Global Die Bonder Equipment Market

Market Size in USD Million

CAGR :

%

USD

886.78 Million

USD

1,167.73 Million

2024

2032

USD

886.78 Million

USD

1,167.73 Million

2024

2032

| 2025 –2032 | |

| USD 886.78 Million | |

| USD 1,167.73 Million | |

|

|

|

|

Die Bonder Equipment Market Size

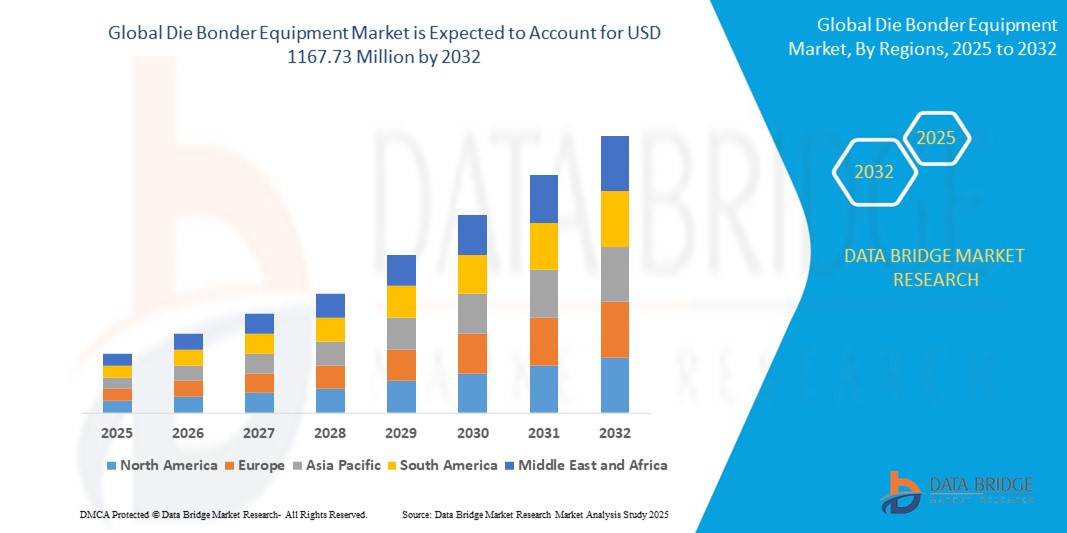

- The global die bonder equipment market size was valued at USD 886.78 million in 2024 and is expected to reach USD 1167.73 million by 2032, at a CAGR of 3.50% during the forecast period

- The market growth is largely fuelled by the rising demand for high-performance semiconductors across electronics, automotive, and telecommunications industries, along with ongoing advancements in die bonding technologies to support miniaturized and high-density packaging

- Increasing adoption of automation and Industry 4.0 in semiconductor manufacturing is accelerating the deployment of advanced die bonder equipment to enhance production efficiency, precision, and throughput across global fabrication facilities

Die Bonder Equipment Market Analysis

- The die bonder equipment market is witnessing steady growth due to rising demand for compact and high-performance semiconductor devices in consumer electronics and industrial applications

- Continuous innovation in bonding technologies is enabling enhanced speed, accuracy, and automation in packaging processes, meeting the evolving needs of manufacturers

- North America dominated the die bonder equipment market in 2024, driven by strong demand from consumer electronics, telecommunications, and healthcare industries, alongside the presence of leading semiconductor manufacturers

- The Asia-Pacific region is expected to witness the highest growth rate in the global die bonder equipment market, driven by rapid industrialization, growing electronics manufacturing, and rising investments in semiconductor fabrication across countries such as China, Japan, South Korea, and India

- The fully automatic segment held the largest market share in 2024, attributed to its high precision, speed, and minimal manual intervention, which streamline mass production. These systems are especially favored in high-volume manufacturing environments where consistent throughput and reduced labor costs are critical

Report Scope and Die Bonder Equipment Market Segmentation

|

Attributes |

Die Bonder Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

• Rising Adoption of Automation in Semiconductor Packaging Processes • Growing Demand for Advanced Bonding Techniques in 5G And AI-Enabled Devices |

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Die Bonder Equipment Market Trends

“Adoption of Advanced Automation in Die Bonding Processes”

- The die bonder equipment market is shifting toward advanced automation to enhance efficiency, precision, and output in semiconductor packaging

- Manufacturers are incorporating robotics, artificial intelligence-based inspection, and real-time monitoring to reduce manual effort and improve bonding accuracy

- Automated systems enable consistent quality in large-scale production runs, which is essential for sectors such as consumer electronics and automotive

- For instance, companies are launching equipment with self-calibration and adaptive alignment features to meet the complex requirements of modern chip assemblies

- Automation is also accelerating the move toward Industry 4.0 by supporting data integration, predictive maintenance, and remote operation capabilities

Die Bonder Equipment Market Dynamics

Driver

“Rising Demand for Miniaturized Electronic Devices and Advanced Packaging Technologies”

- The growing demand for compact and high-performance electronic devices in sectors such as consumer electronics, automotive, and healthcare is driving the need for advanced die bonding solutions

- As device miniaturization increases, manufacturers rely on die bonder equipment to ensure precise attachment of semiconductor chips to substrates or lead frames

- The surge in adoption of technologies such as Internet of Things and 5G has pushed the demand for highly integrated circuits with minimal error margins

- For instance, manufacturers developing wearable fitness trackers and smartwatches require high-precision die bonding to assemble multiple chips in limited space

- Advanced bonding formats such as system-in-package and three-dimensional integrated circuits are becoming common, further emphasizing the role of accurate, high-speed die bonder systems in modern electronics manufacturing

Restraint/Challenge

“High Capital Investment and Technological Complexity”

- The die bonder equipment market is challenged by the high upfront investment required for purchasing advanced bonding systems with automation and precision capabilities

- This high cost can be a barrier for small- and medium-sized enterprises that may not have the financial resources to adopt or upgrade such equipment

- Skilled technicians are needed to operate these machines efficiently, as they involve complex software programming and semiconductor packaging knowledge

- For instance, small manufacturers in developing regions often struggle to find and retain trained personnel, affecting equipment performance and reliability

- The need for frequent maintenance, calibration, and adaptation to evolving packaging technologies adds to the operational burden, limiting the pace of adoption among resource-constrained players

Die Bonder Equipment Market Scope

The market is segmented on the basis of type, bonding technique, supply chain participant, application, and device.

- By Type

On the basis of type, the die bonder equipment market is segmented into manual die bonders, semiautomatic die bonders, and fully automatic die bonders. The fully automatic segment held the largest market share in 2024, attributed to its high precision, speed, and minimal manual intervention, which streamline mass production. These systems are especially favored in high-volume manufacturing environments where consistent throughput and reduced labor costs are critical.

The semiautomatic segment is expected to witness the fastest growth rate from 2025 to 2032, supported by its balance of automation and human control, making it ideal for mid-sized manufacturers and prototype development. These machines offer flexibility and cost-effectiveness, which appeals to companies transitioning from manual to automated processes.

- By Bonding Technique

On the basis of bonding technique, the die bonder equipment market is segmented into epoxy, eutectic, soft solder, and others. The epoxy bonding technique dominated the market in 2024, driven by its strong adhesion properties and compatibility with a wide range of substrates and die types. Epoxy die bonding is widely used in electronics packaging due to its cost-efficiency and ease of processing.

The eutectic bonding technique is expected to witness the fastest growth rate from 2025 to 2032, as it provides high thermal and mechanical stability, making it suitable for high-reliability applications. Industries such as aerospace and power electronics increasingly prefer eutectic bonding for its precision and long-term performance under stress.

- By Supply Chain Participant

On the basis of supply chain participant, the die bonder equipment market is segmented into OSAT companies and IDM firms. The OSAT segment held the highest market share in 2024 due to their specialization in outsourced semiconductor assembly and testing services, enabling scalability and cost optimization. OSAT providers are heavily investing in next-generation die bonding systems to meet growing demands from fabless semiconductor companies.

IDM firms is expected to witness the fastest growth rate from 2025 to 2032, as they seek tighter integration of design and manufacturing processes. These firms are increasingly adopting die bonding equipment to enhance in-house capabilities and maintain quality control across production cycles.

- By Application

On the basis of application, the die bonder equipment market is segmented into consumer electronics, automotive, industrial, telecommunications, healthcare, and aerospace and defence. The consumer electronics segment dominated the market in 2024, driven by the mass production of compact devices such as smartphones, tablets, and wearable electronics. The demand for miniaturized and high-performance devices continues to drive the need for precise and fast die bonding equipment.

The automotive segment is expected to witness the fastest growth rate from 2025 to 2032, due to rising integration of advanced electronics in vehicles. Applications such as ADAS, EVs, and infotainment systems require robust packaging solutions, pushing automakers and their suppliers to invest in advanced die bonding technologies.

- By Device

On the basis of device, the die bonder equipment market is segmented into optoelectronics, MEMS and MOEMs, and power devices. The optoelectronics segment accounted for the largest market share in 2024, propelled by increased production of LEDs, photodiodes, and image sensors used across multiple industries. These devices demand high precision and thermal management, which aligns well with advanced die bonding solutions.

The MEMS and MOEMs segment is expected to witness the fastest growth rate from 2025 to 2032, owing to their rising use in applications such as smart sensors, medical diagnostics, and wearable technologies. As the need for miniaturized components with complex architectures grows, the demand for accurate and versatile die bonding equipment will continue to rise.

Die Bonder Equipment Market Regional Analysis

- North America dominated the die bonder equipment market in 2024, driven by strong demand from consumer electronics, telecommunications, and healthcare industries, alongside the presence of leading semiconductor manufacturers

- The region’s emphasis on technological innovation and automation, especially within the U.S., supports the rapid integration of advanced die bonding systems to ensure high throughput and precision

- The availability of capital for infrastructure development, along with the growing push for local chip production, reinforces North America’s leading position in the global die bonder equipment landscape

U.S. Die Bonder Equipment Market Insight

The U.S. die bonder equipment market captured the largest share within North America in 2024, fueled by government investments in semiconductor manufacturing and rising demand for high-performance computing and automotive electronics. The ongoing CHIPS Act initiative and a growing domestic supply chain are key factors encouraging adoption of fully automated die bonding equipment for efficient and scalable production.

Europe Die Bonder Equipment Market Insight

The Europe die bonder equipment market is expected to witness the fastest growth rate from 2025 to 2032, supported by increasing investments in microelectronics and a resurgence in local semiconductor production. Countries such as Germany and the Netherlands are expanding their research and manufacturing capabilities, particularly in photonics and MEMS, thereby boosting demand for high-precision die bonders across the region.

U.K. Die Bonder Equipment Market Insight

The U.K. die bonder equipment market is expected to witness moderate growth over the forecast period, supported by expanding R&D efforts in electronics, medical devices, and defense sectors. Government-backed initiatives to boost semiconductor manufacturing and innovation, along with the country’s focus on next-generation communication technologies, are driving demand for precision bonding equipment in high-value applications.

Germany Die Bonder Equipment Market Insight

The Germany die bonder equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by its status as a hub for automotive and industrial electronics innovation. With increased demand for sensors, microcontrollers, and power devices in electric vehicles and factory automation, manufacturers in Germany are rapidly embracing advanced die attach technologies to meet quality and efficiency standards.

Asia-Pacific Die Bonder Equipment Market Insight

The Asia-Pacific die bonder equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by the concentration of semiconductor foundries and OSAT companies in China, Taiwan, and South Korea. As the region leads in global chip packaging and assembly, there is surging investment in high-speed, flexible die bonding systems to meet the evolving demands of 5G, AI, and IoT applications.

China Die Bonder Equipment Market Insight

The China accounted for the largest revenue share in Asia-Pacific in 2024, backed by its robust electronics manufacturing ecosystem and government-backed efforts to achieve semiconductor self-sufficiency. The rapid expansion of domestic IDM and OSAT firms, coupled with rising demand for locally produced consumer electronics and EV components, is accelerating the deployment of fully automated and high-yield die bonders across the country.

Japan Die Bonder Equipment Market Insight

The Japan die bonder equipment market is expected to witness the fastest growth rate from 2025 to 2032, driven by its well-established semiconductor industry and strong presence in robotics, automotive electronics, and consumer devices. Japanese manufacturers are increasingly adopting advanced die bonding solutions to meet miniaturization and performance demands, especially in optoelectronics and MEMS, further supported by strategic government programs promoting chip resilience and domestic production.

Die Bonder Equipment Market Share

The die bonder equipment industry is primarily led by well-established companies, including:

- DIC Corporation (Japan)

- Flint Group (Luxembourg)

- Hubergroup (Germany)

- Sakata Inx Corporation (Japan)

- Siegwerk Druckfarben AG & Co. KGaA (Germany)

- T&K TOKA Co. Ltd. (Japan)

- Toyo Ink SC Holdings Co., Ltd. (Japan)

- Fujifilm Holdings Corporation (Japan)

- American Inks & Technology (U.S.)

- Wikoff Color Corporation (U.S.)

Latest Developments in Global Die Bonder Equipment Market

- In October 2022, Kulicke and Soffa secured substantial customer orders for its thermo-compression solution and efficiently delivered its inaugural Fluxless Thermo-Compression Bonder (TCB) to a key customer, solidifying its stronghold in advanced LED Assembly

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Die Bonder Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Die Bonder Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Die Bonder Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.