightweight vehicles, regulatory emphasis on sustainability, and the growing preference for recyclable and energy-efficient materials in industrial and consumer applications

- Asia-Pacific dominated the aluminum flat-rolled products market with a share of 68.5% in 2024, due to rapid urbanization, growing infrastructure development, and increasing automotive and electronics manufacturing

- North America is expected to be the fastest growing region in the aluminum flat-rolled products market during the forecast period due to rising demand in automotive, aerospace, packaging, and electronics applications

- Sheets segment dominated the market with a market share of 39% in 2024, due to its versatile applications across multiple industries, including automotive, construction, and consumer goods. Sheets are preferred for their ease of fabrication, lightweight characteristics, and strong corrosion resistance, which makes them suitable for structural and decorative uses. Moreover, their compatibility with various finishing and coating processes enhances their appeal for high-performance and aesthetic applications. The widespread availability of standardized sheet sizes and thicknesses further consolidates their dominance in the market

Report Scope and Aluminum Flat-Rolled Products Market Segmentation

|

Attributes |

Aluminum Flat-Rolled Products Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Aluminum Flat-Rolled Products Market Trends

“Adoption of Low-Carbon and Recycled Aluminum”

- The aluminum flat-rolled products market is experiencing a significant shift with the increasing adoption of low-carbon and recycled aluminum to meet global sustainability goals. Industries such as automotive, construction, and packaging are increasingly prioritizing the use of green aluminum to reduce carbon footprints and comply with stricter environmental regulations

- For instance, Novelis and Hydro are expanding their production of recycled flat-rolled aluminum products to serve the automotive and beverage can sectors. Their initiatives emphasize industry-wide efforts to reduce emissions through closed-loop recycling and sustainable manufacturing processes

- The push for decarbonization in manufacturing is driving end-users to demand low-carbon aluminum, especially in industries with high sustainability commitments such as electric vehicles, renewable energy infrastructure, and circular packaging. This trend is positioning recycled aluminum as a preferred alternative to primary production

- In packaging, beverage companies are increasingly switching to recycled aluminum cans, supported by consumer preference for environmentally friendly products. Similarly, construction and transportation sectors are adopting flat-rolled aluminum products with reduced environmental impact for green building projects and lightweight vehicle design

- Technological advancements in melt refining, alloy innovations, and recycling processes are improving the quality and consistency of recycled flat-rolled aluminum, making it suitable for high-performance applications. These advances are accelerating its integration into mainstream supply chains

- The adoption of low-carbon and recycled aluminum reflects the industry’s shift toward sustainable value chains, ensuring aluminum remains a critical material in the global transition to greener manufacturing practices

Aluminum Flat-Rolled Products Market Dynamics

Driver

“Demand from Automotive, Construction, and Packaging”

- The rising demand from key industries such as automotive, construction, and packaging is a major driver fueling growth in the aluminum flat-rolled products market. The material’s lightweight, corrosion resistance, and recyclability make it indispensable to a broad range of applications

- For instance, aluminum flat-rolled sheets are widely used in automotive bodies and components to reduce vehicle weight, improve fuel efficiency, and support electric vehicle designs. Automotive producers such as Tesla and BMW are increasingly relying on aluminum to meet sustainability targets and enhance vehicle performance

- In construction, flat-rolled aluminum products are used in roofing, facades, and structural components due to their strength-to-weight ratio and resistance to corrosion. The global expansion of commercial and residential infrastructure is further boosting demand for these applications

- In packaging, rolled aluminum is widely used for beverage cans, foils, and food containers due to its ability to preserve freshness, provide barrier protection, and enable recycling. The surge in demand for sustainable packaging solutions is reinforcing aluminum as a primary packaging material globally

- The convergence of automotive lightweighting, sustainable building initiatives, and circular packaging adoption ensures that demand from these three sectors will continue to drive strong market momentum for aluminum flat-rolled products

Restraint/Challenge

“Raw Material and Energy Price Volatility”

- A significant challenge in the aluminum flat-rolled products market is the volatility of raw material and energy prices, particularly bauxite, alumina, and electricity, which collectively represent major cost components in aluminum production. Price fluctuations can disrupt supply stability and impact overall competitiveness

- For instance, spikes in energy prices in Europe have impacted smelting operations for companies such as Hydro, leading to increased costs for downstream flat-rolled product manufacturers. Similar trends have been observed in China, where energy-related cost pressures affect global supply chains

- Bauxite supply disruptions, geopolitical issues, and freight cost fluctuations further contribute to raw material price volatility, creating uncertainty in profitability for aluminum producers. These factors directly translate into unstable pricing for end-users in automotive, construction, and packaging sectors

- Flat-rolled product manufacturers also face increasing challenges from carbon pricing regulations and emissions compliance, intensifying energy cost burdens. This further complicates cost management and long-term supply planning for the industry

- Addressing volatility challenges requires greater reliance on recycled aluminum, investment in energy-efficient smelting technologies, and long-term supplier agreements. Improving supply chain resilience and expanding low-carbon production will be key to ensuring market stability and sustainable growth in aluminum flat-rolled products

Aluminum Flat-Rolled Products Market Scope

The market is segmented on the basis of product type, end-use industry, and grade.

• By Product Type

On the basis of product type, the aluminum flat-rolled products market is segmented into plates, sheets, standard GEQ, circles, foil stock, can stock, and fin stock. The sheets segment dominated the largest market revenue share of 39% in 2024, driven by its versatile applications across multiple industries, including automotive, construction, and consumer goods. Sheets are preferred for their ease of fabrication, lightweight characteristics, and strong corrosion resistance, which makes them suitable for structural and decorative uses. Moreover, their compatibility with various finishing and coating processes enhances their appeal for high-performance and aesthetic applications. The widespread availability of standardized sheet sizes and thicknesses further consolidates their dominance in the market.

The foil stock segment is anticipated to witness the fastest growth rate from 2025 to 2032, fueled by increasing demand in packaging and electronics industries. Aluminum foil offers excellent barrier properties, lightweight performance, and recyclability, making it ideal for food, beverage, and pharmaceutical packaging. Rising consumer preference for sustainable and convenient packaging solutions drives foil stock adoption, while technological advancements in rolling and coating processes enable better quality and thinner gauge products, expanding its market potential globally.

• By End-Use Industry

On the basis of end-use industry, the aluminum flat-rolled products market is segmented into building & construction, automotive & transportation, consumer goods, electrical & electronics, industrial, and packaging. The building & construction segment held the largest market revenue share in 2024, driven by increasing urbanization, demand for lightweight construction materials, and the use of aluminum in roofing, cladding, and structural components. Aluminum flat-rolled products offer durability, corrosion resistance, and design flexibility, making them a preferred choice for modern architecture and sustainable construction projects. Regulatory emphasis on energy-efficient and environmentally friendly building materials further supports growth in this segment.

The automotive & transportation segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by the shift toward lightweight vehicles and electric mobility. Aluminum flat-rolled products help reduce vehicle weight, improve fuel efficiency, and meet stringent emission standards. The increasing adoption of aluminum in body panels, chassis components, and heat exchangers, combined with growing investments in electric vehicles, drives strong demand for high-strength and specialized grades within this sector.

• By Grade

On the basis of grade, the aluminum flat-rolled products market is segmented into 1xxx, 3xxx, 5xxx, and 6xxx series. The 5xxx series dominated the largest market revenue share in 2024, driven by its excellent corrosion resistance, high strength-to-weight ratio, and suitability for both structural and marine applications. Industries such as automotive, construction, and shipbuilding favor the 5xxx series for its durability, weldability, and performance under harsh environmental conditions. The broad availability of different tempers and finishes in this series further enhances its adaptability across multiple applications.

The 6xxx series is anticipated to witness the fastest growth rate from 2025 to 2032, fueled by increasing use in automotive, aerospace, and high-end architectural applications. The 6xxx series combines strength, corrosion resistance, and excellent formability, making it ideal for lightweight structural components. Advancements in alloying and heat treatment processes enhance its mechanical properties, supporting growing demand for high-performance and sustainable materials across advanced industrial sectors.

Aluminum Flat-Rolled Products Market Regional Analysis

- Asia-Pacific dominated the aluminum flat-rolled products market with the largest revenue share of 68.5% in 2024, driven by rapid urbanization, growing infrastructure development, and increasing automotive and electronics manufacturing

- The region’s cost-effective production capabilities, abundant raw material availability, and rising investments in industrial and construction projects are accelerating market growth

- Skilled labor availability, supportive government policies, and increasing adoption of lightweight and corrosion-resistant materials across building, automotive, and consumer goods industries are further contributing to market expansion

China Aluminum Flat-Rolled Products Market Insight

China held the largest share in the Asia-Pacific aluminum flat-rolled products market in 2024, owing to its dominant position in aluminum production and downstream processing. Strong industrial infrastructure, government incentives for construction and automotive sectors, and robust export-oriented manufacturing are major growth drivers. Demand is also fueled by rapid urban development and increasing adoption of aluminum in transportation, packaging, and electrical applications.

India Aluminum Flat-Rolled Products Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by expanding infrastructure projects, increasing automotive production, and rising demand for consumer electronics. Initiatives promoting Make in India and domestic manufacturing, coupled with investments in modern rolling and finishing facilities, are supporting market expansion. Rising industrialization and the adoption of lightweight, sustainable materials are further driving demand for aluminum flat-rolled products.

Europe Aluminum Flat-Rolled Products Market Insight

The Europe aluminum flat-rolled products market is expanding steadily, supported by high demand from the automotive, aerospace, and construction sectors. Stringent environmental regulations, focus on lightweight and energy-efficient materials, and investments in advanced rolling technologies are boosting market adoption. The region’s emphasis on sustainability, recyclability, and high-quality standards in production is encouraging the use of aluminum across diverse applications.

Germany Aluminum Flat-Rolled Products Market Insight

Germany’s market is driven by its strong automotive and industrial base, advanced manufacturing infrastructure, and focus on lightweight materials. Demand is particularly high for high-strength and corrosion-resistant aluminum grades used in construction, automotive, and machinery applications. R&D initiatives and collaborations between academia and industry are fostering continuous innovation in aluminum flat-rolled products.

U.K. Aluminum Flat-Rolled Products Market Insight

The U.K. market is supported by growing automotive and construction sectors, increasing use of aluminum in packaging, and investments in sustainable industrial production. Focus on energy-efficient buildings, lightweight automotive components, and advanced manufacturing technologies is enhancing demand. The country’s mature industrial framework and emphasis on high-quality, recyclable materials further drive market growth.

North America Aluminum Flat-Rolled Products Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by rising demand in automotive, aerospace, packaging, and electronics applications. Technological advancements in aluminum processing, growing reshoring of manufacturing, and strong adoption of lightweight materials in transportation and construction are supporting expansion. Emphasis on sustainability, energy efficiency, and high-performance applications is boosting regional market growth.

U.S. Aluminum Flat-Rolled Products Market Insight

The U.S. accounted for the largest share in the North America market in 2024, underpinned by its mature automotive, aerospace, and packaging industries. Strong R&D infrastructure, advanced production capabilities, and regulatory support for sustainable and lightweight materials are major growth drivers. The presence of leading aluminum manufacturers and extensive downstream supply chains further solidify the country’s dominant position in the region.

Aluminum Flat-Rolled Products Market Share

The aluminum flat-rolled products industry is primarily led by well-established companies, including:

- Evonik Industries AG (Germany)

- Alnor Oil Co Inc (U.S.)

- KRATON CORPORATION (U.S.)

- BASF SE (Germany)

- Cargill, Incorporated (U.S.)

- Eastman Chemical Company (U.S.)

- Procter & Gamble (U.S.)

- Godrej (India)

- PPG Industries, Inc. (U.S.)

- Emery Oleochemicals (U.S.)

- PTT Global Chemical Public Company Limited (Thailand)

- Jet-Hot, Inc. (U.S.)

- ICD High Performance Coatings (U.S.)

- SPI Performance Coatings (U.K.)

- EverCoat Industries Sdn Bhd. (Malaysia)

Latest Developments in Aluminum Flat-Rolled Products Market

- In April 2025, the European Union approved new regulations on aluminum recycling, mandating a minimum recycled content of 50% for all aluminum packaging by 2030. This policy is expected to significantly boost demand for aluminum flat-rolled products in Europe, encouraging manufacturers to invest in sustainable production practices and increasing the adoption of recycled aluminum across packaging, automotive, and industrial applications. The regulation also positions the EU as a leading market for low-carbon aluminum solutions, enhancing opportunities for innovative flat-rolled product technologies

- In May 2024, Rusal completed the acquisition of the Novelis aluminum rolling mill in Dunkirk, France, for €350 million. This acquisition strengthens Rusal’s European footprint and enhances its competitiveness in the global aluminum flat-rolled market. The expanded production capabilities allow Rusal to cater to rising demand for high-quality aluminum sheets, foils, and other flat-rolled products, particularly in automotive, packaging, and industrial sectors, while optimizing operational efficiencies and economies of scale

- In March 2024, Hydro Aluminum and Arconic entered into a strategic partnership to develop and produce advanced aluminum solutions for the automotive industry. This collaboration is poised to accelerate the adoption of lightweight and sustainable aluminum flat-rolled products, addressing growing demand from electric and conventional vehicle manufacturers. By combining technological expertise and production capacity, both companies are better positioned to supply high-strength, corrosion-resistant, and low-carbon materials for automotive and industrial applications

- In January 2024, Novelis launched its OxyAlume technology in Europe, a process that reduces the carbon footprint of aluminum production by up to 30%. This innovation is expected to drive demand for low-carbon aluminum flat-rolled products, particularly in environmentally conscious construction, automotive, and packaging sectors. The technology enhances Novelis’ market positioning as a leader in sustainable aluminum solutions and encourages wider adoption of green production practices across the European aluminum industry

- In July 2022, Steel Dynamics, Inc. received Board approval to construct a 650,000-ton low-carbon, recycled aluminum flat-rolled mill along with two satellite recycled aluminum slab centers. The commercial production is anticipated to start in the first quarter of 2025, with a total estimated investment of $2.2 billion for the three sites. This initiative is expected to strengthen Steel Dynamics’ position in the U.S. market, increase supply of sustainable aluminum products, and meet the rising demand for recycled, low-carbon flat-rolled aluminum across automotive, packaging, and industrial sectors

- In November 2020, Alcoa Corporation announced a deal to sell its rolling mill operations, currently owned by Alcoa Warrick LLC, to Kaiser Aluminum Corporation for approximately $670 million. This divestiture allowed Alcoa to streamline its operations and focus on high-value segments, while Kaiser Aluminum expanded its production capacity and presence in the flat-rolled aluminum market. The transaction enhanced Kaiser’s ability to meet growing demand in automotive, aerospace, and industrial applications, supporting its strategic growth in North America

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Aluminum Flat Rolled Products Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Aluminum Flat Rolled Products Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Aluminum Flat Rolled Products Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.