Global Crystallization Equipment Market

Market Size in USD Billion

CAGR :

%

USD

3.22 Billion

USD

4.51 Billion

2024

2032

USD

3.22 Billion

USD

4.51 Billion

2024

2032

| 2025 –2032 | |

| USD 3.22 Billion | |

| USD 4.51 Billion | |

|

|

|

|

Crystallization Equipment Market Size

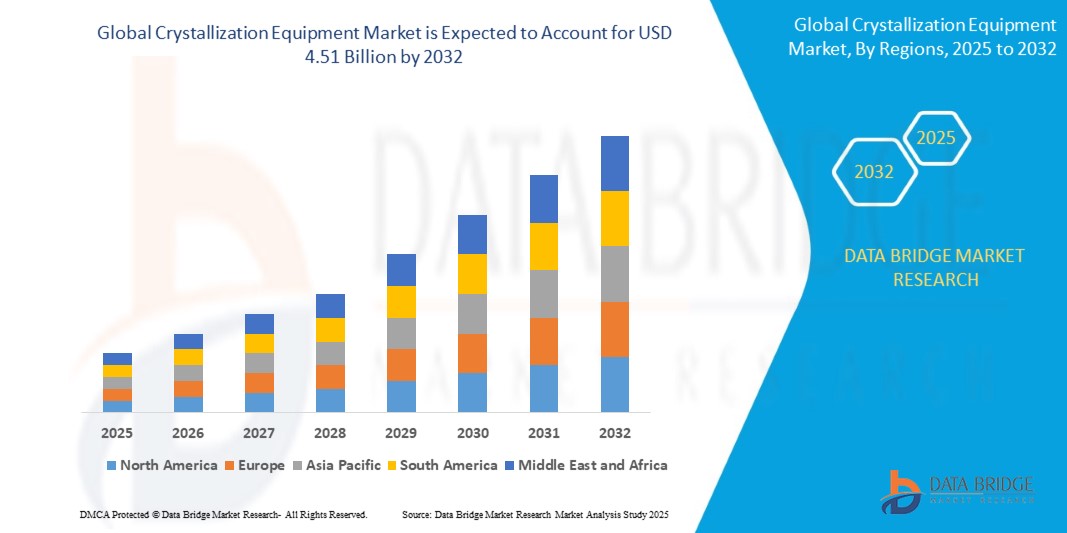

- The global crystallization equipment market size was valued at USD 3.22 billion in 2024 and is expected to reach USD 4.51 billion by 2032, at a CAGR of 4.30% during the forecast period

- The market growth is largely fuelled by increasing demand from the pharmaceutical, chemical, and food & beverage industries, which rely on crystallization processes for product purity, consistency, and quality enhancement

- Rising adoption of continuous crystallization technologies, automation, and process optimization solutions is further driving market expansion

Crystallization Equipment Market Analysis

- The market is witnessing a shift toward advanced crystallization techniques, including batch, continuous, and hybrid processes, tailored to meet diverse industrial needs

- Key applications span pharmaceuticals, fine chemicals, specialty chemicals, and food & beverage sectors, where precise control over crystal size, purity, and morphology is critical for product performance and regulatory compliance

- North America dominated the crystallization equipment market with the largest revenue share of 38.5% in 2024, driven by the presence of leading pharmaceutical, chemical, and food processing companies, coupled with high adoption of advanced and automated crystallization technologies

- Asia-Pacific region is expected to witness the highest growth rate in the global crystallization equipment market, driven by expanding chemical and pharmaceutical industries, government initiatives supporting industrial automation, and increasing demand for efficient, scalable crystallization solutions

- The Cooling Crystallizer segment held the largest market revenue share in 2024, driven by its efficiency in controlling crystal size, purity, and morphology, which is critical for pharmaceutical and chemical applications. Cooling crystallizers are particularly favored for their energy efficiency, ease of operation, and adaptability to various production scales

Report Scope and Crystallization Equipment Market Segmentation

|

Attributes |

Crystallization Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

• Increasing Adoption Of Continuous Crystallization Technologies |

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Crystallization Equipment Market Trends

Increasing Adoption of Continuous and Advanced Crystallization Technologies

- The growing shift toward continuous and advanced crystallization processes is transforming the crystallization equipment landscape by enabling higher purity and consistent product quality. These systems allow manufacturers to optimize yield, reduce cycle times, and minimize energy consumption, improving overall operational efficiency

- Rising demand in pharmaceutical, chemical, and specialty material industries is accelerating the adoption of automated and modular crystallization systems. These solutions provide precise control over process parameters, reducing waste and enhancing reproducibility, while supporting regulatory compliance

- The integration of process analytical technologies (PAT) and real-time monitoring tools is making crystallization equipment more attractive for large-scale production, leading to improved process efficiency and reduced operational risks. Companies benefit from better scalability and lower production costs, which positively impacts market growth

- For instance, in 2023, several pharmaceutical manufacturers in Europe implemented continuous crystallizers with real-time monitoring systems, resulting in higher product quality, reduced energy usage, and optimized throughput

- While advanced crystallization technologies are driving efficiency and product consistency, their market impact depends on ongoing innovation, affordability, and skilled workforce availability. Equipment manufacturers must focus on modular and flexible solutions to fully capitalize on growing industrial demand

Crystallization Equipment Market Dynamics

Driver

Rising Demand for High-Purity Products and Process Efficiency

- Increasing demand for high-purity chemicals and pharmaceutical products is driving investments in advanced crystallization equipment. Industries such as pharma, specialty chemicals, and food additives require precise crystallization processes to meet stringent quality standards, fueling market growth. Additionally, the growing need for consistent particle size, purity, and morphology in specialized applications is further accelerating adoption

- Manufacturers are increasingly aware of the operational advantages offered by continuous crystallizers, including reduced batch variability, higher throughput, and lower energy consumption. This awareness is pushing companies to adopt automated and scalable equipment solutions. Furthermore, continuous systems allow better integration with upstream and downstream processes, optimizing overall production efficiency and reducing waste

- Government regulations and industrial standards are promoting the use of equipment that ensures reproducibility and product safety. Compliance requirements across regions necessitate advanced process control, further boosting demand. In addition, certifications for Good Manufacturing Practices (GMP) and ISO standards are encouraging investment in reliable, modern crystallization equipment

- For instance, in 2022, leading chemical companies in North America adopted continuous crystallization systems for API production, achieving enhanced yield, reduced impurities, and lower production costs. This implementation also helped streamline production schedules and reduced manual intervention, supporting higher operational efficiency and quicker time-to-market

- While rising quality and efficiency demands are fueling growth, manufacturers must continue to innovate and provide cost-effective, energy-efficient solutions to meet diverse industry requirements. Companies focusing on modular, flexible, and compact systems are likely to capture a larger market share, as these solutions allow faster deployment and lower maintenance costs

Restraint/Challenge

High Capital Investment and Limited Technical Expertise

- The high upfront cost of advanced crystallization equipment, including continuous and modular systems, limits accessibility for small and medium-scale manufacturers. Significant investment in installation, automation, and maintenance acts as a barrier to market penetration. Additionally, long ROI cycles for high-capital systems discourage smaller players from adopting advanced technologies

- Many regions lack trained personnel capable of operating and maintaining sophisticated crystallization systems. The absence of technical expertise and supporting infrastructure hinders adoption, particularly in emerging markets. This shortage often results in suboptimal utilization of equipment and increases the risk of operational downtime and process inefficiencies

- Market growth is also constrained by the complexity of process integration, especially when retrofitting continuous systems into existing batch production lines. This requires careful process design and specialized knowledge, which not all companies possess. Furthermore, coordinating upstream and downstream operations while maintaining product consistency poses additional operational challenges

- For instance, in 2023, chemical manufacturers in Southeast Asia reported delays in adopting advanced crystallization solutions due to limited technical expertise and high initial investments. These delays also led to slower modernization of existing plants and limited the adoption of energy-saving and high-efficiency systems, affecting overall competitiveness

- While technological advancements are gradually improving efficiency, addressing capital costs, training needs, and integration challenges remains essential for unlocking the full potential of the global crystallization equipment market. Collaboration with equipment suppliers for training programs, service agreements, and modular solutions can help manufacturers overcome these hurdles and accelerate market adoption

Crystallization Equipment Market Scope

The market is segmented on the basis of type, process, crystallization type, and end-use industry.

• By Type

On the basis of type, the crystallization equipment market is segmented into Batch Vacuum Crystallizer, Cooling Crystallizer, Draft Tube Baffle Crystallizer, Evaporative Crystallizers, Fluidized Bed Crystallizers, Forced-Circulation Crystallizer, Oslo Crystallizer, Surface-Cooled Crystallizer, and Vacuum Crystallizer. The Cooling Crystallizer segment held the largest market revenue share in 2024, driven by its efficiency in controlling crystal size, purity, and morphology, which is critical for pharmaceutical and chemical applications. Cooling crystallizers are particularly favored for their energy efficiency, ease of operation, and adaptability to various production scales.

The Batch Vacuum Crystallizer segment is expected to witness the fastest growth rate from 2025 to 2032, owing to its capability to handle high-purity and heat-sensitive products. These systems are ideal for small- to medium-scale operations, offering precise control over supersaturation, crystallization kinetics, and product quality, making them increasingly popular in specialty chemical and pharmaceutical industries.

• By Process

On the basis of process, the crystallization equipment market is segmented into Batch and Continuous. The Continuous process segment held the largest market revenue share in 2024, driven by its ability to deliver consistent product quality, reduced batch-to-batch variability, and high throughput for large-scale chemical and pharmaceutical production. Continuous systems are favored for their automation, energy efficiency, and integration with downstream processing.

The Batch process segment is expected to witness the fastest growth rate from 2025 to 2032, due to its flexibility and adaptability for small- and medium-scale operations. These systems allow precise control over crystallization conditions, making them suitable for specialty chemicals, fine chemicals, and pharmaceutical APIs where quality and consistency are critical.

• By Crystallization Type

On the basis of crystallization type, the market is segmented into Cooling, Evaporative, and Reactive. The Cooling crystallization segment held the largest market revenue share in 2024, driven by its ability to produce uniform crystals, improve purity, and reduce impurities for chemical, pharmaceutical, and food applications. Cooling crystallizers are particularly valued for energy efficiency and ease of operation.

The Evaporative crystallization segment is expected to witness the fastest growth rate from 2025 to 2032, owing to its effectiveness in concentrating solutions and recovering high-value products. These systems are widely used in chemical and pharmaceutical industries for energy-efficient product recovery and high-purity crystallization.

• By End-Use Industry

On the basis of end-use industry, the crystallization equipment market is segmented into Agrochemical, Chemical, Food & Beverage, Metal & Mineral, Pharmaceutical, and Wastewater Treatment. The Pharmaceutical segment held the largest market revenue share in 2024, driven by high demand for APIs, controlled crystal morphology, and regulatory compliance for quality and safety. Pharmaceutical companies prefer advanced crystallization systems for consistent quality and yield.

The Chemical segment is expected to witness the fastest growth rate from 2025 to 2032, fueled by growing demand for specialty chemicals, intermediates, and fine chemicals. These systems provide precise particle size control, high efficiency, and scalability, making them popular in industrial chemical manufacturing.

Crystallization Equipment Market Regional Analysis

- North America dominated the crystallization equipment market with the largest revenue share of 38.5% in 2024, driven by the presence of leading pharmaceutical, chemical, and food processing companies, coupled with high adoption of advanced and automated crystallization technologies.

- Manufacturers in the region highly value the operational efficiency, precision, and reproducibility offered by modern crystallization systems, which help meet stringent quality and regulatory standards.

- This widespread adoption is further supported by well-established infrastructure, strong R&D capabilities, and the growing emphasis on sustainable and energy-efficient production processes, establishing crystallization equipment as a critical solution for high-purity product manufacturing.

U.S. Crystallization Equipment Market Insight

The U.S. crystallization equipment market captured the largest revenue share in 2024 within North America, fueled by increasing demand for high-purity chemicals, APIs, and specialty products. Companies are investing in continuous and automated crystallization systems to optimize production, reduce batch variability, and lower energy consumption. Moreover, government regulations, quality standards, and strong industrial infrastructure are significantly contributing to the expansion of the crystallization equipment market in the U.S.

Europe Crystallization Equipment Market Insight

The Europe crystallization equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by stringent regulatory compliance requirements, advanced manufacturing practices, and high demand for specialty chemicals and pharmaceuticals. The region is experiencing growth across pharmaceutical, chemical, and food & beverage sectors, with companies increasingly adopting scalable and energy-efficient crystallization solutions. Urbanization, industrial automation, and innovation-focused policies further foster the adoption of advanced crystallization technologies.

U.K. Crystallization Equipment Market Insight

The U.K. crystallization equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by the rising pharmaceutical and chemical production activities, alongside an increasing focus on process optimization and energy efficiency. Additionally, compliance with international quality standards and increasing R&D investments are encouraging manufacturers to adopt continuous and modular crystallization systems. The region’s technological infrastructure and skilled workforce further stimulate market growth.

Germany Crystallization Equipment Market Insight

The Germany crystallization equipment market is expected to witness the fastest growth rate from 2025 to 2032, fueled by increasing production of high-purity chemicals, APIs, and specialty materials. Germany’s emphasis on industrial innovation, sustainability, and energy-efficient processes promotes the adoption of advanced crystallization technologies. Integration of modern crystallization systems with automated and digital control processes is becoming increasingly prevalent, aligning with local industrial standards and operational expectations.

Asia-Pacific Crystallization Equipment Market Insight

The Asia-Pacific crystallization equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by rapid industrialization, growing chemical and pharmaceutical production, and increasing investment in advanced manufacturing technologies in countries such as China, India, and Japan. Government initiatives promoting industrial automation, R&D investments, and the emergence of APAC as a manufacturing hub for high-purity chemicals are supporting market growth. Furthermore, increasing affordability and accessibility of crystallization systems are expanding adoption across SMEs and large-scale operations.

Japan Crystallization Equipment Market Insight

The Japan crystallization equipment market is expected to witness the fastest growth rate from 2025 to 2032 due to the country’s advanced industrial infrastructure, strong focus on high-purity pharmaceuticals, and demand for energy-efficient production processes. The market emphasizes precision, reproducibility, and automation, which drive adoption of continuous and modular crystallization systems. Integration of crystallization technologies with digital and automated process controls is fueling growth, particularly in the pharmaceutical, chemical, and food & beverage sectors.

China Crystallization Equipment Market Insight

The China crystallization equipment market accounted for the largest market revenue share in Asia Pacific in 2024, attributed to the country’s booming chemical, pharmaceutical, and food processing industries. High production volumes, rapid urbanization, and increasing adoption of automated and continuous crystallization systems are key factors propelling the market. The expansion of domestic manufacturers, government support for industrial innovation, and the rising focus on high-purity products further accelerate the demand for advanced crystallization equipment in China.

Crystallization Equipment Market Share

The Crystallization Equipment industry is primarily led by well-established companies, including:

- GEA Group (Germany)

- Sulzer Chemtech (Switzerland)

- Fives (U.S.)

- Tsukishima Kikai (Japan)

- Hebei Yunhao (China)

- Whiting Equipment (Canada)

- Technoforce (India)

- SPX FLOW (U.S.)

- Alfa Laval (Sweden)

- Andritz AG (Austria)

- Bosch Packaging Technology (Germany)

- BÜHLER AG (Switzerland)

- API Schmidt-Bretten (Germany)

- L.G. Chemtech (South Korea)

- HENKEL (Germany)

- Union Process Inc. (U.S.)

- Patterson-Kelley (U.S.)

Latest Developments in Global Crystallization Equipment Market

- In June 2023, GEA Group launched an advanced melt crystallization system, marking a significant development in crystallization equipment. This system is designed to deliver high efficiency and precise control over crystallization processes across industries such as pharmaceuticals, chemicals, and cosmetics. By enhancing product purity, consistency, and yield, the solution helps manufacturers optimize production while reducing energy consumption and operational costs. Its adoption is expected to strengthen GEA Group’s market position and drive innovation in high-performance crystallization technologies globally

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Crystallization Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Crystallization Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Crystallization Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.