Global Bag In Box Packaging Machine Market

Market Size in USD Billion

CAGR :

%

USD

2.18 Billion

USD

3.27 Billion

2024

2032

USD

2.18 Billion

USD

3.27 Billion

2024

2032

| 2025 –2032 | |

| USD 2.18 Billion | |

| USD 3.27 Billion | |

|

|

|

|

Bag-in-Box Packaging Machine Market Analysis

The Bag-in-Box (BIB) packaging machine market has witnessed significant growth due to the rising demand for convenient, cost-effective, and sustainable packaging solutions across various industries such as food and beverages, personal care, and healthcare. BIB packaging offers multiple benefits, including product preservation, easy handling, and space efficiency, driving its adoption, particularly in liquid packaging such as wines, juices, and sauces.

Advancements in BIB packaging machines have been focused on improving automation, digitalization, and sustainability. The integration of automated filling systems, enhanced precision, and smart technologies enables faster production cycles and improved accuracy, reducing waste and boosting operational efficiency. In addition, the development of eco-friendly packaging materials, such as recyclable and biodegradable films, aligns with growing environmental concerns and regulatory pressures for sustainable packaging solutions.

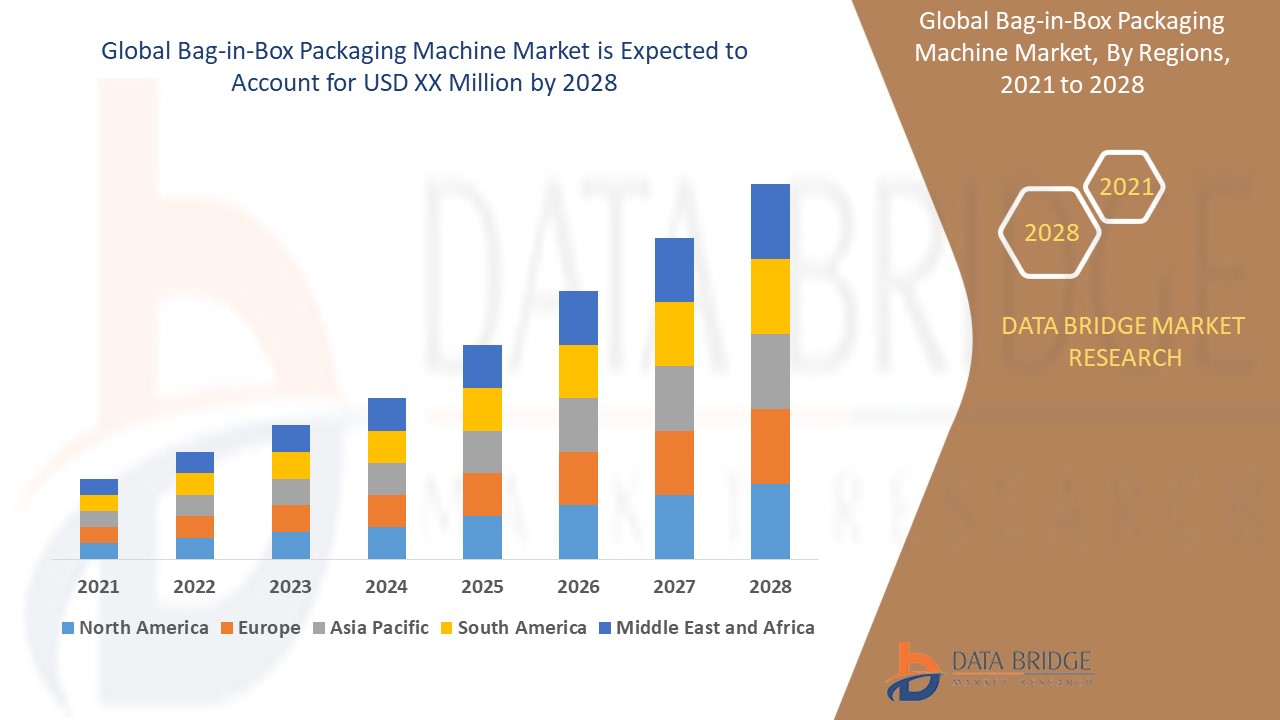

The Asia-Pacific region is experiencing substantial growth in the BIB packaging machine market, driven by industrialization, urbanization, and an expanding consumer base. North America and Europe continue to be key markets, with a strong focus on advanced packaging solutions and automation. As the demand for sustainable, high-quality packaging continues to rise, innovations in BIB technology are expected to shape the future of the packaging industry.

Bag-in-Box Packaging Machine Market Size

The bag-in-box packaging machine market size was valued at USD 2.18 billion in 2024 and is projected to reach USD 3.27 billion by 2032, with a CAGR of 5.20% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Bag-in-Box Packaging Machine Market Trends

“Increasing Need for Sustainable and Cost-Effective Packaging Solutions”

The Bag-in-Box (BIB) packaging machine market is experiencing a growing demand driven by the increasing need for sustainable and cost-effective packaging solutions in industries such as food and beverages, personal care, and healthcare. One prominent trend in the market is the integration of automation and digitalization in BIB packaging machines. This trend focuses on enhancing operational efficiency by enabling faster filling cycles and reducing product waste. For instance, companies such as TORR Industries have introduced automated BIB machines that offer higher precision and speed, significantly improving productivity while maintaining product quality. The growing preference for eco-friendly packaging also plays a vital role, as consumers and businesses increasingly prioritize recyclable and biodegradable materials. As a result, the Asia-Pacific region, with its expanding packaging industry and rising disposable incomes, is projected to lead the market. Innovations in automation and sustainability are expected to drive further growth in the BIB packaging machine market, aligning with consumer demand for more efficient and environmentally friendly packaging solutions.

Report Scope and Bag-in-Box Packaging Machine Segmentation

|

Attributes |

Bag-in-Box Packaging Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

TORR Industries (U.S.), ABCO Automation (U.S.), IC Filling Systems (U.K.), Kreuzmayr Maschinenbau GmbH (Austria), Innovative Packaging Company (U.S.), Triangle Package Machinery Company (U.S.), Quadrant Equipment (U.S.), voran Maschinen GmbH (Austria), Smurfit Kappa (Ireland), Liquibox (U.S.), DS Smith (U.K.), Robert Bosch GmbH (Germany), ALFA LAVAL (Sweden), Engi-O (U.K.), Pattyn (Belgium), SACMI IMOLA S.C Via Selice (Italy), SIG (Switzerland), Technibag (France), Franz Haniel & Cie. GmbH (Germany), ProXES GmbH (Germany), Flexifill Ltd. (U.K.), and Amcor plc (Switzerland) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Bag-in-Box Packaging Machine Market Definition

A Bag-in-Box packaging machine is a type of automated equipment used to package liquids, powders, and other products into flexible bags that are placed inside a cardboard box. The bag typically features a tap or spout for easy dispensing, making it ideal for products such as wines, juices, sauces, and cleaning products.

Bag-in-Box Packaging Machine Market Dynamics

Drivers

- Increasing Demand for Sustainable Packaging

The rising demand for sustainable packaging is a key driver in the Bag-in-Box (BIB) packaging machine market, as environmental concerns are prompting businesses and consumers asuch as to seek eco-friendly alternatives. BIB packaging is considered more sustainable compared to traditional glass bottles or plastic containers because it uses significantly less material, reducing overall waste. In addition, the outer box is typically made from recyclable cardboard, and the inner bag can often be recycled or disposed of more easily. For instance, companies such as Liquibox have been at the forefront of promoting sustainable BIB packaging solutions, offering products that help reduce carbon footprints and minimize packaging waste. As businesses increasingly adopt such packaging options to meet both consumer demand and regulatory pressures for greener alternatives, the BIB packaging market is expanding. This shift addresses environmental concerns and reduces transportation costs due to the lightweight nature of BIB packaging, making it a cost-effective and sustainable choice for various industries, particularly in food and beverages.

- Increasing Demand Convenience and Cost-Effectiveness

Convenience and cost-effectiveness are driving the growth of the Bag-in-Box (BIB) packaging machine market, as businesses and consumers increasingly prioritize packaging solutions that are both economical and user-friendly. BIB packaging is cost-effective because it uses less material compared to traditional glass bottles or rigid plastic containers, reducing production costs. Moreover, the lightweight nature of the packaging lowers transportation expenses, as more units can be shipped in the same amount of space. For instance, companies such as Smurfit Kappa have leveraged BIB technology to provide cost-efficient packaging solutions for products such as wine and juices, offering a packaging format that is easier to handle, store, and transport. In addition, BIB packaging provides significant convenience for consumers, as the flexible bags with spouts allow for easy dispensing without the need for additional tools, and the sealed bags help extend product shelf life by limiting air exposure. These factors make BIB packaging an attractive choice for companies looking to reduce costs while enhancing the consumer experience, thereby fueling the market's growth.

Opportunities

- Growing Food and Beverage Industry

The growth of the food and beverage industry presents a significant market opportunity for the Bag-in-Box (BIB) packaging machine market, as the sector increasingly demands bulk packaging solutions for liquids such as wine, juices, and sauces. BIB packaging offers the ability to maintain product quality and extend shelf life, making it an ideal choice for products that require both efficient storage and long-lasting freshness. For instance, companies such as Triangle Package Machinery provide advanced BIB machines that cater to the growing need for high-volume, cost-effective packaging in the beverage sector. By using BIB packaging, food and beverage manufacturers can reduce packaging costs, enhance distribution efficiency, and ensure their products remain fresh during transport and storage. This growing adoption of BIB packaging in the food and beverage industry, driven by the demand for bulk packaging and quality preservation, represents a major opportunity for companies in the market to expand their offerings and capitalize on this trend.

- Increasing Technological Advancements in Automation and Digitalization

Technological advancements in automation and digitalization are creating a substantial market opportunity for the Bag-in-Box (BIB) packaging machine market, as these innovations significantly enhance operational efficiency. The integration of automated systems for filling, sealing, and quality control is streamlining production processes, reducing human error, and improving consistency in packaging. For instance, companies such as IC Filling Systems have developed advanced BIB machines with automated filling lines that ensure precise packaging and faster production cycles, which leads to reduced waste and increased productivity. In addition, the adoption of digital technologies, such as remote monitoring and smart sensors, enables manufacturers to track production in real-time, optimize workflows, and make data-driven decisions that further boost efficiency. These technological advancements improve the cost-effectiveness of BIB packaging and allow manufacturers to meet the growing demand for high-quality, environmentally-friendly packaging solutions. As industries look for ways to enhance productivity while minimizing costs, these innovations present a significant opportunity for companies to tap into an evolving market.

Restraints/Challenges

- Required High Initial Investment

The high initial investment required for acquiring and maintaining Bag-in-Box (BIB) packaging machines is a significant market challenge, particularly for small and medium-sized manufacturers. These machines can cost hundreds of thousands of dollars depending on their capacity, complexity, and automation features. For instance, a fully automated BIB machine capable of high-speed filling, sealing, and labeling can cost anywhere from $100,000 to $500,000, which can be prohibitive for smaller businesses with limited budgets. In addition, the cost of regular maintenance, parts replacement, and the need for skilled labor further increases the total cost of ownership. This high financial barrier can prevent smaller manufacturers from entering the market or upgrading their outdated systems, thus hindering their competitiveness in a market where larger companies with more resources can more easily afford such investments. Consequently, the challenge of high initial investment can restrict market growth and the adoption of BIB packaging in various sectors.

- Regulatory Compliance and Labeling

Regulatory compliance is a critical market challenge for businesses in the Bag-in-Box (BIB) packaging sector, particularly for those operating on a global scale. Different regions have unique regulations regarding packaging materials, labeling, and safety standards, which can create complexities for companies aiming to distribute their products internationally. For instance, the European Union enforces strict regulations on plastic usage and recycling under the Packaging and Packaging Waste Directive, requiring manufacturers to adhere to specific standards for environmental sustainability. Meanwhile, in the U.S., the FDA has stringent requirements for labeling food and beverage packaging to ensure proper consumer information. Navigating these diverse regulatory landscapes demands significant investment in legal expertise and frequent updates to packaging designs and labeling practices. Non-compliance with these regulations can lead to legal penalties, product recalls, or damage to brand reputation, making it crucial for businesses to stay informed and adaptable. This regulatory complexity often acts as a barrier to entry for new companies and can slow down market expansion, adding to the challenge in a competitive landscape.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an analyst brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Bag-in-Box Packaging Machine Market Scope

The market is segmented on the basis of machine type, automation type, packaging material, output capacity, filling technology, and end user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Machine Type

- Standalone

- Integrated

Automation Type

- Semi-Automatic

- Automatic

- Manual

Packaging Material

- Plastic

- Paper and Paperboard

- Metal

- Others

Output Capacity

- 10 Bags/min

- 11-50 Bags/min

- 51-100 Bags/min

- Above 100 Bags/min

Filling Technology

- Aseptic

- Non-Aseptic

End User

- Food and Beverages

- Paints and Lubricants

- Personal Care

- Household Products

- Healthcare

- Others

Bag-in-Box Packaging Machine Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, machine type, automation type, packaging material, output capacity, filling technology, and end user as referenced above.

The countries covered in the market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa

Asia-Pacific is expected to dominate the market due to rising disposable incomes among consumers and the growing popularity of wine and other beverage products. In addition, the demand for convenient, cost-effective packaging solutions in the food and beverage sector is steadily increasing, further fueling market expansion. These factors collectively position the region as a key driver of market growth during the forecast period.

North America is anticipated to experience fastest growth, supported by its well-established market and the robust demand for sustainable and convenient packaging solutions in the food and beverage industry. Furthermore, the adoption of advanced, highly automated, and digitalized bag-in-box packaging machines is on the rise, driven by the need to enhance operational efficiency and overall productivity.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Bag-in-Box Packaging Machine Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Bag-in-Box Packaging Machine Market Leaders Operating in the Market Are:

- TORR Industries (U.S.)

- ABCO Automation (U.S.)

- IC Filling Systems (U.K.)

- Kreuzmayr Maschinenbau GmbH (Austria)

- Innovative Packaging Company (U.S.)

- Triangle Package Machinery Company (U.S.)

- Quadrant Equipment (U.S.)

- voran Maschinen GmbH (Austria)

- Smurfit Kappa (Ireland)

- Liquibox (U.S.)

- DS Smith (U.K.)

- Robert Bosch GmbH (Germany)

- ALFA LAVAL (Sweden)

- Engi-O (U.K.)

- Pattyn (Belgium)

- SACMI IMOLA S.C Via Selice (Italy)

- SIG (Switzerland)

- Technibag (France)

- Franz Haniel & Cie. GmbH (Germany)

- ProXES GmbH (Germany)

- Flexifill Ltd. (U.K.)

- Amcor plc (Switzerland)

Latest Developments in Bag-in-Box Packaging Machine Market

- In February 2024, Smurfit Kappa Group announced plans to open a new bag-in-box machine plant in Alicante, Spain, with an investment of USD 58.2 million. The facility aims to double production capacity and expand the company’s product portfolio in bag-in-box machines

- In February 2024, Aran Group completed the acquisition of a majority stake in IBA Germany from Liquid Concept GmbH

- In January 2024, WestRock Company unveiled plans to construct a new corrugated box plant in Pleasant Prairie, Wisconsin, to address growing demand in the Great Lakes region. The project, estimated at USD 140 million, will be partially funded through property sales

- In October 2023, Amcor introduced a circular connector as part of its sustainable packaging solutions. This innovation offers a 70% lower carbon footprint compared to existing market products, helping Walmart and other retailers reduce their environmental impact

- In April 2022, TORR Industries launched a new bag-in-box wine packaging machine for the food and beverage sector. The machine features an advanced filling head that minimizes oxygen exposure, achieving less than 2 ppm total oxygen in the bag post-packaging. It has a packaging capacity of 20 three-liter bags per minute

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Bag In Box Packaging Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Bag In Box Packaging Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Bag In Box Packaging Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.