Global Corrosion And Scale Inhibitors Market

Market Size in USD Billion

CAGR :

%

USD

10.13 Billion

USD

16.76 Billion

2025

2033

USD

10.13 Billion

USD

16.76 Billion

2025

2033

| 2026 –2033 | |

| USD 10.13 Billion | |

| USD 16.76 Billion | |

|

|

|

|

Corrosion and Scale Inhibitors Market Size

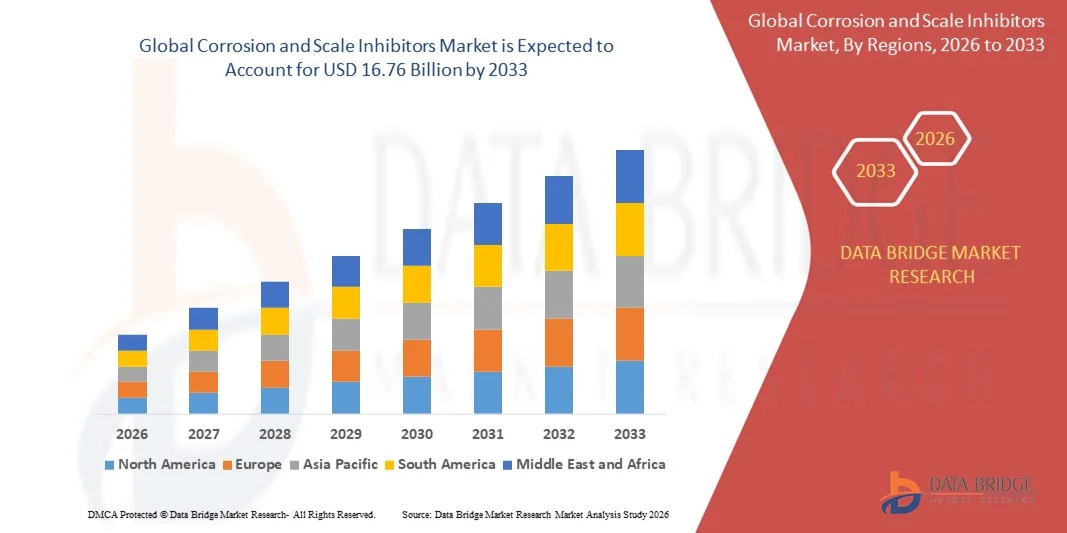

- The global corrosion and scale inhibitors market size was valued at USD 10.13 billion in 2025 and is expected to reach USD 16.76 billion by 2033, at a CAGR of 6.50% during the forecast period

- The market growth is largely fuelled by the rising demand for water treatment solutions across industrial sectors, including oil & gas, power generation, and chemical manufacturing, to prevent equipment corrosion and scaling

- Increasing awareness regarding maintenance of operational efficiency, equipment longevity, and regulatory compliance for industrial water systems is further driving market adoption

Corrosion and Scale Inhibitors Market Analysis

- The market is witnessing innovation in environmentally friendly and sustainable inhibitor chemistries, including green and biodegradable solutions, which are gaining traction among end-users

- Growing emphasis on process optimization, cost reduction, and minimization of unplanned downtime in industrial operations is boosting the adoption of corrosion and scale inhibitors across various applications

- North America dominated the corrosion and scale inhibitors market with the largest revenue share in 2025, driven by the rising industrial water usage, stringent environmental regulations, and growing focus on equipment longevity and operational efficiency

- Asia-Pacific region is expected to witness the highest growth rate in the global corrosion and scale inhibitors market, driven by expanding industrial activities, increasing investments in infrastructure, and rising awareness about sustainable water treatment practices

- The Phosphonate Scale Inhibitor segment held the largest market revenue share in 2025, driven by its wide applicability in preventing scale formation and corrosion in industrial water systems. These inhibitors are highly effective in high-temperature and high-hardness water conditions, making them a preferred choice across multiple industries

Report Scope and Corrosion and Scale Inhibitors Market Segmentation

|

Attributes |

Corrosion and Scale Inhibitors Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• Clariant (Switzerland) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Corrosion and Scale Inhibitors Market Trends

Rise of Advanced and Environmentally Friendly Inhibitors

• The growing focus on environmentally friendly and sustainable corrosion and scale inhibitors is transforming the water treatment landscape by enabling effective protection of industrial equipment while minimizing environmental impact. The adoption of green chemistries supports compliance with stringent regulations and reduces hazardous waste generation. Manufacturers are increasingly investing in R&D to develop biodegradable and phosphate-free formulations that maintain high efficiency across diverse industrial applications. This trend is also driven by growing pressure from environmental agencies and sustainability-conscious clients

• The high demand for advanced inhibitors in industries such as oil & gas, power generation, and chemical manufacturing is accelerating the use of specialty formulations. These solutions are particularly effective in preventing equipment degradation in high-temperature, high-pressure, and chemically aggressive environments. Advanced inhibitors also offer multifunctional benefits, protecting against multiple types of corrosion simultaneously, thereby reducing chemical inventory requirements. Companies are leveraging these solutions to enhance operational reliability and extend equipment life cycles

• The development of multifunctional inhibitors that provide simultaneous protection against scaling, corrosion, and fouling is gaining traction among industrial users. These solutions improve operational efficiency and reduce maintenance frequency, thereby lowering overall operational costs. The integration of smart dosing and monitoring systems further optimizes chemical usage, minimizes waste, and ensures consistent protection of critical infrastructure. This holistic approach is increasingly favored in sectors where downtime is costly

• For instance, in 2023, several large-scale chemical plants reported a reduction in equipment downtime and maintenance expenses after implementing phosphate-free and biodegradable corrosion inhibitors in cooling water systems. These plants also achieved lower environmental discharge levels, helping them comply with local regulations and sustainability initiatives. Early adopters are now demonstrating measurable ROI, encouraging wider industry adoption

• While advanced and green inhibitor formulations are gaining popularity, their adoption depends on cost-effectiveness, compatibility with existing water treatment systems, and regulatory approvals. Manufacturers must focus on continuous innovation, localized solutions, and scalable production to meet the growing industrial demand. Partnerships with technology providers and end-users are increasingly critical to develop tailored solutions that address specific operational challenges

Corrosion and Scale Inhibitors Market Dynamics

Driver

Increasing Industrial Water Usage and Emphasis on Equipment Longevity

• The rise in industrial water usage across sectors such as power generation, oil & gas, and chemicals is driving demand for corrosion and scale inhibitors to ensure long-term equipment reliability. Industries are increasingly focused on maintaining operational efficiency and preventing unplanned downtime. The expansion of industrial capacity and the rising complexity of industrial systems are further amplifying demand for high-performance inhibitors. Proactive water treatment programs are now considered integral to operational risk management

• Companies are recognizing the financial risks associated with corrosion and scaling, including reduced equipment lifespan, higher maintenance costs, and potential safety hazards. This awareness is leading to consistent adoption of high-performance inhibitors. Maintenance budgets are being increasingly allocated to preventive chemical treatments rather than reactive repairs, providing predictable cost management. In addition, industrial operators are adopting real-time monitoring technologies to optimize chemical usage and prevent failures

• Regulatory frameworks and industry standards promoting water conservation and safe chemical use are further accelerating market demand. Compliance with these regulations necessitates the use of effective corrosion and scale control solutions. Governments and industry associations are introducing stricter guidelines for industrial water discharge, further incentivizing the adoption of eco-friendly inhibitor solutions. Companies integrating sustainable chemicals are also benefiting from improved corporate image and stakeholder trust

• For instance, several refineries and chemical manufacturing facilities upgraded their water treatment programs in 2022 to include advanced inhibitor formulations, significantly reducing corrosion-related maintenance issues. These upgrades also led to improved energy efficiency and reduced operational risks associated with scaling and fouling. Such case studies are frequently cited by industrial associations as benchmarks for best practices

• While industrial water usage and regulatory compliance are driving adoption, continuous innovation in inhibitor chemistries and system integration is required to sustain long-term market growth. Companies investing in digital monitoring, AI-driven predictive maintenance, and customizable chemical solutions are likely to gain competitive advantages. Collaboration with chemical suppliers ensures ongoing formulation improvements and faster adoption across industrial sectors

Restraint/Challenge

High Cost of Advanced Inhibitors and Technical Expertise Requirements

• The high cost of specialty and environmentally friendly inhibitors creates adoption challenges, particularly for small and mid-sized industrial operators. Complex formulations often require precise dosing and monitoring, which adds to operational expenses. In addition, the cost of retrofitting existing water treatment systems to accommodate advanced inhibitors can be prohibitive, slowing adoption among budget-conscious facilities

• Limited availability of trained personnel to implement and maintain advanced inhibitor programs further restricts usage, especially in remote or underdeveloped industrial regions. Improper application can reduce effectiveness and increase operational risks. Training programs and certification for water treatment technicians are now emerging as critical enablers of inhibitor adoption, but gaps still remain in many regions

• Supply chain constraints and fluctuations in raw material availability may affect timely production and distribution of corrosion and scale inhibitors, impacting industrial operations relying on continuous water treatment. Price volatility of key chemical inputs, including specialty polymers and phosphonates, can also affect procurement planning. Companies are increasingly exploring local sourcing and alternative chemistries to mitigate these risks

• For instance, in 2023, several chemical plants in Southeast Asia reported delays in inhibitor supply due to raw material shortages, affecting system maintenance schedules and equipment reliability. These delays led to increased operational costs and temporary use of less effective substitutes, highlighting the importance of a resilient supply chain strategy

• While inhibitor technologies continue to advance, addressing cost, expertise, and supply chain challenges remains critical. Stakeholders must focus on developing scalable, easy-to-apply solutions and training programs to maximize market penetration and long-term adoption. Strategic partnerships with local distributors and technology providers are increasingly being used to overcome these barriers and ensure uninterrupted chemical supply

Corrosion and Scale Inhibitors Market Scope

The market is segmented on the basis of product and application.

- By Product

On the basis of product, the corrosion and scale inhibitors market is segmented into Phosphonate Scale Inhibitor, Carboxylate/Acrylic Scale Inhibitor, Sulfonate Scale Inhibitor, and Others. The Phosphonate Scale Inhibitor segment held the largest market revenue share in 2025, driven by its wide applicability in preventing scale formation and corrosion in industrial water systems. These inhibitors are highly effective in high-temperature and high-hardness water conditions, making them a preferred choice across multiple industries.

The Carboxylate/Acrylic Scale Inhibitor segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by its cost-effectiveness, ease of use, and compatibility with various water chemistries. These inhibitors are increasingly adopted in industrial water treatment processes where multifunctional protection and operational efficiency are critical.

- By Application

On the basis of application, the market is segmented into Power and Construction Industry, Mining Industry, Oil and Gas Industry, Water and Wastewater Treatment Industry, and Food and Beverage Industry. The Power and Construction Industry segment held the largest market share in 2025, driven by the rising demand for industrial boilers, cooling towers, and water circulation systems that require effective corrosion and scale control.

The Oil and Gas Industry segment is expected to witness the fastest growth rate from 2026 to 2033, owing to the increasing complexity of industrial processes and the need to protect expensive infrastructure from scaling and corrosion in high-pressure and high-temperature conditions.

Corrosion and Scale Inhibitors Market Regional Analysis

- North America dominated the corrosion and scale inhibitors market with the largest revenue share in 2025, driven by the rising industrial water usage, stringent environmental regulations, and growing focus on equipment longevity and operational efficiency

- Companies in the region highly value advanced inhibitor formulations for preventing corrosion and scale formation in industrial water systems, cooling towers, and process pipelines, ensuring minimal downtime and maintenance costs

- This widespread adoption is further supported by the presence of major industrial hubs, technological expertise, and well-established water treatment infrastructure, making corrosion and scale inhibitors essential across power generation, oil & gas, and chemical industries

U.S. Corrosion and Scale Inhibitors Market Insight

The U.S. corrosion and scale inhibitors market captured the largest revenue share in 2025 within North America, fueled by the increasing industrial water usage and regulatory compliance requirements. Industrial operators are prioritizing high-performance inhibitors to protect critical equipment from scaling and corrosion, reducing unplanned downtime and maintenance expenses. Furthermore, the integration of advanced, environmentally friendly formulations and continuous monitoring systems is significantly contributing to market expansion.

Europe Corrosion and Scale Inhibitors Market Insight

The Europe corrosion and scale inhibitors market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by strict environmental regulations, water conservation mandates, and growing industrial modernization. European industries are adopting multifunctional inhibitors that provide simultaneous protection against scaling, corrosion, and fouling. Rising industrial investments in sectors such as power, chemical, and oil & gas are further accelerating market growth.

U.K. Corrosion and Scale Inhibitors Market Insight

The U.K. corrosion and scale inhibitors market is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing industrial water consumption and the need to enhance equipment lifespan while complying with stringent environmental regulations. Industrial operators are increasingly opting for advanced, eco-friendly inhibitor solutions to optimize operational efficiency and minimize maintenance costs. The strong focus on sustainability and regulatory adherence continues to boost market demand.

Germany Corrosion and Scale Inhibitors Market Insight

The Germany corrosion and scale inhibitors market is expected to witness the fastest growth rate from 2026 to 2033, fueled by the adoption of green and multifunctional inhibitor formulations and rising awareness of operational efficiency. Germany’s well-established industrial infrastructure, coupled with strict regulatory frameworks for water treatment and chemical usage, promotes consistent adoption. Integration of monitoring systems with inhibitor programs is also enhancing preventive maintenance across industrial facilities.

Asia-Pacific Corrosion and Scale Inhibitors Market Insight

The Asia-Pacific corrosion and scale inhibitors market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid industrialization, increasing water-intensive operations, and government initiatives promoting sustainable water treatment practices. The region's focus on cost-effective and multifunctional inhibitors supports their widespread adoption across power, chemical, and oil & gas industries. Furthermore, emerging industrial hubs and growing investments in water treatment infrastructure are enhancing accessibility and affordability of advanced inhibitors.

Japan Corrosion and Scale Inhibitors Market Insight

The Japan corrosion and scale inhibitors market is expected to witness the fastest growth rate from 2026 to 2033 due to high industrial water usage, stringent regulatory standards, and emphasis on equipment longevity. Japanese industries are increasingly adopting multifunctional and environmentally friendly inhibitor formulations to optimize operational efficiency and minimize maintenance costs. The integration of advanced monitoring technologies with inhibitor programs is also driving growth in both industrial and commercial applications.

China Corrosion and Scale Inhibitors Market Insight

The China corrosion and scale inhibitors market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to rapid industrialization, rising water-intensive operations, and growing awareness of equipment maintenance and safety. China’s expanding power, chemical, and oil & gas industries are increasingly adopting advanced inhibitor solutions, including green and multifunctional formulations. Government initiatives promoting sustainable industrial practices and water treatment infrastructure development further support market growth.

Corrosion and Scale Inhibitors Market Share

The Corrosion and Scale Inhibitors industry is primarily led by well-established companies, including:

• Clariant (Switzerland)

• Kemira (Finland)

• GENERAL ELECTRIC (U.S.)

• Dow (U.S.)

• Lenntech B.V. (Netherlands)

• Solvay (Belgium)

• Ashland (U.S.)

• Avista Technologies Inc. (U.S.)

• Innovative Chemical Technologies (U.S.)

• BASF SE (Germany)

• Ecolab (U.S.)

• Akzo Nobel N.V. (Netherlands)

• Gulf Coast Chemical LLC (U.S.)

• Henkel AG & Co. KGaA (Germany)

• Innospec (U.K.)

• Eastman Chemical Company (U.S.)

• Dai-ichi India Pvt Ltd (India)

• Cortec Corporation (U.S.)

• Suez Environnement (France)

• Arkema (France)

• Solenis (U.S.)

Latest Developments in Global Corrosion and Scale Inhibitors Market

- In August 2025, Ecolab Inc. (U.S.) announced a strategic partnership with a leading technology firm to develop AI-driven water treatment solutions. The collaboration aims to enhance predictive maintenance capabilities, reducing downtime and operational costs for clients. This initiative strengthens Ecolab’s position in the digital transformation of the water treatment sector and underscores its commitment to integrating advanced technologies, potentially driving greater market adoption of intelligent water management solutions

- In September 2025, BASF SE (Germany) launched a new line of eco-friendly corrosion inhibitors targeting the oil and gas industry. These inhibitors comply with stringent environmental regulations while delivering superior performance compared to traditional solutions. The launch reinforces BASF’s focus on sustainability and innovation, positioning the company as a market leader and influencing industry standards for environmentally responsible corrosion control

- In October 2025, Dow Chemical Company (U.S.) expanded its operations in Asia by establishing a new manufacturing facility for advanced scale inhibitors. This development enables Dow to meet the rising demand in the rapidly growing Asia-Pacific industrial market. By increasing production capacity, Dow strengthens its market presence, ensures reliable product supply, and supports the region’s industrial growth with high-quality inhibitor solutions

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Corrosion And Scale Inhibitors Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Corrosion And Scale Inhibitors Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Corrosion And Scale Inhibitors Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.