Global Cold Gas Spray Equipment Market

Market Size in USD Million

CAGR :

%

USD

230.69 Million

USD

343.44 Million

2024

2032

USD

230.69 Million

USD

343.44 Million

2024

2032

| 2025 –2032 | |

| USD 230.69 Million | |

| USD 343.44 Million | |

|

|

|

|

Cold Gas Spray Equipment Market Size

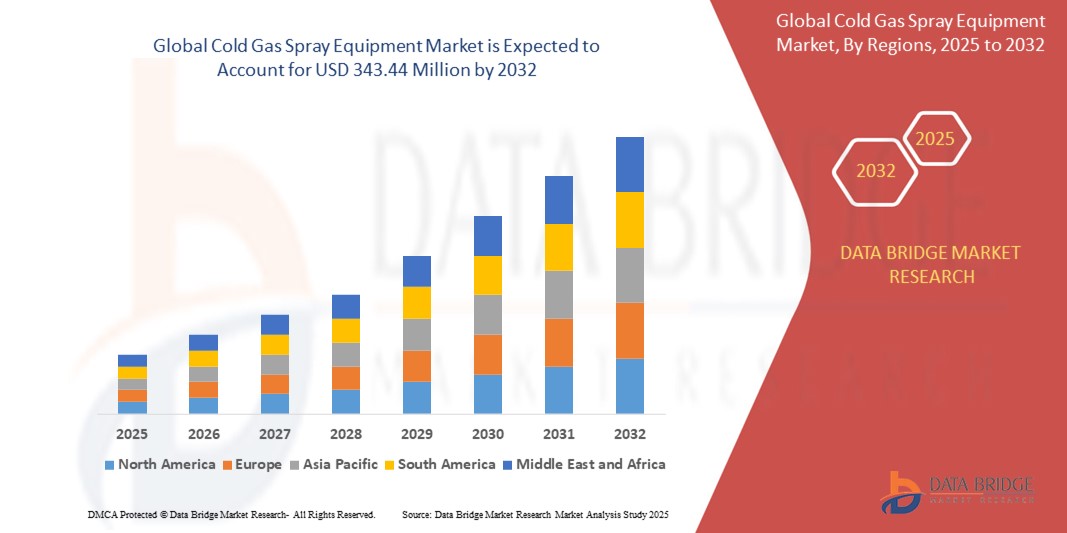

- The global cold gas spray equipment market was valued at USD 230.69 million in 2024 and is expected to reach USD 343.44 million by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 5.10%, primarily driven by the increasing demand for advanced coating technologies across various industrial applications

- This growth is driven by factors such as the rising need for high-performance coatings

Cold Gas Spray Equipment Market Analysis

- The global cold gas spray equipment market is experiencing significant growth, driven by advancements in coating technologies and increased demand for durable, high-performance coatings

- Cold gas spray technology offers several advantages, including minimal thermal distortion during application, which preserves the integrity of sensitive substrates

- This characteristic makes it particularly suitable for coating complex geometries and intricate designs that traditional thermal spray methods may struggle to handle

- Furthermore, cold gas spray facilitates effective material deposition with reduced oxidation, enhancing the performance and durability of coated components. As industries such as aerospace, automotive, and electronics increasingly prioritize the longevity and performance of their products, the adoption of cold gas spray technology is expected to surge

- In addition, the technology's capability for repairing worn parts and enhancing surface properties positions it as a viable solution in various applications, driving further growth in the market

- Overall, cold gas spray represents a significant advancement in manufacturing and surface engineering, offering a versatile and efficient method for enhancing material properties and extending the lifespan of components

Report Scope and Cold Gas Spray Equipment Market Segmentation

|

Attributes |

Cold Gas Spray Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Cold Gas Spray Equipment Market Trends

“Integration of Nanotechnology in Cold Gas Spray Coatings”

- A notable trend in the cold gas spray equipment market is the increasing integration of nanotechnology into coatings

- This advancement allows for the deposition of nanostructured and amorphous materials, which are particularly beneficial in industries requiring high-performance coatings

- For instance, in the aerospace sector, these advanced coatings can enhance the durability and functionality of components without adding significant weight

- The ability to apply such materials effectively using cold gas spray technology is driving its adoption across various industries seeking to improve product performance and longevity

Cold Gas Spray Equipment Market Dynamics

Driver

“Rising Demand in Aerospace and Defense Sectors”

- The aerospace and defense industries are significant drivers of the cold gas spray equipment market

- Cold gas spray technology is increasingly utilized for coating and repairing critical components such as turbine blades and structural parts

- This method extends the lifespan of components, reduces maintenance costs, and enhances performance, which is crucial in these sectors

- The emphasis on maintaining and refurbishing high-value components in aerospace and defense applications is propelling the demand for cold gas spray equipment

Opportunity

“Adoption in Additive Manufacturing Processes”

- An emerging opportunity in the cold gas spray equipment market lies in its integration with additive manufacturing processes

- Cold gas spray technology can be used to repair and improve 3D-printed components, offering a solution to enhance the quality and durability of additive manufactured parts

- This synergy is particularly beneficial in industries such as aerospace, where complex geometries and material properties are critical

- The combination of additive manufacturing and cold gas spray technology opens new avenues for producing high-performance components with improved material properties

Restraint/Challenge

“High Initial Investment and Operational Costs”

- A significant restraint in the cold gas spray equipment market is the high initial investment and operational costs associated with the technology

- The specialized equipment, including high-pressure gas systems and advanced control units, requires substantial capital expenditure

- Additionally, operating and maintaining cold gas spray systems necessitate specialized technical knowledge, which can lead to increased operational costs

- These financial barriers may limit the adoption of cold gas spray technology, especially among smaller manufacturers or those with limited budgets

Cold Gas Spray Equipment Market Scope

The market is segmented on the basis type, material, end-use, and application.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Material |

|

|

By End-Use |

|

|

By Application |

|

Cold Gas Spray Equipment Market Regional Analysis

“North America is the Dominant Region in the Cold Gas Spray Equipment Market”

- The region's robust aerospace and defense industries are significant drivers, utilizing cold gas spray technology for coating and repairing critical components such as turbine blades and structural parts

- North America's strong emphasis on advanced manufacturing technologies, including additive manufacturing, further propels the demand for cold gas spray equipment

- The presence of leading companies and research institutions fosters innovation, enhancing the capabilities and applications of cold gas spray technology

- The region is expected to maintain its leadership, with sustained growth anticipated due to continuous investments in high-performance coating solutions

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia-Pacific is witnessing the highest growth rate in the cold gas spray equipment market, driven by rapid industrialization in countries such as China, Japan, and India

- The region's burgeoning aerospace and automotive industries are increasingly adopting cold gas spray technology for component repair and coating, enhancing performance and longevity

- Significant investments in infrastructure development across the region contribute to the rising demand for durable and efficient coating solutions

- The integration of cold gas spray technology with additive manufacturing processes presents new opportunities for producing high-performance components

- With a growing manufacturing base and increasing adoption of advanced coating technologies, Asia Pacific is poised to become a key player in the global cold gas spray equipment market

Cold Gas Spray Equipment Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- CenterLine (Windsor) Limited (Canada)

- Plasma Giken Co., Ltd. (Japan)

- TWI Ltd. (U.K.)

- SpiraLinks Corporation (U.S.)

- Kaiser AG (Liechtenstein)

- Impact Innovations GmbH (Germany)

- Flame Spray Technologies B.V. (Netherlands)

- VRC Metal Systems (U.S.)

- ALTRAD (France)

- Linde PLC 2018 (U.K.)

- OC Oerlikon Management AG (Switzerland)

- GTV Verschleißschutz GmbH (Germany)

- L3Harris Technologies, Inc. (U.S.)

- Airbus (U.K.)

Latest Developments in Global Cold Gas Spray Equipment Market

- In March 2023, Oerlikon, a leader in polymer processing, surface engineering, and additive manufacturing, acquired Riri. This strategic acquisition enhances Oerlikon's capabilities, particularly in coatings, allowing the company to broaden its product portfolio and strengthen its position in the market, ultimately driving innovation and customer solutions in surface technologies

- In March 2023, Linde, a prominent player in the industrial gases and engineering sector, unveiled its cutting-edge gas supply solution for post-additive manufacturing, named LINSPRAY Connect. This breakthrough aims to bolster the reliability and safety of the cold spraying process, addressing the surging demand for precision in post-additive manufacturing

- In 2021, Plasma Giken Co., Ltd. unveiled the PCS-1000 and Portable cold gas spray equipment, marking a pivotal moment in their product lineup. This introduction stands out due to its emphasis on boosting the adaptability and effectiveness of cold gas spraying technologies for diverse industrial uses. The PCS-1000 is equipped with cutting-edge features that facilitate accurate material deposition, empowering users to obtain superior coatings while minimizing thermal effects

- In November 2021, EWI launched a new Cold Spray Research Center aimed at exploring and advancing the potential of cold spray technology. This initiative focuses on innovative applications and enhancements, driving research that could lead to improved manufacturing processes and materials, ultimately benefiting various industries through cutting-edge solutions

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cold Gas Spray Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cold Gas Spray Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cold Gas Spray Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.