Global Electro Hydraulic Servo Valve Market

Market Size in USD Billion

CAGR :

%

USD

1.92 Billion

USD

2.89 Billion

2024

2032

USD

1.92 Billion

USD

2.89 Billion

2024

2032

| 2025 –2032 | |

| USD 1.92 Billion | |

| USD 2.89 Billion | |

|

|

|

|

Electro Hydraulic Servo Valve Market Size

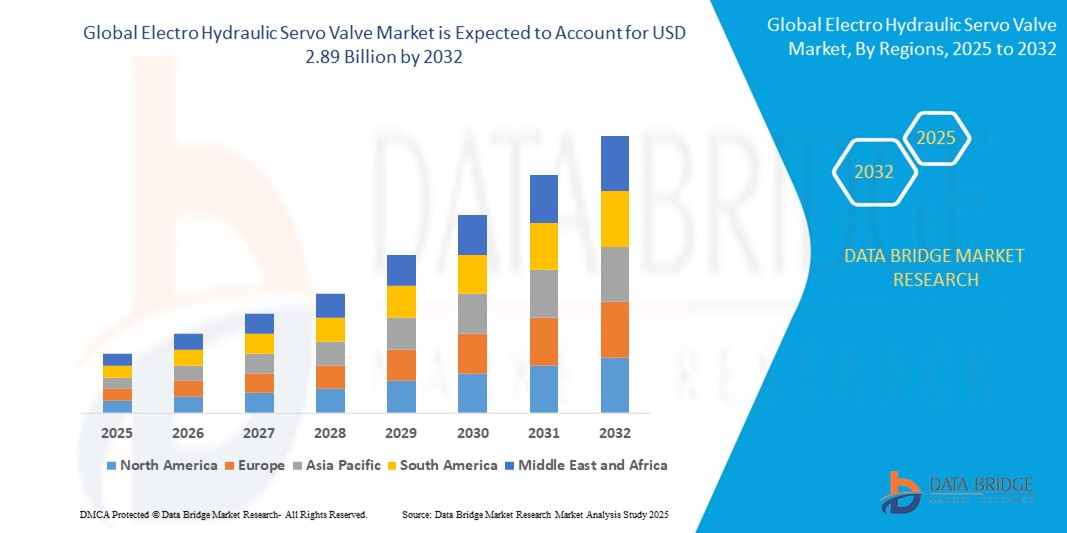

- The global electro hydraulic servo valve market size was valued at USD 1.92 billion in 2024 and is expected to reach USD 2.89 billion by 2032, at a CAGR of 5.2% during the forecast period

- The market growth is largely fueled by increasing industrial automation and the rising need for precise motion and fluid control across sectors such as aerospace, oil and gas, and heavy machinery, which demand high-performance hydraulic systems for operational efficiency

- Furthermore, the integration of electro hydraulic servo valves with advanced control technologies to improve system responsiveness, reliability, and energy efficiency is driving demand across modern manufacturing and process industries, thereby significantly boosting the market's expansion

Electro Hydraulic Servo Valve Market Analysis

- Electro hydraulic servo valves, which regulate fluid flow with high precision through electrical signals, are increasingly vital components in advanced hydraulic systems across aerospace, industrial automation, and heavy equipment applications due to their ability to provide responsive and accurate control

- The escalating demand for electro hydraulic servo valves is primarily fueled by the growing adoption of high-performance motion control systems, rising emphasis on automation and energy efficiency, and the need for reliable operation in demanding environments

- North America dominated the electro hydraulic servo valve market with a share of 40.07% in 2024, due to the strong presence of aerospace and defense industries, along with advanced manufacturing infrastructure

- Asia-Pacific is expected to be the fastest growing region in the electro hydraulic servo valve market during the forecast period due to rapid industrialization, expanding aerospace capabilities, and growing investment in infrastructure projects

- Less than 20 LPM segment dominated the market with a market share of 55.2% in 2024, due to its extensive usage in precision applications requiring low flow rates, such as laboratory testing systems, medical devices, and aerospace actuation systems. These valves are typically chosen for their responsiveness and control accuracy in environments where even minimal deviations in fluid flow can impact performance

Report Scope and Electro Hydraulic Servo Valve Market Segmentation

|

Attributes |

Electro Hydraulic Servo Valve Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Electro Hydraulic Servo Valve Market Trends

“Integration with Advanced Industrial Automation Systems”

- A significant and accelerating trend in the global electro hydraulic servo valve market is the integration of these valves with advanced industrial automation systems, driven by the need for real-time precision control and predictive maintenance across manufacturing and aerospace sectors. This trend is enabling seamless coordination between mechanical systems and digital controllers, enhancing productivity and system responsiveness

- For instance, smart servo valves equipped with sensors and communication interfaces are being adopted in Industry 4.0 applications, allowing for remote monitoring, diagnostics, and adaptive performance tuning, which contribute to reduced downtime and operational efficiency

- The adoption of smart manufacturing practices, including AI and IoT-enabled control systems, is reshaping hydraulic applications, with servo valves playing a central role in ensuring accurate actuation and fluid control

- These valves are being integrated into highly dynamic environments such as aircraft flight control systems and CNC machinery, where milliseconds of response time can impact performance and safety, underlining their importance in next-gen engineering

- The compatibility of servo valves with digital twins and automated feedback loops enables real-time adjustments and energy savings, making them a preferred choice in modern industrial systems

- As industries continue to move toward intelligent, interconnected operations, the role of electro hydraulic servo valves in enabling high-performance, adaptive control systems is expected to grow significantly, driving innovation and adoption across critical sectors

Electro Hydraulic Servo Valve Market Dynamics

Driver

“Rising Demand for Precision Motion Control in Aerospace and Industry”

- The rising demand for high-precision motion control systems in aerospace, industrial automation, and heavy machinery is a major driver fueling the growth of the electro hydraulic servo valve market. These sectors require highly responsive and reliable control for mission-critical operations involving variable loads and high-frequency actuation

- For instance, aircraft flight control surfaces, wind tunnel testing rigs, and robotic arms in industrial settings increasingly rely on servo valves to deliver fine-tuned control and fluid responsiveness under high-pressure conditions

- Servo valves provide the accuracy and repeatability necessary for maintaining operational safety, performance, and energy efficiency, especially in environments where traditional valves fall short in dynamic applications

- Their ability to precisely modulate fluid flow and force makes them indispensable in hydraulic systems requiring real-time feedback, such as test stands and injection molding machines

- The increased investment in aerospace R&D, automated production lines, and intelligent machinery globally ensures sustained demand for servo valves as a critical component of precision control infrastructure

Restraint/Challenge

“High Cost of Maintenance and System Complexity”

- Concerns surrounding the high cost of maintenance and system complexity present a major challenge to the widespread adoption of electro hydraulic servo valves. Their sophisticated design and sensitivity to contamination demand specialized maintenance and frequent calibration to ensure optimal performance

- For instance, failure to maintain clean hydraulic fluid or misalignment in control systems can lead to premature wear, operational disruptions, and costly downtime in high-stakes applications such as aerospace test rigs or industrial presses

- These challenges are compounded by the need for skilled technicians and high-precision diagnostic tools, which raise the total cost of ownership and deter small- to mid-sized operators from adopting these solutions

- Although advanced filtration systems and predictive maintenance technologies are helping mitigate risks, the complex nature of electro hydraulic servo valve integration still requires considerable investment in training, infrastructure, and system diagnostics

- Addressing this challenge will involve manufacturers focusing on robust design improvements, modular systems, and user-friendly interfaces to simplify maintenance, reduce operational friction, and enhance long-term system reliability

Electro Hydraulic Servo Valve Market Scope

The market is segmented on the basis of stage type, valve type, LPM type, and application.

• By Stage Type

On the basis of stage type, the electro hydraulic servo valve market is segmented into single stage servo valve, two stage servo valve, and three stage servo valve. The two stage servo valve segment accounted for the largest market revenue share in 2024, primarily due to its optimal balance of performance, precision, and reliability across a wide range of industrial applications. These valves are favored in aerospace and defense systems, where accurate flow control and stability are critical under dynamic conditions. The widespread integration of two stage configurations in motion control systems for aircraft, turbines, and testing equipment further reinforces their dominance in the market.

The three stage servo valve segment is projected to witness the fastest growth rate from 2025 to 2032, driven by rising adoption in high-power applications that require extremely fine flow control at elevated pressures and volumes. Industries such as heavy manufacturing, offshore drilling, and steel production are increasingly implementing three stage valves to meet demanding operational loads while maintaining system precision and efficiency.

• By Valve Type

On the basis of valve type, the market is segmented into nozzle flapper valve, jet pipe servo valve, deflector jet, and others. The nozzle flapper valve segment led the market in terms of revenue in 2024, attributed to its long-standing use, proven stability, and suitability in closed-loop control systems. These valves offer a compact design and have low power requirements, making them ideal for applications with limited installation space or power availability. Their ability to provide high dynamic performance in feedback control systems continues to secure their widespread deployment in industrial automation and aerospace systems.

The jet pipe servo valve segment is anticipated to record the fastest CAGR from 2025 to 2032, supported by increasing demand in critical high-response applications. Jet pipe valves offer superior contamination resistance and operate effectively in harsher environments, making them a preferred choice in oil and gas drilling platforms, turbine control systems, and marine propulsion setups.

• By LPM Type

On the basis of LPM (liters per minute) type, the market is divided into less than 20 LPM and more than 20 LPM. The less than 20 LPM segment dominated the market share of 55.2% in 2024, supported by its extensive usage in precision applications requiring low flow rates, such as laboratory testing systems, medical devices, and aerospace actuation systems. These valves are typically chosen for their responsiveness and control accuracy in environments where even minimal deviations in fluid flow can impact performance.

The more than 20 LPM segment is expected to witness the highest growth rate through 2032, driven by its increasing relevance in industrial machinery and large-scale hydraulic systems. As sectors such as steel manufacturing, oil refining, and construction adopt more automated and high-volume control mechanisms, the demand for valves capable of handling higher flow rates is expected to rise substantially.

• By Application

On the basis of application, the electro hydraulic servo valve market is segmented into aerospace, power industry, steel industry, chemical industry, oil and gas, marine industry, construction industry, healthcare, and others. The aerospace segment held the largest revenue share in 2024, owing to the critical need for precision hydraulic control in flight control systems, landing gear operations, and simulation platforms. With a strong emphasis on safety, responsiveness, and load handling in this sector, electro hydraulic servo valves play an indispensable role in ensuring the reliability and performance of aircraft systems.

The oil and gas segment is projected to grow at the fastest CAGR from 2025 to 2032, driven by the increasing deployment of advanced servo valves in offshore and onshore drilling operations, where robust performance under high pressure, temperature, and corrosive conditions is vital. The growing focus on automation, predictive maintenance, and remote operation in exploration and refining activities is further accelerating the adoption of high-performance servo valve systems in this industry.

Electro Hydraulic Servo Valve Market Regional Analysis

- North America dominated the electro hydraulic servo valve market with the largest revenue share of 40.07% in 2024, driven by the strong presence of aerospace and defense industries, along with advanced manufacturing infrastructure

- The region benefits from early adoption of precision fluid control systems and a high concentration of OEMs and industrial automation providers utilizing servo valves across multiple applications

- The robust investment in R&D, presence of key industry players, and a demand for highly responsive and accurate hydraulic systems are major factors supporting the dominance of the North American market

U.S. Electro Hydraulic Servo Valve Market Insight

The U.S. electro hydraulic servo valve market captured the largest revenue share in 2024 within North America, driven by its extensive use in the aerospace, military, and industrial sectors. The country’s advanced aircraft manufacturing ecosystem and high defense spending continue to boost demand for servo valves in flight control and weapon systems. Additionally, increased automation in oil & gas, energy, and heavy manufacturing is further contributing to market expansion, as precision control and system responsiveness remain critical performance metrics.

Europe Electro Hydraulic Servo Valve Market Insight

The Europe electro hydraulic servo valve market is expected to grow at a steady CAGR throughout the forecast period, supported by the rising adoption of automated control systems in industrial and energy sectors. Countries across the region are implementing servo valves in wind turbines, steel plants, and offshore drilling systems to enhance performance reliability and environmental compliance. The shift toward energy-efficient technologies and modernizing infrastructure in Western Europe also promotes servo valve integration in power and process industries.

U.K. Electro Hydraulic Servo Valve Market Insight

The U.K. electro hydraulic servo valve market is anticipated to expand at a moderate CAGR during the forecast period, driven by investments in aerospace engineering, naval defense, and industrial upgrades. The growing focus on sustainable manufacturing and predictive maintenance is encouraging the use of high-precision hydraulic components. Moreover, the U.K.'s emphasis on defense modernization and export of advanced machinery is contributing to increased demand for servo valve systems.

Germany Electro Hydraulic Servo Valve Market Insight

The Germany electro hydraulic servo valve market is projected to grow at a significant CAGR, owing to its strong industrial base and focus on technological innovation. Germany’s leadership in machinery, automotive manufacturing, and renewable energy sectors is driving the need for precision hydraulic controls. The country’s adoption of Industry 4.0 and support for smart factory development is further accelerating the integration of servo valves in automated systems and production lines.

Asia-Pacific Electro Hydraulic Servo Valve Market Insight

The Asia-Pacific electro hydraulic servo valve market is forecasted to grow at the fastest CAGR from 2025 to 2032, driven by rapid industrialization, expanding aerospace capabilities, and growing investment in infrastructure projects. Countries such as China, Japan, and India are increasingly deploying servo valves in energy, manufacturing, and transportation sectors. The availability of cost-effective production capabilities and growing emphasis on automation are enhancing market penetration across the region.

Japan Electro Hydraulic Servo Valve Market Insight

The Japan electro hydraulic servo valve market is gaining traction due to its technologically advanced manufacturing ecosystem and high standards for product performance and reliability. Japan’s aerospace and industrial robotics sectors are key contributors to servo valve adoption. Furthermore, the country’s ongoing push for smart factory initiatives and energy-efficient systems is fostering the growth of servo valve applications in high-precision industries.

China Electro Hydraulic Servo Valve Market Insight

The China electro hydraulic servo valve market accounted for the largest market share within Asia Pacific in 2024, fueled by large-scale investments in aviation, marine, and energy sectors. The presence of major domestic manufacturing hubs and government-driven industrial automation policies support rapid adoption of servo valves. China's expanding exports of machinery and the growth of its defense and aerospace segments are further amplifying demand for reliable hydraulic control technologies.

Electro Hydraulic Servo Valve Market Share

The electro hydraulic servo valve industry is primarily led by well-established companies, including:

- YUKEN KOGYO CO., LTD (Japan)

- MTS Systems (U.S.)

- Moog Inc. (U.S.)

- Atos spa (Italy)

- PARKER HANNIFIN CORP (U.S.)

- AVIC Nanjing Servo Control System Co., Ltd. (China)

- Continental Hydraulics Inc. (U.S.)

- JASC (U.S.)

- Bosch Rexroth AG (Germany)

- Woodward, Inc. (U.S.)

- Eaton (Ireland)

- Honeywell International Inc. (U.S.)

- Voith GmbH & Co. KGaA (Germany)

- Star Hydraulics Limited (U.K.)

- SCHNEIDER SERVOHYDRAULICS (Germany)

- HAWE Hydraulik SE (Germany)

- DUPLOMATIC MS Spa (Italy)

Latest Developments in Global Electro Hydraulic Servo Valve Market

- In August 2023, Honeywell launched a new electro-hydraulic servo valve designed for industrial automation, which is expected to significantly boost market growth by enhancing the precision and reliability of fluid control in demanding environments. The valve’s compatibility with applications such as robotics and heavy machinery directly addresses the rising need for advanced automation technologies. This development strengthens Honeywell’s position in the market and aligns with the broader shift toward high-performance control solutions

- In September 2022, Moog Inc. launched its X700 Series servo cartridge valves, boasting a robust design capable of withstanding a maximum main stage operating pressure of 420 bar. This release signifies Moog's strategic move to bolster its presence in the premium market segment, offering advanced hydraulic solutions to meet the demanding needs of various industries

- In August 2022, Voith GmbH & Co. KGaA finalized the acquisition of ARGO-HYTOS Group, marking a significant expansion in its hydraulics business. By integrating ARGO-HYTOS, Voith aims to enhance its capabilities in developing and producing hydraulic components and system solutions, particularly focusing on the off-highway sector. This strategic acquisition is expected to accelerate Voith's growth trajectory in the competitive hydraulics market

- In September 2021, Parker Hannifin Corporation acquired a technology firm to strengthen its electro-hydraulic capabilities, a move that is anticipated to enhance its market share in sectors requiring advanced control systems. By incorporating new technologies, Parker aims to improve system efficiency and performance across aerospace, automation, and mobile equipment applications. This acquisition reflects the market’s trend toward strategic investments that expand product capabilities and customer reach

- In April 2021, Moog Inc. launched a new line of high-performance electro-hydraulic servo valves for aerospace applications, targeting the growing demand for sophisticated motion control solutions. The valves’ enhanced flow performance and precise control over aircraft systems such as flight controls and landing gear contribute to safety and reliability in aviation. This launch is expected to further Moog’s impact on the aerospace segment of the market and support the industry’s push for advanced hydraulic control

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Electro Hydraulic Servo Valve Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Electro Hydraulic Servo Valve Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Electro Hydraulic Servo Valve Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.