Global Automotive Tube Bending Assembly Parts Market

Market Size in USD Billion

CAGR :

%

USD

5.79 Billion

USD

7.72 Billion

2024

2032

USD

5.79 Billion

USD

7.72 Billion

2024

2032

| 2025 –2032 | |

| USD 5.79 Billion | |

| USD 7.72 Billion | |

|

|

|

|

Global Automotive Tube Bending Assembly Parts Market Size

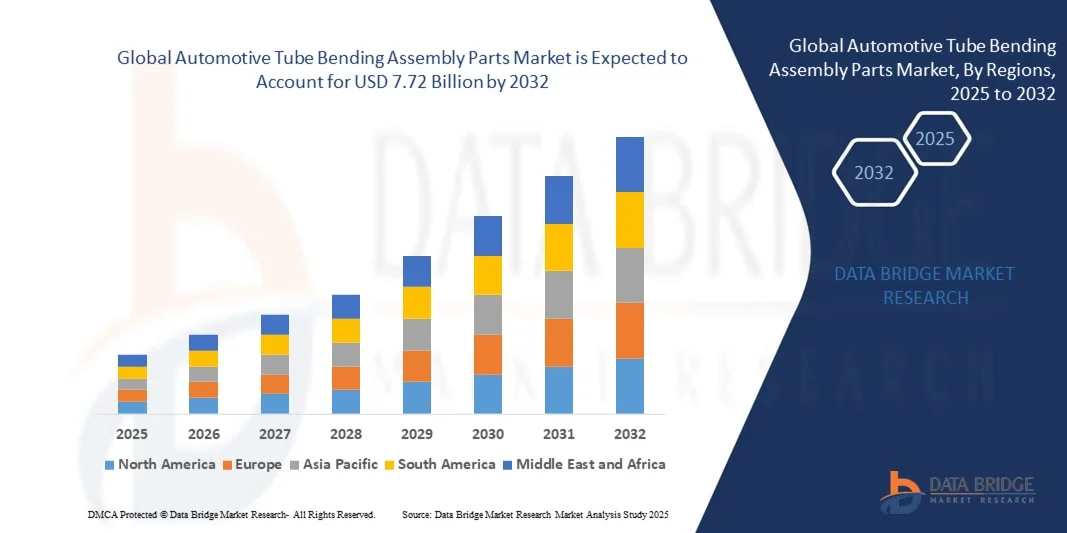

- The global Automotive Tube Bending Assembly Parts Market size was valued at USD 5.79 billion in 2024 and is projected to reach USD 7.72 billion by 2032, growing at a CAGR of 3.67% during the forecast period.

- Market growth is primarily driven by the increasing demand for lightweight and durable automotive components, coupled with advancements in manufacturing technologies such as CNC bending and automation.

- Additionally, the rising production of electric vehicles and stringent government regulations on vehicle emissions are propelling the need for efficient tube bending solutions, further accelerating market expansion over the coming years.

Global Automotive Tube Bending Assembly Parts Market Analysis

- Automotive tube bending assembly parts, essential for shaping and assembling tubular components in vehicles, are critical to manufacturing lightweight, durable, and efficient automotive systems used across passenger cars, commercial vehicles, and electric vehicles.

- The growing demand for fuel-efficient vehicles, stringent emission regulations, and advancements in tube bending technologies such as CNC and robotic bending are the primary factors driving market growth.

- Europe Dominated the automotive tube bending assembly parts market with the largest revenue share of 34.5% in 2024, supported by rapid automotive production growth, expanding electric vehicle manufacturing, and a strong supplier network in countries like China, Japan, and South Korea.

- Asia-Pacific is expected to be the fastest-growing region during the forecast period due to increased investments in automotive innovation, rising adoption of electric and autonomous vehicles, and modernization of manufacturing plants with advanced bending technologies.

- The exhaust systems segment dominated the market with the largest revenue share of 38.6% in 2024, owing to the widespread use of bent tubes in exhaust routing, emission reduction, and thermal management

Report Scope and Global Automotive Tube Bending Assembly Parts Market Segmentation

|

Attributes |

Automotive Tube Bending Assembly Parts Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Global Automotive Tube Bending Assembly Parts Market Trends

Smart Automation and AI Integration in Manufacturing Processes

- A significant and accelerating trend in the global Automotive Tube Bending Assembly Parts Market is the growing adoption of artificial intelligence (AI) and automation technologies in tube bending and assembly operations. These advancements are transforming traditional manufacturing by increasing efficiency, improving precision, and reducing human error.

- For instance, leading manufacturers are implementing AI-powered CNC (Computer Numerical Control) machines that optimize bend angles and tube alignment in real-time, minimizing material waste and ensuring consistent product quality. AI algorithms can also predict maintenance needs and detect anomalies in the bending process, reducing downtime and enhancing production flow.

- Robotic tube bending systems equipped with AI capabilities are gaining popularity due to their ability to perform complex multi-axis bends with high repeatability. These systems also adapt to design changes quickly, allowing for flexible and scalable production suited to electric vehicle (EV) platforms and modern vehicle architectures.

- The integration of AI-driven process monitoring tools enables real-time data analytics and quality control, allowing manufacturers to track each production cycle and implement corrective measures instantly. This contributes to improved overall equipment effectiveness (OEE) and supports lean manufacturing principles.

- As vehicle designs become more complex and lightweight materials such as aluminum and advanced high-strength steel are increasingly used, AI and smart automation offer solutions to maintain structural integrity while achieving precise geometries essential for crash performance and fuel efficiency.

- This shift toward intelligent, automated production environments is driving competitive differentiation across the industry. Companies such as Unison Ltd. and BLM Group are at the forefront, offering fully automated tube bending solutions with integrated AI and remote monitoring capabilities, catering to the evolving needs of automotive OEMs and Tier 1 suppliers.

- As the automotive industry moves toward electrification and digitalization, the demand for AI-enabled tube bending and assembly technologies is rising rapidly, enabling manufacturers to meet higher production standards, adapt to custom designs, and reduce operational costs.

Global Automotive Tube Bending Assembly Parts Market Dynamics

Driver

Growing Need Due to Rising Vehicle Production and Lightweight Component Demand

- The steady growth in global vehicle production, alongside increasing demand for lightweight and efficient automotive components, is significantly driving the demand for tube bending assembly parts across the automotive industry. Manufacturers are increasingly focusing on optimizing vehicle performance and fuel efficiency, making precision-formed tube assemblies a critical component in both traditional internal combustion engine (ICE) vehicles and electric vehicles (EVs).

- For instance, in March 2024, Benteler Automotive announced the expansion of its advanced manufacturing facility in the Czech Republic to increase production capacity for tubular components and assemblies used in electric drivetrains. Such strategic investments by key players are expected to further propel the growth of the automotive tube bending assembly parts market in the coming years.

- Tube bending assembly parts are extensively used in vehicle exhaust systems, brake lines, fuel lines, and air conditioning systems, offering enhanced durability, weight reduction, and improved performance over traditional rigid components. The rising trend toward vehicle electrification and hybrid systems has further increased the need for precision tubing solutions for battery cooling and other thermal management systems.

- Furthermore, the growing emphasis on reducing vehicular emissions and complying with stringent environmental regulations has led automakers to adopt lightweight metal alloys, such as aluminum and stainless steel, in tube assemblies. This supports both emissions compliance and overall vehicle efficiency.

- The push towards modular vehicle platforms and automated manufacturing processes has also accelerated the adoption of highly customized tube bending assembly parts. With advancements in CNC bending technology and 3D laser cutting, manufacturers can now deliver complex tube geometries that are essential for modern automotive design, further driving market expansion.

Restraint/Challenge

Fluctuating Raw Material Prices and High Capital Investment Requirements

- One of the key challenges facing the global automotive tube bending assembly parts market is the volatility in raw material prices—particularly metals such as steel, aluminum, and copper. These materials form the backbone of tube assembly components, and their fluctuating prices directly impact production costs and profit margins, especially for small- to medium-scale suppliers.

- For instance, the sharp increase in global steel prices observed in late 2023 affected the operational costs of many tier-2 and tier-3 suppliers, forcing some to delay expansion plans or renegotiate supply contracts. Such economic pressures can disrupt the overall supply chain and slow market growth.

- In addition, the high capital investment required for advanced tube bending machinery, CNC systems, and automated assembly lines presents a barrier to entry for new players. The precision required in tube bending, particularly for EV and hybrid applications, demands state-of-the-art technology and skilled labor, which can be cost-prohibitive in emerging markets or for companies with limited R&D budgets.

- The complexity of maintaining dimensional accuracy and repeatability in tube bending processes also increases the need for rigorous quality control, driving up production costs. While Industry 4.0 technologies and automation are helping reduce waste and improve efficiency, the upfront investment remains a challenge.

- Addressing these challenges will require strategic partnerships, long-term raw material sourcing contracts, and investments in flexible, multi-purpose production lines. Furthermore, financial support and incentives from governments to modernize automotive supply chains—particularly in developing regions—could play a crucial role in overcoming cost barriers and driving sustainable market growth.

Global Automotive Tube Bending Assembly Parts Market Scope

The market is segmented on the basis of application, material, end use type, Manufacturing Process.

- By Application

On the basis of application, the automotive tube bending assembly parts market is segmented into exhaust systems, fuel systems, hydraulic systems, and brake systems. The exhaust systems segment dominated the market with the largest revenue share of 38.6% in 2024, owing to the widespread use of bent tubes in exhaust routing, emission reduction, and thermal management. These systems require durable and heat-resistant tubing that can be shaped precisely for efficient gas flow and noise reduction.

The hydraulic systems segment is projected to witness the fastest CAGR from 2025 to 2032, driven by growing demand in heavy-duty vehicles and off-road machinery, where hydraulic applications are critical. The rise in electric and hybrid commercial vehicles, which also rely on hydraulic components for steering and braking, further supports this growth. As automation and active safety systems become more prevalent, hydraulic tubing’s role in energy transfer and control expands rapidly.

- By Material

On the basis of material, the market is categorized into aluminum, steel, stainless steel, and copper. The steel segment dominated the market in 2024 with a revenue share of 45.8%, supported by its high tensile strength, affordability, and suitability for structural and high-temperature applications, especially in exhaust and fuel systems. Steel tubing remains the preferred choice for most OEMs due to its established reliability and cost efficiency in mass production.

The aluminum segment is anticipated to witness the fastest CAGR from 2025 to 2032, owing to the rising adoption of lightweight materials in electric vehicles and fuel-efficient cars. Aluminum offers excellent corrosion resistance and helps reduce overall vehicle weight, which contributes to better range and fuel economy. It is particularly favored in cooling systems and EV battery thermal management, where precision-bent aluminum tubes enhance performance and efficiency.

- By End Use Type

On the basis of end use type, the market is segmented into passenger vehicles, commercial vehicles, and heavy-duty vehicles. The passenger vehicles segment held the largest market share of 52.4% in 2024, driven by the high global production volume and increasing consumer demand for compact, fuel-efficient, and safe vehicles. Tube bending assemblies are widely used in HVAC, braking, and fuel delivery systems within this segment, supporting both comfort and performance.

The heavy-duty vehicles segment is expected to grow at the fastest CAGR from 2025 to 2032, as demand rises for rugged and reliable tubing solutions in trucks, buses, and construction vehicles. These vehicles require robust hydraulic and exhaust tube assemblies for high-pressure systems, often under extreme environmental conditions. Additionally, the electrification of buses and freight vehicles necessitates new thermal management designs, driving demand for specialized tube bending assemblies.

- By Manufacturing Process

Based on the manufacturing process, the market is segmented into mandrel bending, rotary bending, compression bending, and push bending. The rotary bending segment dominated the market in 2024 with a 39.1% revenue share, attributed to its widespread application and versatility. It is the preferred method for creating accurate, high-volume tube bends with tight radii, essential in fuel lines, chassis, and HVAC systems.

The mandrel bending segment is expected to exhibit the fastest CAGR from 2025 to 2032, as it provides superior bend quality without collapsing or wrinkling the tube—especially for thin-walled or tight-radius bends. Mandrel bending is increasingly important in electric vehicles, where space constraints and complex designs require high-precision bends. The growing need for lightweight and compact components is accelerating the use of mandrel bending across OEMs and tier-1 suppliers globally.

Global Automotive Tube Bending Assembly Parts Market Regional Analysis

- Europe dominated the global automotive tube bending assembly parts market with the largest revenue share of 34.5% in 2024, driven by robust vehicle production, the presence of leading automotive OEMs and suppliers, and a strong focus on technological advancements in manufacturing processes.

- Automotive manufacturers in the region increasingly emphasize fuel efficiency, emissions compliance, and lightweight vehicle architecture—all of which rely heavily on precision-bent tubing for applications such as exhaust systems, brake lines, fuel systems, and EV battery cooling assemblies.

- The adoption of advanced bending technologies like CNC and mandrel bending, along with the use of lightweight materials such as aluminum and stainless steel, is further supported by North America’s mature manufacturing ecosystem. Additionally, the region benefits from a growing electric vehicle (EV) market and increasing investments in vehicle electrification, making North America a key hub for innovation and growth in automotive tube bending assembly parts across both passenger and commercial vehicle segments.

U.S. Automotive Tube Bending Assembly Parts Market Insight

The U.S. automotive tube bending assembly parts market captured the largest revenue share of 82% within North America in 2024, driven by the country’s large-scale vehicle production and strong presence of automotive OEMs and suppliers. The increasing shift toward electric vehicles (EVs) and stringent emission regulations are fueling demand for advanced tube bending assemblies in exhaust, fuel, and cooling systems. Additionally, the adoption of lightweight materials such as aluminum and stainless steel, combined with investments in automated manufacturing technologies, is propelling market growth. The rising trend of vehicle electrification and increasing use of mandrel and rotary bending techniques for precision components further strengthen the U.S. market outlook.

Europe Automotive Tube Bending Assembly Parts Market Insight

The Europe market is projected to expand at a substantial CAGR throughout the forecast period, supported by strict emissions standards and growing demand for lightweight vehicle components. Countries such as Germany, France, and Italy are major contributors due to their strong automotive manufacturing sectors and focus on innovation. Increasing adoption of electric and hybrid vehicles in Europe is driving demand for specialized tube bending assemblies used in battery cooling and hydraulic systems. The region’s emphasis on sustainability, fuel efficiency, and safety regulations is encouraging OEMs to invest in advanced tube bending technologies and materials like aluminum and stainless steel.

Germany Automotive Tube Bending Assembly Parts Market Insight

Germany holds a key position in the European automotive tube bending assembly parts market, expected to grow at a considerable CAGR due to the country’s leadership in automotive engineering and innovation. Germany’s stringent environmental policies and commitment to vehicle electrification boost demand for precision bending in exhaust and thermal management systems. The well-developed manufacturing infrastructure and high adoption of Industry 4.0 practices facilitate the use of mandrel bending and rotary bending processes. German consumers’ preference for premium vehicles with advanced safety and performance features also drives demand for high-quality tube bending components.

Asia-Pacific Automotive Tube Bending Assembly Parts Market Insight

The Asia-Pacific market is anticipated to grow at the fastest CAGR of 25% during the forecast period (2025–2032), fueled by rapid urbanization, rising vehicle production, and increasing demand for electric and hybrid vehicles in countries like China, India, Japan, and South Korea. The region serves as a global manufacturing hub for automotive components, with cost advantages and increasing adoption of modern manufacturing processes. Government initiatives promoting clean energy vehicles and emission reductions further accelerate the need for sophisticated tube bending assemblies. Moreover, the rising demand for passenger and commercial vehicles with advanced safety and fuel efficiency features supports market expansion.

Japan Automotive Tube Bending Assembly Parts Market Insight

Japan’s automotive tube bending assembly parts market is growing steadily, supported by the country’s advanced automotive technology and strong focus on innovation. The market benefits from the widespread production of hybrid and electric vehicles, which require specialized tube assemblies for battery cooling and hydraulic systems. Japan’s aging population also contributes to demand for safer and more reliable automotive components, including precision bent tubes used in braking and fuel systems. Integration of automated and robotics-based bending technologies enhances production efficiency and quality, strengthening Japan’s position in this market.

China Automotive Tube Bending Assembly Parts Market Insight

China accounted for the largest market revenue share in the Asia-Pacific region in 2024, driven by the country’s dominant position as the world’s largest automobile producer and consumer. Rapid urbanization, increasing disposable income, and government policies favoring new energy vehicles have created significant demand for advanced tube bending assemblies. The rise of domestic automotive OEMs and tier-1 suppliers, alongside growing investments in EV technology, supports the demand for precision-bent tubing in exhaust, fuel, and thermal management systems. Additionally, China’s expanding electric vehicle market and push for smart manufacturing are key growth factors for tube bending assembly parts.

Global Automotive Tube Bending Assembly Parts Market Share

The Automotive Tube Bending Assembly Parts industry is primarily led by well-established companies, including:

- Benteler Automotive (Germany)

- Norma Group (Germany)

- Lander Automotive (U.K.)

- Unison Ltd. (U.K.)

- Maruichi Kokan Co., Ltd. (Japan)

- H-P Products, Inc. (U.S.)

- Tube Specialties Company, Inc. (U.S.)

- H&H Tube (U.S.)

- Salzgitter Mannesmann Stainless Tubes (Germany)

- United Automotive Tube Bending, Inc. (U.S.)

- Fischer Group (Germany)

- Baumann Springs Ltd. (Switzerland)

- KSM Castings Group GmbH (Germany)

- Tenneco Inc. (United States)

- Magna International Inc. (Canada)

- Martinrea International Inc. (Canada)

- Nippon Steel & Sumitomo Metal Corporation (Japan)

- Vallourec S.A. (France)

- Voestalpine AG (Austria)

- Yorozu Corporation (Japan)

What are the Recent Developments in Global Automotive Tube Bending Assembly Parts Market?

- In April 2023, BENTELER International AG, a global leader in automotive steel tube solutions, announced the launch of a new advanced mandrel bending production line in Germany. This strategic investment aims to enhance precision and efficiency in manufacturing tube bending assembly parts for exhaust and fuel systems, supporting growing demand from European automakers. The initiative highlights BENTELER’s commitment to innovation and quality, strengthening its competitive position in the expanding global automotive tube bending assembly parts market.

- In March 2023, Tubacex Group, a prominent manufacturer specializing in stainless steel and high-alloy tubes, introduced a new rotary bending technology designed for heavy-duty vehicle hydraulic systems. The technology improves bend accuracy and material durability, catering to the stringent requirements of commercial vehicle manufacturers. This advancement underscores Tubacex’s dedication to delivering cutting-edge manufacturing solutions that enhance component reliability and performance.

- In March 2023, Ningbo Kinetics Machinery Co., Ltd. successfully completed the installation of an automated push bending system for a major Chinese EV manufacturer. This deployment supports the production of lightweight aluminum tube assemblies for battery cooling and fuel systems, reflecting the rising demand for electrified vehicle components. The project highlights the integration of advanced manufacturing processes in Asia-Pacific, contributing to the region’s leadership in automotive tube bending innovations.

- In February 2023, Jiangsu Zhongtian Technology Co., Ltd. announced a strategic partnership with several leading commercial vehicle OEMs in China to co-develop custom tube bending solutions for brake and hydraulic systems. This collaboration is aimed at improving fuel efficiency and reducing emissions, aligning with China’s national policies on sustainable transportation. The initiative exemplifies Zhongtian’s focus on customer-centric innovation and regional market expansion.

- In January 2023, American Industrial Company (AIC) unveiled its new compression bending technology platform at the SAE World Congress, designed to optimize tube assembly production for passenger vehicles. The system offers enhanced flexibility and faster turnaround times, allowing OEMs to meet increasing demand for complex bent components. This launch reaffirms AIC’s role as a technology leader committed to advancing automotive manufacturing efficiency globally.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.