Global Computer Numerical Control Machines Market

Market Size in USD Billion

CAGR :

%

USD

72.50 Billion

USD

91.80 Billion

2024

2032

USD

72.50 Billion

USD

91.80 Billion

2024

2032

| 2025 –2032 | |

| USD 72.50 Billion | |

| USD 91.80 Billion | |

|

|

|

|

Computer Numerical Control Machines Market Size

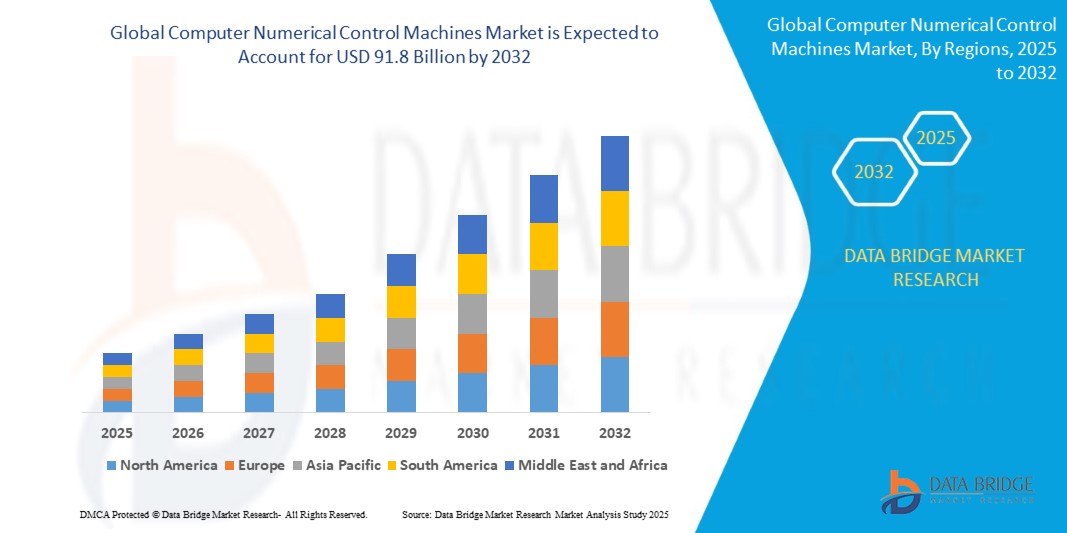

- The Computer Numerical Control Machines Market was valued at USD 72.5 billion in 2024 and is projected to reach USD 91.8 billion by 2032, growing at a CAGR of 3.4% during the forecast period.

- Growth is driven by the increasing adoption of automation in manufacturing, demand for high-speed machining, mass production needs, and integration of AI and IoT technologies to improve machine precision and productivity.

Computer Numerical Control Machines Market Analysis

- CNC machines enable automation, consistency, and accuracy in metalworking, shaping, and cutting applications across various industries.

- Modern CNC systems are being equipped with AI-based programming, remote monitoring, predictive maintenance, and cloud connectivity to enable smart factory operations.

- Demand is particularly strong in the automotive and aerospace sectors for complex component manufacturing, as well as electronics and medical devices for miniaturized, high-precision parts.

- The integration of CAD/CAM software with CNC machines is reducing product development cycles and supporting mass customization trends.

- Manufacturers are increasingly opting for multi-axis machines to enhance flexibility, reduce tooling time, and increase operational throughput.

Report Scope and Computer Numerical Control Machines Market Segmentation

|

Attributes |

Computer Numerical Control Machines Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Computer Numerical Control Machines Market Trends

AI-Driven Machining, Multi-Axis Integration, and Smart Manufacturing

- A key and rapidly accelerating trend in the CNC Machines Market is the integration of artificial intelligence (AI) and machine learning (ML) into CNC control systems to optimize machining parameters, predictive maintenance, and production quality in real time.

- The rise of multi-axis CNC machines (5-axis and beyond) is enabling manufacturers to produce complex geometries with fewer setups, improving accuracy and cycle times while reducing labor costs and errors.

- Adoption of smart manufacturing and Industry 4.0 practices is driving the demand for interconnected CNC machines that offer real-time monitoring, digital twin capabilities, and seamless integration with enterprise resource planning (ERP) and manufacturing execution systems (MES).

- Hybrid CNC machines that combine additive and subtractive manufacturing processes are gaining momentum, especially in aerospace, defense, and automotive sectors, where prototyping and lightweight component fabrication are critical.

- Manufacturers are increasingly prioritizing sustainability by adopting energy-efficient CNC systems, advanced cooling technologies, and low-waste machining strategies that align with environmental compliance requirements.

Computer Numerical Control Machines Market Dynamics

Driver

Mass Customization and Automation Demand Boosting CNC Adoption

- The demand for mass customization, especially in industries like automotive, aerospace, and consumer electronics, is pushing manufacturers toward highly flexible CNC machining solutions that can handle small batch sizes with high precision.

- Automation in manufacturing, driven by labor shortages and rising wages, is accelerating the deployment of CNC machines integrated with robotic arms, automated tool changers, and smart sensors to improve throughput and efficiency.

- Digital transformation initiatives are prompting manufacturers to invest in advanced CNC systems equipped with AI, IoT connectivity, and real-time analytics to optimize operations and reduce downtime.

- The growth of automotive electrification and lightweighting trends is increasing the need for precision machining of aluminum, composites, and exotic alloys—applications well-suited to CNC technologies.

- Government initiatives supporting industrial automation and smart factory development (such as Industry 4.0 and Made in China 2025) are fueling CNC machine investments across both developed and emerging markets.

Restraint/Challenge

High Capital Investment and Skill Gap Limiting Adoption

- CNC machines, particularly multi-axis or hybrid models, involve significant capital expenditure in terms of machinery cost, tooling, software licenses, and setup, creating entry barriers for small manufacturers.

- Operating and maintaining advanced CNC machines requires a skilled workforce proficient in CAD/CAM programming, CNC code optimization, and equipment calibration—skills that are in short supply globally.

- The integration of CNC systems into existing production lines or digital ecosystems can be complex, requiring customized interfaces, middleware, and compatibility checks with MES and ERP software.

- Small and medium enterprises (SMEs) often face challenges related to financing, training, and managing digital transformation—slowing down the rate of CNC technology adoption.

- The cost of downtime due to software glitches, tool wear, or programming errors can be high, particularly in high-volume manufacturing environments, requiring strong preventive maintenance and support infrastructure.

Computer Numerical Control Machines Market Scope

The market is segmented on the basis of product type, offering and end use

• By Product Type

Product types include Lathe Machines, Milling Machines, Laser Machines, Grinding Machines, and Welding Machines.Lathe Machines hold the largest market share in 2025 due to their widespread use in metal cutting, shaping, and part manufacturing across automotive and general engineering sectors. Milling Machines are extensively adopted in mold-making, aerospace, and die industries for precision shaping. Laser Machines are gaining traction in electronics and medical device manufacturing for their accuracy and minimal material wastage. Grinding Machines are critical in finishing and precision surface machining, while Welding Machines are increasingly used in heavy fabrication, railways, and construction.

- By Offering

Offerings are segmented into Machines, Parts & Accessories, and Services.Machines dominate the segment as demand rises for multi-axis, high-speed CNC systems integrated with automation. Parts & Accessories—including tool holders, spindles, controllers, and rotary tables—support ongoing customization and maintenance needs. Services such as installation, training, predictive maintenance, and remote diagnostics are growing steadily, particularly among SMEs implementing smart manufacturing for the first time.

- By End User

End users include Automotive, Aerospace & Defense, Electronics, Healthcare, Industrial Machinery, and Others.Automotive leads the end-user segment owing to the high precision requirements in engine components, transmissions, and EV parts. Aerospace & Defense follows closely due to its demand for machining of complex alloys and composites. Electronics leverages CNC systems for intricate PCB drilling and component fabrication. Healthcare is witnessing rising use of CNC in surgical instruments, implants, and diagnostic equipment. Industrial Machinery uses CNC systems to manufacture heavy-duty tools and infrastructure components. The Others category includes education and R&D institutes that are increasingly incorporating CNC machines for prototyping and training purposes.

Computer Numerical Control Machines Market Regional Analysis

- North America dominates the Computer Numerical Control (CNC) Machines Market with the largest revenue share in 2025, driven by robust manufacturing activity, automation in aerospace and automotive sectors, and the early adoption of Industry 4.0 technologies. The presence of leading CNC machine manufacturers and high investment in R&D across U.S. and Canada further boosts market expansion.

- Additionally, high investments in advanced manufacturing, including multi-axis CNC systems, AI-integrated controls, and IoT-enabled machining, are boosting regional innovation. The presence of major machine tool manufacturers and R&D hubs in the United States and Canada continues to enhance growth potential.

- The Europe CNC Machines Market is expected to grow steadily during the forecast period, driven by rising automation across automotive and heavy machinery sectors. Initiatives like Germany’s Industry 4.0 and France’s “Industrie du Futur” are accelerating the adoption of CNC technologies in small and medium enterprises (SMEs) across the region.

- The Asia-Pacific region is poised to grow at the fastest CAGR through 2032, driven by rapid industrialization, infrastructure development, and growing investments in smart manufacturing across China, India, Japan, and South Korea. Cost advantages and increasing foreign direct investment (FDI) in production facilities make the region highly attractive for CNC machine vendor.

- The MEA CNC Machines Market is witnessing gradual growth, primarily fueled by economic diversification initiatives in countries like the UAE and Saudi Arabia. These nations are investing heavily in non-oil sectors, including aerospace, automotive assembly, and defense manufacturing, driving demand for precision machining tools like CNC machines.

- The South America CNC Machines Market is projected to grow steadily through 2032, driven by increased investment in industrial automation and government support for manufacturing localization in countries like Brazil, Argentina, and Colombia.

United States

The U.S. CNC Machines Market captured the largest revenue share within North America in 2025. The country benefits from advanced manufacturing infrastructure, strong aerospace and defense production, and increasing reshoring of industrial capabilities. Ongoing government initiatives supporting domestic manufacturing and high demand for CNC retrofitting in legacy systems are driving sustained growth.

Germany

Germany leads the European CNC market owing to its engineering excellence and dominance in machine tools, automotive production, and advanced manufacturing solutions. The country’s industrial base is increasingly integrating CNC machines with MES and ERP systems to improve flexibility, traceability, and operational efficiency in smart factories.

France

France's CNC market is expanding with rising investments in aerospace, precision engineering, and healthcare manufacturing. Supportive government policies, digital transformation in SMEs, and focus on additive and subtractive hybrid manufacturing are fostering adoption of high-speed and multi-axis CNC machines across industries.

Japan

Japan’s CNC market is driven by its leadership in robotics, electronics, and automotive innovation. The country is focusing on next-gen CNC machines integrated with AI, real-time monitoring, and compact high-speed spindles—enhancing productivity in ultra-precision applications such as semiconductor tooling and medical device manufacturing.

China

China dominates the Asia-Pacific CNC machines market in revenue share as of 2025. Strong government support for domestic manufacturing, rising exports of precision parts, and demand for automated metalworking in automotive and electronics sectors are propelling CNC adoption. The "Made in China 2025" initiative continues to support domestic production of advanced CNC systems.

Saudi Arabia

Saudi Arabia is emerging as a strategic hub for industrial automation and precision manufacturing in the MEA CNC machines market. Backed by the Saudi Vision 2030 initiative, the country is investing heavily in non-oil sectors, including aerospace, automotive components, and defense manufacturing. The government’s push to develop smart industrial zones and attract foreign direct investment is accelerating demand for CNC machinery, particularly in metalworking and 3D milling applications.

Brazil

Brazil leads the South American CNC machines market due to its robust automotive, aerospace, and machinery sectors. The country is witnessing steady modernization of production facilities, with increasing adoption of multi-axis CNC systems and robotic integration. Incentives for industrial automation, rising exports, and the need for precision and efficiency in metal fabrication are driving CNC machine penetration across key manufacturing zones like São Paulo and Minas Gerais.

Computer Numerical Control Machines Market Share

The Computer Numerical Control (CNC) Machines Market is primarily led by a combination of global CNC manufacturers, automation leaders, and advanced precision engineering companies. These players are actively investing in smart manufacturing, multi-axis technologies, and AI-integrated control systems to enhance performance, precision, and scalability across industries:

- AMADA MACHINERY CO., LTD. (Japan)

- Amera Seiki (US)

- DMG MORI CO., LTD. (Japan)

- General Technology Group Dalian Machine Tool Corporation (China)

- DATRON AG (Germany)

- FANUC CORPORATION (Japan)

- Haas Automation, Inc. (US)

- Hurco Companies, Inc. (US)

- Mitsubishi Electric Corporation (Japan)

- OKUMA Corporation (Japan)

- Shenyang Machine Tool Part Co., Ltd. (China)

- YAMAZAKI MAZAK CORPORATION (Japan)

Latest Developments in Computer Numerical Control Machines Market

- In February 2025, DMG MORI introduced its next-generation LASERTEC 30 DUAL SLM system for additive-subtractive manufacturing, combining metal 3D printing and 5-axis milling for hybrid production applications in aerospace and medical sectors.

- In January 2025, FANUC CORPORATION launched its upgraded ROBODRILL α-DiB Plus Series CNC machine, offering faster tool change times and enhanced spindle performance, aimed at improving cycle times for electronics and automotive component manufacturers.

- In November 2024, YAMAZAKI MAZAK CORPORATION unveiled its INTEGREX i-H Series, featuring integrated automation, AI-powered tool wear monitoring, and digital twin support for predictive maintenance in smart factories.

- In September 2024, Haas Automation, Inc. rolled out a new line of UMC-1000SS 5-axis CNC machines, with enhanced speed and accuracy for large-scale precision components, targeting aerospace and defense manufacturing.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Computer Numerical Control Machines Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Computer Numerical Control Machines Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Computer Numerical Control Machines Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.