Global Electric Vehicles Battery Tray Market

Market Size in USD Billion

CAGR :

%

USD

600.23 Billion

USD

1,204.80 Billion

2024

2032

USD

600.23 Billion

USD

1,204.80 Billion

2024

2032

| 2025 –2032 | |

| USD 600.23 Billion | |

| USD 1,204.80 Billion | |

|

|

|

|

Electric Vehicles Battery Tray Market Size

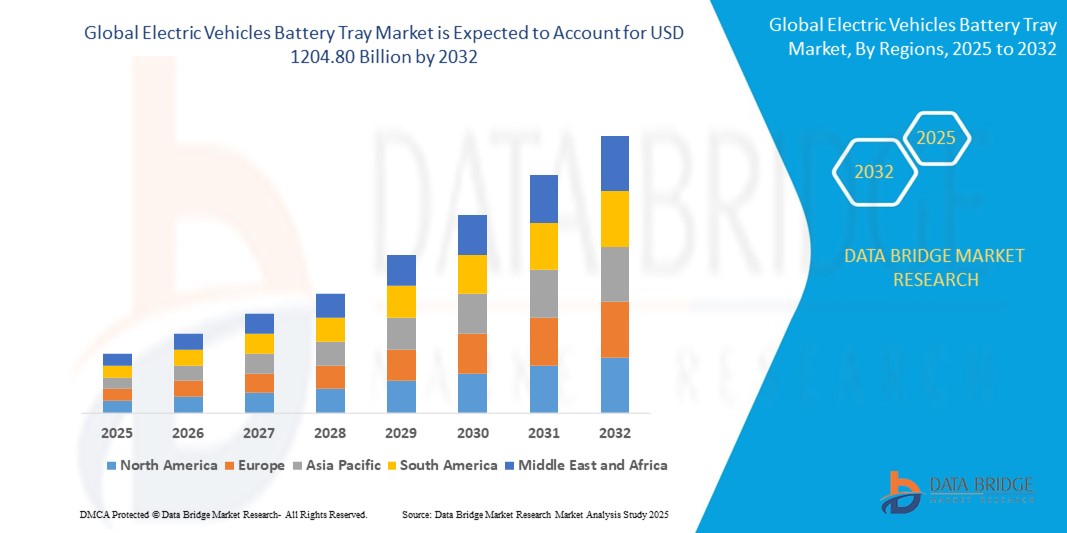

- The global electric vehicles battery tray market was valued at USD 600.23 billion in 2024 and is expected to reach USD 1204.80 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 9.10%, primarily driven by increasing adoption of electric vehicles

- This growth is driven by factors such as demand for lightweight materials, government incentives, expanding EV models, and increased focus on safety and durability

Electric Vehicles Battery Tray Market Analysis

- An electric vehicle battery tray is a structural component designed to house, protect, and support the battery pack, ensuring thermal stability, mechanical safety, and integration within the vehicle chassis

- Market growth is driven by rising EV adoption, government incentives, demand for lightweight materials, and increased focus on battery safety and structural integrity

- Advancements in material technology, thermal management systems, and precision manufacturing are propelling innovation in battery tray design and functionality

- For instance, companies such as Novelis and Constellium are developing advanced aluminum-based battery trays that enhance vehicle range and meet stringent safety standards

- The electric vehicles battery tray market is projected to grow steadily from 2025 to 2032, fueled by expanding EV production, stricter emission regulations, and the need for efficient energy storage solutions

Report Scope and Electric Vehicles Battery Tray Market Segmentation

|

Attributes |

Electric Vehicles Battery Tray Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Electric Vehicles Battery Tray Market Trends

“Rising Demand for Lightweight Vehicles”

- One prominent trend in the global electric vehicles battery tray market is the rising demand for lightweight vehicles

- This trend is driven by the need to enhance EV range, improve energy efficiency, and meet regulatory standards for emissions and fuel economy

- For instance, companies such as Constellium and Novelis are focusing on lightweight aluminum-based battery trays that reduce vehicle weight without compromising strength or safety

- The push for lightweight solutions is also accelerating material innovation, particularly in composites and advanced alloys, to optimize performance and durability

- As automakers strive to deliver longer-range, energy-efficient EVs, the emphasis on lightweight battery tray materials is expected to remain a key trend, shaping product development and market growth

Electric Vehicles Battery Tray Market Dynamics

Driver

“Rising Investments in EV Infrastructure”

- The rise in investments in EV infrastructure is a key driver of growth in the electric vehicles battery tray market. As the demand for electric vehicles increases, substantial investments are being made in charging stations, production facilities, and battery manufacturing plants, boosting the need for reliable battery components

- This shift is particularly noticeable in regions such as Europe, North America, and Asia, where governments and private entities are focused on building robust EV infrastructure to accelerate EV adoption

- With increasing demand for EVs and the expansion of related infrastructure, automakers and suppliers are enhancing battery tray designs to support the efficient integration of larger, more powerful batteries

- The growth in charging infrastructure, coupled with advancements in energy storage and vehicle-to-grid technology, is accelerating the demand for optimized battery trays that offer safety, thermal management, and weight reduction

- Companies in the EV sector are investing heavily in infrastructure to ensure smoother adoption of electric mobility

For instance,

- Tesla and BMW are expanding their EV manufacturing capabilities alongside charging infrastructure projects, driving the need for innovative, high-performance battery trays

- Volkswagen is increasing its investments in EV infrastructure through the "ID" series and the expansion of its global charging network, which has boosted demand for advanced battery trays in their EV models

- As the push for cleaner transportation intensifies, these investments are expected to remain a key driver, propelling the growth of the electric vehicles battery tray market in the coming years

Opportunity

“Development of Recycling Technologies for Battery Trays”

- The development of recycling technologies presents a significant opportunity in the electric vehicles battery tray market. Recycling technologies can help reduce material waste, lower production costs, and improve the sustainability of battery tray components

- Recycling allows for the recovery of valuable materials from used battery trays, such as aluminum and steel, which can be reused in manufacturing, thereby minimizing the need for raw material extraction and reducing environmental impact

- This technology also enables manufacturers to meet growing regulatory requirements for recycling and sustainability while improving the circular economy within the automotive industry

For instance,

- Companies such as Alcoa and Novelis are developing advanced recycling techniques for aluminum, aiming to improve the reuse rate of materials used in battery trays, contributing to more sustainable EV manufacturing processes

- BMW and Renault are working on battery recycling programs to enhance the reuse of materials from EV batteries, which can also benefit the recycling of battery tray components

- As recycling technologies continue to advance, their integration into battery tray production is expected to grow, offering manufacturers the opportunity to reduce costs, meet sustainability goals, and improve the environmental footprint of electric vehicles

Restraint/Challenge

“Complexity of Battery Tray Design and Manufacturing”

- The complexity of battery tray design and manufacturing presents a significant challenge in the electric vehicles battery tray market. As battery trays must meet stringent safety, thermal management, and structural integrity standards, designing and manufacturing them becomes a technically demanding process

- Challenges such as material selection, weight reduction, integration with battery systems, and meeting regulatory requirements can complicate the design process, especially as battery tray designs become more sophisticated with new vehicle models

- This issue is particularly significant in a rapidly evolving market where constant innovation in battery technology and vehicle design requires frequent updates and adjustments to tray designs, increasing manufacturing complexity

For instance,

- Manufacturers that lack the expertise to integrate advanced materials, such as lightweight composites or aluminum alloys, may struggle with balancing weight reduction and durability in battery trays, impacting overall EV performance

- Without addressing design and manufacturing complexities through advanced technology, efficient supply chain management, and skilled labor, these challenges could slow the market’s growth and limit the potential for innovation in the electric vehicles battery tray market

Electric Vehicles Battery Tray Market Scope

The market is segmented on the basis of material type and application.

|

Segmentation |

Sub-Segmentation |

|

By Material Type |

|

|

By Application |

|

Electric Vehicles Battery Tray Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Electric Vehicles Battery Tray Market”

- Asia-Pacific dominates the electric vehicles battery tray market, driven by the region’s leadership in EV manufacturing and the presence of key battery manufacturers

- China holds a significant share due to its strong manufacturing capabilities, cost-effective production, and extensive supply chain network

- The region's rapid urbanization, government incentives promoting EV adoption, and stringent environmental regulations further fuel market growth

- In addition, the availability of raw materials, skilled labor, and advanced manufacturing infrastructure across Asia-Pacific makes the region a cost-effective hub for battery tray production, further solidifying its market leadership

“North America is Projected to Register the Highest Growth Rate”

- North America is expected to witness the highest growth rate in the electric vehicles battery tray market, driven by region's accelerating shift toward electric mobility, driven by both consumer demand and government policies aimed at reducing carbon emissions

- U.S. has introduced significant tax incentives and funding for EV infrastructure development through initiatives such as the Inflation Reduction Act, which is spurring EV production and adoption

- Major automakers, including Tesla, Ford, and General Motors, are expanding their electric vehicle lines, creating a surge in demand for battery components such as trays. The region is also seeing rapid advancements in battery technology, which requires innovative tray designs to support new-generation batteries

- Furthermore, the growing network of charging stations and increased investments in EV-related research and development are expected to propel North America’s market growth at a faster pace compared to other regions

Electric Vehicles Battery Tray Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- ZEISS Group (Germany)

- Foshan Shijun Hongmao Aluminum Technology (China)

- Minth Group Co., Ltd. (Taiwan)

- Guangdong Hoshion Aluminium Co., Ltd. (China)

- Shanghai Yousheng Aluminum Co., Ltd. (China)

- Chongqing Nanfu Aluminum Co., Ltd. (China)

- Wencan (China)

- Dura (U.S.)

- Atlas Copco AB (Sweden)

- BENTELER International AG (Austria)

- Gestamp Automoción (Spain)

- Constellium (France)

- Aluminum Extruders Council (U.S.)

- Waldaschaff Automotive GmbH (Germany)

Latest Developments in Global Electric Vehicles Battery Tray Market

- In April 2024, Hyundai Motor Company and Kia Corporation announced a partnership with Exide Energy Solutions Ltd to localize electric vehicle (EV) battery production in India. The collaboration was formalized through a Memorandum of Understanding (MOU) signed by Hyundai Motor Group and Exide Energy Solutions. This initiative is part of their strategic expansion in the EV sector, with a focus on manufacturing lithium iron phosphate (LFP) cells to bolster their market presence in India.

- In January 2024, SGL Carbon teamed up with E-Works Mobility on a technology initiative. SGL Carbon provided a battery case made of glass fiber-reinforced plastic for E-Works Mobility, a Munich-based company specializing in electric van development. This collaboration aimed to enhance the E-Works HEERO, a high-performance e-transporter. Engineers recently completed a complete redesign of the battery box, replacing the previous aluminium construction, which represents a significant advancement in the vehicle's development.

- In March 2023, Atlas Copco Power and Flow introduced the WEDA D95, a next-generation electric submersible pump featuring advanced wear protection technology. This robust and dependable pump offers superior performance and longevity in highly abrasive environments such as mining, tunneling, and construction, helping users boost both sustainability and productivity in their operations

- In April 2023, LG Energy Solution formed a strategic partnership with General Motors (GM) to develop innovative battery tray designs. This collaboration aims to improve battery pack performance and configuration for GM’s upcoming electric vehicle (EV) models

- In August 2020, DURA Automotive Systems announced in the past plans to invest $59 million in a new manufacturing facility in Muscle Shoals, Alabama, dedicated to producing battery trays for electric vehicles. The project, supported by the Shoals Economic Development Authority, created 279 direct jobs, enhancing Alabama’s auto industry potential amid the growing EV demand. Local leaders expressed excitement over the investment and job opportunities

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Electric Vehicles Battery Tray Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Electric Vehicles Battery Tray Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Electric Vehicles Battery Tray Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.