Global Computerized Numerical Control Cnc Router Market

Market Size in USD Million

CAGR :

%

USD

722.16 Million

USD

1,168.50 Million

2024

2032

USD

722.16 Million

USD

1,168.50 Million

2024

2032

| 2025 –2032 | |

| USD 722.16 Million | |

| USD 1,168.50 Million | |

|

|

|

|

Computerized Numerical Control (CNC) Router Market Size

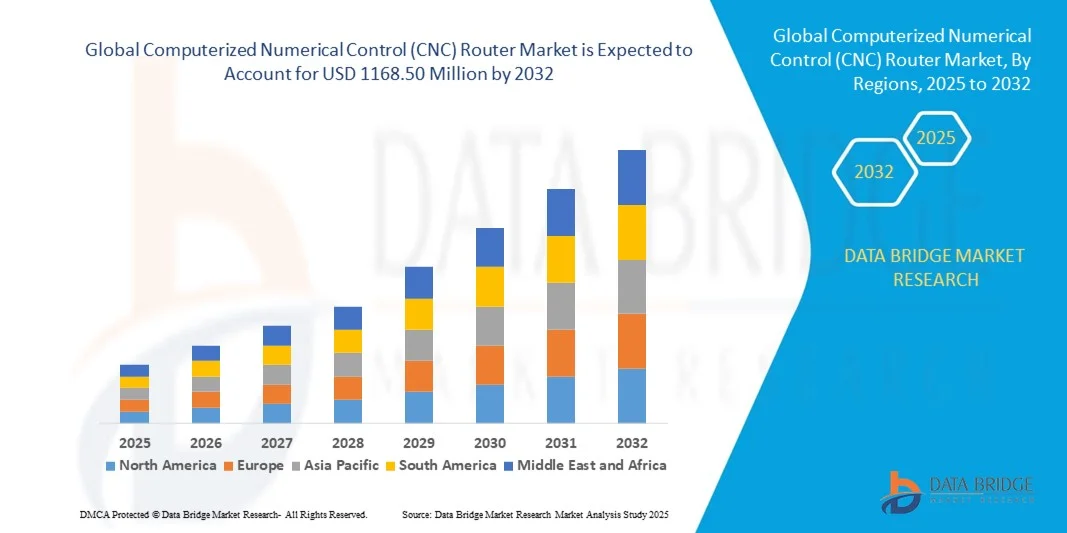

- The global computerized numerical control (CNC) router market size was valued at USD 722.16 million in 2024 and is expected to reach USD 1168.50 million by 2032, at a CAGR of 6.2% during the forecast period

- The market growth is largely fueled by the increasing adoption of automation and advanced manufacturing technologies across industries, driving demand for precision, efficiency, and reduced human intervention in production processes. Rising emphasis on mass customization, cost reduction, and higher productivity is further accelerating the uptake of computerized numerical control routers in global markets

- Furthermore, growing applications of computerized numerical control routers in woodworking, metalworking, and stone cutting, along with their ability to deliver complex designs with high accuracy, are making them indispensable tools in modern manufacturing. These factors collectively enhance operational efficiency, leading to significant market expansion

Computerized Numerical Control (CNC) Router Market Analysis

- Computerized numerical control routers are computer-controlled cutting machines used for engraving, drilling, milling, and cutting a wide variety of materials including wood, metal, plastics, glass, and stone. These systems ensure high precision, repeatability, and efficiency, making them vital in industries such as automotive, construction, furniture, and industrial manufacturing

- The escalating demand for computerized numerical control routers is primarily driven by the rise of Industry 4.0 practices, rapid growth in the furniture and construction industries, and the need for automated, cost-effective production solutions. Their versatility in handling different materials and integration with CAD/CAM software is further boosting market adoption across diverse applications

- Asia-Pacific dominated the computerized numerical control (CNC) router market in 2024, due to rapid industrialization, growing manufacturing output, and increasing adoption of automation technologies across the region

- North America is expected to be the fastest growing region in the computerized numerical control (CNC) router market during the forecast period due to increasing industrial automation, adoption of advanced manufacturing technologies, and rising demand for high-precision production across automotive, aerospace, and woodworking sectors

- Industrial computerized numerical control routers segment dominated the market with a market share of 65.8% in 2024, due to their high precision, durability, and capacity to handle continuous, large-scale production requirements. They are extensively used in manufacturing industries such as automotive, aerospace, and furniture production, where consistent quality and efficiency are critical. The wide availability of advanced features such as multi-axis machining, automatic tool changers, and integration with CAD/CAM software enhances their demand among professional manufacturers

Report Scope and Computerized Numerical Control (CNC) Router Market Segmentation

|

Attributes |

Computerized Numerical Control (CNC) Router Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Computerized Numerical Control (CNC) Router Market Trends

Integration of Industry 4.0 and IoT in CNC Routers

- The computerized numerical control router market is witnessing transformative growth fueled by the integration of Industry 4.0 concepts and the Internet of Things (IoT), enabling smarter and more connected manufacturing environments. Real-time data monitoring, machine-to-machine communication, and predictive maintenance have become key features enhancing operational efficiency and reducing downtime

- For instance, Thermwood Corporation has developed computerized numerical control routers embedded with IoT sensors that provide continuous performance monitoring and enable proactive maintenance scheduling. Similarly, Laguna Tools offers routers compatible with Industry 4.0 standards, allowing seamless integration into smart factory ecosystems

- The adoption of advanced software solutions leveraging artificial intelligence and cloud computing allows computerized numerical control routers to optimize cutting paths, improve precision, and facilitate remote diagnostics. These intelligent systems reduce human intervention while enhancing production consistency and quality control

- Manufacturers across automotive, aerospace, woodworking, and signage industries are increasingly investing in automated computerized numerical control router solutions aligned with smart manufacturing initiatives. This direction supports better resource utilization and accelerates innovation cycles, helping companies maintain competitive advantages

- The proliferation of affordable compact computerized numerical control routers that integrate IoT and Industry 4.0 capabilities has expanded accessibility to small and medium-sized enterprises. This trend is democratizing advanced manufacturing technologies beyond large industrial players, fostering broader adoption

- The ongoing emphasis on Industry 4.0 and connected manufacturing is expected to remain a dominant trend shaping the computerized numerical control router market. Continuous innovation in IoT integration and advanced analytics will drive future growth and operational excellence

Computerized Numerical Control (CNC) Router Market Dynamics

Driver

Rising Demand for Automation and Precision in Manufacturing

- Increasing automation demands from manufacturing sectors are propelling growth in computerized numerical control router adoption, as industries seek highly precise and repeatable machining to meet quality and efficiency targets. The need to reduce manual intervention while enhancing output consistency is critical across automotive, aerospace, and wood product manufacturing

- For instance, C.R. Onsrud Inc. has deployed advanced computerized numerical control routers in automotive component fabrication to ensure precision tolerances and process repeatability. iGoldenCNC’s solutions for aerospace manufacturing emphasize automation for high-complexity parts production with minimal error margins

- Advances in computerized numerical control software and hardware contribute to faster production cycles and improved surface finishes, meeting the stringent requirements of modern manufacturing. The ability to handle complex designs, composite materials, and multi-axis operations also supplements demand from high-tech sectors

- Manufacturers benefit from computerized numerical control routers by achieving cost savings through reduced waste, lower labor costs, and quicker machine setup times. This value proposition is particularly relevant for industries undergoing digital transformation and emphasizing Lean manufacturing principles

- Growing customization trends in industrial and consumer goods require flexible production capabilities, which computerized numerical control routers support effectively. This adaptability, combined with precision and automation, is reinforcing the market’s expansion in various application segments

Restraint/Challenge

High Initial Investment and Maintenance Costs

- The substantial capital expenditure required for acquiring advanced computerized numerical control routers and the ongoing costs associated with maintenance present significant hurdles for market growth. High upfront costs restrict access, particularly for small and emerging manufacturers with limited financial resources

- For instance, smaller enterprises in Asia, despite growing interest, often delay computerized numerical control router adoption due to costs of equipment purchase, installation, and skilled operator training. The financial burden of routine maintenance, spare parts, and software upgrades further complicates affordability

- Advanced computerized numerical control machines require regular calibration, software updates, and sometimes costly component replacements, which add to total cost of ownership. The need for specialized technical staff to manage operations and troubleshoot contributes to operational expenses, deterring some users

- Fluctuations in raw material prices and supply chain challenges can increase equipment costs, affecting budget planning and investment decisions. These factors create uncertainty and raise barriers for manufacturers to transition fully to automated computerized numerical control router systems

- In conclusion, while computerized numerical control routers offer significant operational benefits, the high initial and maintenance costs remain a notable challenge. Addressing these barriers through cost innovations, leasing options, and training programs will be essential to widening adoption and sustaining long-term market growth

Computerized Numerical Control (CNC) Router Market Scope

The market is segmented on the basis of type, category, product, application, sales channel, and end-use industry.

- By Type

On the basis of type, the computerized numerical control router market is segmented into stationary gantry type, movable gantry type, and cross-feed unit type. The stationary gantry type segment dominated the market in 2024, capturing the largest revenue share, owing to its stability, precision, and suitability for high-volume industrial operations. These routers are preferred in industries requiring consistent accuracy over large workpieces, such as metalworking and woodworking. Their robust construction and ability to handle heavier materials make them a reliable choice for long-term production setups. In addition, the stationary gantry type supports a wide variety of tooling options, enhancing operational flexibility and overall efficiency.

The movable gantry type segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by its flexibility and space-efficient design. Movable gantry routers are increasingly adopted in small- to medium-scale manufacturing units, as they allow processing of different sizes of workpieces without extensive facility modifications. Their cost-effectiveness and adaptability for both industrial and consumer applications are key factors fueling their rapid uptake across emerging markets.

- By Category

On the basis of category, the computerized numerical control router market is segmented into industrial computerized numerical control routers and consumer computerized numerical control routers. Industrial computerized numerical control routers dominated the market with a share of 65.8% in 2024 due to their high precision, durability, and capacity to handle continuous, large-scale production requirements. They are extensively used in manufacturing industries such as automotive, aerospace, and furniture production, where consistent quality and efficiency are critical. The wide availability of advanced features such as multi-axis machining, automatic tool changers, and integration with CAD/CAM software enhances their demand among professional manufacturers.

Consumer computerized numerical control routers are expected to register the fastest growth from 2025 to 2032, driven by increasing adoption among hobbyists, small workshops, and educational institutions. Their relatively lower cost, compact design, and user-friendly interface make them suitable for prototyping, DIY projects, and small-scale production. Growing interest in maker culture and home-based manufacturing is further propelling demand for consumer-grade computerized numerical control routers.

- By Product

On the basis of product, the computerized numerical control router market is segmented into plasma, laser, water jet, and metal tool routers. Laser routers dominated the market in 2024, owing to their precision, speed, and ability to handle a wide range of materials including wood, acrylic, and metals. They are particularly valued in industries requiring detailed engraving, cutting, and intricate designs, making them a preferred choice for both industrial and commercial applications. Their low maintenance requirements and high repeatability contribute to their strong market presence.

Plasma routers are expected to witness the fastest growth from 2025 to 2032, driven by their capability to cut thick metal sheets efficiently and cost-effectively. Industries such as construction, automotive, and heavy machinery are increasingly adopting plasma computerized numerical control routers for structural fabrication and component manufacturing. Technological improvements in plasma cutting systems and affordability are further supporting their rapid adoption.

- By Application

On the basis of application, the computerized numerical control router market is segmented into woodworking, stoneworking, metalworking, and others. The woodworking segment dominated the market in 2024, fueled by the growing demand for customized furniture, cabinetry, and interior decor solutions. computerized numerical control routers provide precise and intricate cuts, reducing manual labor while improving productivity. The compatibility with a wide range of woodworking materials, along with integration with CAD/CAM software, makes them indispensable in both industrial and small-scale woodworking operations.

Metalworking is expected to register the fastest growth from 2025 to 2032, driven by rising industrialization and the need for high-precision metal components in automotive, aerospace, and machinery sectors. The ability of computerized numerical control routers to handle complex shapes, maintain tight tolerances, and enhance production speed is driving adoption in metalworking applications.

- By Sales Channel

On the basis of sales channel, the computerized numerical control router market is segmented into direct channel and distribution channel. The distribution channel dominated the market in 2024 due to its extensive reach, enabling manufacturers to supply computerized numerical control routers to multiple regions efficiently. Distributors often provide installation, after-sales support, and training services, which enhance customer confidence in high-value machinery. This channel is especially prominent in regions with a growing industrial base where customers rely on local partners for machine support and maintenance.

The direct channel is expected to witness the fastest growth from 2025 to 2032, driven by manufacturers increasingly offering customized solutions, online ordering, and direct engagement with clients. Direct sales allow companies to maintain control over pricing, service quality, and delivery timelines, appealing to large industrial buyers and end-users seeking tailored computerized numerical control solutions.

- By End-Use Industry

On the basis of end-use industry, the computerized numerical control router market is segmented into automotive, construction, industrial, and others. The industrial sector dominated the market in 2024, benefiting from widespread adoption of computerized numerical control routers for mass production, prototyping, and precision machining applications. Industrial users prioritize durability, high throughput, and advanced features to optimize manufacturing efficiency, which makes computerized numerical control routers critical assets in factories and workshops.

The automotive sector is expected to witness the fastest growth from 2025 to 2032, driven by the rising demand for customized auto components, lightweight materials, and enhanced production efficiency. computerized numerical control routers enable high precision cutting and shaping of metal, plastic, and composite parts, meeting stringent automotive industry standards and accelerating adoption in vehicle manufacturing and assembly processes.

Computerized Numerical Control (CNC) Router Market Regional Analysis

- Asia-Pacific dominated the computerized numerical control (CNC) router market with the largest revenue share in 2024, driven by rapid industrialization, growing manufacturing output, and increasing adoption of automation technologies across the region

- The region’s cost-effective manufacturing landscape, availability of skilled labor, and rising investments in smart factories and digital manufacturing solutions are accelerating market expansion

- Government initiatives promoting industrial automation, Industry 4.0 adoption, and infrastructure development are contributing to increased consumption of computerized numerical control routers in automotive, woodworking, metalworking, and other sectors

China Computerized Numerical Control Router Market Insight

China held the largest share in the Asia-Pacific computerized numerical control router market in 2024, owing to its position as a global manufacturing hub and high adoption of automated production technologies. The country’s strong industrial base, investments in smart factories, and domestic computerized numerical control router manufacturing capabilities are major growth drivers. Rising demand from automotive, metalworking, and woodworking sectors, along with government initiatives supporting digital manufacturing, further bolster market growth.

India Computerized Numerical Control Router Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by expanding manufacturing facilities, increasing industrial automation, and rising investments in computerized numerical control machinery. The “Make in India” initiative and focus on self-reliance in precision manufacturing are strengthening the demand for computerized numerical control routers. In addition, growing woodworking, metalworking, and automotive industries, along with government incentives for industrial modernization, are contributing to rapid market expansion.

Europe Computerized Numerical Control Router Market Insight

The Europe computerized numerical control router market is expanding steadily, supported by increasing industrial automation, strict quality standards, and high adoption of advanced manufacturing technologies. The region emphasizes precision engineering, energy efficiency, and sustainable production, particularly in automotive, aerospace, and furniture industries. Growing investments in smart manufacturing, R&D in automation solutions, and regulatory focus on product quality and safety are driving market growth.

Germany Computerized Numerical Control Router Market Insight

Germany’s computerized numerical control router market is driven by its leadership in precision engineering, strong industrial infrastructure, and emphasis on high-quality manufacturing processes. The country has well-established R&D networks and collaborations between manufacturers and academic institutions, fostering continuous innovation in computerized numerical control technology. Demand is particularly strong in automotive, metalworking, and woodworking applications, where high-precision production is critical.

U.K. Computerized Numerical Control Router Market Insight

The U.K. market is supported by a mature manufacturing industry, growing adoption of smart factories, and increasing demand for precision computerized numerical control routers in automotive, furniture, and metalworking sectors. Focus on R&D, digital manufacturing initiatives, and collaboration between industry and academic institutions are driving growth. In addition, SMEs and specialized manufacturers are increasingly integrating computerized numerical control technology to enhance productivity and maintain competitiveness.

North America Computerized Numerical Control Router Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by increasing industrial automation, adoption of advanced manufacturing technologies, and rising demand for high-precision production across automotive, aerospace, and woodworking sectors. The region’s focus on smart factories, digital manufacturing, and Industry 4.0 solutions is accelerating computerized numerical control router adoption.

U.S. Computerized Numerical Control Router Market Insight

The U.S. accounted for the largest share in the North America computerized numerical control router market in 2024, underpinned by its robust industrial infrastructure, strong R&D capabilities, and widespread adoption of automated manufacturing solutions. Rising demand from automotive, aerospace, and precision component manufacturing, coupled with availability of advanced computerized numerical control technologies and skilled labor, is reinforcing the country’s leading position in the region.

Computerized Numerical Control (CNC) Router Market Share

The computerized numerical control (CNC) router industry is primarily led by well-established companies, including:

- BIESSE GROUP (Italy)

- FlexiCAM (Germany)

- Exel CNC Automation (U.K.)

- Thermwood Corporation (U.S.)

- AXYZ Automation Inc. (Canada)

- Anderson (Taiwan)

- HOMAG Group (Germany)

- Carbide 3D LLC (U.S.)

- MultiCam Inc. (U.S.)

- C.R. Onsrud, Incorporated (U.S.)

- SHODA SHOYU CO., LTD (Japan)

- ShopSabre CNC (U.S.)

- Solar Industries (U.S.)

- Tommotek (Germany)

- Shenhui Laser (China)

Latest Developments in Global Computerized Numerical Control (CNC) Router Market

- In August 2025, the computerized numerical control router market experienced a strong surge in demand fueled by advancements in automation and precision manufacturing. Industries such as woodworking, automotive, aerospace, and signage are increasingly relying on computerized numerical control routers to enhance efficiency, maintain superior quality, and lower operational costs. The integration of digital manufacturing and smart factory solutions is accelerating adoption, making computerized numerical control routers central to industrial modernization

- In July 2025, the face of modern manufacturing is being reshaped by cutting-edge computerized numerical control machining technologies. With rising demand for higher quality, faster turnaround, and sustainable production, advanced computerized numerical control systems are driving a new era of precision and efficiency. Manufacturers are embedding these routers into automated workflows, ensuring consistent results and scaling production capacity to meet growing global demand

- In July 2025, the market saw a decisive shift toward customization and individualized production. The rising need for bespoke furniture, signage, and decorative elements is boosting adoption of high-precision computerized numerical control routers. Enhanced with AI, IoT, and real-time monitoring, these routers support predictive maintenance, reduce downtime, and empower manufacturers to deliver client-specific solutions with unmatched speed and accuracy

- In June 2025, heightened investments in research and development brought forward next-generation computerized numerical control routers with expanded capabilities. New features such as multi-axis cutting, high-speed performance, and intuitive user-friendly interfaces are addressing evolving industrial demands. These innovations minimize errors, improve safety, and promote energy-efficient manufacturing, opening doors for computerized numerical control router applications in wider industrial domains

- In July 2024, SCM launched the SCM Maker, a portable computerized numerical control router built for ease of use and flexibility. Its lightweight, compact design allows placement directly on the work surface, enabling routing on larger surfaces without requiring dedicated installation space. This development is democratizing computerized numerical control technology, making it more accessible for small businesses, educational institutes, and hobbyists while supporting scalable production in industrial use cases

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Computerized Numerical Control Cnc Router Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Computerized Numerical Control Cnc Router Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Computerized Numerical Control Cnc Router Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.