Concrete Delivery Hose Market Size

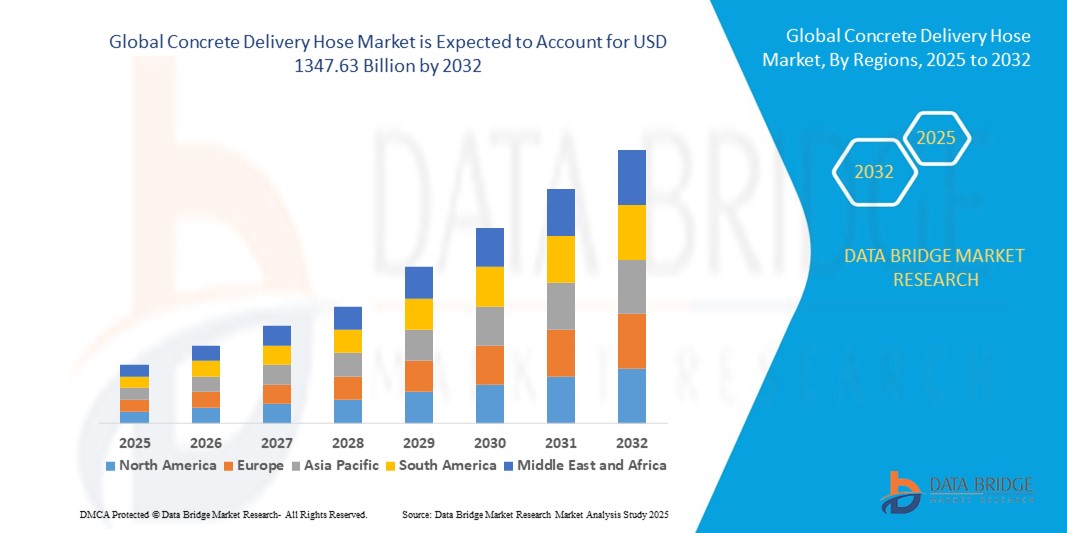

- The global concrete delivery hose market size was valued at USD 821. 65 million in 2024 and is expected to reach USD 1347.63 billion by 2032, at a CAGR of 6.38% during the forecast period

- The market growth is largely fueled by increasing investments in infrastructure, urbanization, and large-scale commercial and residential construction projects, which are driving the demand for efficient concrete delivery solutions

- Furthermore, rising adoption of high-performance, durable, and flexible hoses for safe and rapid concrete pumping is enabling faster project execution and reducing labor dependency. These factors are accelerating the uptake of advanced concrete delivery hoses, significantly boosting the industry's growth

Concrete Delivery Hose Market Analysis

- Concrete delivery hoses are specialized hoses designed to transport and pump concrete efficiently from mixers to construction sites, supporting applications in high-rise buildings, bridges, tunnels, dams, pavements, and drainage systems. They are available in rubber, wire-reinforced, and composite types, providing varying levels of flexibility, durability, and pressure handling

- The escalating demand for concrete delivery hoses is primarily driven by the growth of large-scale infrastructure and urban construction projects, the need for mechanized and time-efficient concrete placement, and increasing adoption of advanced pumping technologies to improve operational safety and efficiency

- Asia-Pacific dominated the concrete delivery hose market with a share of 35.5% in 2024, due to rapid urbanization, large-scale infrastructure development, and increasing investments in high-rise and commercial construction projects

- North America is expected to be the fastest growing region in the concrete delivery hose market during the forecast period due to

- Rubber hose segment dominated the market with a market share of 45.8% in 2024, due to its flexibility, durability, and ease of handling on construction sites. Rubber hoses are widely preferred for various construction applications due to their resistance to wear, abrasion, and the corrosive effects of concrete mixtures. Contractors also favor rubber hoses for their compatibility with different pumping systems and the relatively lower cost of installation and maintenance compared to reinforced or composite alternatives. The segment’s established presence in both small- and large-scale construction projects further supports its dominant position

Report Scope and Concrete Delivery Hose Market Segmentation

|

Attributes |

Concrete Delivery Hose Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Concrete Delivery Hose Market Trends

Growing Use of High-Pressure Concrete Hoses

- High-pressure concrete hoses are gaining rising adoption as construction projects require durable and flexible piping solutions for handling abrasive concrete materials. The demand for longer-lasting hoses is directly linked to efficiency and worker safety improvements

- For instance, Bridgestone Corporation has been introducing high-pressure hoses designed for large-scale construction and infrastructure activities. These hoses feature improved reinforcement layers to withstand demanding environments while offering higher safety margins and operational reliability

- The increasing trend toward high-rise urban infrastructure is reshaping requirements for concrete placement. Stronger delivery hoses are essential in pumping concrete across extended distances and vertical heights, ensuring durability, suspension strength, and consistent performance levels

- In addition, growing investments in tunnel and bridge construction drive demand for robust hoses capable of withstanding repeated pressure cycles. Advanced engineered materials are helping manufacturers deliver enhanced flexibility paired with superior pressure endurance capabilities

- The integration of safety-focused designs, such as abrasion-resistant covers and wear indication layers, is shaping product innovation. Such technology reduces downtime and also supports compliance with strict site safety standards globally

- Sustainability initiatives are encouraging the use of recyclable and eco-friendly hose materials. This reflects broader trends in the construction sector highlighting sustainable solutions while addressing long-term cost savings associated with product life-cycle efficiencies

Concrete Delivery Hose Market Dynamics

Driver

Rising Urbanization and Construction Projects

- The expansion of urban infrastructure is fueling demand for concrete delivery hoses. Rapid city growth and large-scale real estate developments are increasing reliance on durable pumping systems necessary for transferring concrete efficiently across worksites

- For instance, Eaton Corporation has expanded its construction-focused product line with high-performance hoses engineered for concrete delivery operations. This ensures consistent reliability for contractors during demanding building projects across emerging and developed construction markets

- The surge in government-backed smart city and infrastructure initiatives is strongly stimulating hose demand. Massive construction projects such as highways, airports, and metros require robust distribution systems that withstand wear without frequent replacement needs

- In addition, residential and commercial real estate expansion across Asia-Pacific and Middle Eastern nations is boosting pipeline requirements. Concrete delivery hoses are becoming crucial for consistent pumping operations in both small-scale and large-scale projects

- Growing contractor awareness of operational efficiency is further driving adoption. The use of reliable hoses reduces maintenance downtime and ensures delivery accuracy, enabling builders to meet construction deadlines within tighter project completion schedules

Restraint/Challenge

Wear and Maintenance Issues

- The concrete delivery hose market faces significant restraints due to wear and frequent maintenance needs. Abrasive concrete slurry leads to faster degradation, raising operating costs for contractors and reducing overall worksite reliability in demanding applications

- For instance, several construction contractors have reported high replacement rates of delivery hoses during mega-projects such as Dubai’s high-rise expansions. This highlights the urgent need for more durable solutions capable of minimizing frequent product replacements

- Frequent hose wear increases maintenance interventions, contributing to workflow disruptions. Construction teams face downtime associated with inspecting and changing hoses, resulting in productivity losses that affect project timelines and increase operational expenses significantly

- In addition, safety risks associated with hose bursts remain a challenge. Regular wear builds vulnerability to sudden failures during high-pressure pumping, threatening operator safety and potentially causing damage to costly construction equipment on site

- Research into longer-lasting composite materials and improved reinforcement technologies is ongoing. However, the high costs of advanced hoses present adoption challenges for smaller contractors, limiting widespread usage and creating gaps between premium and budget solutions

Concrete Delivery Hose Market Scope

The market is segmented on the basis of type, diameter, and application.

- By Type

On the basis of type, the concrete delivery hose market is segmented into rubber hose, wire-reinforced hose, and composite hose. The rubber hose segment dominated the largest market revenue share of 45.8% in 2024, attributed to its flexibility, durability, and ease of handling on construction sites. Rubber hoses are widely preferred for various construction applications due to their resistance to wear, abrasion, and the corrosive effects of concrete mixtures. Contractors also favor rubber hoses for their compatibility with different pumping systems and the relatively lower cost of installation and maintenance compared to reinforced or composite alternatives. The segment’s established presence in both small- and large-scale construction projects further supports its dominant position.

The wire-reinforced hose segment is anticipated to witness the fastest growth from 2025 to 2032, driven by increasing adoption in high-pressure and heavy-duty concrete pumping operations. Wire-reinforced hoses offer enhanced structural integrity, reduced risk of kinking, and superior pressure handling capacity, making them suitable for high-rise building projects, long-distance pumping, and challenging site conditions. The combination of strength, safety, and reliability in delivering concrete efficiently is boosting demand for this type of hose across commercial and infrastructure projects.

- By Diameter

On the basis of diameter, the concrete delivery hose market is segmented into DN100, DN125, and others. The DN100 segment held the largest market revenue share in 2024, as it strikes a balance between flow rate and maneuverability, making it ideal for a wide range of construction projects. DN100 hoses are compatible with standard concrete pumps and are commonly used in urban and mid-scale construction where space constraints and handling efficiency are key considerations. Their moderate size allows for easier transport, setup, and maintenance without compromising on performance.

The DN125 segment is expected to register the fastest growth from 2025 to 2032, driven by the rising demand in large-scale infrastructure projects and high-rise construction. DN125 hoses provide higher concrete flow capacity and reduced pumping time, enabling faster project execution in bridge construction, tunnels, and dam applications. Their ability to handle high-pressure pumping and long-distance delivery requirements makes them increasingly preferred for commercial and industrial construction projects.

- By Application

On the basis of application, the concrete delivery hose market is segmented into high-rise buildings, bridge construction, tunnels and underground structures, dams and reservoirs, floor slabs and pavements, drainage systems, and others. The high-rise buildings segment dominated the largest market revenue share in 2024, driven by the rapid urbanization and growing demand for vertical construction in metropolitan areas. Concrete hoses in high-rise projects are critical for delivering concrete efficiently to elevated floors, ensuring consistent quality, and minimizing labor-intensive handling. The segment benefits from technological advancements in high-pressure hoses and concrete pumping equipment that enhance construction speed and safety.

The bridge construction segment is anticipated to witness the fastest growth from 2025 to 2032, fueled by increasing investments in infrastructure development and government-backed transportation projects. Concrete delivery hoses are essential for bridging long spans and handling high-volume concrete placements in remote or challenging locations. Wire-reinforced and larger diameter hoses are particularly preferred in this application due to their durability, pressure resistance, and ability to sustain continuous operations, supporting faster and safer project execution.

Concrete Delivery Hose Market Regional Analysis

- Asia-Pacific dominated the concrete delivery hose market with the largest revenue share of 35.5% in 2024, driven by rapid urbanization, large-scale infrastructure development, and increasing investments in high-rise and commercial construction projects

- The region’s cost-effective manufacturing, growing construction equipment adoption, and expanding real estate and infrastructure projects are accelerating market growth

- Availability of skilled labor, favorable government policies, and increasing mechanization of concrete pumping and delivery operations are further boosting demand across residential, commercial, and industrial construction segments

Australia Concrete Delivery Hose Market Insight

Australia held the largest share in the Asia-Pacific market in 2024, supported by extensive infrastructure development, urbanization, and government-backed construction projects. Strong investment in commercial, residential, and transport infrastructure, combined with increasing adoption of mechanized concrete delivery solutions, is driving demand. The country’s focus on durable, high-performance construction materials and equipment further strengthens market growth.

India Concrete Delivery Hose Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by rapid urbanization, increasing investments in infrastructure, and rising high-rise and commercial construction projects. Government initiatives such as “Smart Cities” and infrastructure development programs are boosting demand for durable and high-performance concrete hoses. Expansion of industrial parks, urban redevelopment projects, and growing foreign investments are further supporting market adoption.

Europe Concrete Delivery Hose Market Insight

The Europe market is expanding steadily, driven by modernization of infrastructure, growing demand for high-rise and complex construction projects, and increasing adoption of advanced concrete delivery solutions. Emphasis on efficiency, safety, and durability in construction operations is encouraging the use of wire-reinforced and composite hoses. The region’s stringent construction standards and focus on sustainable building practices are further enhancing market growth.

Germany Concrete Delivery Hose Market Insight

Germany’s market is supported by its leadership in precision engineering and infrastructure development, strong industrial base, and adoption of advanced construction technologies. Demand is particularly strong for high-pressure, durable concrete hoses in bridge construction, tunnels, and high-rise buildings. Ongoing investments in smart construction equipment and safety-focused construction practices are driving further adoption.

U.K. Concrete Delivery Hose Market Insight

The U.K. market is bolstered by modernization of urban infrastructure, commercial real estate growth, and adoption of high-performance concrete delivery systems. Growing focus on construction efficiency, durability, and compliance with building regulations is supporting demand. Increasing use of mechanized concrete pumping solutions in large-scale projects also contributes to market growth.

North America Concrete Delivery Hose Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by extensive infrastructure development, rising urbanization, and the adoption of advanced concrete pumping technologies. Increasing focus on large-scale commercial, bridge, and tunnel projects is boosting demand for durable and high-capacity concrete hoses. The trend toward mechanization, safety optimization, and high-efficiency delivery solutions is further supporting market expansion.

U.S. Concrete Delivery Hose Market Insight

The U.S. accounted for the largest share in the North America market in 2024, underpinned by its robust construction industry, extensive infrastructure projects, and growing adoption of high-performance concrete delivery equipment. Demand is fueled by urban redevelopment, highway and bridge construction, and commercial high-rise projects. Presence of key equipment manufacturers and a mature distribution network further solidify the U.S.’s leading position in the region.

Concrete Delivery Hose Market Share

The concrete delivery hose industry is primarily led by well-established companies, including:

- ContiTech Deutschland GmbH (Germany)

- Hebei Orient ADMA Tech Group Co., Ltd. (China)

- Jason Industrial (U.S.)

- Qingdao Everflex Rubber & Plastic Co., Ltd. (China)

- IVG Colbachini SpA (Italy)

- Novaflex (U.S.)

- CON FORMS (U.S.)

- Capital Rubber Corp (U.S.)

- Parker Hannifin Corp (U.S.)

- PAR Group (U.S.)

- UIP International (U.S.)

- McGill Hose & Coupling, Inc. (U.S.)

- The Briggs Company (U.K.)

- Seal Fast, Inc. (U.S.)

Latest Developments in Global Concrete Delivery Hose Market

- In January 2024, Continental announced an investment of USD 90 million in a new hydraulic hose production plant in Aguascalientes, Mexico, aimed at expanding manufacturing capabilities and creating over 200 jobs. Scheduled to commence operations in the second half of 2025, the plant will significantly strengthen Continental’s presence in the Americas and support rising demand for high-quality hydraulic and concrete delivery hoses. By offering a broader range of durable hoses for industrial and construction applications, the investment is expected to enhance supply chain efficiency, reduce lead times, and enable contractors and construction companies to access advanced hose solutions for high-pressure concrete pumping operations

- In October 2023, Bredel launched the NR Transfer hose, a natural rubber hose engineered for general fluid transfer applications with pressure ratings up to 12 bar. This product introduction is poised to impact the concrete delivery hose market by providing a cost-effective and versatile solution for fluid handling in construction projects. Its flexibility and durability reduce operational downtime, improve safety during pumping and transfer, and allow for smoother handling in high- and mid-rise building projects, as well as infrastructure developments such as tunnels, bridges, and drainage systems

- In February 2023, Danfoss Power Solutions rolled out a series of high-performance hydraulic crimping equipment and tooling across Europe and the Middle East. These advanced tools enable precise assembly of hydraulic hoses, ensuring reliability, safety, and high-pressure tolerance in concrete delivery operations. The launch addresses a growing market demand for durable and high-capacity hoses, particularly in large-scale infrastructure projects, and facilitates faster, more efficient installation and maintenance of hose systems, which in turn reduces project delays and enhances operational efficiency

- In March 2022, Quikrete Holdings Inc., a U.S.-based building materials company, acquired Forterra Inc. to strengthen its portfolio in water and drainage infrastructure. Forterra’s expertise in manufacturing concrete rubber hoses and building products, when combined with Quikrete’s extensive range of concrete and mortar mixes, enhances product availability and market reach. This acquisition is expected to drive growth in construction applications, particularly in civil engineering projects requiring reliable concrete hose solutions, such as floor slabs, pavements, and high-volume water drainage infrastructure

- In November 2021, Gates Corporation expanded its global distribution network for concrete delivery hoses by partnering with regional construction equipment suppliers across North America and Europe. This strategic move improves accessibility to high-performance rubber and wire-reinforced hoses, enabling contractors and construction firms to source hoses more efficiently. The expansion addresses the rising demand for durable, high-pressure hoses in complex infrastructure and commercial construction projects, supporting faster concrete pumping operations, reduced downtime, and enhanced project execution quality across multiple construction applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Concrete Delivery Hose Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Concrete Delivery Hose Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Concrete Delivery Hose Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.