Global Blow Molding Machine Market

Market Size in USD Billion

CAGR :

%

USD

6.04 Billion

USD

8.20 Billion

2024

2032

USD

6.04 Billion

USD

8.20 Billion

2024

2032

| 2025 –2032 | |

| USD 6.04 Billion | |

| USD 8.20 Billion | |

|

|

|

|

Blow Molding Machine Market Analysis

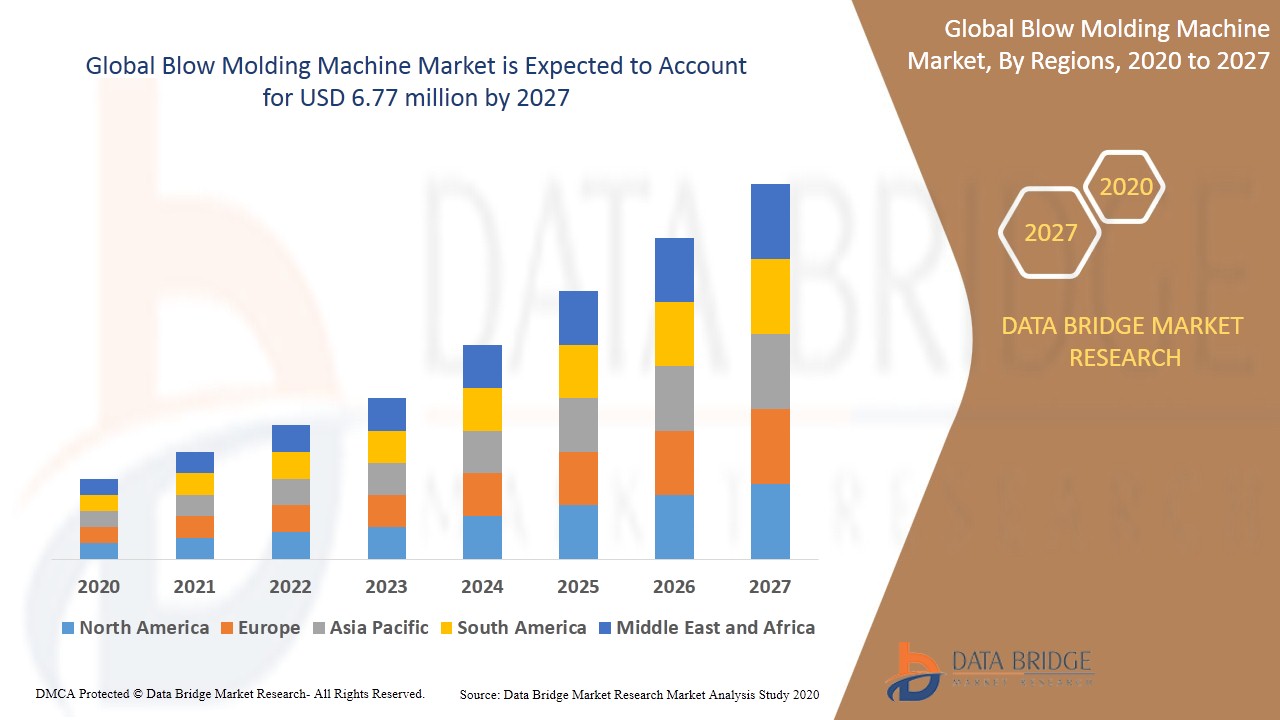

The blow molding machine market is driven by the increasing demand for plastic products across various industries such as packaging, automotive, and consumer goods. These machines are crucial for producing hollow plastic products, including bottles, containers, and other complex shapes. The market is witnessing growth due to advancements in technology, including automation, energy efficiency, and the development of multi-layer blow molding machines that enhance product quality and production capacity. The rise in eco-conscious consumers has also led to a demand for recyclable and sustainable packaging solutions, further boosting market growth. Recent developments include the integration of IoT and AI in machines, which allow for predictive maintenance and improved operational efficiency. The Asia-Pacific region is expected to dominate the market due to rapid industrialization and high demand for packaging solutions in countries such as China and India. With ongoing innovation, the blow molding machine market continues to evolve, meeting diverse consumer needs across the globe.

Blow Molding Machine Market Size

The blow molding machine market size was valued at USD 6.04 billion in 2024 and is projected to reach USD 8.20 billion by 2032, with a CAGR of 3.90% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Blow Molding Machine Market Trends

“Increasing Demand for Lightweight Packaging”

A key trend in the blow molding machine market is the growing demand for lightweight, durable, and sustainable packaging solutions. With increasing consumer preference for eco-friendly products, blow molding is increasingly used to produce plastic bottles and containers that are not only lightweight but also strong and durable. Manufacturers are adopting innovative techniques to design packaging that meets sustainability goals by using recyclable materials and reducing plastic waste. In addition, there is a significant shift towards utilizing biodegradable or bio-based plastics in blow molding processes to minimize environmental impact. This trend is driven by regulatory pressure, consumer awareness, and the need for cost-effective packaging solutions. As a result, blow molding is playing a critical role in creating packaging that aligns with modern environmental and functional requirements.

Report Scope and Blow Molding Machine Market Segmentation

|

Attributes |

Blow Molding Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

The Japan Steel Works, LTD (Japan), Jomar Corp. (U.S.), PARKER PLASTIC MACHINERY CO., LTD (Taiwan), Jiangsu Victor Machinery CO., Ltd (China), GOLFANG Mfg. & Development Co., Ltd (Taiwan), BLOW ENTERPRISES (India), NISSEI ASB MACHINE CO., LTD (Japan), Bekum Maschinenfabriken GmbH (Germany), Chia Ming Machinery Co., Ltd. (Taiwan), ELEGANCE INDUSTRIES (India), Kautex Maschinenbau (Germany), Meccanoplastica (Italy), Polymechplast Machines Ltd (India) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Blow Molding Machine Market Definition

A blow molding machine is a manufacturing device used to produce hollow plastic products, such as bottles, containers, and other complex shapes. The process involves melting plastic and forming it into a mold cavity using air pressure to shape the material into the desired form. There are three primary types of blow molding: extrusion blow molding, injection blow molding, and stretch blow molding, each suited to different production requirements. These machines are commonly used in industries such as packaging, automotive, and consumer goods, offering high efficiency and the ability to produce large volumes of plastic items with precision.

Blow Molding Machine Market Dynamics

Drivers

- Growing Packaging Demand

The increasing consumption of packaged products, particularly in the food and beverage, pharmaceuticals, and cosmetics industries, significantly boosts the demand for blow molded containers. As consumer preference shifts towards convenience, hygiene, and longer shelf life, these industries rely heavily on blow molding technology to produce a wide variety of containers, including bottles, jars, and tubes. The versatility and cost-effectiveness of blow molding make it an ideal solution for creating packaging that meets the specific needs of each product. This surge in demand for diverse packaging options further drives the growth of the blow molding machine market, positioning it as a key market driver.

- Rising Environmental Awareness

The growing demand for sustainable and recyclable plastic packaging solutions is a key driver for the blow molding machine market. As environmental concerns increase, manufacturers are focusing on developing eco-friendly materials and adopting production methods that minimize waste. Blow molding machines are evolving to incorporate these materials, such as biodegradable plastics and recycled PET, to meet consumer and regulatory demands for sustainability. In addition, innovations in machine design are helping improve energy efficiency and reduce material waste during production. This shift towards greener practices is reducing environmental impact and fueling the market’s growth as more industries prioritize sustainability in packaging.

Opportunities

- Expansion in Emerging Markets

Rapid industrialization and urbanization in regions such as Asia-Pacific, Latin America, and Africa are creating significant growth opportunities for the blow molding machine market. As these regions develop, there is a rising demand for packaging solutions to cater to the expanding consumer base in industries such as food and beverage, pharmaceuticals, and consumer goods. Increased disposable income and changing lifestyles further drive the need for packaged products, boosting demand for blow molded containers. In addition, the growing middle class and shift toward modern retailing in these regions are further accelerating the need for advanced blow molding machines to meet the packaging requirements, creating a substantial market opportunity.

- Integration with Smart Technologies

The integration of IoT and AI technologies into blow molding machines presents a significant market opportunity by enabling predictive maintenance and process optimization. IoT sensors can collect real-time data on machine performance, while AI algorithms analyze this data to predict potential failures, allowing manufacturers to perform maintenance before issues arise. This proactive approach reduces downtime, enhances machine efficiency, and lowers operational costs. In addition, AI-driven optimization of the molding process improves product quality and consistency, offering manufacturers a competitive edge. As industries increasingly prioritize efficiency and cost-effectiveness, the adoption of IoT and AI technologies in blow molding machines is set to drive substantial market growth.

Restraints/Challenges

- Complexity in Material Handling

Handling a wide variety of materials, particularly those with varying properties such as recyclability and biodegradability, presents a significant challenge in the blow molding machine market. Manufacturers must invest in advanced technology and specialized expertise to manage the different behaviors of these materials during the molding process. For instance, recyclable or biodegradable plastics often require specific processing conditions to ensure product quality and structural integrity. This added complexity can increase production time, reduce efficiency, and require more frequent machine adjustments. As demand for sustainable packaging grows, manufacturers face the challenge of adapting their machines and processes to meet these evolving material requirements, complicating overall production.

- High Initial Investment

The cost of acquiring and maintaining advanced blow molding machines is a significant restraint, particularly for smaller manufacturers with limited financial resources. High initial investment costs for state-of-the-art machinery can be a barrier to entry for small and medium-sized enterprises (SMEs), restricting their ability to compete with larger, well-established companies. In addition, ongoing maintenance and operational costs, including spare parts, labor, and energy consumption, further strain budgets. As these machines often require specialized knowledge for operation and upkeep, smaller manufacturers may also face challenges in finding skilled labor, adding another layer of financial burden and limiting their market potential.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an analyst brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Blow Molding Machine Market Scope

The market is segmented on the basis of type, application, and raw material. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Extrusion

- Injection

- Injection Stretch

Application

- Packaging

- Consumable

- Automotive

- Electronics

- Construction

- Other Applications

Raw Material

- Polyethylene Terephthalate (PET)

- Polyethylene (PE)

- Polypropylene (PP)

- Polybutylene Terephthalate (PBT)

- Polyvinyl Chloride (PVC)

- Polystyrene (PS)

- Other Plastic Materials

Blow Molding Machine Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, type, application, and raw material as referenced above.

The countries covered in the market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa

Asia-Pacific dominates the blow molding machine market, driven by rising disposable incomes and rapid modernization across the region. The growing demand for packaging products, fueled by expanding industries such as food and beverage, pharmaceuticals, and consumer goods, further accelerates market growth. In addition, the increasing adoption of advanced packaging solutions in emerging economies supports the region's dominance in the market.

North American region is anticipated to experience the highest growth rate in the blow molding machine market, driven by the expanding automotive, food and beverage, and other key industries. The increasing demand for packaging solutions in these sectors, combined with advancements in manufacturing technology, contributes to market expansion. In addition, the region's focus on innovation and efficiency in production processes further boosts the adoption of blow molding machines.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Blow Molding Machine Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Blow Molding Machine Market Leaders Operating in the Market Are:

- The Japan Steel Works, LTD (Japan)

- Jomar Corp. (U.S.)

- PARKER PLASTIC MACHINERY CO., LTD (Taiwan)

- Jiangsu Victor Machinery CO., Ltd (China)

- GOLFANG Mfg. & Development Co., Ltd (Taiwan)

- BLOW ENTERPRISES (India)

- NISSEI ASB MACHINE CO., LTD (Japan)

- Bekum Maschinenfabriken GmbH (Germany)

- Chia Ming Machinery Co., Ltd. (Taiwan)

- ELEGANCE INDUSTRIES (India)

- Kautex Maschinenbau (Germany)

- Meccanoplastica (Italy)

- Polymechplast Machines Ltd (India)

Latest Developments in Blow Molding Machine Market

- In February 2024, Uniloy Inc., a leading blow molding machinery manufacturer, announced a USD 1 million investment to expand its operations in India. This includes relocating to a new factory, which will ultimately double its production capacity in the region

- In January 2024, Jwell Machinery, based in China, acquired the German blow molding machine manufacturer Kautex Maschinenbau. Despite the acquisition, Kautex will continue to operate as an independent entity under Jwell's ownership

- In January 2024, Container Services, Inc. (CSI), known for its custom blow-molded honey bear bottle, acquired Apex Plastics, a company specializing in blow molding for the beverage and domestic sectors. CSI also launched FirmaPak, a platform uniting customer-focused blow molders

- In March 2023, Jagmohan Pla-Mach Pvt. Ltd. acquired an additional 50,000 square feet of land to expand its existing facility in Asagaon, located along the Mumbai-Nashik Highway. This expansion will enhance the company’s production capacity by adding more floor space to increase product variety and boost output. The new area will focus on injection blow molding machines and high-speed auto deflashing blow molding machines for both multilayer and mono-layer applications

- In October 2022, blow molding equipment manufacturer Ossberger introduced the Pressblower SB2-260, an advanced injection blow molder specifically designed for producing boots, or gaiters, used in automotive air springs. This new machine aims to enhance production efficiency and precision in the automotive sector. The SB2-260 showcases Ossberger’s commitment to innovation, meeting the growing demand for high-quality automotive components

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL BLOW MOULDING MACHINE MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL BLOW MOULDING MACHINE MARKET SIZE

2.3 MARKETS COVERED

2.4 GEOGRAPHIC SCOPE

2.5 YEARS CONSIDERED FOR THE STUDY

2.6 RESEARCH METHODOLOGY

2.7 TECHNOLOGY LIFE LINE CURVE

2.8 MULTIVARIATE MODELLING

2.9 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.1 DBMR MARKET POSITION GRID

2.11 MARKET APPLICATION COVERAGE GRID

2.12 DBMR MARKET CHALLENGE MATRIX

2.13 IMPORT AND EXPORT DATA

2.14 SECONDARY SOURCES

2.15 GLOBAL BLOW MOULDING MACHINE MARKET: RESEARCH SNAPSHOT

2.16 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 RAW MATERIAL COVERAGE

5.2 PRODUCTION CONSUMPTION ANALYSIS

5.3 IMPORT EXPORT SCENARIO

5.4 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

5.5 PORTER’S FIVE FORCES

5.6 VENDOR SELECTION CRITERIA

5.7 PESTEL ANALYSIS

5.8 REGULATION COVERAGE

5.8.1 PRODUCT CODES

5.8.2 CERTIFIED STANDARDS

5.8.3 SAFETY STANDARDS

5.8.3.1. MATERIAL HANDLING & STORAGE

5.8.3.2. TRANSPORT & PRECAUTIONS

5.8.3.3. HARAD IDENTIFICATION

6 PRICING ANALYSIS

7 PRODUCTION CAPACITY OVERVIEW

8 SUPPLY CHAIN ANALYSIS

8.1 OVERVIEW

8.2 LOGISTIC COST SCENARIO

8.3 IMPORTANCE OF LOGISTICS SERVICE PROVIDERS

9 CLIMATE CHANGE SCENARIO

9.1 ENVIRONMENTAL CONCERNS

9.2 INDUSTRY RESPONSE

9.3 GOVERNMENT’S ROLE

9.4 ANALYST RECOMMENDATIONS

10 GLOBAL BLOW MOULDING MACHINE MARKET, BY TYPE, (2018-2032), (USD MILLION) (UNITS)

10.1 OVERVIEW

10.2 EXTRUSION BLOW MOULDING MACHINES

10.2.1 BY PROCESS

10.2.1.1. CONTINUOUS

10.2.1.2. INTERMITTENT

10.2.2 BY MACHINE CONFIGURATION

10.2.2.1. SINGLE-STATION

10.2.2.2. MULTI-STATION

10.2.3 BY AUTOMATION

10.2.3.1. SEMI-AUTOMATIC

10.2.3.2. FULLY AUTOMATIC

10.3 INJECTION BLOW MOULDING MACHINE

10.3.1 BY MACHINE CONFIGURATION

10.3.1.1. SINGLE-STAGE

10.3.1.2. TWO-STAGE

10.3.2 BY ORIENTATION TYPE

10.3.2.1. ROTARY TYPE MACHINE

10.3.2.2. LINEAR TYPE MACHINE

10.3.3 BY AUTOMATION

10.3.3.1. SEMI-AUTOMATIC

10.3.3.2. FULLY AUTOMATIC

10.4 STRETCH BLOW MOULDING MACHINE

10.4.1 BY MACHINE CONFIGURATION

10.4.1.1. SINGLE-STAGE

10.4.1.2. TWO-STAGE

10.4.2 BY ORIENTATION TYPE

10.4.2.1. ROTARY TYPE MACHINE

10.4.2.2. LINEAR TYPE MACHINE

10.4.3 BY AUTOMATION

10.4.3.1. SEMI-AUTOMATIC

10.4.3.2. FULLY AUTOMATIC

11 GLOBAL BLOW MOULDING MACHINE MARKET, BY AUTOMATION, (2018-2032), (USD MILLION)

11.1 OVERVIEW

11.2 SEMI-AUTOMATIC

11.3 FULLY AUTOMATIC

12 GLOBAL BLOW MOULDING MACHINE MARKET, BY TONNAGE, (2018-2032), (USD MILLION)

12.1 OVERVIEW

12.2 UPTO 50 TONS

12.3 50-TO 150 TONS

12.4 150 TO 500 TONS

12.5 MORE THAN 500 TONS

13 GLOBAL BLOW MOULDING MACHINE MARKET, BY FEED MATERIAL, (2018-2032), (USD MILLION)

13.1 OVERVIEW

13.2 POLYETHYLENE TEREPHTHALATE (PET)

13.3 POLYETHYLENE (PE)

13.4 POLYPROPYLENE (PP)

13.5 POLYVINYL CHLORIDE (PVC)

13.6 POLYSTYRENE (PS)

13.7 POLYBUTYLENE TEREPHTHALATE (PBT)

13.8 OTHERS

14 GLOBAL BLOW MOULDING MACHINE MARKET, BY APPLICATION (2018-2032), (USD MILLION)

14.1 OVERVIEW

14.2 PACKAGING

14.2.1 PACKAGING, BY PROCESSED OUTPUT

14.2.1.1. BOTTLES

14.2.1.2. CONTAINERS

14.2.1.3. JERRY CANS

14.2.1.4. TUBES

14.2.1.5. OTHERS

14.2.2 PACKAGING, BY CATEGORY

14.2.2.1. FOOD AND BEVERAGE

14.2.2.1.1. FOOD & BEVERAGES, BY CATEGORY

14.2.2.1.1.1 WATER

14.2.2.1.1.2 CSD

14.2.2.1.1.3 JUICE

14.2.2.1.1.4 TEAS

14.2.2.1.1.5 ALCOHOLIC DRINKS

14.2.2.1.1.5.1. ALCOHOLIC DRINKS, BY TYPE

A. BEER

B. CRAFT BEER

C. SPIRITS

D. WINE

E. OTHERS

14.2.2.1.1.6 DRINKS

14.2.2.1.1.7 OILS

14.2.2.1.1.8 SAUCES

14.2.2.1.1.9 KETCHUP

14.2.2.1.1.10 VINEGAR

14.2.2.1.1.11 OTHERS

14.2.2.2. CONSUMER GOODS

14.2.2.2.1. PERSONAL CARE AND COSMETICS

14.2.2.2.1.1 PERSONAL CARE & COSMETICS, BY CATEGORY

14.2.2.2.1.1.1. SKIN CARE

14.2.2.2.1.1.2. HAIR CARE

14.2.2.2.1.1.3. COSMETICS PRODUCTS

14.2.2.2.1.1.4. OTHERS

14.2.2.2.2. HOME CARE PRODUCTS

14.2.2.2.3. TOYS

14.2.2.2.4. OTHERS

14.3 AUTOMOTIVE

14.3.1 AUTOMOTIVE, BY CATEGORY

14.3.1.1. FUEL TANKS

14.3.1.2. AIR DUCTS

14.3.1.3. FLUID RESERVOIRS

14.3.1.4. SEATING COMPONENTS

14.3.1.5. HVAC COMPONENTS

14.3.1.6. OTHERS

14.4 HEALTHCARE

14.4.1 HEALTHCARE, BY CATEGORY

14.4.1.1. MEDICINES

14.4.1.2. MEDICAL SUPPLIES

14.4.1.2.1. BALLOON CATHETER

14.4.1.2.2. ENDOTRACHEAL TUBE

14.4.1.2.3. INFLATABLE BALLOON

14.4.1.2.4. OTHERS

14.5 CONSTRUCTION

14.6 ELECTRONICS

14.7 OTHERS

15 GLOBAL BLOW MOULDING MACHINE MARKET, BY GEOGRAPHY, 2018-2032 (USD MILLION) (UNITS)

GLOBAL BLOW MOULDING MACHINE MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

15.1 NORTH AMERICA

15.1.1 U.S.

15.1.2 CANADA

15.1.3 MEXICO

15.2 EUROPE

15.2.1 GERMANY

15.2.2 U.K.

15.2.3 ITALY

15.2.4 FRANCE

15.2.5 SPAIN

15.2.6 SWITZERLAND

15.2.7 RUSSIA

15.2.8 TURKEY

15.2.9 BELGIUM

15.2.10 NETHERLANDS

15.2.11 REST OF EUROPE

15.3 ASIA-PACIFIC

15.3.1 JAPAN

15.3.2 CHINA

15.3.3 SOUTH KOREA

15.3.4 INDIA

15.3.5 AUSTRALIA AND NEW ZELAND

15.3.6 SINGAPORE

15.3.7 THAILAND

15.3.8 HONG KONG

15.3.9 TAIWAN

15.3.10 INDONESIA

15.3.11 MALAYSIA

15.3.12 PHILIPPINES

15.3.13 REST OF ASIA-PACIFIC

15.4 SOUTH AMERICA

15.4.1 BRAZIL

15.4.2 ARGENTINA

15.4.3 REST OF SOUTH AMERICA

15.5 MIDDLE EAST AND AFRICA

15.5.1 SOUTH AFRICA

15.5.2 EGYPT

15.5.3 SAUDI ARABIA

15.5.4 UNITED ARAB EMIRATES

15.5.5 ISRAEL

15.5.6 REST OF MIDDLE EAST AND AFRICA

16 GLOBAL BLOW MOULDING MACHINE MARKET, COMPANY LANDSCAPE

16.1 COMPANY SHARE ANALYSIS: GLOBAL

16.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

16.3 COMPANY SHARE ANALYSIS: EUROPE

16.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

16.5 MERGERS & ACQUISITIONS

16.6 NEW PRODUCT DEVELOPMENT & APPROVALS

16.7 EXPANSIONS

16.8 REGULATORY CHANGES

16.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

17 GLOBAL BLOW MOULDING MACHINE MARKET- SWOT ANALYSIS

18 GLOBAL BLOW MOULDING MACHINE MARKET- COMPANY PROFILES

18.1 ASB INTERNATIONAL PRIVATE LIMITED

18.1.1 COMPANY OVERVIEW

18.1.2 REVENUE ANALYSIS

18.1.3 PRDUCT PORTFOLIO

18.1.4 RECENT DEVELOPMENTS

18.2 AOKI TECHNICAL LABORATORY, INC

18.2.1 COMPANY OVERVIEW

18.2.2 REVENUE ANALYSIS

18.2.3 PRDUCT PORTFOLIO

18.2.4 RECENT DEVELOPMENTS

18.3 MILACRON

18.3.1 COMPANY OVERVIEW

18.3.2 REVENUE ANALYSIS

18.3.3 PRDUCT PORTFOLIO

18.3.4 RECENT DEVELOPMENTS

18.4 KRUPP MACHINERY (GUANGDONG) CO., LTD.

18.4.1 COMPANY OVERVIEW

18.4.2 REVENUE ANALYSIS

18.4.3 PRDUCT PORTFOLIO

18.4.4 RECENT DEVELOPMENTS

18.5 RANDB PLASTICS MACHINERY, LLC

18.5.1 COMPANY OVERVIEW

18.5.2 REVENUE ANALYSIS

18.5.3 PRDUCT PORTFOLIO

18.5.4 RECENT DEVELOPMENTS

18.6 GUANGZHOU TECH-LONG PACKING MACHINE CO LTD

18.6.1 COMPANY OVERVIEW

18.6.2 REVENUE ANALYSIS

18.6.3 PRDUCT PORTFOLIO

18.6.4 RECENT DEVELOPMENTS

18.7 AMSLER EQUIPMENT INC

18.7.1 COMPANY OVERVIEW

18.7.2 REVENUE ANALYSIS

18.7.3 PRDUCT PORTFOLIO

18.7.4 RECENT DEVELOPMENTS

18.8 KRONES AG

18.8.1 COMPANY OVERVIEW

18.8.2 REVENUE ANALYSIS

18.8.3 PRDUCT PORTFOLIO

18.8.4 RECENT DEVELOPMENTS

18.9 NISSEI ASB MACHINE CO. LTD

18.9.1 COMPANY OVERVIEW

18.9.2 REVENUE ANALYSIS

18.9.3 PRDUCT PORTFOLIO

18.9.4 RECENT DEVELOPMENTS

18.1 SACMI IMOLA S.C.

18.10.1 COMPANY OVERVIEW

18.10.2 REVENUE ANALYSIS

18.10.3 PRDUCT PORTFOLIO

18.10.4 RECENT DEVELOPMENTS

18.11 SIPA S.P.A.

18.11.1 COMPANY OVERVIEW

18.11.2 REVENUE ANALYSIS

18.11.3 PRDUCT PORTFOLIO

18.11.4 RECENT DEVELOPMENTS

18.12 KHS GMBH

18.12.1 COMPANY OVERVIEW

18.12.2 REVENUE ANALYSIS

18.12.3 PRDUCT PORTFOLIO

18.12.4 RECENT DEVELOPMENTS

18.13 SIDEL

18.13.1 COMPANY OVERVIEW

18.13.2 REVENUE ANALYSIS

18.13.3 PRDUCT PORTFOLIO

18.13.4 RECENT DEVELOPMENTS

18.14 CHUMPOWER MACHINERY CORP

18.14.1 COMPANY OVERVIEW

18.14.2 REVENUE ANALYSIS

18.14.3 PRDUCT PORTFOLIO

18.14.4 RECENT DEVELOPMENTS

18.15 SMI S.P.A.

18.15.1 COMPANY OVERVIEW

18.15.2 REVENUE ANALYSIS

18.15.3 PRDUCT PORTFOLIO

18.15.4 RECENT DEVELOPMENTS

18.16 KEENPRO INDUSTRY CORP.

18.16.1 COMPANY OVERVIEW

18.16.2 REVENUE ANALYSIS

18.16.3 PRDUCT PORTFOLIO

18.16.4 RECENT DEVELOPMENTS

18.17 KENPLAS INDUSTRY LTD.

18.17.1 COMPANY OVERVIEW

18.17.2 REVENUE ANALYSIS

18.17.3 PRDUCT PORTFOLIO

18.17.4 RECENT DEVELOPMENTS

18.18 DEMARK HOLDING GROUP

18.18.1 COMPANY OVERVIEW

18.18.2 REVENUE ANALYSIS

18.18.3 PRDUCT PORTFOLIO

18.18.4 RECENT DEVELOPMENTS

18.19 JOMAR

18.19.1 COMPANY OVERVIEW

18.19.2 REVENUE ANALYSIS

18.19.3 PRDUCT PORTFOLIO

18.19.4 RECENT DEVELOPMENTS

18.2 PARKER PLASTIC MACHINERY CO., LTD

18.20.1 COMPANY OVERVIEW

18.20.2 REVENUE ANALYSIS

18.20.3 PRDUCT PORTFOLIO

18.20.4 RECENT DEVELOPMENTS

18.21 PET ALL MANUFACTURING INC

18.21.1 COMPANY OVERVIEW

18.21.2 REVENUE ANALYSIS

18.21.3 PRDUCT PORTFOLIO

18.21.4 RECENT DEVELOPMENTS

18.22 TAIZHOU GUANGDU PLASTIC MACHINERY CO.,LTD

18.22.1 COMPANY OVERVIEW

18.22.2 REVENUE ANALYSIS

18.22.3 PRDUCT PORTFOLIO

18.22.4 RECENT DEVELOPMENTS

18.23 HUNAN CHINA SUN

18.23.1 COMPANY OVERVIEW

18.23.2 REVENUE ANALYSIS

18.23.3 PRDUCT PORTFOLIO

18.23.4 RECENT DEVELOPMENTS

18.24 KEENPRO INDUSTRY CORP

18.24.1 COMPANY OVERVIEW

18.24.2 REVENUE ANALYSIS

18.24.3 PRDUCT PORTFOLIO

18.24.4 RECENT DEVELOPMENTS

18.25 CHIA MING MACHINERY CO., LTD.

18.25.1 COMPANY OVERVIEW

18.25.2 REVENUE ANALYSIS

18.25.3 PRDUCT PORTFOLIO

18.25.4 RECENT DEVELOPMENTS

18.26 LINGMA PLASTIC MACHINERY CO., LTD

18.26.1 COMPANY OVERVIEW

18.26.2 REVENUE ANALYSIS

18.26.3 PRDUCT PORTFOLIO

18.26.4 RECENT DEVELOPMENTS

18.27 KRONES AG

18.27.1 COMPANY OVERVIEW

18.27.2 REVENUE ANALYSIS

18.27.3 PRDUCT PORTFOLIO

18.27.4 RECENT DEVELOPMENTS

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST”

19 QUESTIONNAIRE

20 RELATED REPORTS

21 ABOUT DATA BRIDGE MARKET RESEARCH

Global Blow Molding Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Blow Molding Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Blow Molding Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.