Global Cast In Place Concrete Flooring Market

Market Size in USD Billion

CAGR :

%

USD

6.55 Billion

USD

9.98 Billion

2024

2032

USD

6.55 Billion

USD

9.98 Billion

2024

2032

| 2025 –2032 | |

| USD 6.55 Billion | |

| USD 9.98 Billion | |

|

|

|

|

Cast-in-Place Concrete Flooring Market Size

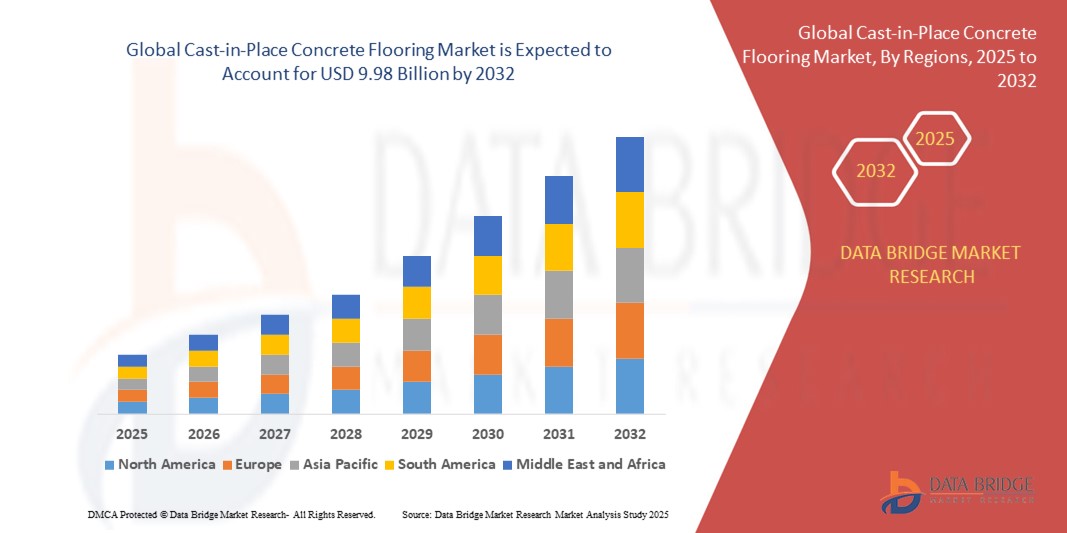

- The global cast-in-place concrete flooring market size was valued at USD 6.55 billion in 2024 and is expected to reach USD 9.98 billion by 2032, at a CAGR of 5.4% during the forecast period

- The market growth is largely fueled by the increasing demand for durable, cost-effective, and high-performance flooring systems across industrial, commercial, and infrastructure projects, leading to the widespread adoption of cast-in-place concrete techniques

- Furthermore, rising investments in logistics hubs, manufacturing facilities, data centers, and transportation infrastructure are driving the need for seamless, load-bearing, and customizable flooring solutions, making cast-in-place concrete flooring a preferred choice for large-scale applications

Cast-in-Place Concrete Flooring Market Analysis

- Cast-in-place concrete flooring involves pouring concrete directly on-site into formwork to create a continuous and monolithic floor slab, offering enhanced strength, crack resistance, and design flexibility for a variety of structural needs

- The growing popularity of cast-in-place flooring is supported by its ability to meet specific project requirements, reduce jointing, and accommodate modern technologies such as post-tensioning and fiber reinforcement, making it ideal for warehouses, hospitals, airports, and heavy-duty industrial environments

- North America dominated the cast-in-place concrete flooring market with a share of over 35% in 2024, due to significant infrastructure development and high demand for durable flooring solutions across industrial and commercial sectors

- Asia-Pacific is expected to be the fastest growing region in the cast-in-place concrete flooring market during the forecast period due to robust industrialization, urban expansion, and infrastructure upgrades across China, India, Japan, and Southeast Asia

- Traditional floor segment dominated the market with a market share of 52.8% in 2024, due to its well-established application methods, cost-effectiveness, and flexibility in onsite modifications. Contractors and developers favor traditional cast-in-place floors for their ease of construction, familiarity across the workforce, and compatibility with varying site conditions and formwork systems

Report Scope and Cast-in-Place Concrete Flooring Market Segmentation

|

Attributes |

Cast-in-Place Concrete Flooring Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Cast-in-Place Concrete Flooring Market Trends

Increasing Demand for Sustainable Construction

- The cast-in-place concrete flooring market is growing steadily due to rising emphasis on sustainable construction practices that prioritize long-lasting, eco-friendly materials, and reduced carbon footprints in building projects

- For instance, use of recycled aggregates, supplementary cementitious materials such as fly ash or slag, and energy-efficient installation techniques are increasingly adopted to meet green building certifications such as LEED and BREEAM

- The inherent durability, recyclability, and thermal mass benefits of cast-in-place concrete flooring contribute to energy savings and reduced environmental impact over building lifecycles, supporting market growth

- Urbanization and infrastructure expansion in emerging economies drive demand for cost-effective, sustainable flooring solutions in residential, commercial, and industrial buildings

- Advances in concrete technology, including self-leveling and fiber reinforcement, enhance performance and reduce material waste, aligning with circular economy principles

- Growing awareness among architects, contractors, and end-users regarding sustainable material selections promotes wider acceptance of cast-in-place concrete flooring in eco-conscious construction projects

Cast-in-Place Concrete Flooring Market Dynamics

Driver

Increased Adoption in Commercial Spaces

- Commercial buildings are a major segment driving demand for cast-in-place concrete flooring owing to its high load-bearing capacity, durability, and low maintenance compared to alternate flooring materials

- For instance, expanding office complexes, retail developments, warehouses, and logistics centers prefer cast-in-place concrete floors for their robustness and cost-effectiveness across large surface areas

- Rising urban development and commercial real estate investments in regions such as Asia Pacific, North America, and Europe encourage use of concrete flooring to meet stringent building codes and sustainability standards

- The popularity of polished and decorative concrete finishes enhances aesthetic appeal while retaining functional benefits, motivating adoption in showrooms, airports, and institutional buildings

- Integration of smart sensors and IoT-enabled concrete monitoring during installation and curing improves quality control and long-term performance, further boosting commercial sector confidence. The resistance of concrete floors to chemicals, abrasion, and fire hazards makes them suitable for demanding commercial environments including manufacturing and healthcare facilities

Restraint/Challenge

Cracking and Maintenance Issues

- Cracking due to shrinkage, thermal stress, and improper curing remains a significant challenge affecting the structural integrity and appearance of cast-in-place concrete floors, impacting customer satisfaction and lifecycle costs

- For instance, uneven subgrade preparation or inadequate joint placement can lead to surface defects, necessitating costly repairs or early replacement in commercial and industrial sites

- Maintenance challenges include the need for periodic sealing, polishing, and surface treatments to prevent dusting, staining, and moisture penetration, especially in high-traffic areas. The repair process can be disruptive and expensive owing to the monolithic nature of cast-in-place flooring, requiring downtime that affects facility operations and productivity

- Environmental factors such as freeze-thaw cycles and chemical exposure can exacerbate degradation, demanding more robust material formulations and maintenance protocols

- The upfront selection of flooring design, quality control during placement, and skilled workforce availability are critical to minimizing cracking risks but can increase project complexity and costs

Cast-in-Place Concrete Flooring Market Scope

The market is segmented on the basis of application, technique, and end-user industry.

- By Application

On the basis of application, the cast-in-place concrete flooring market is segmented into residential, non-residential, and infrastructure. The non-residential segment accounted for the largest market revenue share in 2024, driven by growing demand from commercial buildings, industrial facilities, and institutional structures where durability and load-bearing capacity are critical. The preference for monolithic concrete floors in warehouses, manufacturing plants, and large-scale retail spaces stems from their seamless finish, longevity, and low maintenance requirements. These attributes make cast-in-place solutions highly favorable for high-traffic and high-load environments where precast options may fall short.

The infrastructure segment is projected to register the fastest growth rate from 2025 to 2032, fueled by increasing public and private investments in transportation, utility, and civic infrastructure. Cast-in-place flooring is widely used in airports, bridges, tunnels, and utility corridors due to its structural integrity, ability to conform to complex layouts, and suitability for large continuous slabs. Governments across regions are prioritizing infrastructure modernization, boosting demand for durable, cost-efficient flooring solutions that can be poured and formed onsite.

- By Technique

On the basis of technique, the market is segmented into prestressed concrete, steel fiber reinforced concrete, and traditional floor. The traditional floor segment held the largest share of 52.8% in 2024, due to its well-established application methods, cost-effectiveness, and flexibility in onsite modifications. Contractors and developers favor traditional cast-in-place floors for their ease of construction, familiarity across the workforce, and compatibility with varying site conditions and formwork systems.

The steel fiber reinforced concrete (SFRC) segment is anticipated to witness the fastest growth from 2025 to 2032, driven by its rising adoption in industrial and heavy-duty flooring applications. SFRC enhances tensile strength, impact resistance, and crack control, making it highly suitable for floors exposed to dynamic and concentrated loads, such as in logistics hubs, recycling plants, and manufacturing facilities. Its ability to reduce or eliminate the need for conventional reinforcement and control joints appeals to builders seeking performance efficiency and reduced labor input.

- By End User Industry

On the basis of end user industry, the cast-in-place concrete flooring market is segmented into logistics and distribution/warehousing, automotive industry, aviation industry, pharmaceutical/chemical industry, data centers, recycling facilities, textile, food and beverage, heavy equipment/construction equipment manufacturing and distribution, and others. The logistics and distribution/warehousing segment dominated the market in 2024, owing to the expanding global e-commerce sector and the need for high-performance flooring that can support heavy racking systems, forklifts, and frequent movement of goods. These facilities demand surfaces that are level, abrasion-resistant, and capable of withstanding operational stress over extended periods.

The data centers segment is expected to register the fastest CAGR from 2025 to 2032, driven by the surge in digital infrastructure projects and the growing emphasis on thermal performance, anti-static surfaces, and floor load capacity. Cast-in-place concrete floors offer robust support for server loads and equipment while facilitating underfloor cabling and cooling systems. As hyperscale data centers multiply globally, demand for precision-poured and customizable flooring solutions is set to rise sharply.

Cast-in-Place Concrete Flooring Market Regional Analysis

- North America dominated the cast-in-place concrete flooring market with the largest revenue share of over 35% in 2024, driven by significant infrastructure development and high demand for durable flooring solutions across industrial and commercial sectors

- The region benefits from mature construction practices, strict building standards, and widespread adoption of on-site casting techniques for customized project requirements

- Strong presence of logistics hubs, automotive manufacturing, and data centers supports continuous demand for high-strength, low-maintenance concrete flooring solutions

U.S. Cast-in-Place Concrete Flooring Market Insight

The U.S. accounted for the largest revenue share in the North America region in 2024. The market is thriving due to strong demand from the logistics and distribution sector, especially amid the e-commerce boom. The proliferation of fulfillment centers, cold chain facilities, and data warehouses is pushing the adoption of cast-in-place flooring known for its strength, load-bearing capacity, and seamless finish. U.S. builders prefer poured-in-place concrete due to its proven performance in high-volume operations, ease of maintenance, and cost-efficiency over large surface areas.

Europe Cast-in-Place Concrete Flooring Market Insight

The Europe market is projected to grow at a steady CAGR over the forecast period, driven by increased renovation activities and rising investment in sustainable building practices. Cast-in-place concrete flooring is widely adopted across commercial and industrial settings for its structural robustness, energy efficiency, and acoustic performance. Growing awareness of lifecycle cost savings and reduced environmental impact is encouraging the shift toward poured flooring systems, particularly in sectors such as automotive, aviation, and advanced manufacturing. Demand is further supported by strict building codes that favor resilient and thermally efficient flooring materials.

U.K. Cast-in-Place Concrete Flooring Market Insight

The U.K. market is expected to grow significantly, supported by expanding logistics infrastructure and ongoing investments in urban development. With the rise of e-commerce and digital services, warehouses and data centers are increasingly specifying cast-in-place concrete flooring to meet durability and performance standards. The flexibility in customizing thickness, reinforcement, and finish makes this method suitable for both new constructions and refurbishments in fast-paced urban zones.

Germany Cast-in-Place Concrete Flooring Market Insight

Germany continues to show strong market performance due to its engineering excellence and demand for precision-driven construction. Cast-in-place floors are widely used in Germany’s automotive plants, heavy equipment manufacturing sites, and cleanroom facilities, where strict tolerances, vibration control, and surface uniformity are essential. Government support for green and energy-efficient buildings is also fueling demand for integrated flooring systems that align with national sustainability goals.

Asia-Pacific Cast-in-Place Concrete Flooring Market Insight

Asia-Pacific is anticipated to register the fastest CAGR from 2025 to 2032, fueled by robust industrialization, urban expansion, and infrastructure upgrades across China, India, Japan, and Southeast Asia. The surge in public-private infrastructure projects, such as smart cities, industrial corridors, and new airport terminals, is creating significant demand for cast-in-place concrete flooring. These solutions are favored for their adaptability to diverse site conditions, long service life, and compatibility with fast-track construction schedules. Increasing use of prestressed and steel fiber reinforced concrete further enhances structural performance in high-load environments.

Japan Cast-in-Place Concrete Flooring Market Insight

Japan’s market is advancing steadily due to its focus on earthquake-resilient infrastructure, advanced industrial facilities, and aging population requiring safer, low-maintenance flooring. Cast-in-place solutions are increasingly used in hospitals, research labs, and technology centers due to their durability and compliance with hygiene and performance standards. The integration of these floors into smart building systems is also gaining traction, aligning with Japan’s vision of connected, sustainable urban spaces.

China Cast-in-Place Concrete Flooring Market Insight

China led the Asia-Pacific region in terms of revenue share in 2024, driven by large-scale investments in manufacturing, urban development, and logistics parks. Cast-in-place flooring is highly preferred in the country’s rapidly growing industrial and construction sectors due to its cost-effectiveness, high load tolerance, and ease of on-site customization. With strong support from local governments and domestic suppliers, the market benefits from quick material availability, skilled labor, and a focus on long-lasting infrastructure solutions suited for both urban and rural developments.

Cast-in-Place Concrete Flooring Market Share

The cast-in-place concrete flooring industry is primarily led by well-established companies, including:

- Boral (Australia)

- CSR Limited (Australia)

- Sika AG (Switzerland)

- Saint-Gobain (France)

- 3M (U.S.)

- Johns Manville (U.S.)

- Milliken (U.S.)

- Interface, Inc. (U.S.)

- Shaw Industries Group, Inc. (U.S.)

- Kajaria Ceramics Limited (India)

- MOHAWK INDUSTRIES, INC. (U.S.)

- Tarkett (France)

- Owens Corning (U.S.)

- Fletcher Building (New Zealand)

- TAMKO Building Products LLC (U.S.)

- SCG (Siam Cement Group) (Thailand)

- The Euclid Chemical Company (U.S.)

- Liberty Industries (U.S.)

- Synetik (U.S.)

- ARDEX Group (Germany)

- Q.E.P. Co., Inc. (U.S.)

Latest Developments in Global Cast-in-Place Concrete Flooring Market

- In February 2025, advancements in digital modeling and eco-friendly concrete mixes began influencing decisions between cast-in-place and precast concrete methods, impacting project budgets, timelines, and sustainability goals. These innovations are enhancing project planning accuracy, reducing material waste, and promoting the use of low-carbon construction materials. As a result, stakeholders are increasingly favoring cast-in-place flooring for its adaptability, environmental compliance, and long-term cost efficiency across large infrastructure and industrial projects

- In March 2024, the International Code Council released the 2024 International Residential Code, introducing significant updates for post-tensioned, slab-on-ground floors, aligning with the latest Post-Tensioning Institute guidelines. This update reinforces structural integrity and safety in residential construction and is expected to drive broader acceptance of cast-in-place flooring systems. The alignment with current engineering best practices supports higher quality control and encourages adoption in regions requiring soil stability and durability in floor slabs

- In April 2022, Geoplast launched the Matrix – our new patented product for concrete raised floors with MEP systems. We implemented an innovative design that combines high load-bearing capacity with simple positioning of MEP. This makes Matrix superior to both metal pedestal floors and full concrete slabs, and irreplaceable for large buildings such as airports, hospitals, or shopping centers. The launch of Matrix significantly expanded the scope of cast-in-place flooring applications by offering a high-performance, easily integrable solution for modern infrastructure needs

- In December 2020, MEGASLAB entered into a significant contract with ARCO Design/Build, Inc. This partnership focused on the innovative construction of a concrete slab designed without traditional reinforcing bars. This unique approach was specifically tailored to support a self-storage facility in Loring Heights, Georgia. The project highlighted MEGASLAB’s commitment to modern construction techniques and efficient design, aiming to optimize both cost and structural integrity for the client

- In November 2020, CIN launched the C-FLOOR PU280 WB, a new water-based polyurethane coating for concrete floors and surfaces. The new CIN product complies with the LEED v4 certification requirements and has an A+ rating for Indoor Air Quality, in addition to being certified with CE Marking, according to European standards EN 1504-2 and EN 13813. This development strengthened the value proposition of cast-in-place flooring by introducing a sustainable, high-performance surface treatment that aligns with green building standards and enhances indoor environmental quality

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cast In Place Concrete Flooring Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cast In Place Concrete Flooring Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cast In Place Concrete Flooring Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.