Global Cling Wrap Machine Market

Market Size in USD Million

CAGR :

%

USD

602.40 Million

USD

830.79 Million

2024

2032

USD

602.40 Million

USD

830.79 Million

2024

2032

| 2025 –2032 | |

| USD 602.40 Million | |

| USD 830.79 Million | |

|

|

|

|

Cling Wrap Machine Market Size

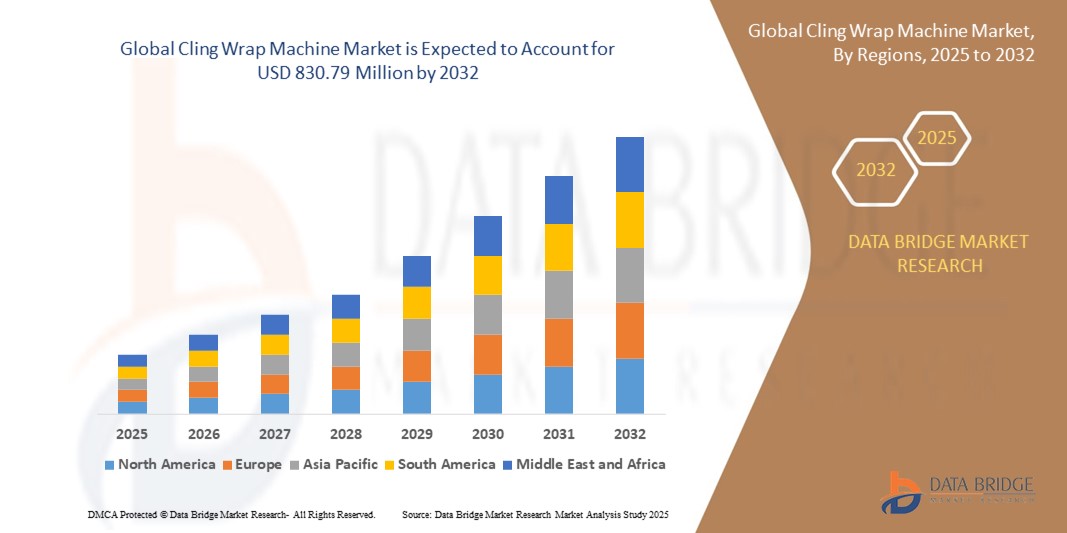

- The global cling wrap machine market size was valued at USD 602.4 million in 2024 and is expected to reach USD 830.79 million by 2032, at a CAGR of 4.1% during the forecast period

- The market growth is largely fuelled by the rising demand for efficient and automated food packaging solutions, increasing adoption in supermarkets and retail stores, and the growing need for extended shelf life of perishable products

Cling Wrap Machine Market Analysis

- The global cling wrap machine market is witnessing steady growth due to the increasing focus on reducing food wastage, coupled with advancements in packaging machinery technology. The rising consumption of packaged and ready-to-eat food products is driving demand for cling wrap machines in both commercial and industrial sectors

- In addition, the integration of energy-efficient and user-friendly machine designs is further contributing to market expansion

- North America dominated the cling wrap machine market with the largest revenue share of 38.5% in 2024, driven by strong demand from the food processing and retail sectors, alongside the region’s well-established packaging industry

- Asia-Pacific region is expected to witness the highest growth rate in the global cling wrap machine market, driven by urbanization, rising disposable incomes, expanding food retail chains, and heightened awareness of food safety and shelf-life extension

- The PVC segment dominated the market with the largest revenue share in 2024, owing to its excellent stretchability, clarity, and suitability for food-grade packaging. PVC films are widely preferred for their ability to maintain product freshness while offering cost efficiency

Report Scope and Cling Wrap Machine Market Segmentation

|

Attributes |

Cling Wrap Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

• Expansion of Automated Packaging Solutions in Emerging Economies |

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Cling Wrap Machine Market Trends

Integration Of Smart and Automated Features in Cling Wrap Machines

- The increasing adoption of smart and automated features in cling wrap machines is transforming packaging operations across food, retail, and industrial sectors. Advanced machines equipped with sensors, touchscreens, and programmable settings allow for precise wrap control, reduced material waste, and improved operational efficiency

- The demand for automation is accelerating in high-volume production environments where consistent wrap quality and speed are essential. Automated systems reduce manual intervention, minimize errors, and improve safety standards, making them ideal for large-scale packaging facilities

- User-friendly interfaces and remote monitoring capabilities are making modern cling wrap machines more accessible to small and medium-sized enterprises (SMEs), allowing them to upgrade their packaging efficiency without extensive operator training

- For instance, in 2024, several bakery chains in Europe reported a 20% reduction in film usage after deploying AI-enabled cling wrap machines that automatically adjusted tension and cutting based on product size. This optimization lowered operational costs while enhancing sustainability

- While automation is enhancing productivity and reducing wastage, its success depends on affordability, ease of integration with existing production lines, and ongoing innovation in eco-friendly packaging materials. Manufacturers are focusing on developing machines compatible with biodegradable films to align with sustainability goals

Cling Wrap Machine Market Dynamics

Driver

Rising Demand or Efficient and Sustainable Food Packaging Solutions

• The surge in demand for efficient and sustainable packaging is a major growth driver for the cling wrap machine market. Growing urban populations and changing consumer lifestyles have increased the consumption of fresh and packaged foods, prompting manufacturers to seek reliable wrapping solutions that extend shelf life and maintain product quality

• Businesses are recognizing the operational benefits of automated cling wrap machines, including reduced labor costs, improved consistency, and faster packaging speeds. This efficiency aligns with the food industry’s need for high throughput and minimal waste

• The shift toward eco-friendly packaging materials, such as biodegradable and recyclable films, is influencing machine design and driving the adoption of advanced wrapping equipment capable of handling these materials without compromising performance

• For instance, in 2023, a U.S.-based supermarket chain implemented high-speed cling wrap machines compatible with compostable films, reducing its single-use plastic footprint and enhancing brand reputation among environmentally conscious consumers

• While the demand for sustainable packaging is driving innovation, ensuring compatibility between new materials and existing machinery remains a key focus for equipment manufacturers to maintain operational efficiency

Restraint/Challenge

High Initial Investment and Maintenance Costs for Advanced Cling Wrap Machines

• The high upfront cost of advanced cling wrap machines, particularly fully automated models, poses a challenge for small-scale businesses and startups. These machines often require substantial capital expenditure, which can deter adoption despite their long-term benefits

• Regular maintenance, software updates, and replacement of specialized parts add to the operational costs, making them less attractive to budget-conscious enterprises. In addition, downtime during repairs can disrupt production schedules

• In developing regions, the lack of technical expertise for operating and maintaining advanced machines further limits market penetration. Businesses may prefer semi-automatic or manual alternatives due to their lower complexity and reduced maintenance requirements

• For instance, in 2024, several small food processing units in Southeast Asia reported delaying automation upgrades due to budget constraints and concerns over long-term maintenance expenses

• While automation offers significant efficiency gains, addressing cost and accessibility barriers through financing options, modular machine designs, and affordable after-sales support will be essential for wider market adoption

Cling Wrap Machine Market Scope

The market is segmented on the basis of film type, type, application, form factor, usage, and end-use industry.

- By Film Type

On the basis of film type, the cling wrap machine market is segmented into polyvinyl chloride (PVC), polyethylene (PE), and polyvinylidene chloride (PVDC). The PVC segment dominated the market with the largest revenue share in 2024, owing to its excellent stretchability, clarity, and suitability for food-grade packaging. PVC films are widely preferred for their ability to maintain product freshness while offering cost efficiency.

The PE segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its eco-friendly attributes and growing use in sustainable packaging solutions. PE films are increasingly favored for their recyclability, lightweight nature, and compatibility with modern automated cling wrap machines.

- By Type

On the basis of type, the market is segmented into tabletop and tray models. The tray segment held the largest market share in 2024, supported by high adoption in large-scale food processing and retail operations where bulk packaging efficiency is essential. Tray models are preferred for their ability to wrap multiple products in one cycle, improving productivity.

The tabletop segment is expected to witness the fastest growth rate from 2025 to 2032, fueled by demand from small businesses and specialty food stores. Tabletop models are compact, cost-effective, and ideal for limited-space environments while still delivering professional-grade packaging.

- By Application

On the basis of application, the cling wrap machine market is segmented into food & beverage packaging, pharmaceutical packaging, and other applications. The food & beverage packaging segment dominated the market in 2024 due to the rising need for extended shelf life, contamination prevention, and attractive product presentation.

The pharmaceutical packaging segment is expected to witness the fastest growth rate from 2025 to 2032, driven by stringent hygiene requirements, tamper-evident sealing, and the growing demand for unit-dose packaging in healthcare facilities.

- By Form Factor

On the basis of form factor, the market is segmented into automatic, semi-automatic, and manual machines. The automatic segment accounted for the largest market revenue share in 2024, favored by high-volume packaging facilities seeking speed, consistency, and minimal labor intervention.

The semi-automatic segment is expected to witness the fastest growth rate from 2025 to 2032, as it offers a balance between automation and affordability, appealing to SMEs transitioning from manual wrapping methods.

- By Usage

On the basis of usage, the cling wrap machine market is segmented into commercial, industrial, and residential. The commercial segment dominated in 2024, driven by supermarkets, bakeries, and catering services relying heavily on cling wrap machines for daily operations.

The industrial segment is expected to witness the fastest growth rate from 2025 to 2032, supported by its adoption in manufacturing plants, warehouses, and bulk packaging operations requiring high-strength wraps for shipping and storage.

- By End-Use Industry

On the basis of end-use industry, the market is segmented into food processing, healthcare, retail, and packaging. The food processing segment led the market in 2024 due to the rising demand for hygienic, airtight packaging that preserves product quality.

The healthcare segment is expected to witness the fastest growth rate from 2025 to 2032, propelled by the need for secure packaging of medical supplies, sterile equipment, and pharmaceuticals to meet strict regulatory standards.

Cling Wrap Machine Market Regional Analysis

• North America dominated the cling wrap machine market with the largest revenue share of 38.5% in 2024, driven by strong demand from the food processing and retail sectors, alongside the region’s well-established packaging industry.

• High consumer expectations for fresh and well-preserved food products, combined with technological advancements in automated packaging machinery, are further accelerating adoption.

• The market growth in this region is also supported by rising investments in modern packaging lines, stringent food safety regulations, and the increasing preference for eco-friendly cling film materials in commercial and industrial applications.

U.S. Cling Wrap Machine Market Insight

The U.S. cling wrap machine market captured the largest revenue share in 2024 within North America, fueled by the growing automation trend in food and beverage packaging and rising demand for high-speed, efficient wrapping solutions. The market is benefiting from the expansion of supermarkets, hypermarkets, and ready-to-eat meal providers that rely heavily on cling wrap for product preservation and presentation. In addition, the presence of leading machine manufacturers and a focus on operational efficiency through advanced technology integration are further driving market growth.

Europe Cling Wrap Machine Market Insight

The Europe cling wrap machine market is expected to witness the fastest growth rate from 2025 to 2032, primarily driven by strong demand from the bakery, meat, and fresh produce sectors. The region’s strict food safety and hygiene regulations are encouraging businesses to invest in high-quality, automated cling wrap machines. In addition, European manufacturers are focusing on energy-efficient and recyclable film-compatible machines to align with the EU’s sustainability goals, thereby boosting adoption across multiple industries.

U.K. Cling Wrap Machine Market Insight

The U.K. cling wrap machine market is expected to witness the fastest growth rate from 2025 to 2032, supported by the country’s dynamic food retail sector and rising demand for pre-packaged convenience foods. Increasing investments in advanced packaging equipment, combined with a strong push for reducing food waste, are encouraging supermarkets, food processors, and catering companies to upgrade their wrapping solutions.

Germany Cling Wrap Machine Market Insight

The Germany cling wrap machine market is expected to witness the fastest growth rate from 2025 to 2032, driven by its robust food processing industry and focus on automation for efficiency and quality assurance. The adoption of high-performance cling wrap machines is supported by Germany’s commitment to technological innovation, energy efficiency, and compliance with stringent packaging regulations. Manufacturers are increasingly integrating smart controls and monitoring systems to optimize performance and reduce downtime.

Asia-Pacific Cling Wrap Machine Market Insight

The Asia-Pacific cling wrap machine market is expected to witness the fastest growth rate from 2025 to 2032, fueled by rapid industrialization, rising disposable incomes, and increasing consumption of packaged food products in countries such as China, Japan, and India. The growing retail sector, expansion of modern food supply chains, and rising adoption of automated machinery in the region’s manufacturing facilities are driving significant market growth.

Japan Cling Wrap Machine Market Insight

The Japan cling wrap machine market is expected to witness the fastest growth rate from 2025 to 2032, supported by the country’s advanced food packaging standards and high consumer expectations for quality and freshness. The adoption of compact, automated wrapping machines is rising among small and medium-sized food enterprises, particularly in urban areas where convenience food demand is high. Technological innovation and precision engineering are key factors enhancing the appeal of Japanese-made cling wrap machines.

China Cling Wrap Machine Market Insight

The China cling wrap machine market accounted for the largest market revenue share in Asia-Pacific in 2024, driven by the country’s rapidly growing packaged food industry, expanding retail infrastructure, and increasing automation in food processing facilities. The market is also benefiting from the presence of numerous domestic machinery manufacturers offering competitively priced, high-speed wrapping solutions. Government initiatives to improve food safety standards and reduce post-harvest losses are further encouraging widespread adoption.

Cling Wrap Machine Market Share

The Cling Wrap Machine industry is primarily led by well-established companies, including:

- Nordipack (Italy)

- HarpakULMAPackaging LLC (U.S.)

- SMIPACK SPA (Italy)

- OCTOPUSMachines S.r.l. (Italy)

- ULMA Packaging (Spain)

- HarpakULMA (U.S.)

- OYSTAR Group (Germany)

- Darioten (China)

- TREPKONEwparaVC999 (Switzerland)

- CAMA S.p.A. (Italy)

- Ilapak (Switzerland)

- T.E.A.M. Group (U.K.)

Latest Developments in Global Cling Wrap Machine Market

- In February 2024, Innova Group, a leading packaging solution provider, introduced a new pallet stretch wrapper that is fully designed and manufactured in Spain using high-quality European components. The system incorporates the fastest rotary arm for wrapping, enabling higher speed and efficiency in pallet stabilization. This advancement is expected to improve packaging productivity for various industries, reduce operational time, and enhance load security during transportation, thereby positively influencing market competitiveness and adoption

- In January 2024, Robopac, a prominent end-of-line packaging machinery manufacturer, unveiled its five-stretch film wrapping solution for fruits and vegetables. The Robot S7, a self-propelled machine, is engineered to wrap and stabilize palletized loads of diverse shapes, sizes, and configurations. This innovation aims to deliver improved load protection, minimize product damage, and increase operational flexibility, which is likely to boost demand for advanced automated packaging solutions in the market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cling Wrap Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cling Wrap Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cling Wrap Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.