Global Chemical Surface Treatments Market

Market Size in USD Billion

CAGR :

%

USD

16.09 Billion

USD

25.07 Billion

2024

2032

USD

16.09 Billion

USD

25.07 Billion

2024

2032

| 2025 –2032 | |

| USD 16.09 Billion | |

| USD 25.07 Billion | |

|

|

|

|

Chemical Surface Market Size

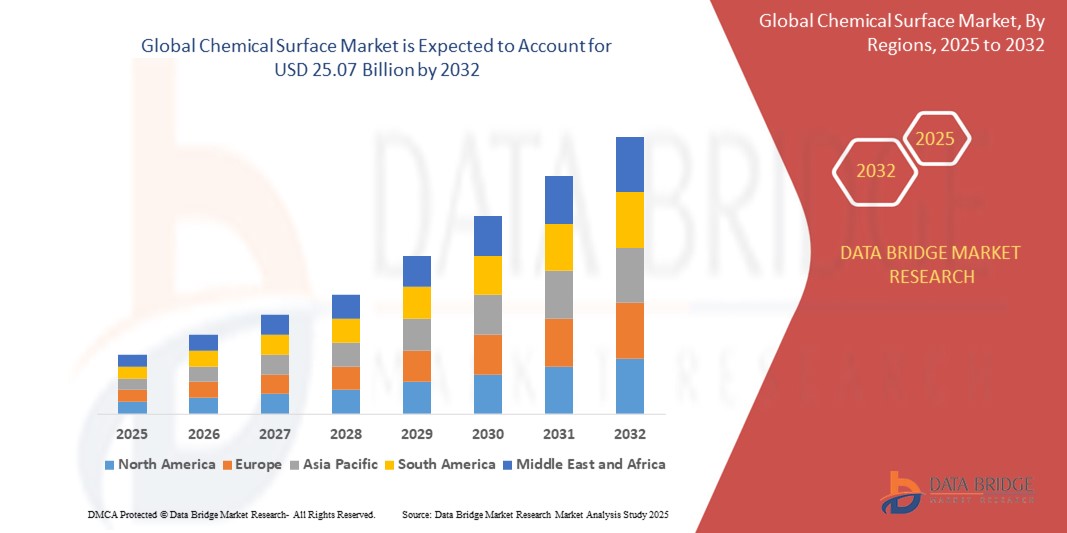

- The global chemical surface market size was valued at USD 16.09 billion in 2024 and is expected to reach USD 25.07 billion by 2032, at a CAGR of 5.70 % during the forecast period

- This growth is driven by factors such as the increasing demand from automotive and aerospace industries, advancements in surface treatment technologies, and rising applications in electronics and construction sectors

Chemical Surface Market Analysis

- The chemical surface treatment market is experiencing steady growth due to increased demand across multiple industries including automotive, construction, and electronics

- Current trends show a strong shift toward eco-friendly and advanced treatment solutions that improve product durability and surface performance

- North America is expected to dominate the chemical surface market due to its well-established manufacturing sectors, strong demand from automotive and aerospace industries, and the presence of major market players driving innovation and production capacity

- Asia-Pacific is expected to be the fastest growing region in the chemical surface market during the forecast period due to rapid industrialization, expanding automotive and electronics industries, and increasing investments in infrastructure and sustainable surface treatment technologies

- The plating chemicals segment is expected to dominate the chemical surface market with the largest share of 42.36% in 2025 due to its extensive use in enhancing corrosion resistance, durability, and aesthetic appeal of metal components. Its applications span key industries such as automotive, electronics, and aerospace, where high-performance surface finishes are essential. The growing demand for metal finishing solutions in manufacturing is further fuelling this segment’s dominance

Report Scope and Chemical Surface Market Segmentation

|

Attributes |

Chemical Surface Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Chemical Surface Market Trends

“Growing Adoption of Eco-Friendly Surface Treatment Solutions”

- Manufacturers are increasingly shifting toward environmentally friendly chemical surface treatments to comply with global sustainability standards and reduce environmental impact

- Water-based and chromium-free surface treatments are gaining traction as safer alternatives to traditional methods, especially in automotive and aerospace sectors

- Major industry players have started investing in green technologies

- For instance, Henkel introduced a sustainable pretreatment process for metal surfaces used in car manufacturing

- Governments and regulatory bodies are tightening environmental regulations, prompting companies to innovate with less hazardous formulations

- For instance, the European Union’s REACH regulation has led many firms to eliminate toxic substances from their processes

Chemical Surface Market Dynamics

Driver

“Rising Demand from The Automotive and Aerospace Industries”

- The automotive and aerospace industries are major consumers of chemical surface treatments, using them to improve durability, appearance, and resistance to corrosion in components

- In automotive manufacturing, treatments such as anodizing and phosphating are essential for ensuring paint adhesion and extending the life of parts under harsh conditions

- For instance, BMW uses advanced pretreatment methods to improve corrosion resistance in electric vehicles

- Aerospace components are exposed to high altitudes and extreme temperatures, requiring treatments that maintain structural integrity and safety

- For instance, Boeing employs passivation and anodizing to protect critical aircraft parts

- The increasing production of electric vehicles and the growing demand for air travel are driving consistent growth in these sectors, fueling the need for reliable surface treatment solutions

- This sustained demand encourages manufacturers to invest in innovation, focusing on more efficient, high-performance, and sustainable chemical surface treatment technologies to meet evolving industry needs

Opportunity

“Growth in Emerging Economies Due to Industrialization”

- Rapid industrialization in emerging economies like India and Indonesia is creating a surge in demand for chemical surface treatments, especially in automotive, construction, and electronics manufacturing

- For instance, India’s automotive sector is projected to become the world’s third-largest by 2030, driving demand for corrosion-resistant surface coatings

- Infrastructure development and urbanization are pushing the need for durable and treated materials, especially in public works and housing

- For instance, Indonesia’s $35 billion infrastructure roadmap includes new highways, airports, and ports, all requiring treated metal and concrete surfaces

- Government initiatives like “Make in India” and China’s “Made in China 2025” promote local manufacturing and quality standards, encouraging industries to adopt advanced surface treatments to meet global requirements

- Low penetration of advanced technologies offers a first-mover advantage for companies that can provide cost-effective, scalable, and environmentally compliant surface treatment solutions

- Rising consumer and industrial awareness of product lifespan, appearance, and performance is increasing the adoption of quality surface treatments in everyday manufacturing

Restraint/Challenge

“High Cost and Complexity Associated with Adopting Advanced Technologies”

- Adopting advanced and environmentally compliant chemical surface treatments involves high costs and technical complexity, making it a major challenge for the industry

- Transitioning to sustainable methods requires significant investment in R&D, equipment, and workforce training; for instance, smaller firms often struggle to afford new treatment systems that meet green standards

- Eco-friendly alternatives may not always match the performance of traditional treatments in sectors such as aerospace and defense, limiting their immediate application

- Global companies face difficulties complying with different regulatory standards across countries, requiring customized solutions and increasing operational complexity

- For instance, AkzoNobel faced delays in launching a chromium-free coating line due to the need to meet differing environmental compliance requirements in both the U.S. and Europe, highlighting the complexity of international regulation in sustainable innovation

Chemical Surface Market Scope

The market is segmented on the basis of product, base, application, and end-user.

|

Segmentation |

Sub-Segmentation |

|

By Product |

|

|

By Base |

|

|

By Application |

|

|

By End-User |

|

In 2025, the plating chemicals is projected to dominate the market with a largest share in product segment

The plating chemicals segment is expected to dominate the chemical surface market with the largest share of 42.36% in 2025 due to its extensive use in enhancing corrosion resistance, durability, and aesthetic appeal of metal components. Its applications span key industries such as automotive, electronics, and aerospace, where high-performance surface finishes are essential. The growing demand for metal finishing solutions in manufacturing is further fuelling this segment’s dominance.

The conversion coating is expected to account for the largest share during the forecast period in product segment

In 2025, the conversion coating segment is expected to dominate the market with the largest market share of 31.84% due to its critical role in improving paint adhesion and protecting surfaces from corrosion. Widely used in pre-treatment processes, especially in automotive and industrial applications, these coatings enhance surface performance and longevity. Their compatibility with eco-friendly formulations also supports their expanding use across regulated industries.

Chemical Surface Market Regional Analysis

“North America Holds the Largest Share in the Chemical Surface Market”

- North America holds the largest share of the global chemical surface treatment market, accounting for approximately 38.5%.

- The U.S. leads the North American market, driven by a robust automotive and aerospace industry demanding advanced surface treatment solutions

- The region's focus on electric vehicle (EV) production, with companies such as General Motors expanding EV portfolios, boosts the demand for surface treatments

- Technological advancements and strategic partnerships in the U.S. are fostering innovation in chemical surface treatments

- The presence of major market players and a strong manufacturing base contribute to North America's market dominance

“Asia-Pacific is Projected to Register the Highest CAGR in the Chemical Surface Market”

- Asia-Pacific is the fastest growing region in the chemical surface market

- Rapid industrialization in countries such as China and India is propelling the demand for chemical surface treatments in various sectors

- China's dominance in automotive manufacturing, producing over 26 million vehicles, significantly drives the surface treatment chemicals market

- Government initiatives and investments in infrastructure development across Asia-Pacific are enhancing market growth

- The region's increasing focus on sustainable and eco-friendly surface treatment solutions aligns with global environmental standards

Chemical Surface Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Element Solutions Inc. (U.S.)

- NOF Corporation (Japan)

- Atotech (Germany)

- Henkel AG & Co. KGaA (Germany)

- Chemetall, Inc. (Germany)

- Nihon Parkerizing Co., Ltd. (Japan)

- PPG Industries, Inc. (U.S.)

- Nippon Paint Holdings Co., Ltd. (Japan)

- Solvay (Belgium)

- OC Oerlikon Management AG (Switzerland)

- McGean-Rohco Inc. (U.S.)

- JCU CORPORATION (Japan)

- Platform Specialty Products Corporation (U.S.)

- Quaker Chemical Corporation (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Chemical Surface Treatments Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Chemical Surface Treatments Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Chemical Surface Treatments Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.