Global Atomizing Metal Powder Market

Market Size in USD Billion

CAGR :

%

USD

3.90 Billion

USD

6.91 Billion

2024

2032

USD

3.90 Billion

USD

6.91 Billion

2024

2032

| 2025 –2032 | |

| USD 3.90 Billion | |

| USD 6.91 Billion | |

|

|

|

|

Global Atomizing Metal Powder Market Size

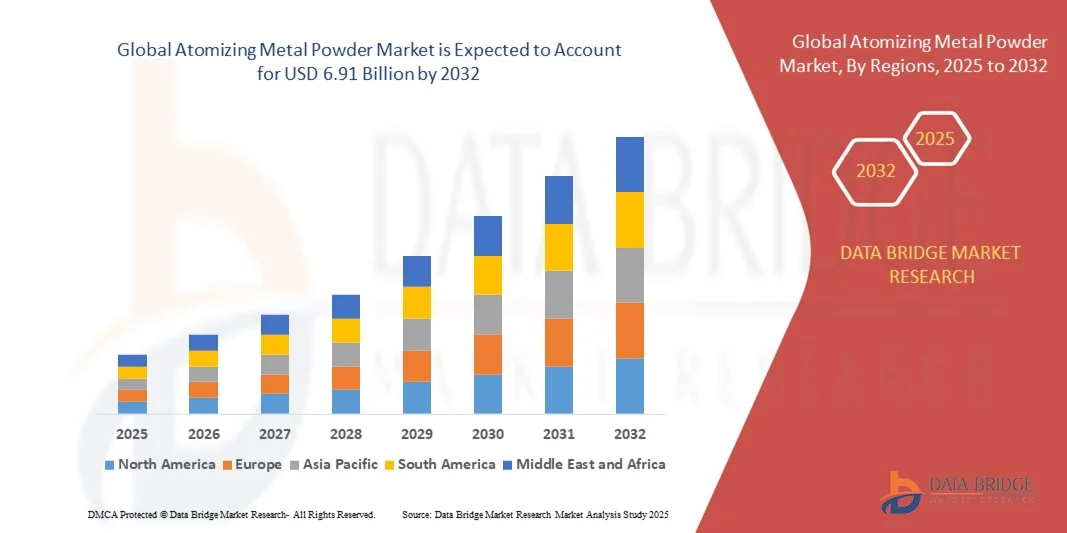

- The global atomizing metal powder market size was valued at USD 3.90 billion in 2024 and is projected to reach USD 6.91 billion by 2032, growing at a CAGR of 7.40% during the forecast period.

- The market expansion is primarily driven by increasing demand across additive manufacturing, automotive, and aerospace sectors, where precision and performance are critical.

- In addition, technological advancements in atomization techniques and the rising need for lightweight, high-strength components are propelling the adoption of metal powders, significantly fueling the growth of the global atomizing metal powder industry.

Global Atomizing Metal Powder Market Analysis

- Atomizing metal powders, produced through various atomization techniques, are essential raw materials for advanced manufacturing processes, including additive manufacturing, metal injection molding, and powder metallurgy, due to their high purity, controlled particle size, and superior flowability.

- The rising demand for atomized metal powders is primarily fueled by the rapid growth of the automotive, aerospace, and medical sectors, where lightweight, high-performance components are crucial, alongside the expanding adoption of 3D printing technologies.

- North America dominated the atomizing metal powder market with the largest revenue share of 38.7% in 2024, supported by robust industrial growth, increasing investments in manufacturing technologies, and rising demand for metal powders in China, Japan, and India for automotive and electronics applications.

- Asia-Pacific is expected to be the fastest-growing region in the atomizing metal powder market during the forecast period, driven by innovation in additive manufacturing, defense sector modernization, and growing investments in sustainable and lightweight materials.

- The gas atomization segment dominated with the largest market revenue share of 57.4% in 2024, due to its established use in producing high-quality spherical metal powders favored across multiple end-use industries

Report Scope and Global Atomizing Metal Powder Market Segmentation

|

Attributes |

Atomizing Metal Powder Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Atomizing Metal Powder Market Trends

Enhanced Performance Through Technological Advancements in Atomization

- A significant and accelerating trend in the global Atomizing Metal Powder Market is the ongoing innovation in atomization techniques, such as gas, water, and centrifugal atomization, which are enabling the production of ultra-fine, high-purity, and customized metal powders tailored for advanced applications like additive manufacturing and metal injection molding.

- For Instance, companies like Sandvik and Höganäs AB have invested in next-generation gas atomization facilities to produce premium-grade metal powders with highly controlled particle size distributions—crucial for 3D printing in aerospace and medical industries. Similarly, Kymera International offers fine and ultrafine powders for precision manufacturing, developed using advanced atomization processes.

- These technological improvements allow manufacturers to fine-tune particle morphology, surface area, and flow characteristics, enhancing the mechanical properties and performance consistency of end-use components. Innovations like plasma atomization are also emerging to meet the demand for reactive and high-performance metal powders such as titanium and its alloys.

- Moreover, integration of automation, real-time monitoring, and AI-driven quality control in the atomization process ensures better consistency and traceability, helping to meet the stringent quality requirements of sectors like automotive, aerospace, and biomedical.

- Companies such as Kobe Steel and JFE Chemical Corporation are developing atomizing technologies capable of supporting high-volume production while maintaining tight quality standards, enabling scalable manufacturing of parts with complex geometries and critical tolerances.

- This shift towards high-performance, precision-engineered metal powders is redefining manufacturing capabilities and expanding the scope of applications. As demand rises for components that are lighter, stronger, and more sustainable, atomization technology continues to play a central role in advancing industrial innovation globally.

Global Atomizing Metal Powder Market Dynamics

Driver

Growing Demand Driven by Advanced Manufacturing and Lightweight Component Needs

- The rising global demand for lightweight, high-performance components across sectors such as automotive, aerospace, and medical is a major driver for the growth of the Atomizing Metal Powder Market.

- For instance, the increasing shift toward electric vehicles (EVs) is accelerating the use of powdered metal parts for lightweighting and energy efficiency. Major industry players like Höganäs AB and Kymera International are investing in powder solutions specifically tailored for EV and additive manufacturing applications.

- Additionally, the adoption of additive manufacturing (3D printing) in prototyping and end-use part production is expanding rapidly, necessitating high-quality metal powders with controlled morphology and particle size. Atomized powders offer superior flowability and sintering behavior, making them ideal for such precision applications.

- Governments and industries alike are supporting sustainability-driven innovations, and powder metallurgy allows for near-net-shape manufacturing, reducing material waste significantly. This efficiency aligns with environmental and cost-saving goals, especially in high-value industries.

- The demand is further fueled by industrial expansion in emerging markets, where increased infrastructure development, defense modernization, and healthcare advancement are creating new opportunities for atomized metal powder applications. Companies are also expanding regional production capacities to meet localized demand efficiently.

Restraint/Challenge

High Production Costs and Raw Material Price Volatility

- A key challenge for the global Atomizing Metal Powder Market is the high production cost associated with advanced atomization processes, such as gas and plasma atomization, which require sophisticated equipment, inert gas environments, and significant energy inputs.

- For example, the production of fine-grade titanium and nickel-based powders for aerospace applications involves tight process controls and costly raw materials, often limiting affordability for smaller manufacturers or cost-sensitive sectors.

- Furthermore, fluctuations in raw material prices—particularly for metals like copper, nickel, and titanium—can significantly impact the cost structure of atomized powders. Global supply chain disruptions, geopolitical instability, and mining constraints exacerbate these pricing issues.

- While technological advancements are gradually improving yield and energy efficiency, the initial capital investment remains a barrier to entry for new players in the market. Smaller manufacturers may struggle to scale up or compete with established players who already have vertically integrated operations.

- Addressing these challenges will require industry-wide collaboration to improve atomization efficiency, explore alternative and recycled feedstocks, and implement cost-control strategies without compromising powder quality. Government incentives and investments in sustainable metallurgy could also play a crucial role in overcoming these cost-related restraints.

Global Atomizing Metal Powder Market Scope

The atomizing metal powder market is segmented on the basis of production method, product and application.

- By Production Method

On the basis of production method, the global atomizing metal powder market is segmented into gas atomization, liquid atomization, and plasma atomization. The gas atomization segment dominated the market with the largest revenue share of 57.4% in 2024, owing to its ability to produce high-purity, spherical metal powders with controlled particle size distribution, which are essential for additive manufacturing, powder metallurgy, and thermal spraying. Gas atomization is widely used for producing powders from reactive and non-reactive metals, including steel, aluminum, and titanium alloys.

The plasma atomization segment is projected to grow at the fastest CAGR of 22.8% from 2025 to 2032, driven by its capability to produce ultra-fine, highly spherical, and contamination-free powders for advanced aerospace, medical, and high-performance 3D printing applications. Although expensive, plasma atomization is gaining popularity for producing niche powders like titanium and Inconel with superior flowability and performance in precision manufacturing environments.

- By Product

On the basis of product, the market is segmented into atomizing iron powder and atomizing copper powder. The atomizing iron powder segment held the largest market share of 48.3% in 2024, due to its extensive use in automotive components, sintered parts, and structural applications via powder metallurgy. Iron powders are cost-effective, widely available, and offer favorable mechanical properties, making them the preferred choice for high-volume manufacturing in the automotive and industrial sectors.

The atomizing copper powder segment is expected to register the fastest CAGR of 20.6% from 2025 to 2032, driven by rising demand in electrical, electronic, and thermal management applications. Copper powders are valued for their excellent electrical and thermal conductivity and are increasingly used in conductive inks, electronic pastes, and brazing materials. Additionally, copper’s antibacterial properties are opening new applications in medical devices and consumer products, supporting the segment’s rapid expansion.

- By Application

On the basis of application, the Global Atomizing Metal Powder Market is segmented into metallurgy industry, chemical industry, electronic materials, diamond tools, automotive industry, welding, and 3D printing. The automotive industry segment dominated the market in 2024 with a market share of 35.9%, due to the extensive use of atomized powders in producing high-precision, wear-resistant parts such as gears, bushings, and sprockets. Powder metallurgy enables lightweighting, cost-efficiency, and performance consistency, making it essential in modern vehicle manufacturing.

The 3D printing segment is anticipated to grow at the fastest CAGR of 24.3% from 2025 to 2032, supported by the global shift toward additive manufacturing in aerospace, medical, and prototyping applications. Atomized metal powders are critical feedstocks for laser powder bed fusion and binder jetting technologies. The increasing adoption of high-performance metal parts in complex, customized applications is driving this rapid growth across multiple industries.

Global Atomizing Metal Powder Market Regional Analysis

- North America dominated the Atomizing Metal Powder Market with the largest revenue share of 38.7% in 2024, driven by rapid industrialization, robust automotive production, and increasing investments in advanced manufacturing technologies across countries like China, India, and Japan.

- Manufacturers in the region are heavily investing in additive manufacturing and powder metallurgy techniques to meet the growing demand for lightweight, high-performance components in automotive, aerospace, and electronics sectors.

- The region’s dominance is further supported by lower production costs, favorable government initiatives for industrial growth, and a strong presence of key metal powder manufacturers, positioning Asia-Pacific as a global hub for atomizing metal powder production and application.

U.S. Atomizing Metal Powder Market Insight

The U.S. Atomizing Metal Powder Market captured the largest revenue share of 81% within North America in 2024, driven by the country’s strong presence in the automotive, aerospace, and additive manufacturing sectors. Rapid advancements in powder metallurgy and increasing demand for lightweight, high-strength components have fueled the uptake of atomized powders across various industries. The U.S. also benefits from a well-established ecosystem of metal powder producers, R&D centers, and end-use industries, creating strong domestic demand. Furthermore, government investments in advanced manufacturing and defense technologies are accelerating the adoption of atomized powders in applications such as 3D printing, metal injection molding (MIM), and thermal spraying.

Europe Atomizing Metal Powder Market Insight

The Europe Atomizing Metal Powder Market is projected to grow at a robust CAGR during the forecast period, supported by the region’s stringent environmental regulations and push for sustainable manufacturing. The automotive and aerospace sectors in Germany, France, and the UK are major consumers of atomized powders due to their need for fuel-efficient, high-performance components. Additionally, Europe's focus on reducing industrial emissions and material waste is increasing the use of powder metallurgy, a near-net-shape technology that aligns with sustainability goals. Innovation in additive manufacturing and strong collaborations between research institutes and industry players are further accelerating market growth across the region.

U.K. Atomizing Metal Powder Market Insight

The U.K. Atomizing Metal Powder Market is anticipated to grow at a noteworthy CAGR from 2025 to 2032, driven by growing demand for advanced manufacturing technologies and lightweight materials across aerospace, defense, and industrial machinery. The UK’s proactive support for innovation and its thriving additive manufacturing ecosystem are creating new opportunities for atomized metal powders, particularly for 3D printing of complex parts. Moreover, the country's commitment to reducing carbon emissions and dependence on traditional manufacturing methods is fostering increased adoption of powder-based technologies in both established and emerging sectors.

Germany Atomizing Metal Powder Market Insight

The Germany Atomizing Metal Powder Market is expected to expand at a considerable CAGR during the forecast period, supported by the country’s engineering expertise, strong industrial base, and focus on digitalization in manufacturing. Germany is a leader in precision manufacturing, and atomized powders play a key role in applications such as metal injection molding, sintered parts, and additive manufacturing. With major automotive OEMs and aerospace suppliers headquartered in Germany, demand for high-performance, sustainable powder-based solutions is on the rise. The country also emphasizes high recycling rates and material efficiency, both of which align with powder metallurgy benefits.

Asia-Pacific Atomizing Metal Powder Market Insight

The Asia-Pacific Atomizing Metal Powder Market is poised to grow at the fastest CAGR of 24% from 2025 to 2032, driven by the rapid industrialization of countries like China, India, South Korea, and Japan. The region’s growing automotive production, infrastructure development, and rising adoption of 3D printing technologies are creating strong demand for atomized metal powders. Furthermore, favorable government initiatives, such as “Make in India” and “Made in China 2025,” are supporting advanced manufacturing practices that rely heavily on powder-based technologies. With increasing local production capacities and cost advantages, APAC is becoming a global hub for atomized powder manufacturing.

Japan Atomizing Metal Powder Market Insight

The Japan Atomizing Metal Powder Market is experiencing strong growth due to the country’s emphasis on high-precision manufacturing, innovation, and quality. Japan’s demand for atomized powders is primarily driven by the electronics, automotive, and healthcare sectors, where miniaturization and performance are critical. As one of the early adopters of powder metallurgy and metal injection molding, Japan continues to lead in technological integration, particularly in producing compact, high-tolerance parts. Additionally, the aging population is creating increased demand for medical implants and devices manufactured using biocompatible atomized metal powders.

China Atomizing Metal Powder Market Insight

The China Atomizing Metal Powder Market held the largest revenue share in Asia-Pacific in 2024, fueled by its dominance in automotive production, infrastructure expansion, and robust growth in the electronics and 3D printing industries. China is also a key exporter and producer of atomized metal powders, supported by a vast manufacturing ecosystem and low production costs. Government support for smart manufacturing and the rapid rise of domestic EV and aerospace sectors are propelling the demand for high-performance metal powders. Local players are increasingly investing in advanced atomization technologies to meet both domestic and global demand for specialized metal powders.

Global Atomizing Metal Powder Market Share

The Atomizing Metal Powder industry is primarily led by well-established companies, including:

- Höganäs AB (Sweden)

- JFE Chemical Corporation (Japan)

- Sandvik AB (Sweden)

- KOBE STEEL, LTD. (Japan)

- SAFINA a.s. (Czech Republic)

- GKN Sinter Metals Components GmbH (Germany)

- Advanced Tech & Materials (China)

- Kymera International (U.S,)

- Makin Metal Powders (U.K.)

- Mitsui Chemicals, Inc. (Japan)

- Pometon Powder (Italy)

- m-tec powder GmbH (Germany)

- Hangzhou Yitong New Material Co., Ltd. (China)

- Laiwu Feilong Powder Metallurgy Co. Ltd. (China)

What are the Recent Developments in Global Atomizing Metal Powder Market?

- In April 2023, Höganäs AB, a global leader in metal powders and powder metallurgy solutions, announced a strategic expansion of its production capabilities in South Africa. This initiative focuses on supplying high-quality atomized metal powders tailored to meet the increasing demand from both automotive and industrial sectors in the region. Leveraging its advanced atomization technologies and global expertise, Höganäs aims to strengthen its position in emerging markets while supporting regional industrial growth and innovation.

- In March 2023, Sandvik AB, a renowned materials technology company based in Sweden, launched a new series of high-performance atomized metal powders specifically engineered for additive manufacturing applications in aerospace and medical sectors. This product line is designed to enhance the mechanical properties and precision of 3D-printed components, reflecting Sandvik’s commitment to advancing powder metallurgy technologies that cater to stringent industry standards and evolving customer requirements.

- In March 2023, Kobe Steel, Ltd., a major player in metal powder production, successfully implemented an advanced plasma atomization system at its manufacturing facility in Japan. This state-of-the-art technology allows Kobe Steel to produce ultra-fine and highly uniform metal powders, crucial for next-generation applications such as electric vehicle batteries and precision electronics. The upgrade underscores the company’s dedication to innovation and sustainability in the powder metallurgy market.

- In February 2023, Mitsui Chemicals, Inc., a leader in chemical and material sciences, announced a strategic partnership with key players in the electronics manufacturing sector to develop specialized copper atomized powders. These powders are intended to improve electrical conductivity and thermal management in semiconductor and electronic devices. The collaboration highlights Mitsui Chemicals’ focus on tailored material solutions to meet the fast-growing demand for high-performance electronic components.

- In January 2023, JFE Chemical Corporation unveiled its latest atomizing gas technology designed to increase efficiency and reduce environmental impact in metal powder production. The technology was showcased at the International Powder Metallurgy Congress and received acclaim for its potential to enhance production yield and powder quality across multiple applications, including automotive and industrial machinery. JFE Chemical’s innovation emphasizes the ongoing commitment to sustainable and efficient manufacturing processes within the global atomizing metal powder market.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Atomizing Metal Powder Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Atomizing Metal Powder Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Atomizing Metal Powder Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.