Global Aramid Prepreg Market

Market Size in USD Billion

CAGR :

%

USD

3.36 Billion

USD

5.71 Billion

2024

2032

USD

3.36 Billion

USD

5.71 Billion

2024

2032

| 2025 –2032 | |

| USD 3.36 Billion | |

| USD 5.71 Billion | |

|

|

|

|

Aramid Prepreg Market Size

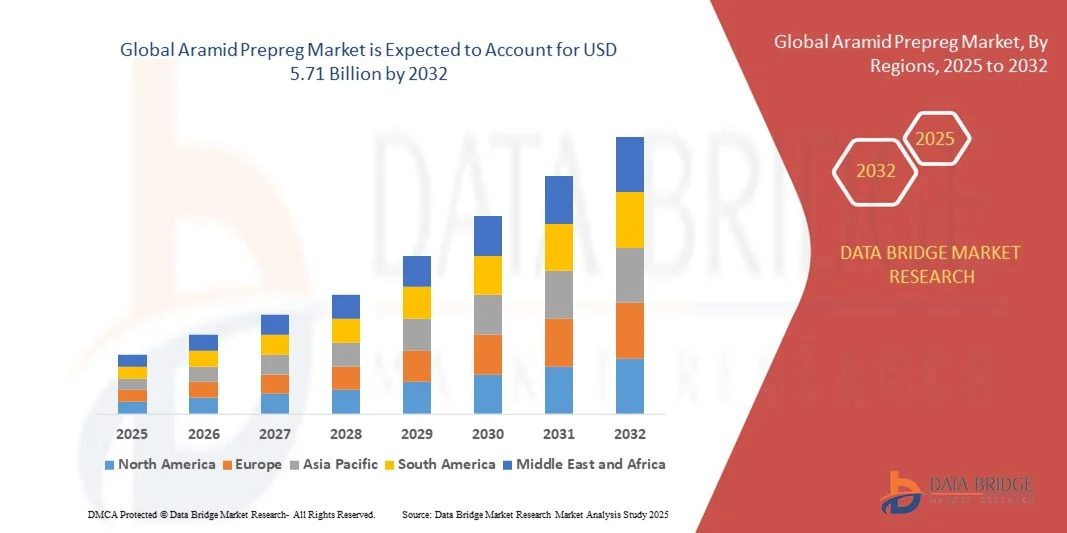

- The global aramid prepreg market size was valued at USD 3.36 billion in 2024 and is expected to reach USD 5.71 billion by 2032, at a CAGR of 11.2% during the forecast period

- The market growth is largely fuelled by the increasing demand for lightweight, high-strength materials in aerospace, defense, automotive, and wind energy applications, where aramid prepregs provide superior mechanical properties and thermal stability

- Rising emphasis on advanced composites for safety-critical and high-performance applications, along with government initiatives supporting aerospace and defense manufacturing, is further propelling the market demand

Aramid Prepreg Market Analysis

- The market is witnessing substantial adoption in aerospace and defense sectors due to aramid prepregs’ high tensile strength, low weight, and excellent impact resistance, which are crucial for aircraft components, ballistic protection, and protective gear

- Automotive and transport industries are increasingly incorporating aramid prepregs in lightweight structural components, improving fuel efficiency and vehicle performance while maintaining safety standards

- Asia-Pacific dominated the aramid prepreg market with the largest revenue share of 38.5% in 2024, driven by rapid industrialization, expansion of the aerospace and defense sectors, and increasing adoption of lightweight composite materials

- North America region is expected to witness the highest growth rate in the global aramid prepreg market, driven by technological advancements, rising adoption in high-performance industries, and strong R&D initiatives supporting material innovation

- The Para-Aramid segment held the largest market revenue share in 2024, driven by its superior strength-to-weight ratio and high thermal stability, making it ideal for aerospace, defense, and high-performance industrial applications. Para-Aramid prepregs are widely preferred for critical applications where enhanced durability and impact resistance are required

Report Scope and Aramid Prepreg Market Segmentation

|

Attributes |

Aramid Prepreg Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Aramid Prepreg Market Trends

Rising Demand For Lightweight And High-Performance Composites

- The growing adoption of aramid prepregs in aerospace, defense, and automotive sectors is transforming the composites market by enabling lightweight, high-strength structural components. Their superior tensile strength and thermal stability allow manufacturers to design fuel-efficient vehicles and high-performance aircraft while maintaining safety standards

- Increasing emphasis on reducing carbon footprint and improving energy efficiency is accelerating the use of aramid prepregs in wind energy turbines, industrial machinery, and sports equipment. These materials offer high durability, impact resistance, and dimensional stability, making them ideal for advanced applications

- The ease of integration of aramid prepregs with automated manufacturing processes, such as autoclave curing and resin transfer molding, is making them attractive for mass production of complex composite parts. This is driving broader adoption across commercial and industrial applications

- For instance, in 2023, several leading aerospace manufacturers in Europe reported enhanced aircraft performance and weight reduction after replacing conventional composites with aramid prepreg components, demonstrating significant fuel savings and structural reliability

- While demand for high-performance materials is rising, their impact depends on continued material innovation, process optimization, and cost-effective production methods. Manufacturers are focusing on R&D to expand applications and improve affordability

Aramid Prepreg Market Dynamics

Driver

Increasing Use Of Advanced Composites In Aerospace And Defense

- The need for lightweight, high-strength materials in aerospace and defense applications is driving investment in aramid prepregs. These materials enhance safety, fuel efficiency, and operational performance of aircraft, military vehicles, and protective gear. In addition, stringent regulatory requirements for performance and durability are accelerating their adoption

- Industries are increasingly aware of the economic benefits of reduced weight and improved durability, which translate into lower operational costs and extended product life. This awareness is encouraging consistent adoption of aramid prepregs in commercial and defense projects, while supporting innovation in hybrid composite structures

- Government programs and industry collaborations supporting innovation in advanced composites are further boosting market growth, as manufacturers develop next-generation prepregs with enhanced thermal and mechanical properties. Public-private partnerships also promote R&D investments to expand applications across emerging sectors

- For instance, in 2022, a major U.S. defense contractor integrated aramid prepregs into armored vehicle panels, significantly improving impact resistance and operational efficiency. Such successful implementations are creating awareness and setting benchmarks for other manufacturers globally

- While aerospace and defense demand is strong, widespread adoption requires ongoing technological improvements and cost reduction to penetrate other high-volume sectors such as automotive and industrial applications. In addition, improving supply chain resilience is key to meet growing global demand

Restraint/Challenge

High Production Costs And Limited Manufacturing Infrastructure

- The high cost of aramid fibers and prepreg manufacturing equipment limits accessibility for small and mid-sized manufacturers. Advanced autoclave and curing systems require substantial capital investment, restricting market penetration in cost-sensitive regions. Price volatility of raw materials also impacts production planning and procurement strategies

- Many regions lack specialized production facilities and skilled personnel to handle prepreg materials and automated manufacturing processes. This infrastructure gap slows the adoption of aramid prepregs in emerging markets and small-scale industries, while necessitating investments in workforce training and technical expertise

- Supply chain challenges, such as limited availability of high-quality aramid fibers and resin systems, further constrain growth. Inconsistent raw material quality can affect product performance, causing delays and higher production costs. Manufacturers must also manage long lead times and logistics challenges, particularly in remote or underdeveloped regions

- For instance, in 2023, several composite component manufacturers in Asia reported delays and increased costs due to scarcity of certified aramid fibers and limited access to advanced curing equipment. These constraints prompted firms to explore local suppliers, alternative resins, and inventory optimization strategies

- While technological advancements continue to improve production efficiency, addressing cost, infrastructure, and supply chain challenges is critical. Stakeholders are focusing on decentralized manufacturing, scalable production techniques, and strategic raw material sourcing to unlock long-term market potential, ensuring both profitability and global competitiveness

Aramid Prepreg Market Scope

The market is segmented on the basis of product, resin, and application.

- By Product

On the basis of product, the aramid prepreg market is segmented into Para-Aramid and Meta-Aramid. The Para-Aramid segment held the largest market revenue share in 2024, driven by its superior strength-to-weight ratio and high thermal stability, making it ideal for aerospace, defense, and high-performance industrial applications. Para-Aramid prepregs are widely preferred for critical applications where enhanced durability and impact resistance are required.

The Meta-Aramid segment is expected to witness the fastest growth rate from 2025 to 2032, fueled by its excellent flame-retardant properties, thermal stability, and cost-effectiveness. Meta-Aramid prepregs are increasingly adopted in automotive, electronics, and protective gear applications, particularly where fire resistance and insulation performance are critical.

- By Resin

On the basis of resin, the market is segmented into Thermosetting and Thermoplastic. The Thermosetting resin segment dominated the market in 2024 due to its superior mechanical properties, dimensional stability, and suitability for high-temperature applications, particularly in aerospace and defense sectors.

The Thermoplastic resin segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its recyclability, faster processing, and adaptability for lightweight composite structures in automotive and consumer electronics industries. Thermoplastic prepregs are increasingly used in applications requiring rapid manufacturing cycles and design flexibility.

- By Application

On the basis of application, the market is segmented into Automotive, Sporting Goods, Aerospace and Defence, Electronics, and Others. The Aerospace and Defence segment held the largest revenue share in 2024, propelled by the growing demand for lightweight, high-strength components in aircraft, military vehicles, and protective equipment.

The Automotive segment is expected to witness the fastest growth rate from 2025 to 2032, fueled by the adoption of aramid prepregs in electric vehicles, high-performance cars, and structural components to reduce weight, improve fuel efficiency, and enhance crash safety performance.

Aramid Prepreg Market Regional Analysis

Asia-Pacific dominated the aramid prepreg market with the largest revenue share of 38.5% in 2024, driven by rapid industrialization, expansion of the aerospace and defense sectors, and increasing adoption of lightweight composite materials

Manufacturers in the region are investing heavily in advanced composite production facilities, while governments support the use of high-performance materials in defense and transportation projects

This widespread adoption is further supported by growing automotive production, rising disposable incomes, and a strong focus on energy-efficient and high-strength materials, establishing aramid prepregs as a preferred solution for multiple industrial applications

China Aramid Prepreg Market Insight

The China aramid prepreg market captured the largest revenue share in 2024 within Asia-Pacific, fueled by the country’s booming aerospace, defense, and automotive sectors. The increasing demand for lightweight, durable materials in commercial aircraft, high-speed trains, and protective gear is driving market growth. Moreover, supportive government policies promoting advanced materials manufacturing and ongoing infrastructure projects are further propelling adoption.

Japan Aramid Prepreg Market Insight

The Japan aramid prepreg market is expected to witness the fastest growth rate from 2025 to 2032, driven by technological advancements and the country’s emphasis on high-performance materials. Japanese manufacturers prioritize the integration of aramid prepregs in aerospace components, sporting goods, and industrial applications. The presence of R&D hubs focusing on composite materials innovation further accelerates market expansion.

Europe Aramid Prepreg Market Insight

The Europe aramid prepreg market is expected to witness the fastest growth rate from 2025 to 2032, primarily driven by aerospace, defense, and automotive regulations emphasizing fuel efficiency and safety. Countries such as Germany, France, and the U.K. are adopting aramid prepregs in both commercial and defense applications to meet performance and durability requirements. Growing collaborations between composite manufacturers and end-users support innovation and regional adoption.

U.K. Aramid Prepreg Market Insight

The U.K. aramid prepreg market is expected to witness the fastest growth rate from 2025 to 2032, fueled by aerospace modernization programs, defense contracts, and automotive lightweighting initiatives. The region’s strong manufacturing base and focus on advanced material R&D encourage aramid prepreg adoption across commercial and industrial sectors. In addition, sustainability goals in manufacturing are driving the use of high-performance, durable composite materials.

Germany Aramid Prepreg Market Insight

The Germany aramid prepreg market is expected to witness the fastest growth rate from 2025 to 2032, driven by increasing industrial automation, adoption of lightweight materials in automotive and aerospace, and technological innovations in prepreg formulations. German manufacturers focus on integrating aramid prepregs into high-performance components, enhancing safety, durability, and operational efficiency. Government support for advanced composites further reinforces market growth.

North America Aramid Prepreg Market Insight

The North America aramid prepreg market is expected to witness the fastest growth rate from 2025 to 2032, fueled by increasing aerospace production, defense modernization, and automotive lightweighting initiatives. The U.S. remains the dominant market, driven by defense contracts, commercial aircraft programs, and investment in high-performance composites manufacturing. In addition, the presence of major global manufacturers and suppliers accelerates innovation and adoption across industrial applications.

U.S. Aramid Prepreg Market Insight

The U.S. aramid prepreg market a is expected to witness the fastest growth rate from 2025 to 2032, attributed to rising demand for lightweight, high-strength materials in aerospace, defense, and automotive sectors. The country’s focus on technological innovation, R&D initiatives, and strategic collaborations with end-users enhances market growth. Furthermore, stringent safety and performance standards in aviation and defense are propelling the widespread adoption of aramid prepregs.

Aramid Prepreg Market Share

The Aramid Prepreg industry is primarily led by well-established companies, including:

- SGL Carbon (Germany)

- Solvay (Belgium)

- Hexcel Corporation (U.S.)

- Axiom Materials, Inc. (U.S.)

- Koninklijke Ten Cate bv. (Netherlands)

- TEIJIN LIMITED (Japan)

- Gurit (Switzerland)

- Mitsubishi Chemical Corporation (Japan)

- Airtech Advanced Materials Group (U.S.)

- TORAY INDUSTRIES, INC. (Japan)

- PARK ELECTROCHEMICAL CORP. (U.S.)

- TCR Composites (U.S.)

- HANKUK CARBON CO.,LTD. (South Korea)

- KINECO - KAMAN (U.S.)

- Barrday, Inc. (U.S.)

- TAIWAN FIRST LI-BOND Co., LTD. (Taiwan)

- Holding company "Composite" (France)

- GMS COMPOSITES (U.K.)

- ABC Composite Materials LLC (U.S.)

- North Thin Ply Technology (Switzerland)

- Plastic Reinforcement Fabrics Ltd (U.K.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Aramid Prepreg Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Aramid Prepreg Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Aramid Prepreg Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.