Global Cold Form Blister Packaging Market

Market Size in USD Billion

CAGR :

%

USD

7.34 Billion

USD

11.02 Billion

2024

2032

USD

7.34 Billion

USD

11.02 Billion

2024

2032

| 2025 –2032 | |

| USD 7.34 Billion | |

| USD 11.02 Billion | |

|

|

|

|

What is the Global Cold Form Blister Packaging Market Size and Growth Rate?

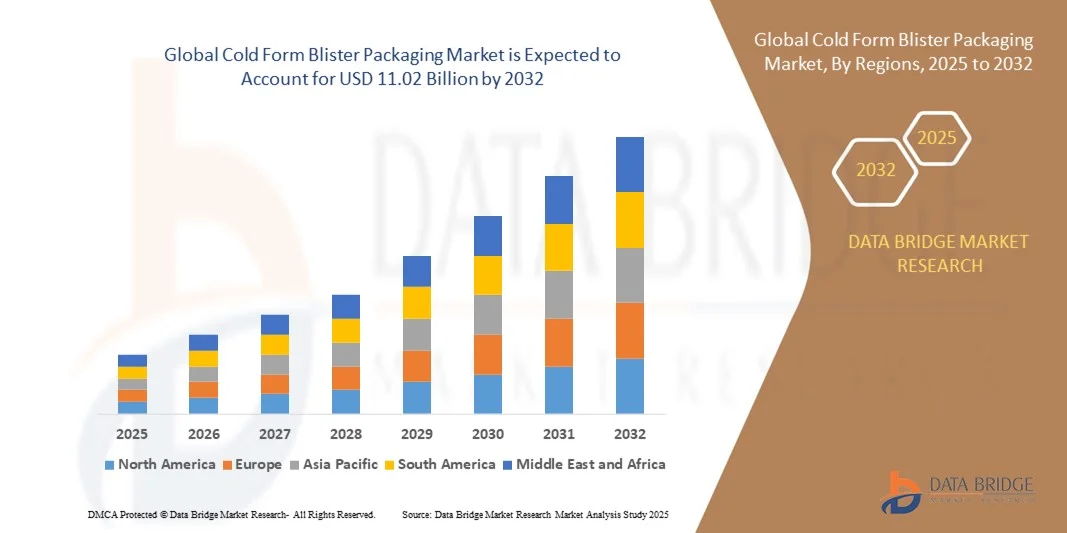

- The global cold form blister packaging market size was valued at USD 7.34 billion in 2024 and is expected to reach USD 11.02 billion by 2032, at a CAGR of 5.20% during the forecast period

- Rise in the preference for safety and protection to increase the longevity of the product is a vital factor driving the growth of cold form blister packaging market, also rise in the government initiatives to promote medical facilities, increase in the disposable income and rise in the urbanization worldwide are the major factors driving the growth of cold form blister packaging market swiftly

What are the Major Takeaways of Cold Form Blister Packaging Market?

- Rise in the demand from emerging economies will further boost various opportunities that will lead to the growth of cold form blister packaging market in the forecast period mentioned above

- However, slow speed of production of cold foam blister packaging and rise in the dearth of transparency of the packager and large size are the major factors which will restrain and challenge the growth of cold form blister packaging market in the forecast period mentioned above

- Asia-Pacific dominated the cold form blister packaging market with the largest revenue share of 41.3% in 2024, driven by the region’s strong pharmaceutical manufacturing base, expanding healthcare infrastructure, and increasing demand for cost-effective and protective packaging solutions

- The North America Cold Form Blister Packaging market is projected to grow at the fastest CAGR of 11.8% during the forecast period from 2025 to 2032, driven by rising pharmaceutical innovation, increasing regulatory emphasis on drug safety, and the shift toward tamper-evident packaging

- The Aluminum segment dominated the market with the largest revenue share of 48.6% in 2024, owing to its superior moisture, oxygen, and light barrier properties, which make it the preferred material for pharmaceutical and healthcare applications

Report Scope and Cold Form Blister Packaging Market Segmentation

|

Attributes |

Cold Form Blister Packaging Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Cold Form Blister Packaging Market?

Sustainability and Material Innovation Driving Packaging Advancements

- A major trend in the global cold form blister packaging market is the growing emphasis on sustainable and eco-friendly materials that minimize environmental impact while maintaining product integrity and barrier protection. The shift toward recyclable and biodegradable materials is reshaping packaging designs and manufacturing processes

- Manufacturers are focusing on aluminum-plastic hybrid laminates, PVC-free structures, and high-barrier films that ensure moisture, oxygen, and light protection while aligning with global sustainability goals. For instance, Amcor plc (Switzerland) introduced recyclable cold form blister packaging designed to reduce plastic use by up to 70%, reflecting the industry's push toward circular economy principles

- The rise of pharmaceutical traceability and anti-counterfeiting measures has also led to innovations in smart blister packs equipped with QR codes and NFC technology, allowing end-to-end product tracking and authentication. Such innovations enhance both consumer safety and regulatory compliance

- In addition, companies are investing in advanced forming technologies that improve material utilization and reduce waste during the production process, lowering the overall carbon footprint of packaging lines

- This trend toward sustainable, smart, and high-performance materials is transforming the Cold Form Blister Packaging market, encouraging key players to innovate and meet stringent pharmaceutical and environmental standards while maintaining product protection and shelf life

What are the Key Drivers of Cold Form Blister Packaging Market?

- The rising demand for long-term drug protection and the growing global pharmaceutical industry are major drivers of the cold form blister packaging market. The packaging’s excellent barrier properties against moisture, oxygen, and light make it ideal for sensitive drugs and biologics

- For instance, in June 2024, Constantia Flexibles (Austria) launched its “Coldform Foil Eco” line, offering PVC-free, recyclable materials that meet high barrier standards for pharmaceutical packaging, aligning with sustainability-driven market growth

- The increasing need for unit-dose packaging, particularly for geriatric and pediatric patients, is further propelling market demand, as cold form blister packaging ensures dosage accuracy and convenience

- Furthermore, stringent pharmaceutical safety regulations and the push for enhanced shelf life are encouraging the adoption of advanced cold form packaging materials

- The expanding use of cold form blister packaging in nutraceuticals, veterinary medicine, and medical devices is another key factor fueling market growth, supported by global healthcare modernization and rising consumer health awareness

Which Factor is Challenging the Growth of the Cold Form Blister Packaging Market?

- One of the major challenges in the cold form blister packaging market is the high production cost associated with aluminum-based materials and the complex forming process. This can limit adoption among small and medium pharmaceutical firms

- For instance, the need for specialized machinery and precision forming often increases setup and maintenance costs, especially in developing regions with cost-sensitive markets

- Another challenge lies in the recycling complexity of multi-layer laminates, as separating aluminum from polymer layers remains technologically challenging and costly. This creates sustainability concerns despite the push for eco-friendly materials

- In addition, supply chain disruptions and fluctuating prices of raw materials, particularly aluminum, can impact overall production efficiency and profit margins for packaging manufacturers

- Overcoming these challenges through technological advancements in recyclability, cost-effective material sourcing, and innovative barrier film alternatives will be critical for sustaining growth and achieving global adoption in the Cold Form Blister Packaging market

How is the Cold Form Blister Packaging Market Segmented?

The market is segmented on the basis of material type and application.

- By Material Type

On the basis of material type, the cold form blister packaging market is segmented into Oriented-Polyamide (OPA), Aluminum, Polyvinyl Chloride (PVC), Polypropylene (PP), and Others. The Aluminum segment dominated the market with the largest revenue share of 48.6% in 2024, owing to its superior moisture, oxygen, and light barrier properties, which make it the preferred material for pharmaceutical and healthcare applications. Aluminum ensures extended product shelf life and protection for sensitive drugs and formulations. Its widespread use in unit-dose packaging for tablets and capsules reinforces its leading position in the market.

The Polypropylene (PP) segment is expected to witness the fastest CAGR of 20.3% from 2025 to 2032, driven by its recyclability, flexibility, and cost-effectiveness. PP-based cold form blisters are increasingly used in food and consumer goods packaging, aligning with global trends toward sustainable and lightweight materials.

- By Application

On the basis of application, the cold form blister packaging market is segmented into Healthcare, Consumer Products, Electronics & Semiconductors, Food, Industrial Goods, Tablets & Capsules, Inhalants, and Others. The Healthcare segment held the largest revenue share of 55.2% in 2024, primarily due to the rising demand for secure, tamper-evident, and moisture-resistant packaging solutions for pharmaceuticals. Cold form blisters are widely used for tablets, capsules, and inhalants, ensuring product integrity and dosage precision while complying with stringent regulatory standards.

The Consumer Products segment is projected to record the fastest CAGR of 19.7% from 2025 to 2032, fueled by increasing adoption in packaging for personal care items, batteries, and small electronics. The growing focus on product safety, visual appeal, and extended shelf life is driving cold form blister usage across diverse consumer applications, broadening the market’s scope beyond pharmaceuticals.

Which Region Holds the Largest Share of the Cold Form Blister Packaging Market?

- Asia-Pacific dominated the cold form blister packaging market with the largest revenue share of 41.3% in 2024, driven by the region’s strong pharmaceutical manufacturing base, expanding healthcare infrastructure, and increasing demand for cost-effective and protective packaging solutions

- The rapid rise in generic drug production, coupled with the growing consumption of over-the-counter (OTC) medicines, has accelerated the adoption of cold form blister packs for their superior barrier properties and compliance with international safety standards

- Moreover, government support for local pharmaceutical production and investments in advanced packaging technology are strengthening the region’s leadership. Countries such as China, India, and Japan are at the forefront of market expansion, driven by their robust export networks and increasing regulatory emphasis on quality assurance in pharmaceutical packaging

China Cold Form Blister Packaging Market Insight

The China cold form blister packaging market captured the largest revenue share of 62% in 2024 within the Asia-Pacific region, driven by the country’s position as a leading global producer of pharmaceutical formulations and packaging materials. The rapid expansion of domestic drug manufacturing, coupled with stringent government regulations to ensure product safety and shelf life, is bolstering demand. Furthermore, local packaging firms are investing in aluminum-based barrier solutions to meet both domestic and export standards. China’s ongoing push for sustainability in packaging is also stimulating innovation in recyclable and eco-friendly cold form materials.

India Cold Form Blister Packaging Market Insight

The India cold form blister packaging market is projected to expand at a robust CAGR during the forecast period, driven by the country’s thriving pharmaceutical export industry and growing demand for protective packaging for tablets and capsules. Government initiatives such as “Make in India” are encouraging local production of packaging materials, reducing import dependency. In addition, the shift toward unit-dose packaging for enhanced patient safety and convenience is fueling adoption. The increasing presence of contract manufacturing organizations (CMOs) and global pharmaceutical companies in India is further contributing to market growth.

Japan Cold Form Blister Packaging Market Insight

The Japan cold form blister packaging market is witnessing steady growth due to the country’s aging population, high healthcare expenditure, and demand for precision medicine packaging. Japanese pharmaceutical companies are adopting advanced cold form materials to ensure drug stability and compliance with global standards. Moreover, Japan’s focus on sustainable packaging is driving innovation in PVC-free and recyclable structures. The integration of automation in blister packaging lines and the strong presence of high-quality healthcare products are further supporting market expansion.

Which Region is the Fastest Growing Region in the Cold Form Blister Packaging Market?

The North America cold form blister packaging market is projected to grow at the fastest CAGR of 11.8% during the forecast period from 2025 to 2032, driven by rising pharmaceutical innovation, increasing regulatory emphasis on drug safety, and the shift toward tamper-evident packaging. The region’s focus on sustainable and child-resistant packaging solutions is also fostering market growth.

U.S. Cold Form Blister Packaging Market Insight

The U.S. cold form blister packaging market accounted for 83% of the North American revenue share in 2024, fueled by the country’s robust pharmaceutical R&D ecosystem and growing demand for high-barrier packaging to extend drug shelf life. Increasing adoption of unit-dose and compliance packaging in healthcare facilities and at-home care is driving demand. Furthermore, major packaging companies are investing in recyclable aluminum laminates to align with environmental goals. The presence of industry leaders such as Amcor plc (Switzerland) and Bemis Company, Inc. (U.S.), with advanced production facilities in North America, strengthens the region’s growth outlook.

Canada Cold Form Blister Packaging Market Insight

The Canada cold form blister packaging market is expected to expand at a substantial CAGR, supported by the country’s growing pharmaceutical exports and government-backed healthcare reforms. The increasing consumption of prescription and OTC medications, along with the demand for eco-conscious packaging materials, is stimulating market growth. Manufacturers are focusing on innovation in cold form laminates that combine high-barrier performance with recyclability, positioning Canada as a key player in sustainable pharmaceutical packaging within North America.

Which are the Top Companies in Cold Form Blister Packaging Market?

The cold form blister packaging industry is primarily led by well-established companies, including:

- Amcor plc (Switzerland)

- Bemis Company, Inc. (U.S.)

- CONSTANTIA (Austria)

- Bilcare Research (India)

- Winpak Ltd. (Canada)

- Uflex Limited (India)

- Svam Toyal Packaging Industries Pvt. Ltd. (India)

- Tekni-Plex (U.S.)

- Essentra plc (U.K.)

- Ningbo Dragon Packaging Technology Co., Ltd. (China)

- Rollprint (U.S.)

- Wasdell Packaging Group (U.K.)

- Haishun New Pharmaceutical Packaging Ltd. (China)

- Flexi Pack (India)

- Accupack (India)

- WISESORBENT TECHNOLOGY LLC (U.S.)

- Aphena Pharma Solutions (U.S.)

- Nuplas Industries (U.K.)

- ROPACK INC. (Canada)

- Green Pack Foils Pvt. Ltd. (India)

What are the Recent Developments in Global Cold Form Blister Packaging Market?

- In July 2023, Constantia Flexibles (Austria) introduced its latest pharmaceutical packaging solution, the cold form foil REGULA CIRC, which replaces traditional PVC with a polyethylene (PE) sealing layer. This innovation reduces plastic content while increasing the proportion of aluminum, promoting sustainability and aligning with the circular economy principles. This launch strengthens Constantia Flexibles’ commitment to eco-friendly pharmaceutical packaging solutions.

- In June 2023, TekniPlex Healthcare (U.S.) expanded its North American presence by inaugurating a new 200,000-square-foot manufacturing plant in Madison, Wisconsin, U.S. The facility enhances the company’s lamination capacity for materials such as PET, nylon, paper, foil, PE, EAA, and ionomer in both peelable and non-peelable structures. This expansion significantly boosts TekniPlex’s production capabilities and strengthens its regional supply network.

- In July 2021, Wasdell Group (U.K.) acquired Planned Packaging Limited & Planned Packaging Films Limited (PPF), specialized suppliers to the medical device and pharmaceutical sectors. The acquisition enhances Wasdell’s capabilities as a fully integrated supplier, supporting its expanding client base in the life sciences and medical device industries. This strategic move reinforces Wasdell’s market leadership and broadens its service portfolio.

- In August 2020, Perlen Packaging (Switzerland) established a new film coating plant at its operating site in Brazil and co-financed a calendaring facility for mono film production. This initiative aims to strengthen the company’s footprint and operations across Latin America. The expansion positions Perlen Packaging for stronger growth in the Latin American pharmaceutical packaging sector.

- In August 2020, Liveo Research Group (Switzerland) announced a 20,000-ton capacity expansion at its Boetzingen, Germany facility to enhance coating capabilities for high-performance barrier films used in pharmaceutical blister packaging. This investment strengthens Liveo’s competitive position in the high-barrier packaging segment

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cold Form Blister Packaging Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cold Form Blister Packaging Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cold Form Blister Packaging Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.