Global Consumables And Reagents In Continuous Bioprocessing For Monoclonal Antibodies And Vaccines Market

Market Size in USD Million

CAGR :

%

USD

392.04 Million

USD

736.45 Million

2025

2033

USD

392.04 Million

USD

736.45 Million

2025

2033

| 2026 –2033 | |

| USD 392.04 Million | |

| USD 736.45 Million | |

|

|

|

|

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Size

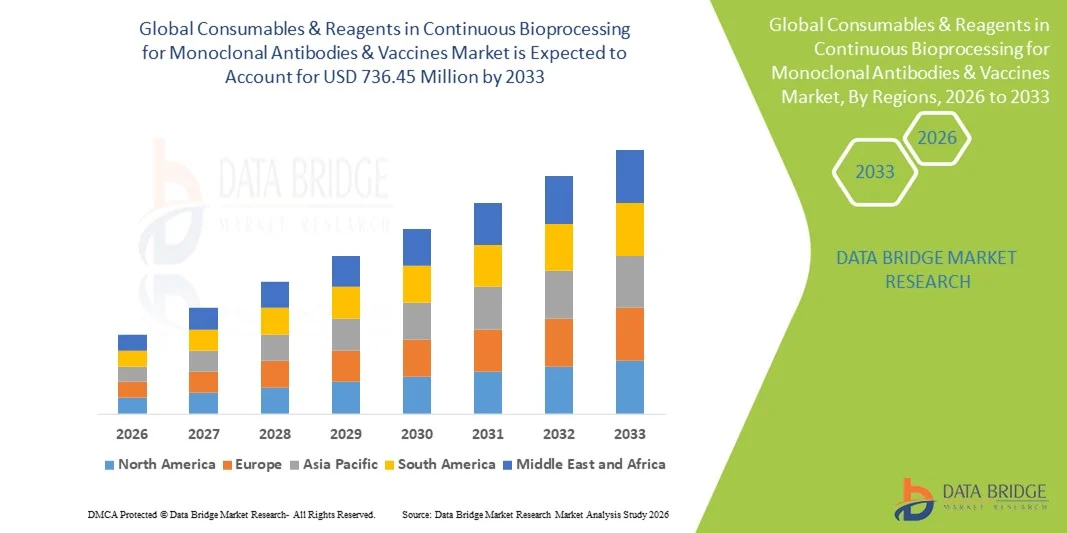

- The global consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market size was valued at USD 392.04 Million in 2025 and is expected to reach USD 736.45 Million by 2033, at a CAGR of 8.20% during the forecast period

- The market growth is largely fueled by the growing adoption and technological progress in continuous bioprocessing systems, which are increasingly replacing traditional batch manufacturing due to higher productivity, reduced footprint, and improved process control

- Furthermore, rising demand for monoclonal antibodies and vaccines, especially for personalized therapies and rapid pandemic response, is driving the need for advanced consumables and reagents that can support continuous manufacturing workflows

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Analysis

- Consumables and reagents used in continuous bioprocessing are critical for enabling high-efficiency monoclonal antibody and vaccine manufacturing, offering improved process control, reduced production time, and lower operational costs compared to traditional batch processing

- Increasing demand for monoclonal antibodies and vaccines, especially due to rising chronic diseases and frequent outbreaks, is driving the adoption of continuous bioprocessing systems, which in turn increases consumption of specialized consumables and reagents

- North America dominated the consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market with the largest revenue share of 39.8% in 2025, supported by strong biopharmaceutical manufacturing infrastructure, high adoption of continuous processing technologies, and significant R&D investments in the U.S. and Canada

- Asia-Pacific is expected to be the fastest-growing region in the consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market during the forecast period, with a projected CAGR of 11.2%, driven by expanding biopharmaceutical manufacturing capacity in China and India, increasing outsourcing to contract manufacturers, and growing government support for life sciences

- The upstream processing segment dominated with 41.0% revenue share in 2025, driven by the high consumption of media, supplements, single-use bags, and bioreactor consumables

Report Scope and Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Segmentation

|

Attributes |

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework. |

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Trends

Rising Adoption of Single-Use Continuous Bioprocessing Systems

- A major trend in the global consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market is the growing adoption of single-use (disposable) continuous bioprocessing systems. These systems reduce contamination risk, enable faster setup, and support flexible production scales—especially for mAbs and vaccine manufacturing

- For instance, many biopharmaceutical companies are increasingly shifting from traditional stainless-steel systems to single-use bioreactors, tubing, connectors, and filters, which boosts demand for disposable consumables and reagents in continuous processes

- Continuous bioprocessing also enables higher productivity and better control of product quality. This is driving the demand for continuous chromatography resins, inline filtration membranes, and automated monitoring reagents, which are essential for steady-state production

- As manufacturers push toward faster and more flexible production, the need for continuous bioprocessing consumables (bags, filters, tubing, resins, media) is increasing globally, especially in North America, Europe, and APAC

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Dynamics

Driver

Growing Demand for Monoclonal Antibodies & Vaccines and Need for Faster Production

- A major driver of the global market is the rapid growth of monoclonal antibodies (mAbs) and vaccine manufacturing, driven by rising chronic diseases and pandemic preparedness needs

- For instance, the increasing demand for mAbs for cancer, autoimmune diseases, and infectious diseases has led biopharma companies to invest heavily in continuous bioprocessing platforms, increasing demand for single-use consumables and reagents

- Continuous bioprocessing supports faster production cycles, higher yields, and improved cost efficiency, which is crucial for vaccine manufacturers who must scale production rapidly during outbreaks

- The trend towards personalized medicine and cell/gene therapies also increases demand for continuous upstream and downstream consumables, especially high-quality media, resins, filters, and analytical reagents

Restraint/Challenge

High Cost of Consumables and Regulatory Compliance Challenges

- A major challenge for the global Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines market is the high cost of single-use consumables and advanced reagents, particularly for continuous manufacturing systems. These costs can limit adoption among small and mid-sized biopharmaceutical companies and in cost-sensitive regions

- For instance, high-performance continuous chromatography resins and virus filtration membranes supplied by leading manufacturers such as Cytiva and Merck represent a significant portion of total manufacturing costs, especially in large-scale monoclonal antibody production. The frequent replacement of these consumables in continuous operations increases operational expenditure compared to traditional batch processing.

- Continuous bioprocessing also requires extensive process validation and regulatory compliance, as manufacturers must demonstrate consistent product quality to regulatory authorities such as the U.S. FDA and European Medicines Agency (EMA). The validation of new consumables, materials, and process changes can be time-consuming and costly

- In addition, concerns related to extractables and leachables from single-use systems, along with dependency on a limited number of qualified suppliers, pose risks to supply chain continuity and long-term process reliability

- Addressing these challenges will require cost optimization strategies, robust supplier qualification, improved material science, and clearer regulatory guidance, which are essential to support wider adoption of continuous bioprocessing consumables and reagents globally

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Scope

The market is segmented on the basis of product type, application, process stage, and end user.

- By Product Type

On the basis of product type, the Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines market is segmented into single-use bags, tubing & connectors, filters & membranes, chromatography resins, media & supplements, bioreactor consumables, and others. The single-use bags segment dominated with 28.5% revenue share in 2025, driven by their flexibility, reduced contamination risk, and ease of integration into continuous bioprocessing systems. They are widely used in upstream and downstream processes for media storage, buffer preparation, and harvest collection. Single-use bags eliminate cleaning and sterilization steps, reducing downtime and operational costs. Their adaptability supports scalable production for monoclonal antibodies and vaccines. Manufacturers prefer single-use systems due to faster turnaround and reduced cross-contamination risk. The increasing adoption of single-use technology in biopharma facilities is fueling demand. In addition, stringent regulatory compliance and quality control requirements support their use. Continuous processing favors single-use bags due to seamless material handling. The availability of customized bag sizes and configurations further strengthens the segment. Growing demand for flexible manufacturing and rapid process changes is driving adoption. Overall, single-use bags remain the most preferred consumable in continuous bioprocessing.

The chromatography resins segment is expected to witness the fastest CAGR of 14.8% from 2026 to 2033, due to increasing demand for high-purity monoclonal antibodies and vaccine products. Chromatography resins play a critical role in downstream purification and ensuring product quality and safety. Continuous bioprocessing requires high-performance resins to maintain constant flow and high binding capacity. Manufacturers are focusing on improving resin lifetimes and reducing process cycle times. Newer resin technologies offer better selectivity and higher throughput. The growing number of biologics and vaccine pipelines is supporting demand for advanced purification solutions. Increasing regulatory emphasis on impurity removal and consistent product quality further accelerates adoption. Resins are also increasingly used in multi-column continuous chromatography systems. Expansion of biopharmaceutical manufacturing facilities worldwide is driving resin consumption. The trend toward process intensification and efficiency improvement boosts growth. Overall, chromatography resins are expected to grow rapidly in continuous bioprocessing applications.

- By Application

On the basis of application, the market is segmented into monoclonal antibodies production, vaccine production, cell therapy manufacturing, gene therapy manufacturing, and others. The monoclonal antibodies production segment dominated with 34.2% revenue share in 2025, driven by high demand for therapeutic antibodies across oncology, autoimmune diseases, and infectious diseases. Continuous bioprocessing provides efficient and scalable manufacturing for monoclonal antibodies, reducing production time and costs. Single-use consumables and advanced filtration systems support uninterrupted production. The rising number of antibody-based drugs and biosimilars is fueling demand. Biopharmaceutical companies are increasingly adopting continuous upstream and downstream processes to improve yield and productivity. Regulatory support for process intensification further encourages implementation. The need for consistent product quality and high purity drives consumable adoption. In addition, increased outsourcing to CMOs is supporting growth in this segment. Continuous bioprocessing enables flexible manufacturing and faster response to market needs. Overall, monoclonal antibodies remain the major application driving the market.

The vaccine production segment is expected to witness the fastest CAGR of 15.1% from 2026 to 2033, driven by increasing global vaccine demand and pandemic preparedness initiatives. Continuous bioprocessing enables higher production efficiency and faster batch turnaround, critical for vaccine manufacturing. Governments and health agencies are investing heavily in vaccine production capacity expansion. The use of single-use consumables, high-performance filters, and advanced media is increasing in vaccine bioprocessing. Rapid development of new vaccines and booster programs supports strong demand. Manufacturers are focusing on scalable continuous platforms to meet urgent supply needs. Improvements in cell culture technologies and downstream purification are further boosting adoption. The growth in emerging economies and increased immunization programs are major drivers. In addition, collaborations between biotech companies and CMOs support capacity expansion. Overall, vaccine production is emerging as the fastest-growing application segment.

- By Process Stage

On the basis of process stage, the market is segmented into upstream processing, downstream processing, and analytical/quality control. The upstream processing segment dominated with 41.0% revenue share in 2025, driven by the high consumption of media, supplements, single-use bags, and bioreactor consumables. Continuous upstream systems are increasingly adopted due to their ability to improve productivity and reduce production time. Single-use bioreactors and perfusion systems are widely used for monoclonal antibodies and vaccine production. The demand for high-quality cell culture media and supplements is increasing to ensure consistent cell growth and productivity. Continuous processing enables stable cell culture conditions and higher cell densities. Manufacturers prefer upstream automation to minimize human intervention and reduce contamination risk. The trend toward intensified bioprocessing is supporting adoption. In addition, growing biopharmaceutical pipelines and clinical trial activities drive upstream consumable usage. Overall, upstream processing remains the largest stage due to high material requirements.

The analytical/quality control segment is expected to witness the fastest CAGR of 13.6% from 2026 to 2033, driven by increasing regulatory emphasis on product quality and process validation. Continuous bioprocessing requires real-time monitoring and control to ensure consistent product attributes. Analytical consumables such as test kits, sensors, and quality control reagents are increasingly used for in-line and at-line testing. The adoption of PAT (Process Analytical Technology) and advanced analytics is growing rapidly. Biopharmaceutical companies are investing in robust QC systems to support continuous manufacturing. The need for rapid release testing and traceability is boosting demand. Increasing outsourcing of QC to CROs is also supporting growth. Continuous processing demands frequent sampling and monitoring, increasing consumable consumption. Overall, analytical and QC stage is becoming crucial for compliance and product safety.

- By End User

On the basis of end user, the market is segmented into biopharmaceutical companies, contract manufacturing organizations (CMOs), research institutes, and academic institutions. The biopharmaceutical companies segment dominated with 46.3% revenue share in 2025, driven by large-scale manufacturing of monoclonal antibodies and vaccines. These companies invest heavily in continuous bioprocessing to reduce costs and improve productivity. They rely on single-use consumables and advanced filtration systems to maintain process efficiency. Continuous manufacturing enables faster time-to-market and flexible production capacity. Biopharma firms are also expanding production facilities and adopting modern technologies for process intensification. Regulatory pressure for high-quality biologics drives demand for reliable consumables and reagents. The presence of leading global manufacturers supports steady supply. In addition, increasing pipeline of biologics and vaccines sustains consumable demand. Overall, biopharmaceutical companies remain the dominant end-user segment due to large-scale production requirements.

The contract manufacturing organizations (CMOs) segment is expected to witness the fastest CAGR of 14.2% from 2026 to 2033, driven by outsourcing of biologics production to specialized manufacturers. CMOs offer flexible capacity and expertise in continuous bioprocessing, attracting biotech startups and mid-size companies. The growing number of clinical trials and biologics pipelines is boosting outsourcing demand. CMOs invest in advanced continuous platforms and single-use systems to meet diverse customer needs. They also support cost-effective manufacturing and faster scale-up. Increasing partnerships between biopharma companies and CMOs enhance market growth. CMOs’ focus on quality compliance and scalability makes them preferred partners. The trend toward flexible manufacturing and reduced capital investment supports CMO growth. Overall, CMOs are the fastest-growing end-user segment due to increasing outsourcing.

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Regional Analysis

- North America dominated the consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market with the largest revenue share of approximately 39.8% in 2025, supported by the region’s strong biopharmaceutical manufacturing base, early adoption of continuous bioprocessing technologies, and high demand for monoclonal antibodies and vaccines

- The presence of leading biopharmaceutical companies, advanced contract manufacturing organizations (CMOs), and well-established regulatory frameworks encourages the widespread use of high-quality consumables and reagents across upstream, downstream, and quality control processes

- Significant investments in R&D, process intensification, and single-use technologies further reinforce North America’s leadership, particularly in large-scale biologics and vaccine production facilities

U.S. Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

The U.S. consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market accounted for approximately 81% of the North American market revenue in 2025, driven by its dominant position in global biologics production and innovation. The country benefits from a high concentration of pharmaceutical and biotechnology companies actively transitioning from batch to continuous manufacturing to improve productivity, consistency, and cost efficiency. Strong federal funding, robust clinical pipelines for monoclonal antibodies, and increasing vaccine development programs support sustained demand for media, chromatography resins, filters, and single-use consumables. In addition, the growing reliance on CMOs and CDMOs in the U.S. further accelerates recurring demand for consumables used in continuous bioprocessing workflows.

Europe Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

The Europe consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market is projected to grow at a steady CAGR during the forecast period, driven by increasing adoption of advanced biomanufacturing technologies and a strong focus on process optimization. European biopharmaceutical companies are increasingly investing in continuous processing to meet stringent regulatory requirements and improve production scalability. Supportive government initiatives, growing biosimilar development, and rising demand for vaccines and therapeutic antibodies across the region are fueling consistent consumption of reagents and consumables.

U.K. Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

The U.K. consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market is expected to witness notable growth over the forecast period, supported by strong academic–industry collaboration, expanding biologics research, and increasing investments in bioprocess innovation. The country’s emphasis on advanced manufacturing, coupled with government-backed life sciences programs, is driving the adoption of continuous bioprocessing platforms. Growing clinical research activity and rising outsourcing to CMOs are further boosting demand for high-performance consumables and reagents used in monoclonal antibody and vaccine manufacturing.

Germany Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

Germany consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market is anticipated to expand at a considerable CAGR, supported by its robust pharmaceutical manufacturing infrastructure and leadership in bioprocess engineering. The country’s strong focus on quality, efficiency, and sustainability is accelerating the transition toward continuous bioprocessing solutions. Increasing investments in biologics, vaccine production, and cell-based therapies are driving demand for filtration systems, chromatography resins, and analytical reagents. Germany’s regulatory expertise and technological innovation further strengthen its position within the European market.

Asia-Pacific Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

The Asia-Pacific consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market region is expected to be the fastest-growing market, registering a projected CAGR of approximately 11.2% from 2026 to 2033. Growth is driven by rapidly expanding biopharmaceutical manufacturing capacity in China and India, increasing adoption of continuous processing technologies, and rising outsourcing to regional CMOs. Government initiatives supporting biotechnology, improving healthcare infrastructure, and growing demand for cost-effective biologics and vaccines are significantly accelerating the consumption of consumables and reagents across the region.

Japan Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

Japan’s consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market is gaining steady traction due to strong investments in advanced biologics manufacturing, precision medicine, and vaccine development. The country’s focus on innovation, quality assurance, and automation is encouraging the adoption of continuous bioprocessing systems. Increasing R&D activities and the presence of established pharmaceutical companies are driving consistent demand for specialized reagents, single-use systems, and analytical consumables across both commercial manufacturing and research settings.

China Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Insight

China consumables & reagents in continuous bioprocessing for monoclonal antibodies & vaccines market accounted for the largest revenue share in the Asia-Pacific market in 2025, driven by rapid expansion of domestic biopharmaceutical manufacturing, strong government support for biologics development, and rising investments in vaccine and monoclonal antibody production. The country’s growing number of CMOs, increasing clinical trial activity, and focus on self-sufficiency in biologics manufacturing are significantly boosting demand for consumables and reagents used in continuous bioprocessing. Affordable production capabilities and strong local suppliers further reinforce China’s market leadership in the region.

Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market Share

The Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines industry is primarily led by well-established companies, including:

• Thermo Fisher Scientific (U.S.)

• Merck KGaA (Germany)

• Sartorius AG (Germany)

• Danaher Corporation (U.S.)

• GE Healthcare (U.S.)

• Cytiva (U.S.)

• Pall Corporation (U.S.)

• Eppendorf (Germany)

• Repligen Corporation (U.S.)

• 3M (U.S.)

• Corning Incorporated (U.S.)

• Cytiva (Sweden)

• Lonza Group (Switzerland)

• Tecan Group (Switzerland)

• Avantor, Inc. (U.S.)

• Fujifilm Diosynth Biotechnologies (Japan)

• Takeda Pharmaceutical Company Limited (Japan)

• Merck Life Science (U.S.)

• Becton, Dickinson and Company (U.S.)

• Novasep (France)

Latest Developments in Global Consumables & Reagents in Continuous Bioprocessing for Monoclonal Antibodies & Vaccines Market

- In February 2021, 3M Health Care launched the 3M Polisher ST, an innovative single-use anion exchange polishing solution designed to replace traditional reusable AEX polishing columns in biologics manufacturing. This product aimed to streamline downstream purification by reducing processing steps and improving operational efficiency in continuous bioprocessing workflows

- In April 2022, Thermo Fisher Scientific opened a new single-use technologies production facility in Ogden, Utah (USA) as part of a multi-year investment plan to expand manufacturing of consumables to meet rising global demand for continuous bioprocessing and novel biologics production

- In July 2023, Waters Corporation and Sartorius AG announced a collaboration to integrate analytical solutions for downstream biomanufacturing, combining Sartorius’ chromatography platforms with Waters’ process analysis systems to enhance data strength and efficiency in continuous downstream operations — a development that influences reagent and consumable usage in high-throughput workflows

- In September 2023, Getinge launched the AppliFlex ST GMP single-use bioreactor system optimized for mRNA manufacturing and cell/gene therapies, offering a scalable, disposable upstream processing platform compatible with continuous bioprocessing — reinforcing single-use consumable demand in biologics manufacturing

- In April 2023, Merck KGaA introduced its Ultimus single-use process container film, designed to offer enhanced strength and leak resistance for single-use assemblies used in bioprocessing. This development improves reliability and integrity of disposable consumables in continuous workflows globally

- In May 2023, 3M announced a major investment to expand its bioprocessing consumables production capabilities in Europe, specifically aimed at boosting supply of single-use bags, tubing, and assemblies to support the growing adoption of continuous processing platforms in biologics manufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.