Global Cartesian Robots Market

Market Size in USD Billion

CAGR :

%

USD

112.55 Billion

USD

284.51 Billion

2024

2032

USD

112.55 Billion

USD

284.51 Billion

2024

2032

| 2025 –2032 | |

| USD 112.55 Billion | |

| USD 284.51 Billion | |

|

|

|

|

Cartesian Robots Market Size

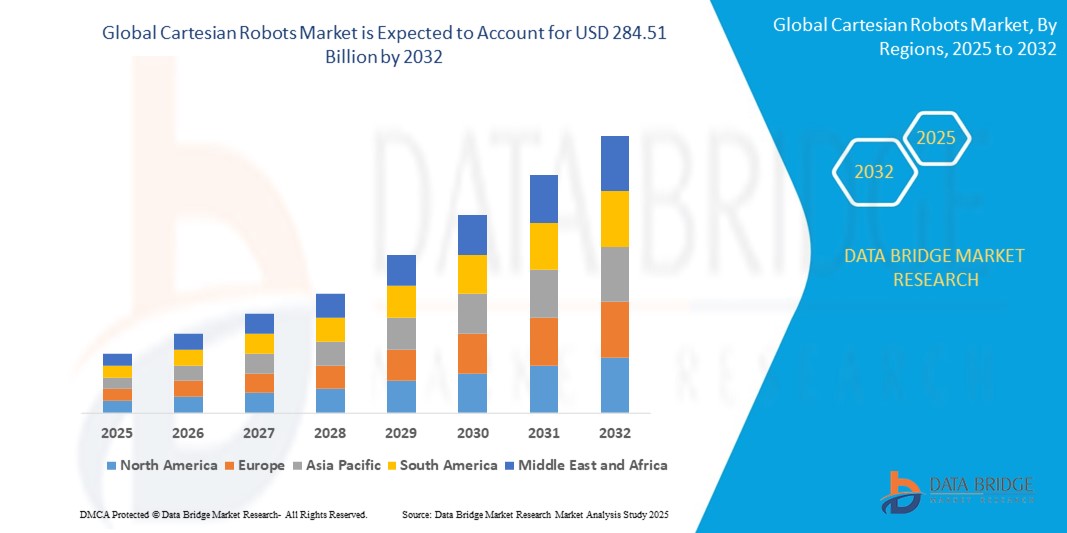

- The global cartesian robots market size was valued at USD 112.55 billion in 2024 and is expected to reach USD 284.51 billion by 2032, at a CAGR of 12.29% during the forecast period

- The market growth is largely fueled by the rising demand for precision-driven automation across manufacturing sectors such as automotive, electronics, and industrial machinery, supported by technological advancements in robotic systems and increasing integration of smart factory solutions

- Furthermore, growing pressure to enhance operational efficiency, reduce labor costs, and maintain consistency in high-volume production is accelerating the adoption of Cartesian robots, particularly for tasks requiring linear motion and accuracy, thereby significantly boosting the industry's growth

Cartesian Robots Market Analysis

- Cartesian robots are industrial automation systems that operate along linear X, Y, and Z axes, offering high precision, repeatability, and customization for applications such as pick-and-place, assembly, packaging, and material handling

- The escalating demand for Cartesian robots is primarily driven by their cost-effectiveness, ease of programming, and adaptability in constrained or structured environments—making them a preferred solution in industries seeking scalable and accurate automation systems

- Asia-Pacific dominated the cartesian robots market with a share of 48.5% in 2024, due to rapid industrial automation, expanding manufacturing bases, and increasing adoption of robotics across electronics, automotive, and machinery sectors

- North America is expected to be the fastest growing region in the cartesian robots market during the forecast period due to rapid technological adoption, high labor costs, and the growing need for productivity enhancements across manufacturing sectors

- Pick and place segment dominated the market with a market share of 35.6% in 2024, due to its foundational role in assembly lines across electronics, automotive, and food processing industries. Cartesian robots are favored in pick and place applications due to their precision, fast cycle times, and ability to handle delicate components without damage

Report Scope and Cartesian Robots Market Segmentation

|

Attributes |

Cartesian Robots Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Cartesian Robots Market Trends

“Increasing Automation Demands Across Various Industries”

- A significant and accelerating trend in the global cartesian robots market is the increasing demand for automation across a wide range of industries, including manufacturing, automotive, electronics, pharmaceuticals, and food and beverage

- For instance, major companies such as Yamaha Robotics, ABB, and IAI Corporation are expanding their cartesian robot offerings to address the need for precise, programmable, and scalable automation solutions in material handling, assembly, palletizing, and packaging applications

- The integration of advanced technologies such as IoT connectivity, 3D vision systems, and supply chain automation is enhancing the capabilities of cartesian robots, enabling higher productivity, improved quality control, and reduced labor costs

- The trend toward Industry 4.0 and the globalization of supply chains is driving adoption, as companies seek to streamline operations and respond quickly to changing market demands

- The demand for cartesian robots is growing rapidly, with the market expected to reach $10.23 billion by 2029, driven by their flexibility, scalability, and ability to automate repetitive tasks with high precision

Cartesian Robots Market Dynamics

Driver

“Increasing Technological Advancements”

- Ongoing technological advancements are a significant driver for the cartesian robots market, enabling higher speed, payload capacity, and precision in industrial automation

- For instance, companies such as Bosch Rexroth and Mitsubishi Electric are investing in R&D to develop next-generation cartesian robots equipped with advanced end-of-arm tooling, smart sensors, and collaborative features for safer human-robot interaction

- The adoption of digital twins, AI-based optimization, and modular robot architectures is expanding the range of applications and improving ease of programming and integration into existing workflows

- The versatility and adaptability of cartesian robots make them attractive for both large manufacturers and small and medium-sized enterprises (SMEs), supporting automation in diverse sectors such as electronics, automotive, and logistics

- These advancements are enabling manufacturers to achieve greater operational efficiency, reduce errors, and respond more flexibly to market changes

Restraint/Challenge

“High Initial Investment”

- High initial investment costs represent a significant challenge in the cartesian robots market, particularly for small and medium-sized enterprises (SMEs) and new entrants

- For instance, the purchase and integration of advanced cartesian robots from leading manufacturers such as Yamaha Robotics, ABB, and IAI Corporation require substantial capital outlay for equipment, installation, and workforce training

- Additional expenses include maintenance, customization, and system integration with existing production lines, which can further increase the financial burden on organizations

- This high barrier to entry can slow the adoption of cartesian robots, especially in cost-sensitive industries or regions with limited access to automation funding

- Overcoming this challenge will require the development of more affordable robot solutions, flexible financing options, and increased awareness of long-term cost savings and productivity gains associated with automation

Cartesian Robots Market Scope

The market is segmented on the basis of type, function, application, and end user.

- By Type

On the basis of type, the Cartesian robots market is segmented into transportation handling robots, positioning, unit load formation robots, articulated robots, Cartesian robot, SCARA robots, and storage, identification, and control robots. The Cartesian robot segment dominated the largest market revenue share in 2024, owing to its precision, cost-effectiveness, and ease of customization for various industrial tasks. These robots are widely adopted in applications requiring linear motion such as CNC machinery and 3D printing due to their simple mechanical structure and scalability. Industries favor Cartesian systems for their ability to operate in confined spaces with high repeatability and low maintenance, which helps reduce operational costs while improving throughput.

The SCARA robots segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by rising demand in electronics and consumer goods manufacturing. SCARA robots are valued for their compact footprint and speed in performing lateral movements, especially in high-speed pick-and-place and small part assembly operations. Their increasing deployment in cleanroom environments and compact production lines supports their rapid adoption across precision-driven manufacturing sectors.

- By Function

On the basis of function, the market is segmented into assembly, packaging, transportation, distribution, storage, and waste handling. The assembly segment held the largest market share in 2024, as Cartesian robots are extensively used in tasks requiring consistent force application and high positioning accuracy. Industries such as automotive and electronics leverage Cartesian robots in assembling components such as circuit boards and engine parts, where uniformity and low error margins are critical.

The transportation segment is projected to grow at the fastest CAGR from 2025 to 2032, driven by automation trends in intralogistics and smart warehousing. Cartesian robots are increasingly deployed in linear transfer systems to streamline material flow, reduce human error, and improve overall operational efficiency. Their adaptability to conveyor-based systems and integration with vision technologies makes them ideal for dynamic load transportation.

• By Application

On the basis of application, the market is segmented into pick and place, palletizing/de-palletizing, packing and packaging, product/part transfer, and machine tending. The pick and place segment accounted for the largest revenue share of 35.6% in 2024, driven by its foundational role in assembly lines across electronics, automotive, and food processing industries. Cartesian robots are favored in pick and place applications due to their precision, fast cycle times, and ability to handle delicate components without damage.

The palletizing/de-palletizing segment is expected to grow at the highest CAGR from 2025 to 2032, spurred by growing demand for end-of-line automation in logistics and FMCG sectors. Cartesian robots offer high payload capacities and structured linear motion, making them well-suited for stacking and unloading heavy or bulky packages in repetitive, high-volume workflows.

• By End User

On the basis of end user, the market is segmented into automotive, chemical, electrical and electronics, industrial machinery, food and beverage, and others. The automotive segment led the market in 2024 due to the high volume of Cartesian robot deployment in precision assembly and material handling tasks across vehicle manufacturing plants. The sector’s focus on automation to ensure quality control and reduce cycle time has made Cartesian robots integral to both chassis and component assembly lines.

The electrical and electronics segment is projected to record the fastest growth from 2025 to 2032, driven by the rising need for precise and delicate handling of micro-components. Cartesian robots are widely utilized in PCB assembly, semiconductor production, and device testing, where their linear motion and fine control support intricate operations while minimizing product defects.

Cartesian Robots Market Regional Analysis

- Asia-Pacific dominated the cartesian robots market with the largest revenue share of 48.5% in 2024, driven by rapid industrial automation, expanding manufacturing bases, and increasing adoption of robotics across electronics, automotive, and machinery sectors

- The region’s strong presence of OEMs, skilled workforce, and supportive government initiatives promoting smart factories are key growth enablers

- Rising labor costs, especially in China, Japan, and South Korea, are further encouraging industries to invest in high-precision and cost-efficient Cartesian robotic systems to enhance productivity and quality control

Japan Cartesian Robots Market Insight

The Japan market is expanding steadily due to high demand for precision and reliability in industrial automation. Japanese manufacturers are deeply invested in robotics innovation, especially for electronics, automotive, and semiconductor sectors. The aging workforce and labor shortages are accelerating the shift toward automated systems such as Cartesian robots, which are well-suited for repetitive, high-accuracy tasks in compact environments.

China Cartesian Robots Market Insight

China held the largest share in the Asia-Pacific Cartesian robots market in 2024, fueled by its dominance in electronics and automotive manufacturing. Government-backed initiatives such as “Made in China 2025” are promoting advanced manufacturing technologies, including industrial robotics. Chinese firms are also investing in cost-effective Cartesian systems for flexible assembly and material handling, aiming to enhance efficiency and global competitiveness.

Europe Cartesian Robots Market Insight

Europe is projected to grow at a significant CAGR over the forecast period, supported by increasing investments in industrial automation and strong demand for robotics in automotive, aerospace, and electronics sectors. The region benefits from a mature industrial base, focus on energy-efficient solutions, and regulatory support for smart manufacturing technologies. Growth is particularly strong in countries emphasizing sustainability, labor optimization, and digital transformation in production processes

Germany Cartesian Robots Market Insight

Germany’s Cartesian robots market is experiencing strong growth due to its well-established industrial ecosystem and leadership in advanced automation technologies. High adoption rates in automotive, machinery, and electronics industries are bolstered by Germany’s strong engineering capabilities and focus on precision manufacturing. The country’s emphasis on Industry 4.0 is driving the deployment of Cartesian systems for smart production environments.

U.K. Cartesian Robots Market Insight

The U.K. market is poised for steady growth, supported by demand for flexible and modular automation solutions across food, pharmaceutical, and packaging sectors. Post-Brexit labor shortages and rising input costs are pushing manufacturers to automate key operations. Cartesian robots, with their high accuracy and adaptability, are gaining traction in small to mid-scale industries focused on cost optimization and production efficiency.

North America Cartesian Robots Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by rapid technological adoption, high labor costs, and the growing need for productivity enhancements across manufacturing sectors. The region's strong foothold in automotive, aerospace, and consumer electronics industries supports demand for Cartesian robots. Increasing focus on reshoring manufacturing operations, coupled with investments in smart factories and AI-integrated robotics, is accelerating adoption across the U.S. and Canada

U.S. Cartesian Robots Market Insight

The U.S. captured the largest revenue share in North America in 2024, underpinned by growing deployment of Cartesian robots in precision manufacturing, warehousing, and automated testing systems. The country’s leadership in innovation, combined with a highly competitive industrial landscape, is driving companies to adopt flexible, high-throughput robotic systems. The demand for scalable automation in small and mid-sized enterprises is also boosting market penetration of Cartesian robots.

Cartesian Robots Market Share

The cartesian robots industry is primarily led by well-established companies, including:

- ABB (Switzerland)

- DENSO WAVE INCORPORATED (Japan)

- Midea Group (China)

- Seiko Epson Corporation (Japan)

- Shibaura Machine CO., LTD (Japan)

- Yamaha Motor Co., Ltd. (Japan)

- MKS Instruments (U.S.)

- KUKA AG (Germany)

- Güdel Group AG (Switzerland)

- Bosch Rexroth AG (Germany)

- AKRIBIS SYSTEMS (France)

- Aerotech Inc (U.S.)

- Stone Technologies Limited (U.K.)

- MoTeC Pty Ltd (Australia)

- Promot Switches (Germany)

- Advokatfirmaet BAHR AS (Norway)

- Fibro, Inc. (Germany)

- PARKER HANNIFIN CORP (U.S.)

- Star Automation, Inc. (U.S.)

- FANUC (Japan)

- Comau (Italy)

Latest Developments in Global Cartesian Robots Market

- In April 2024, Automata announced its participation in Interplast 2024, marking a significant milestone with the launch of its first 100% Brazil-manufactured Cartesian Robot. This customizable and cost-effective industrial manipulator is designed to streamline automation in injection molding processes, offering enhanced flexibility and accessibility for local manufacturers. The launch is expected to strengthen domestic production capabilities and accelerate the adoption of Cartesian robots in the Latin American market by offering a localized, affordable automation solution

- In April 2021, KUKA AG introduced the first version of iiQKA.OS, a next-generation operating system aimed at simplifying robotic operation and integration. This platform lays the groundwork for a complete robotics ecosystem, enabling users to easily connect and expand with compatible hardware, applications, and services. The launch of iiQKA.OS is expected to significantly lower barriers to robot adoption, especially for small and mid-sized enterprises, and boost demand for Cartesian robots by making robotic systems more user-friendly and scalable

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cartesian Robots Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cartesian Robots Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cartesian Robots Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.